Patents

Literature

37results about How to "Good rigidity and flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

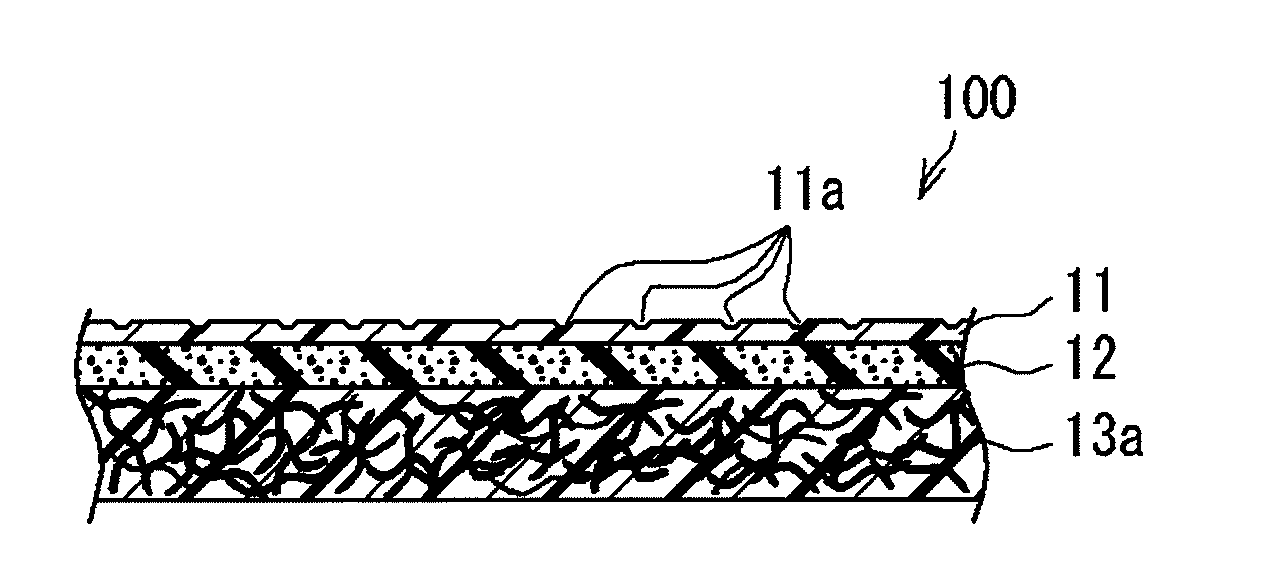

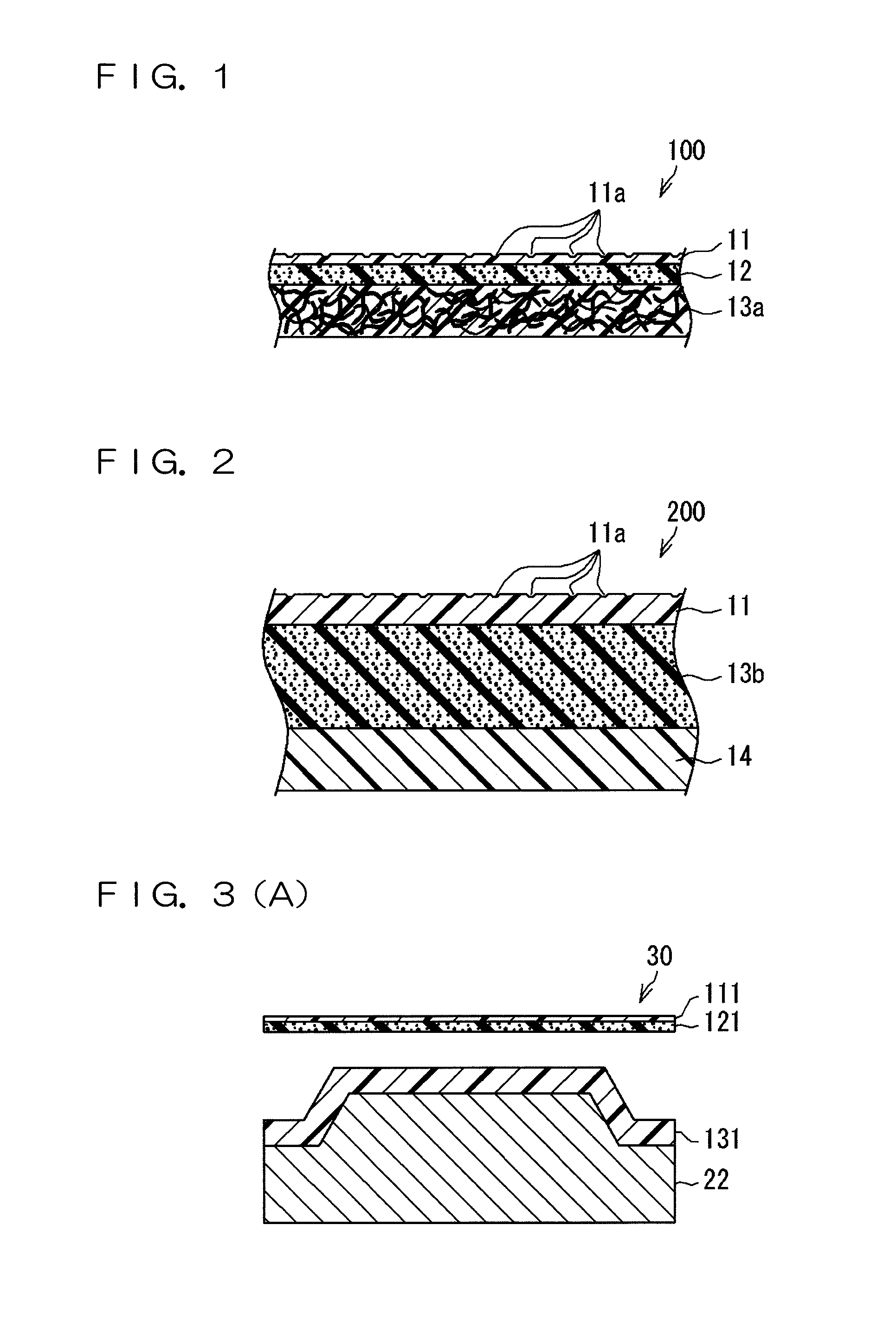

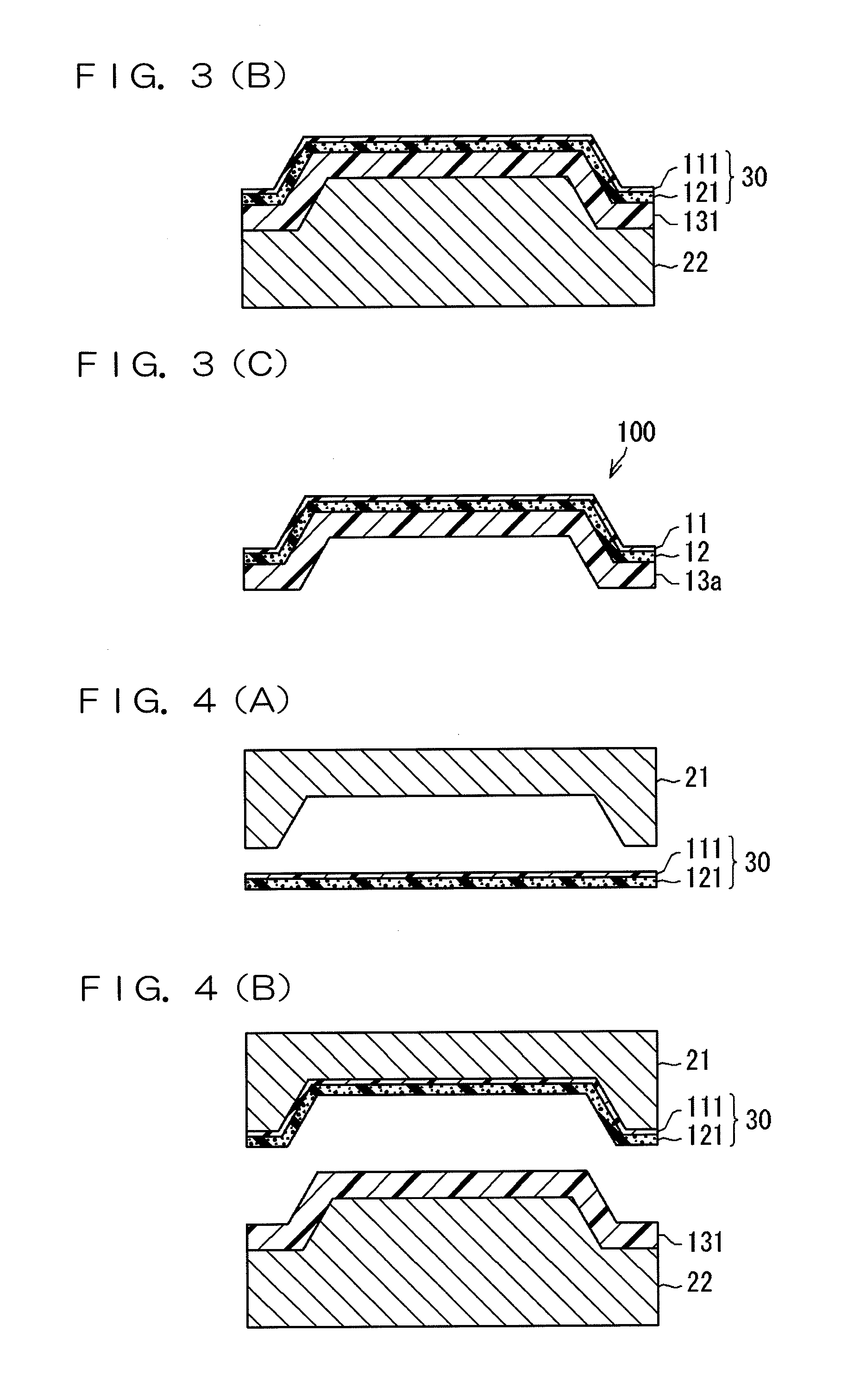

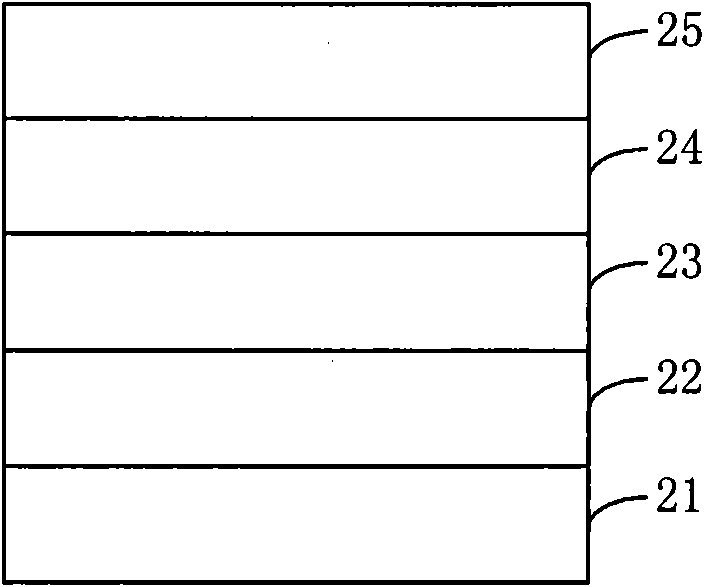

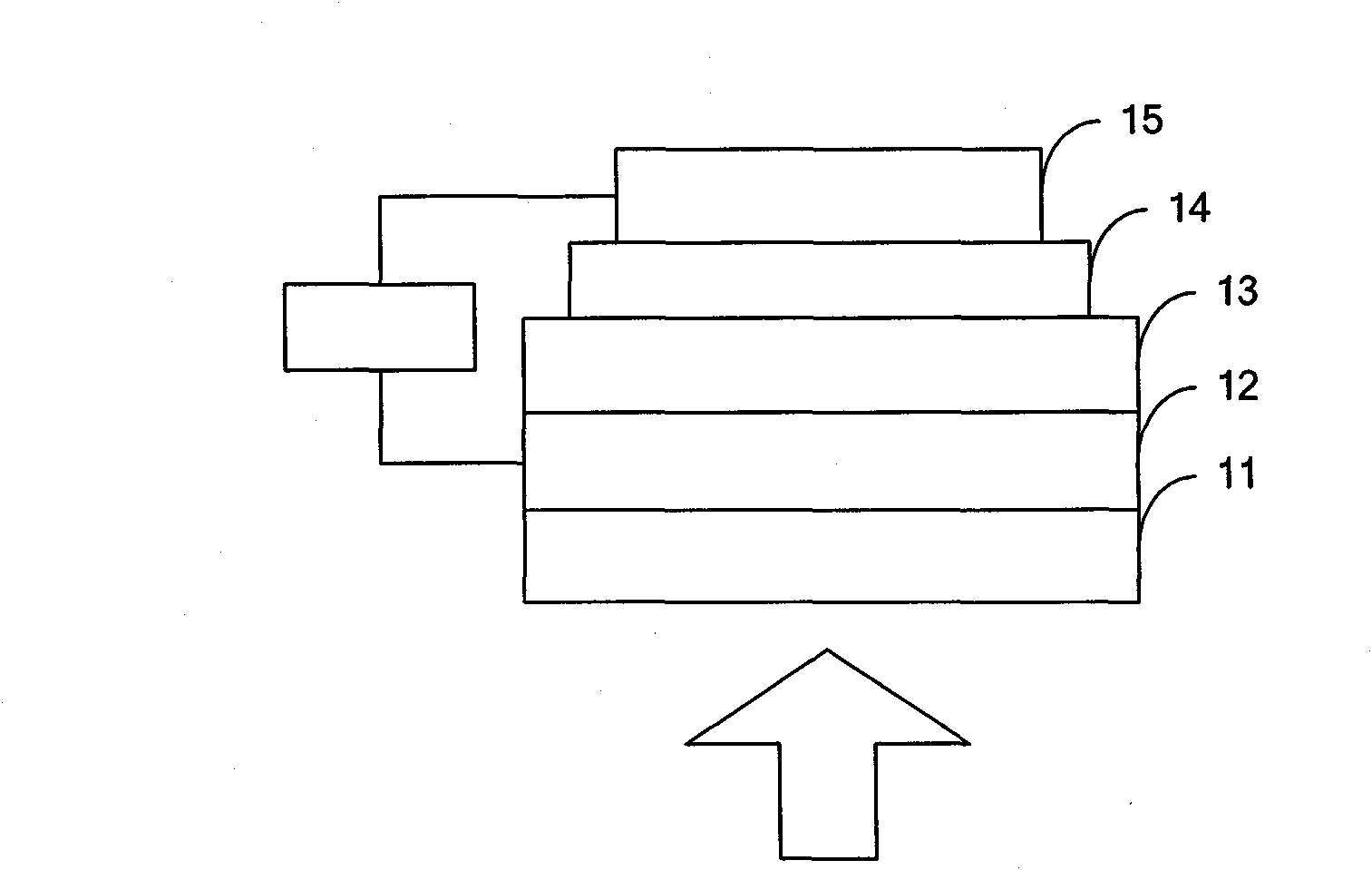

Interior material for vehicle

ActiveUS20100323182A1Good rigidity and flexibilityGood light fastnessSynthetic resin layered productsVehicle componentsNatural fiberPolyolefin

The present invention is an interior material for a vehicle having a skin layer and a base layer. The skin layer contains an olefin-based thermoplastic elastomer, a polyolefin resin, a polylactic acid resin and a styrene-based thermoplastic elastomer, in amounts of respectively 20% to 70% by weight, 10% to 50% by weight, 5% to 30% by weight and 5% to 30% by weight based on 100% by weight of the total of these. The base layer is preferably a thin layer in which a natural fiber is dispersed in a phase of a thermoplastic resin such as a polyolefin resin, or a polyurethane foam layer.

Owner:TOYOTA BOSHOKU KK

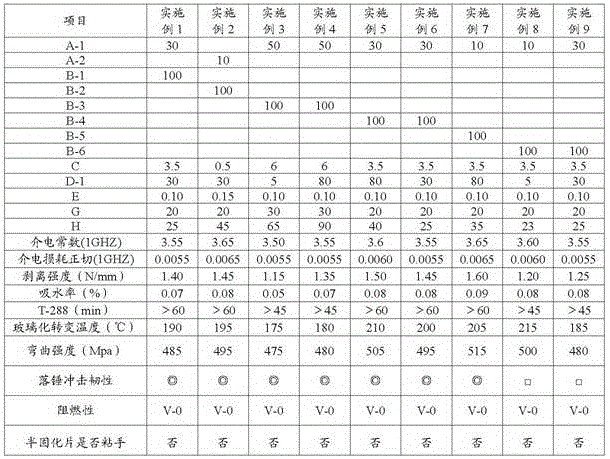

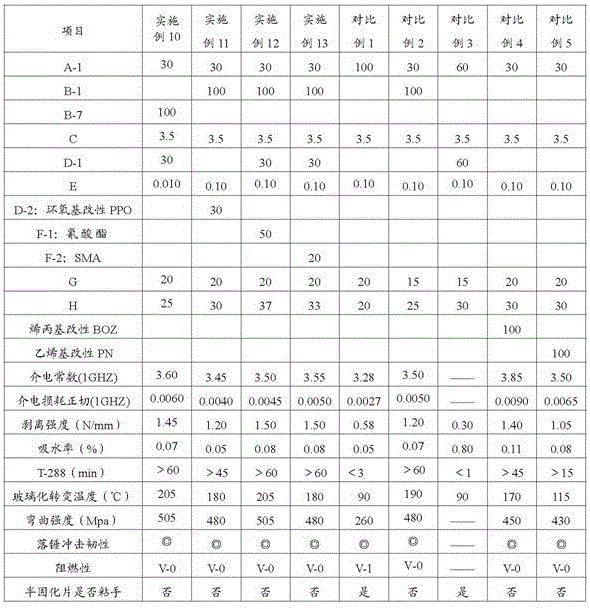

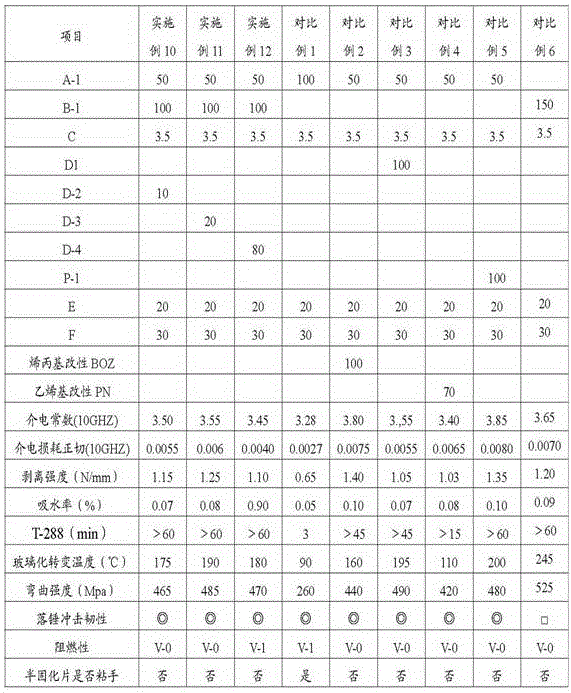

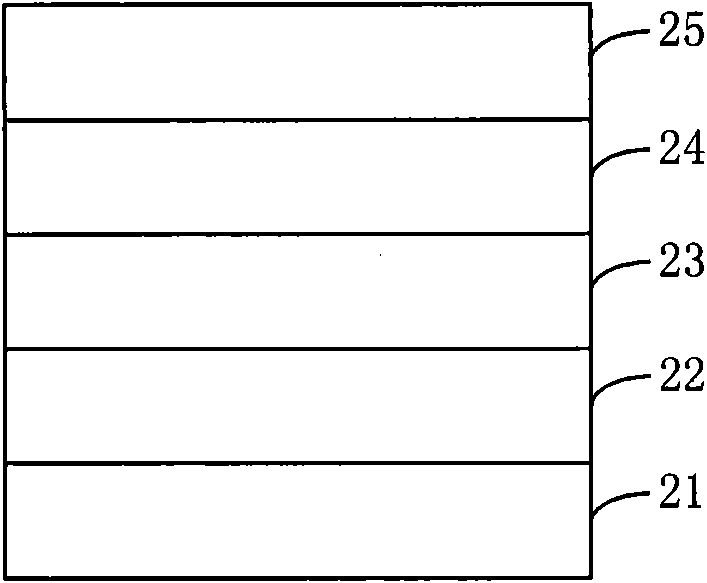

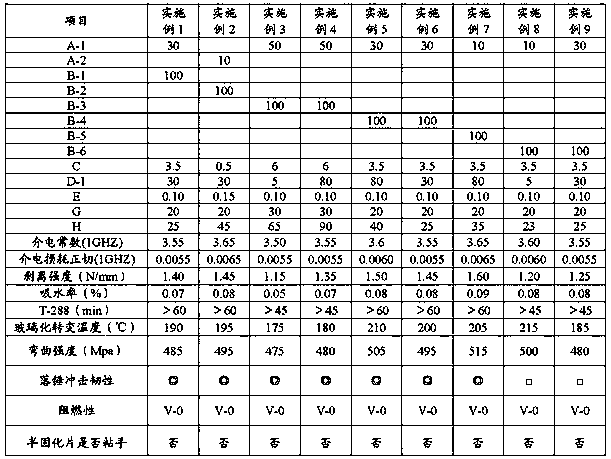

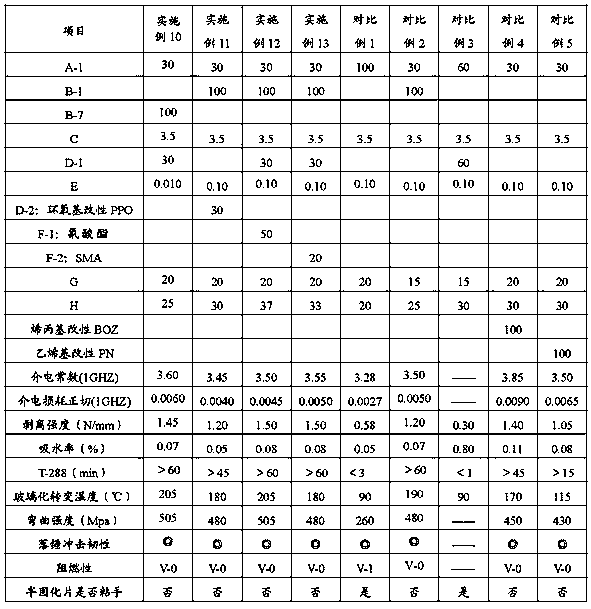

Thermosetting resin composition, prepreg prepared from thermosetting resin composition and laminated board

ActiveCN109810468AImprove heat resistanceHigh mechanical strengthMetal layered productsShrinkage rateHeat resistance

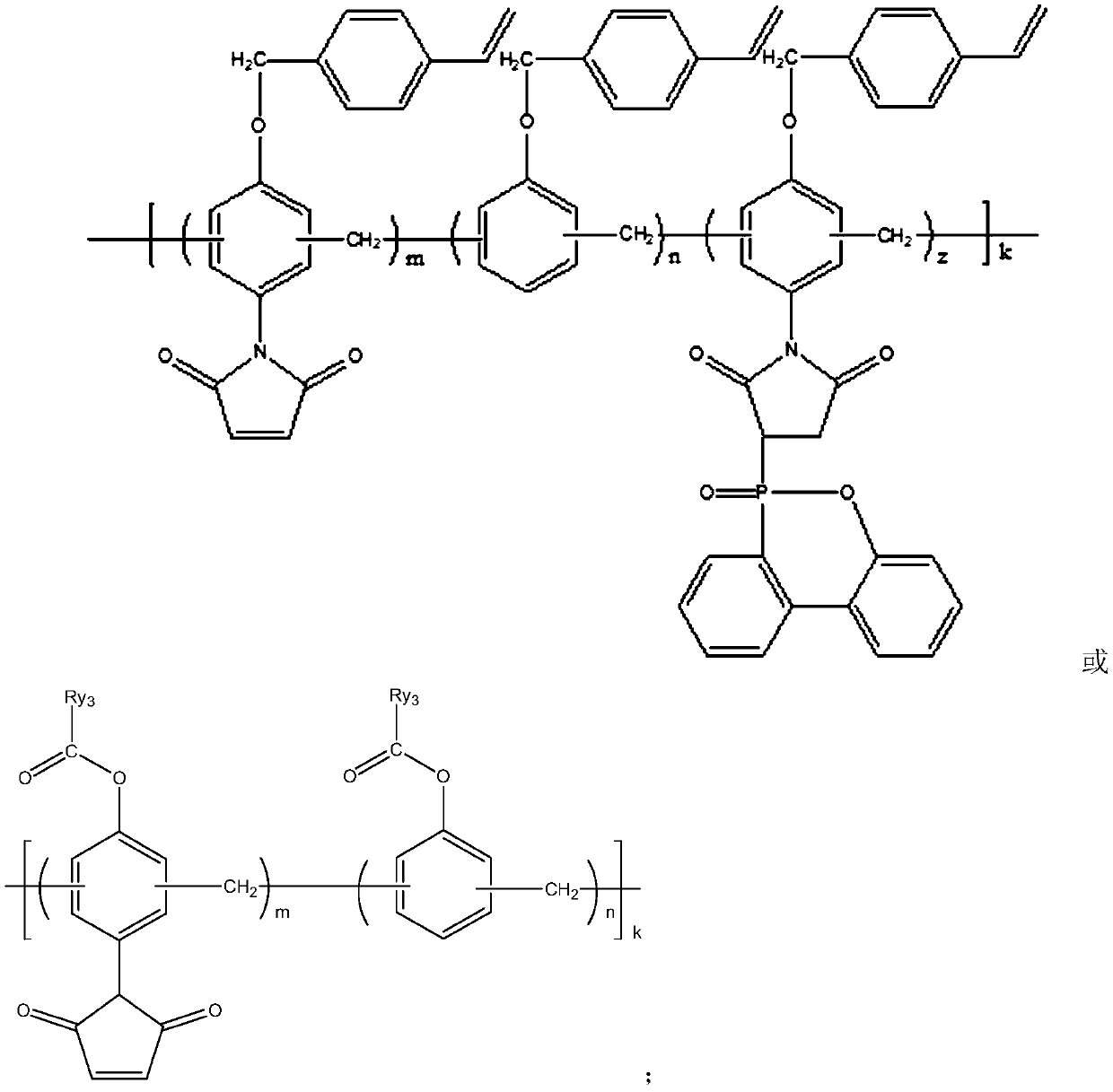

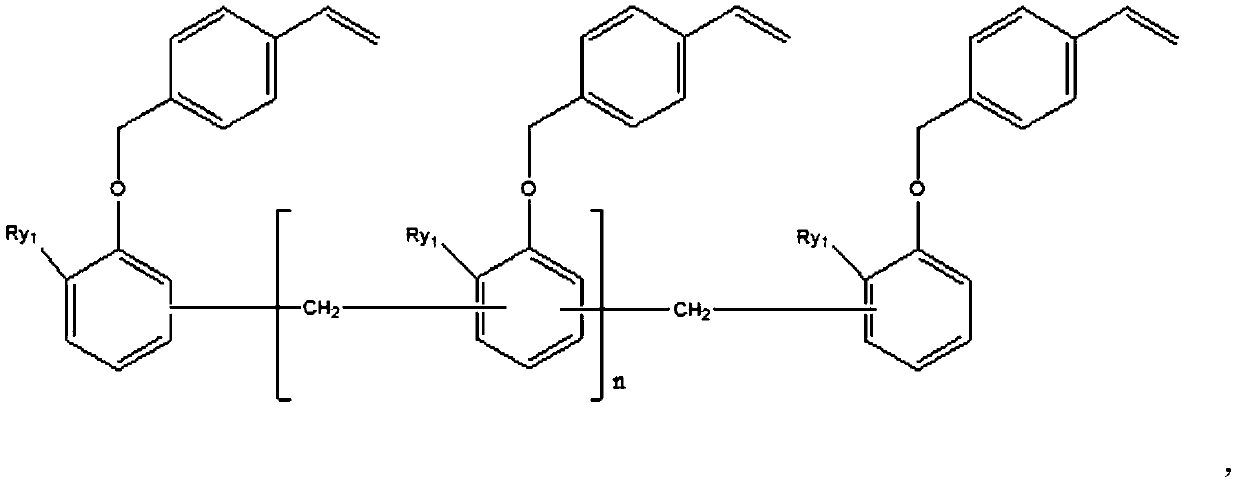

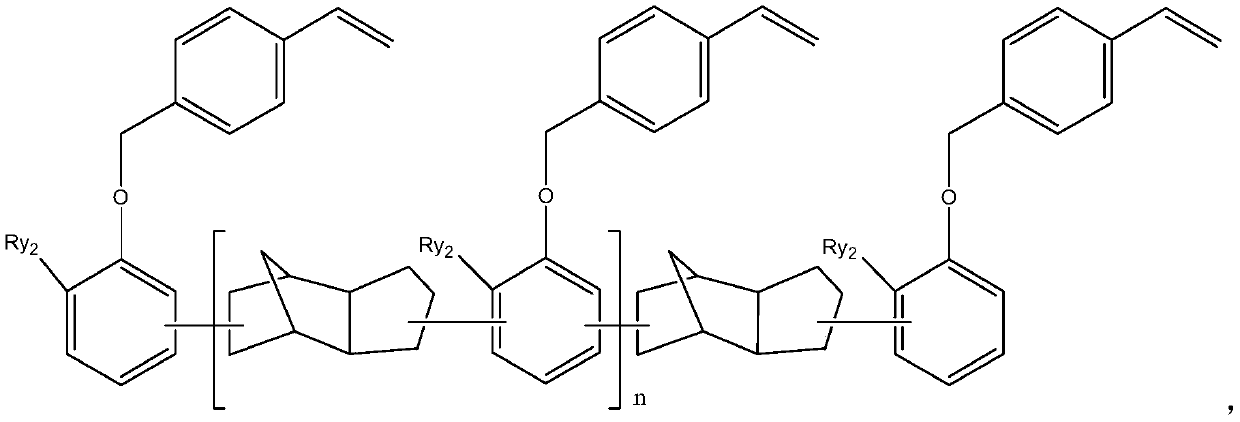

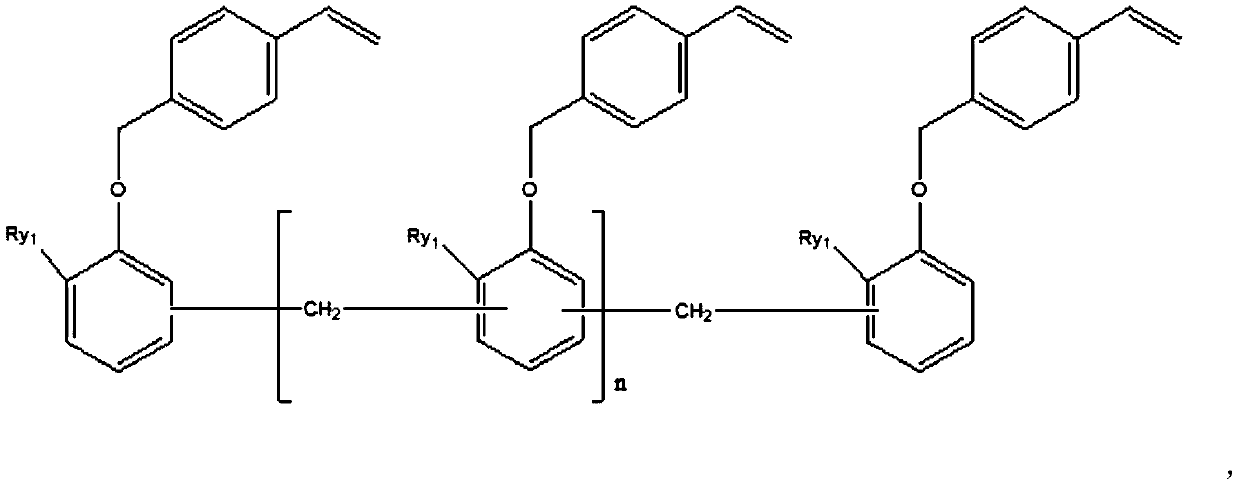

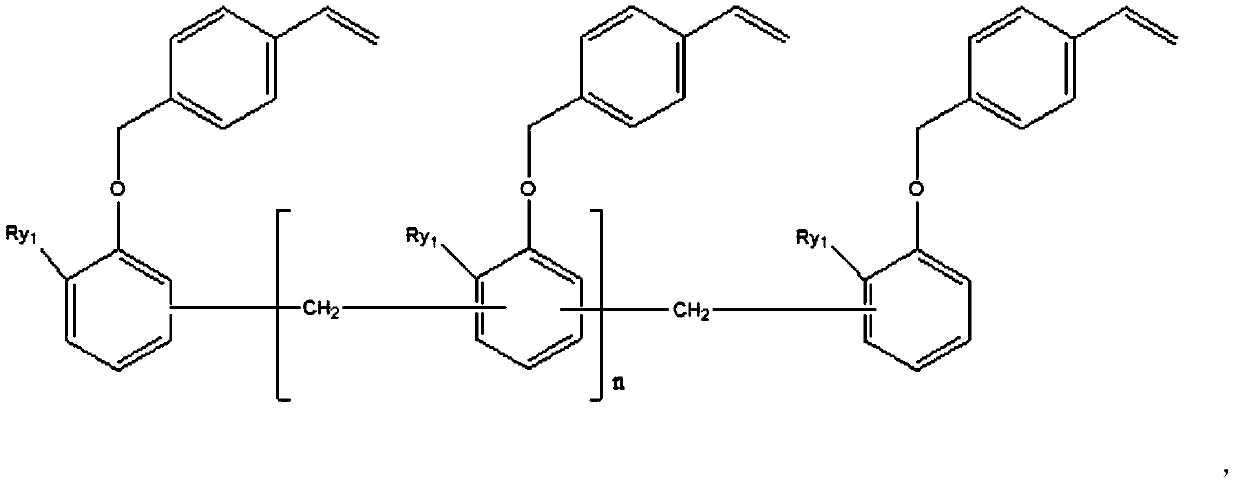

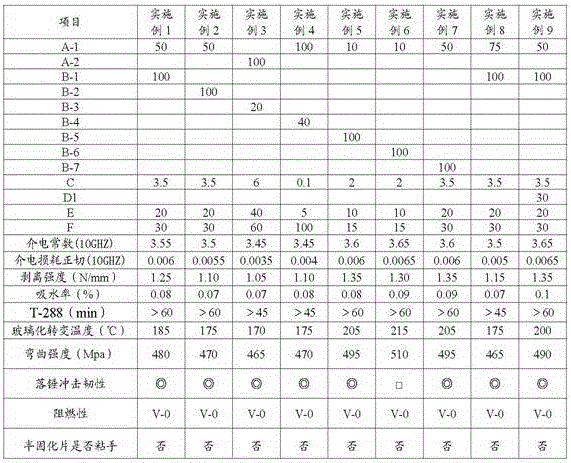

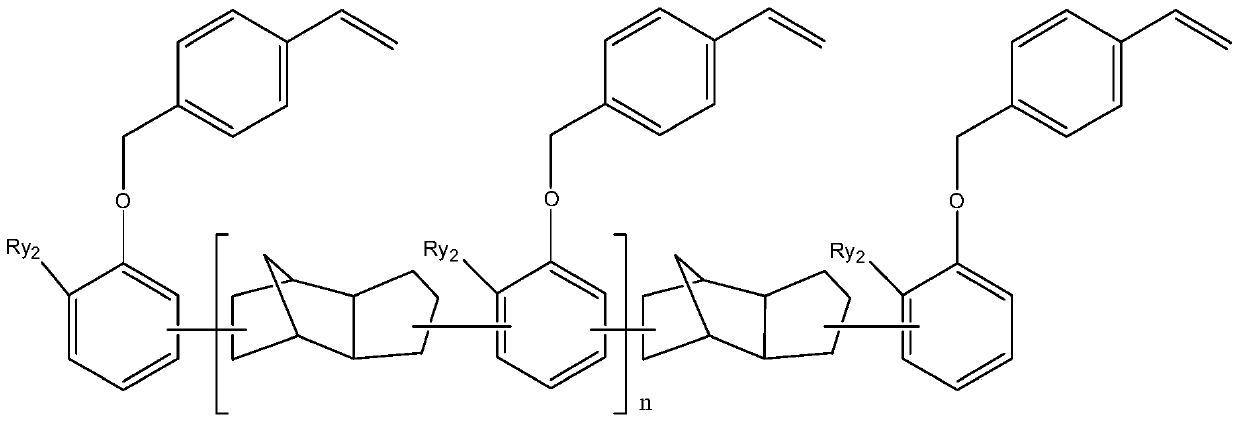

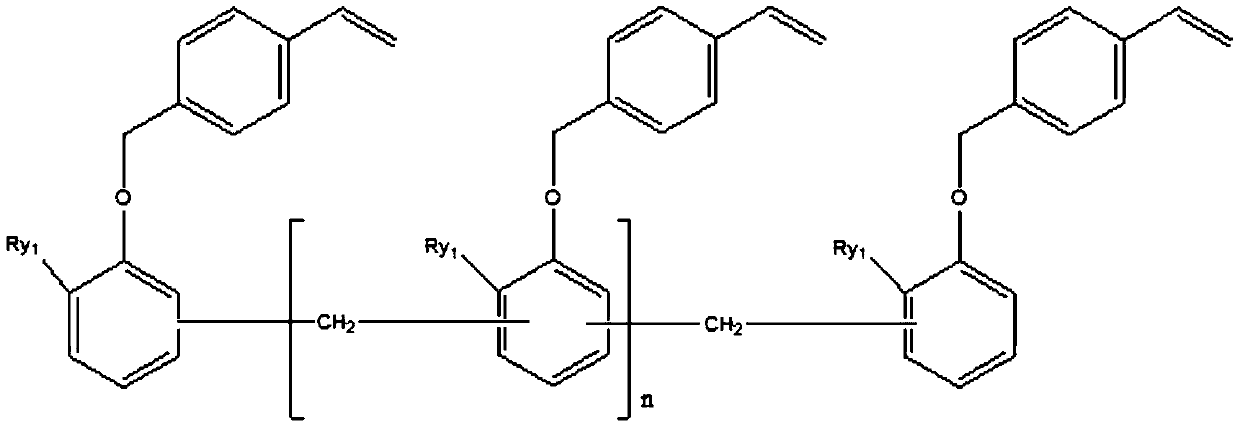

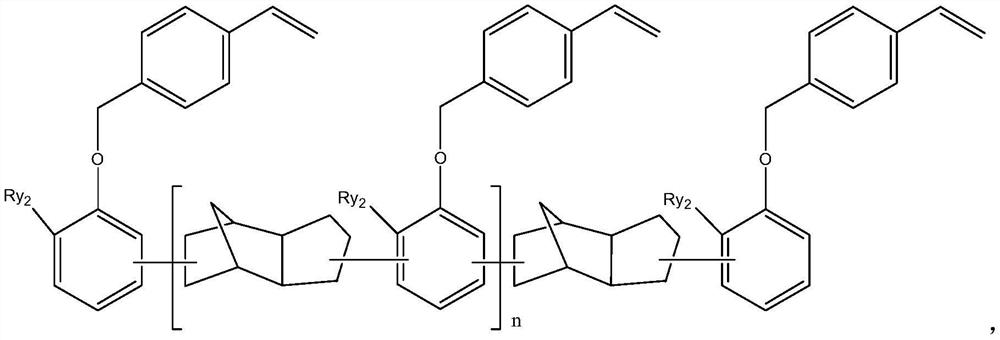

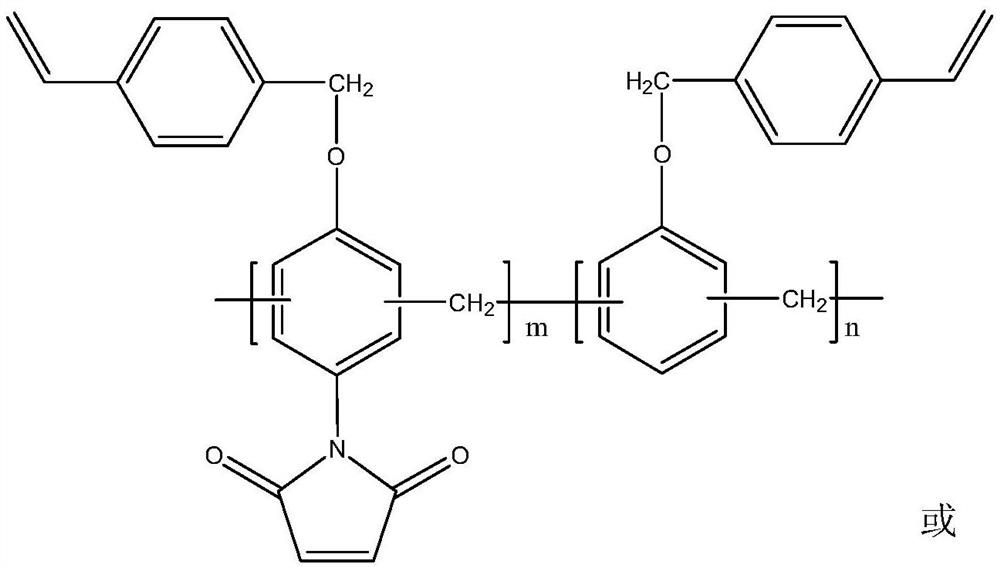

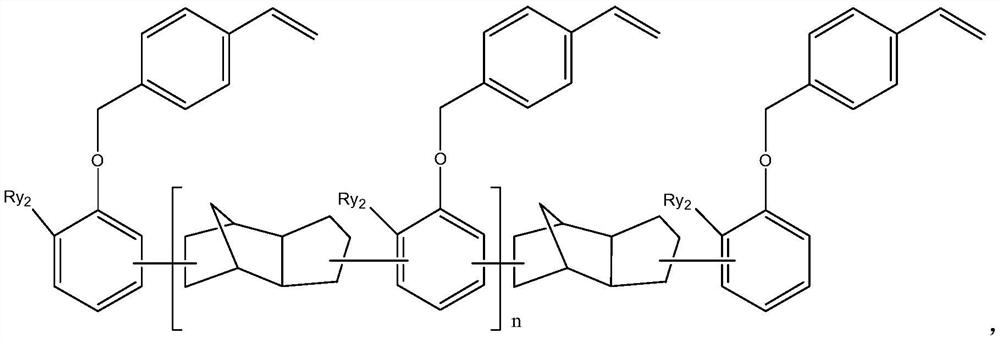

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from the materials in parts by weight: (a) 100 parts of epoxy resin, (b) 50-200 parts of unsaturated polyester active-ester resin shown in the structural formula (I), (c) 10-200 parts of resin which contains maleimido and vinyl simultaneously and is shown in the structural formula (II), (d) 10-200 parts of cyanate ester resin and (e) 0.05-4 parts of an accelerant. Through unsaturated-bond reactivity between unsaturated polyester active-ester, the resin which contains the maleimido and thevinyl simultaneously and cyanate ester, the epoxy resin, the maleimide resin and the cyanate ester resin are effectively combined in a resin system, and thus a cured resin composition has excellent dielectricity, heat resistance, strength and stiffness and flexibility, is high in peel strength, low in water absorption and small in hot-shrinkage rate, and can be applied to high-speed and high-frequency printed circuit boards.

Owner:常熟生益科技有限公司

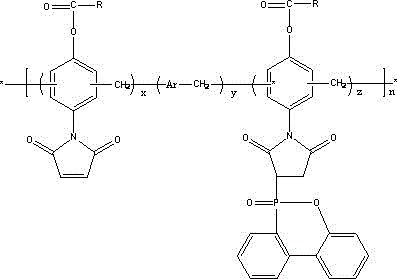

Thermosetting resin composition, and prepreg and laminated plate produced by using thermosetting resin composition

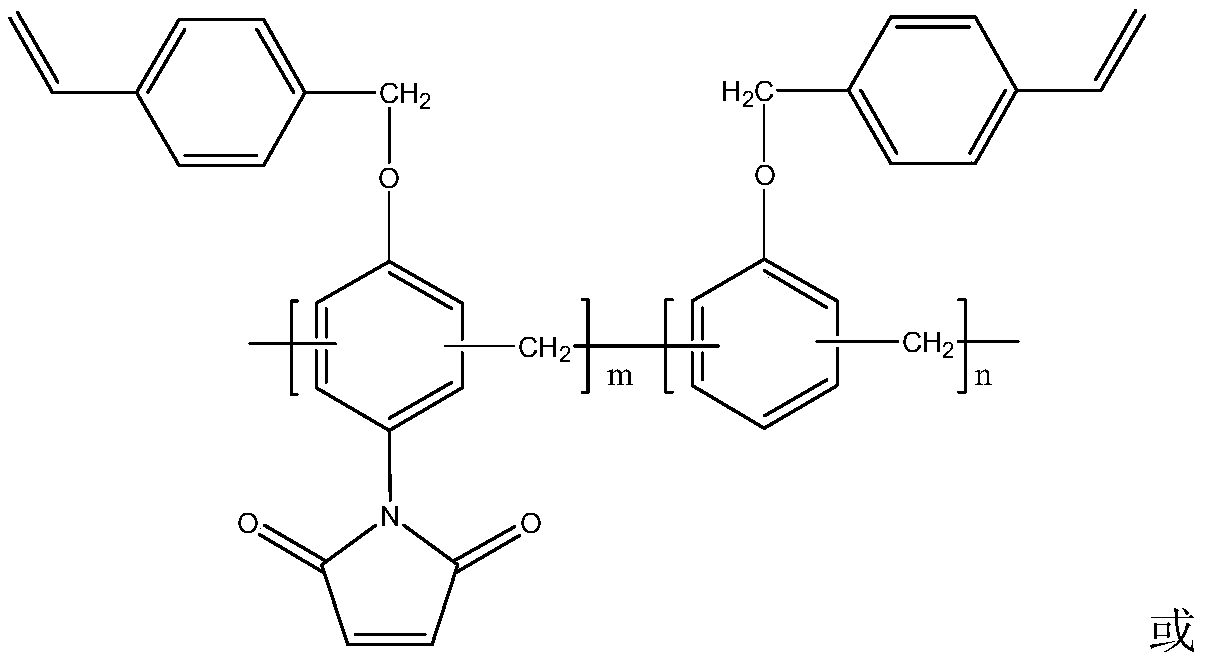

ActiveCN106243626AGood compatibilityImprove interface performanceSynthetic resin layered productsElectrical equipmentImideEpoxy

The present invention discloses a thermosetting resin composition, which comprises (calculated as the solid weight): (a) 10-80 parts of a hydrocarbon resin, (b) 20-100 parts of maleimide ester, (c) 0.1-8 parts of an initiator, and (d) 5-100 parts of an epoxy resin. According to the present invention, the maleimide ester having the polyfunctional long-chain structure and the rigid imide ring is used and is matched with the hydrocarbon resin having the flexibility to form the thermosetting composition, such that the thermosetting resin composition and the prepared printed circuit prepreg and laminated plate produced by using thermosetting resin composition have characteristics of excellent dielectric property, excellent heat resistance, excellent adhesion, excellent flame retardancy, excellent flexural strength, excellent toughness, high peel strength, low water absorption, excellent processability and the like through the interaction between the hydrocarbon resin and the maleimide ester.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepreg and laminated board prepared by using composition

ActiveCN109867912AImprove heat resistanceHigh mechanical strengthMetal layered productsEpoxyAbsorption ratio

The present invention discloses a thermosetting resin composition. The composition comprises the following components, in parts by weight: (a) 100 parts of epoxy resin; (b) 50-200 parts of unsaturatedpolyester active ester resin; (c) 10-200 parts of vinyl benzyl modified phenolic resin; and (d) 0.05-4 parts of an accelerant. According to the composition provided by the invention, the unsaturatedpolyester active ester resin can effectively combine an active ester curing epoxy resin system, a hydrocarbon resin curing system and a vinyl benzyl modified phenolic resin system through chemical bonding, the excellent properties of the active ester curing epoxy system, the excellent properties of the hydrocarbon resin and the excellent properties of the vinyl benzyl modified phenolic resin system are combined effectively, so that the resin composition has excellent dielectric properties, heat resistance, strength, stiffness flexibility, high peeling strength, a low water absorption ratio anda low heat shrinkage ratio after being cured, and can be applied to high-speed high-frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepreg made of thermosetting resin composition, as well as laminated board

ActiveCN106221126AImprove toughnessImprove heat resistanceSynthetic resin layered productsLaminationImideDielectric

The invention discloses a thermosetting resin composition which is prepared from the following components based on the weight of solids: (a) 10 to 100 parts of hydrcarbon resin, (b) 20 to 100 parts of maleimide ester, and (c) 0.1 to 8 parts of an initiator. According to the thermosetting resin composition, the maleimide ester with a polyfunctional long chain structure and a rigid imide ring works together with the flexible hydrcarbon resin to form a thermosetting composition, and the maleimide ester and the rigid imide ring react with each other, so that finally the thermosetting resin composition and a prepreg made of the thermosetting resin composition as well as a laminated board have the characteristics of excellent dielectric property, heat resistance, adhesion property, flame retardancy, bending strength and toughness, high peeling strength, low water absorption rate, excellent processing property and the like.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepregs and laminates produced by using the same

ActiveCN106349442AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideEpoxy

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight: (a) 10-80 parts of hydrocarbon resin; (b) 100 parts of phosphoric maleimide; (c) 0.1-8 parts of initiator; (d) 5-100 parts of epoxy resin. he thermosetting resin composition applies the maleimide with multi-functional long-chain structure and rigid imide ring and combines with a flexible hydrocarbon resin to form a thermosetting composition through the interaction, and finally makes the thermosetting resin composition and prepregs and laminates produced by using the same for the printed circuit have the characteristics of excellent dielectrical property, heat resistance, adhesion, flame resistance, bending strength, toughness, high peel strength, low water absorption, excellent processing performance and others.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepreg and laminated board prepared by applying same

ActiveCN109943047AImprove heat resistanceHigh mechanical strengthSynthetic resin layered productsMetal layered productsEpoxyHeat resistance

The invention discloses a thermosetting resin composition which is prepared from the following components in parts by weight: (a) 100 parts of epoxy resin, (b) 50-200 parts of unsaturated polyester active ester resin, (c) 10-200 parts of vinyl modified polyphenyl ether ester, and (d) 0.05-4 parts of an accelerant. The unsaturated polyester active ester resin can combine an active ester cured epoxyresin system, a hydrocarbon resin curing system and a polyphenyl ether system effectively by means of chemical bonds and combine excellent performance of the active ester cured epoxy resin system, the hydrocarbon resin curing system and the polyphenyl ether system effectively, so that the resin composition which is cured has excellent dielectric property, heat resistance, strength, stiffness andflexibility, high peel strength, low water absorption and small heat shrinkage, and can be applied to high speed and high frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

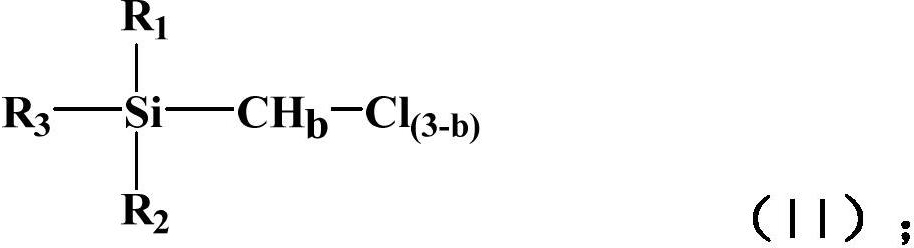

Siloxane-terminated polyether type lithium battery adhesive and preparation method thereof

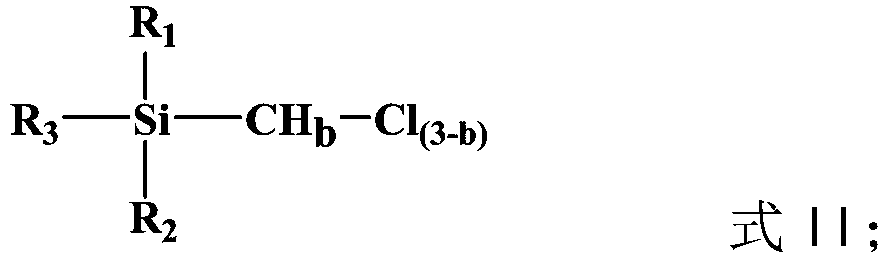

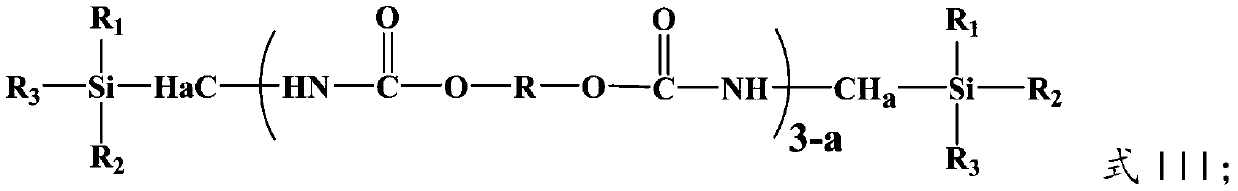

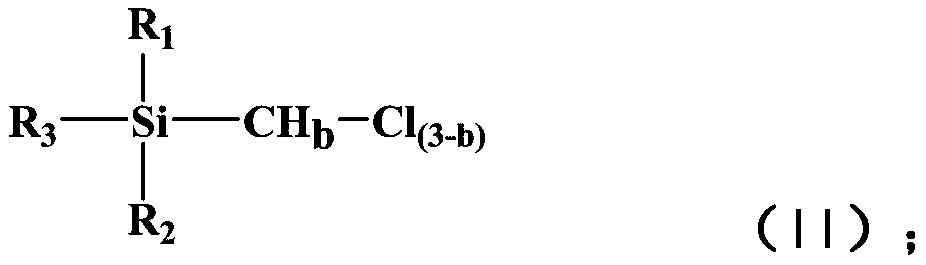

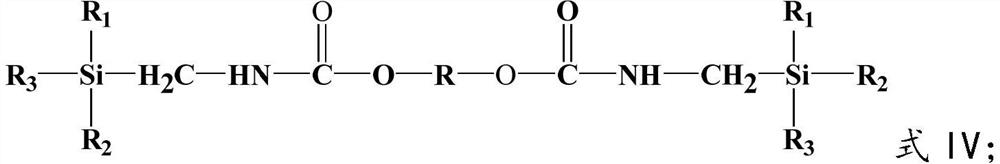

ActiveCN110746922AMeet compatibilityModerate degree of crosslinkingPolyether adhesivesPolyesterPtru catalyst

The invention discloses a siloxane-terminated polyether type lithium battery adhesive and a preparation method thereof. The preparation method comprises the following steps: 1) sequentially adding a solvent and cyanate into a reaction bottle, performing stirring and mixing, further adding a phase transfer catalyst, performing heating to 70-100 DEG C, and performing uniform constant temperature activation and dispersion for 30 minutes; and 2) respectively dropwise adding measured chlorosilane and polyether alcohol, or chlorosilane and polyester alcohol into the activation solution in the step 1), increasing the exothermic reaction temperature to 90-120 DEG C, maintaining the temperature range, performing a continuous reaction for 6-8 hours, after the reaction is completed, performing cooling to the room temperature, performing filtering so as to obtain filtrate, and removing the solvent, so as to obtain the siloxane-terminated polyether type lithium battery adhesive. The siloxane-terminated polyether type lithium battery adhesive disclosed by the invention is simple in preparation method, low in cost, high in efficiency, fast in adhesion and easy in industrialization. Prepared siloxane-terminated polyether for adhesion of lithium batteries is capable of improving the efficiency of the lithium batteries, high and low temperature resistance, stable charge and discharge efficiencyand bonding properties of the lithium batteries.

Owner:HUBEI UNIV

High-temperature-resistant anti-radiation mortar and preparation method thereof

The invention discloses high-temperature-resistant anti-radiation mortar and a preparation method thereof, and belongs to the technical field of anti-radiation mortar. The high-temperature-resistant anti-radiation mortar consists of the following components in parts by weight: 5 to 15 parts of cement, 6 to 10 parts of mineral powder, 3 to 5 parts of dispersed emulsion powder, 30 to 50 parts of vitrified micro-beads, 2 to 4 parts of glass fibres, 2 to 4 parts of aluminium oxide, 3 to 5 parts of perlite powder, 5 to 7 parts of nano-lead particles, and 2 to 4 parts of rubber powder. The invention aims to provide the high-temperature-resistant anti-radiation mortar and the preparation method thereof. The inherent characteristics of the aluminium oxide and the nano-lead particles are utilized and are combined with the interactions of other components, so that the high-temperature-resistant anti-radiation mortar has good rigid-flexible characteristics, does not layer, segregate and sag, has high structural stability under a high temperature, and meanwhile, has the characteristics of corrosion resistance, wear resistance and the like, and has high anti-radiation performance; the safety level of the anti-radiation mortar is improved.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

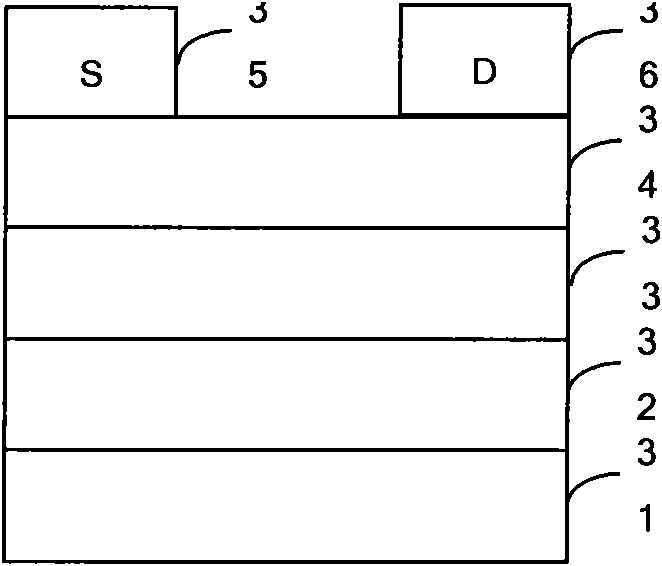

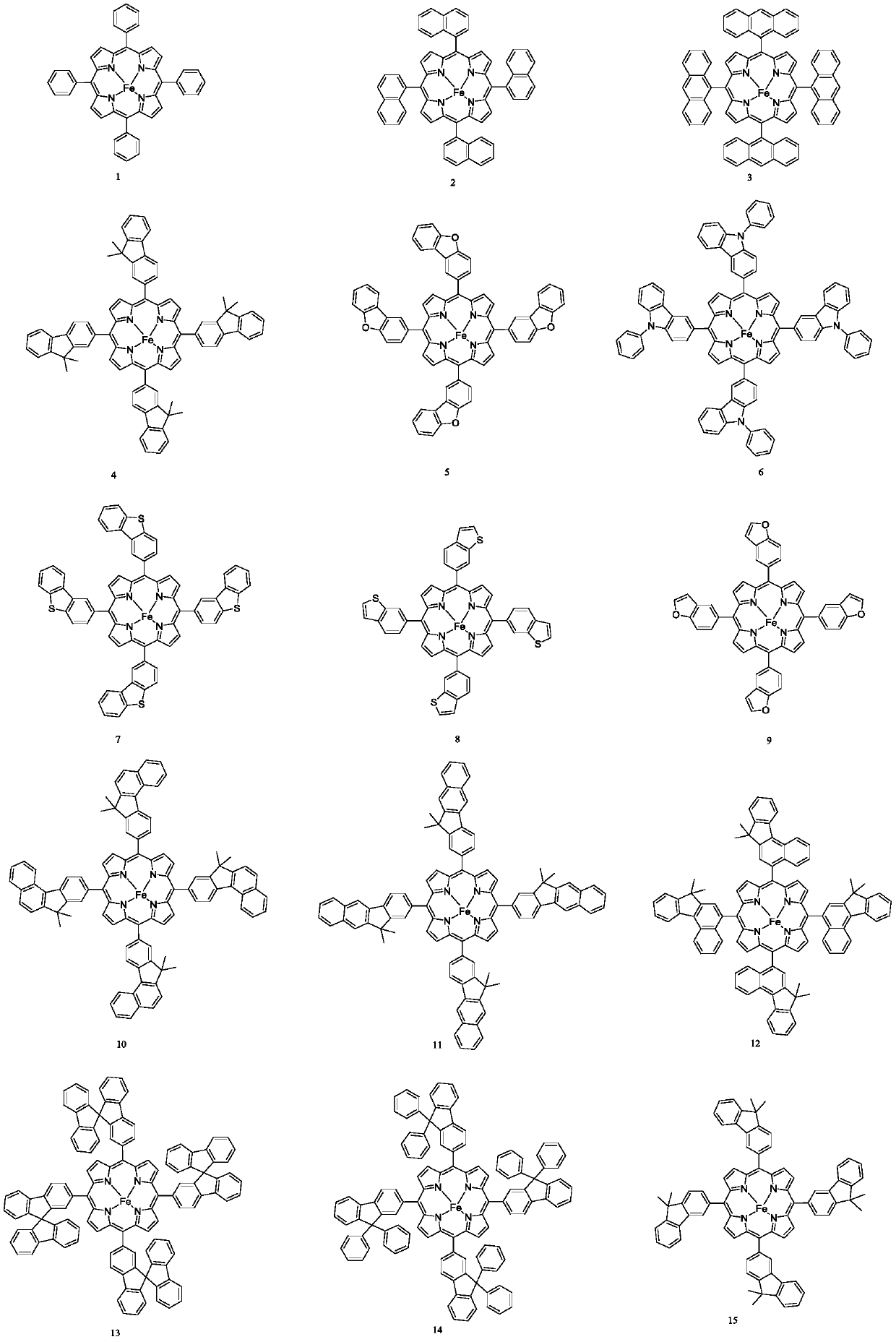

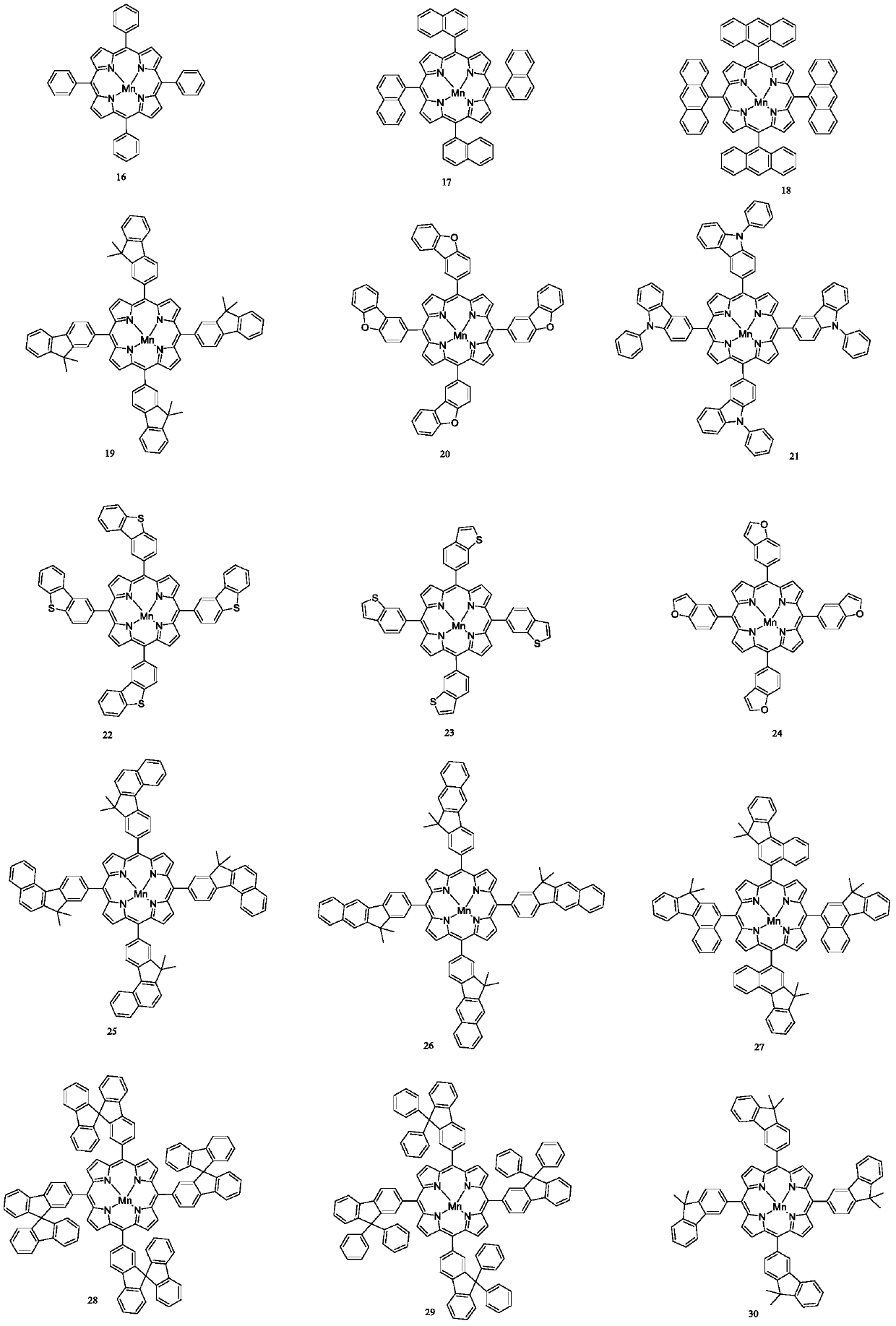

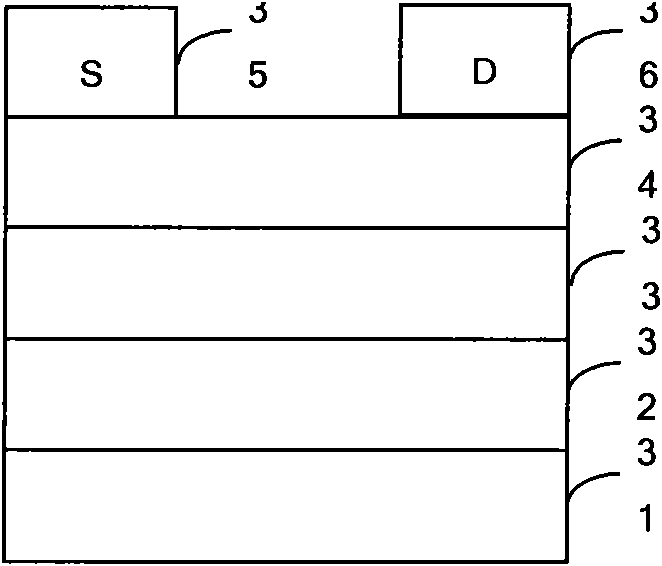

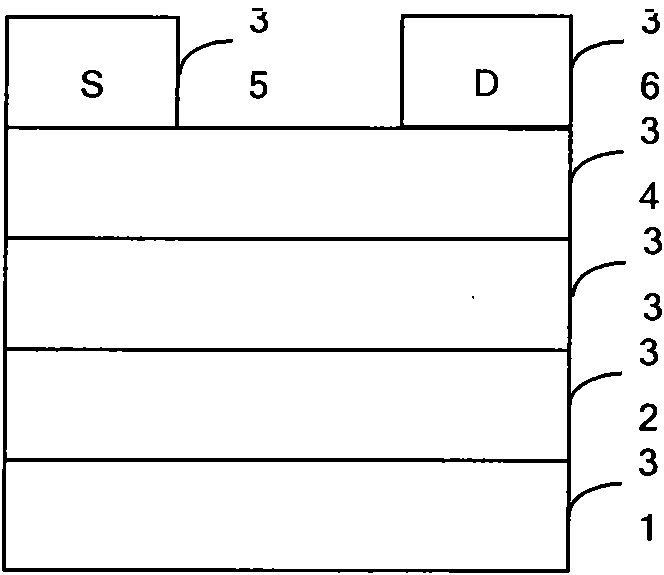

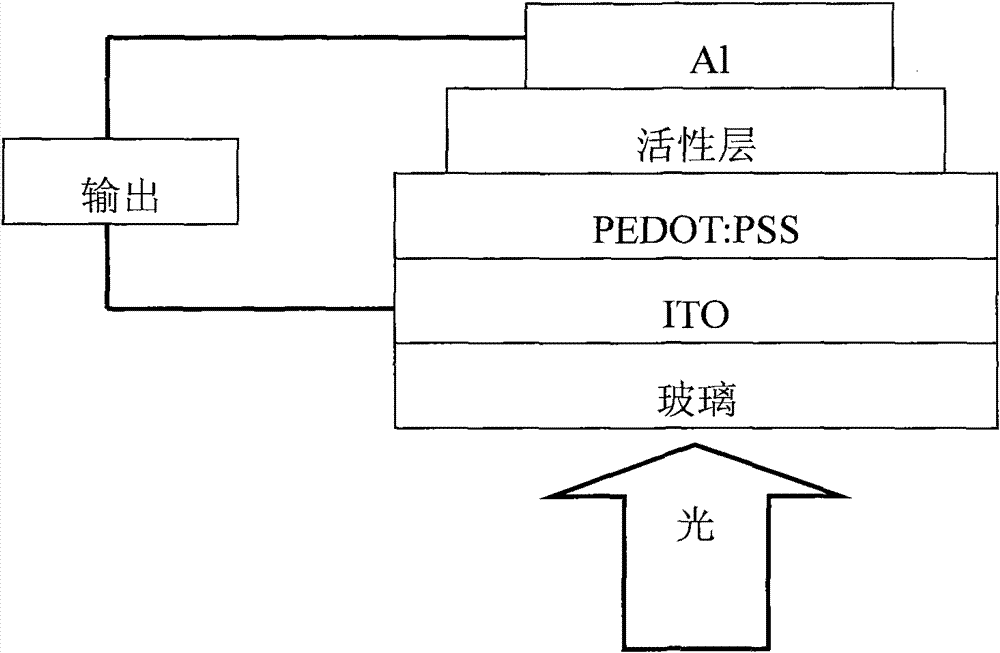

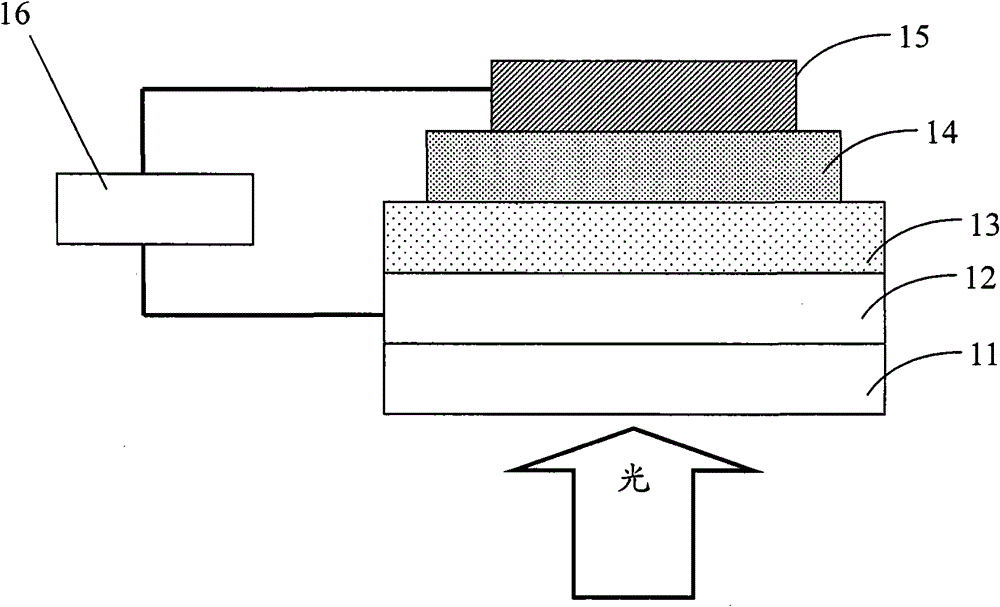

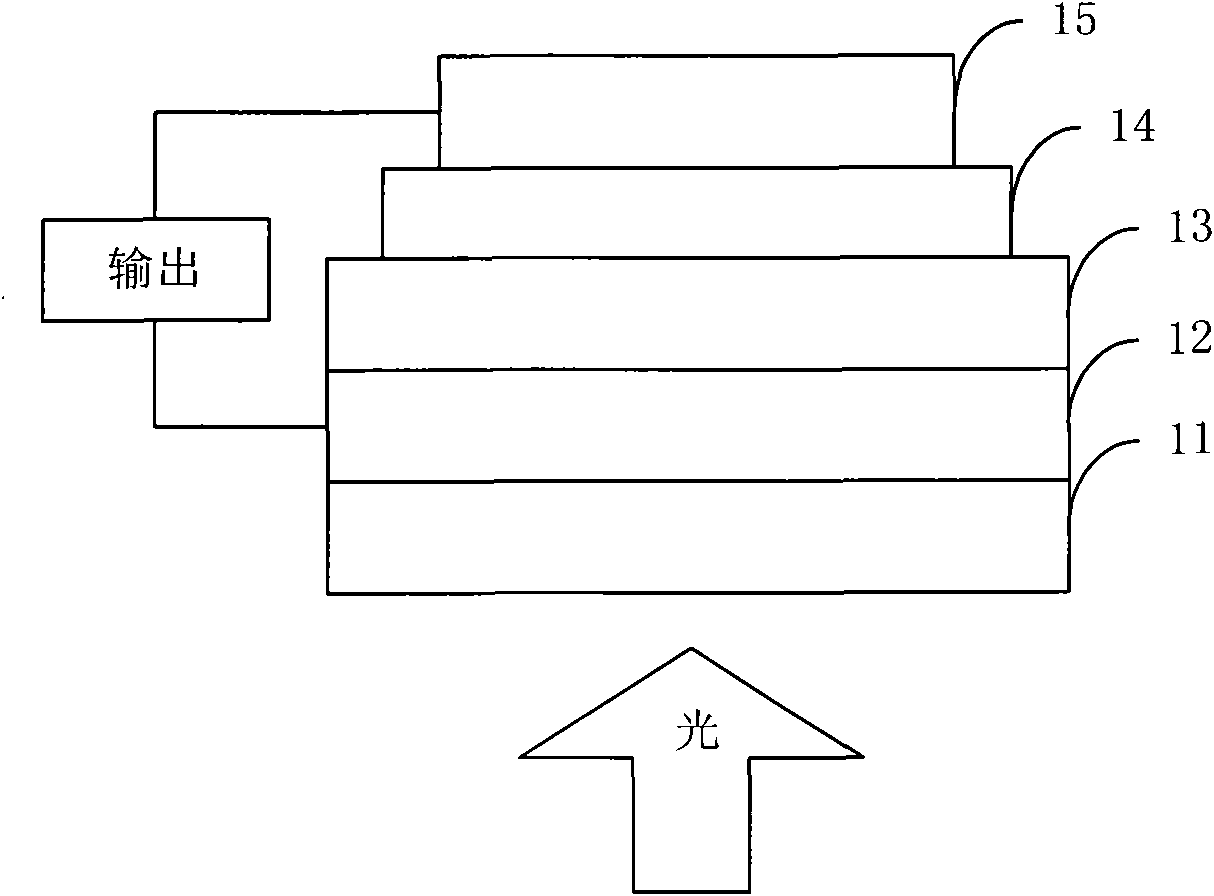

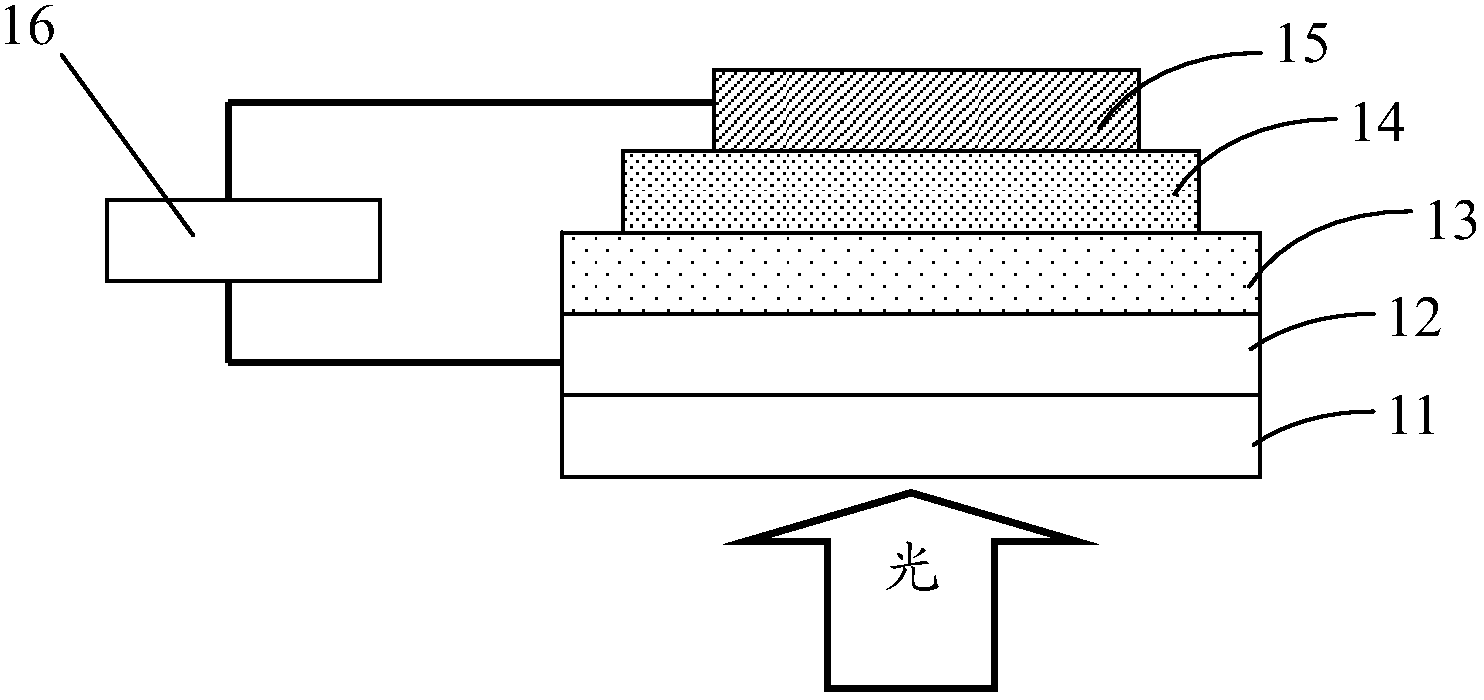

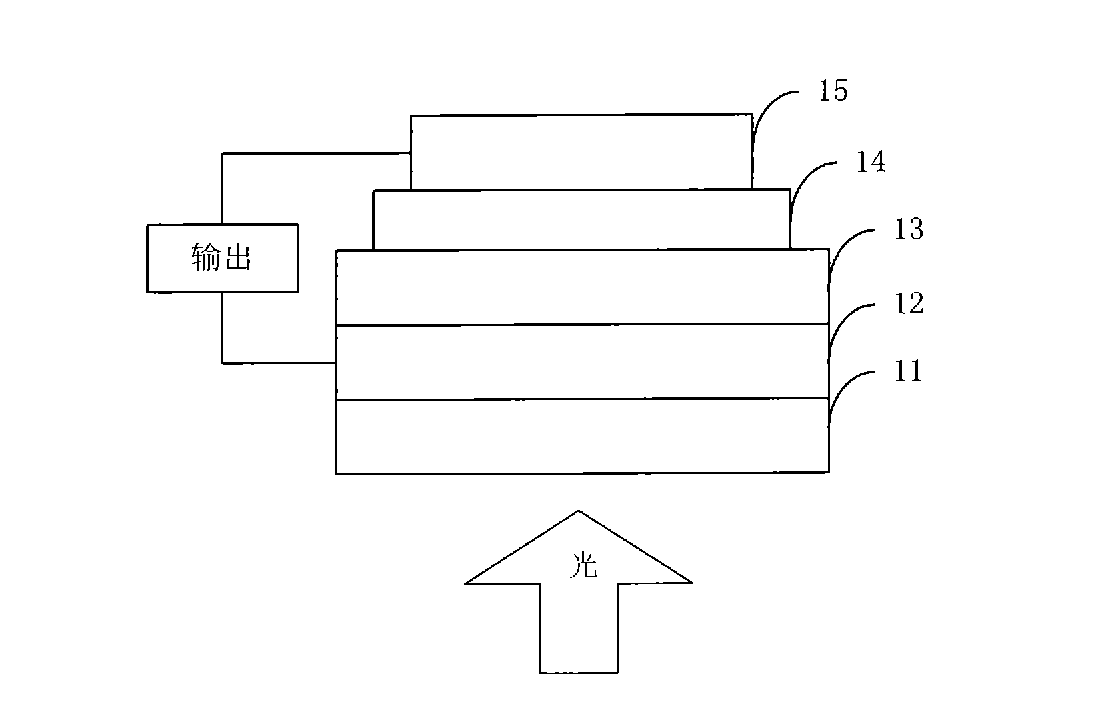

Metal porphyrin-diazosulfide organic semiconductor material as well as preparation method and application thereof

InactiveCN102417586AHigh affinityEasy injectionGroup 4/14 element organic compoundsLaser active region structureSemiconductor materialsPorphyrin

The invention belongs to the field of photoelectron materials, which discloses a metal porphyrin-diazosulfide organic semiconductor material as well as a preparation method and application thereof. The metal porphyrin-diazosulfide organic semiconductor material has a structural formula (P), wherein n is an integer from 1-100, R1, R2, R3 and R4 is H, the alkyl of C1-C32, phenyl and alkylbenzene oralkoxy benzene containing one or a plurality of C1-C32, and M is a metal ion. The metal porphyrin-diazosulfide organic semiconductor material provided by the invention has the advantages of good filmforming property, strong absorbance and wide light absorption range, and the use ratio of the metal porphyrin-diazosulfide organic semiconductor material on sunlight is improved. The metal porphyrin-diazosulfide organic semiconductor material has better thermal stability and environment stability. In addition, the preparation method has a simple technology and is easy to operate and control.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

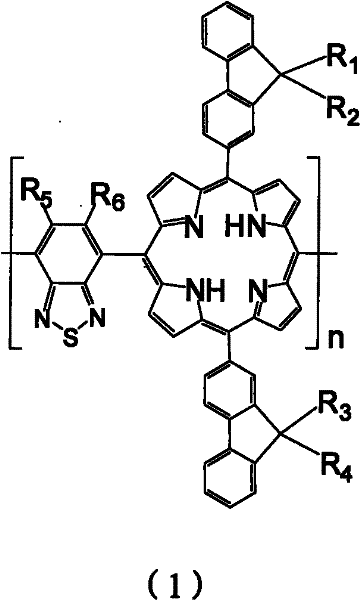

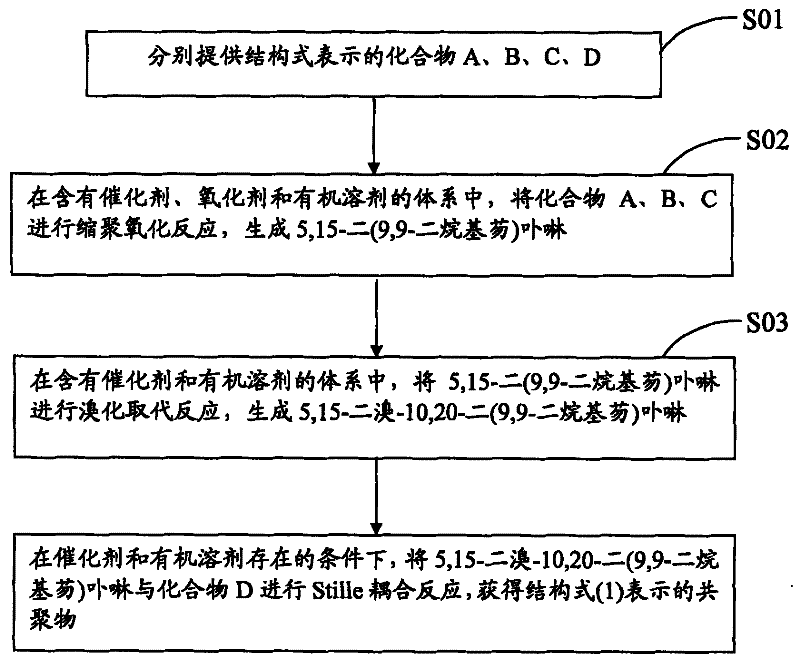

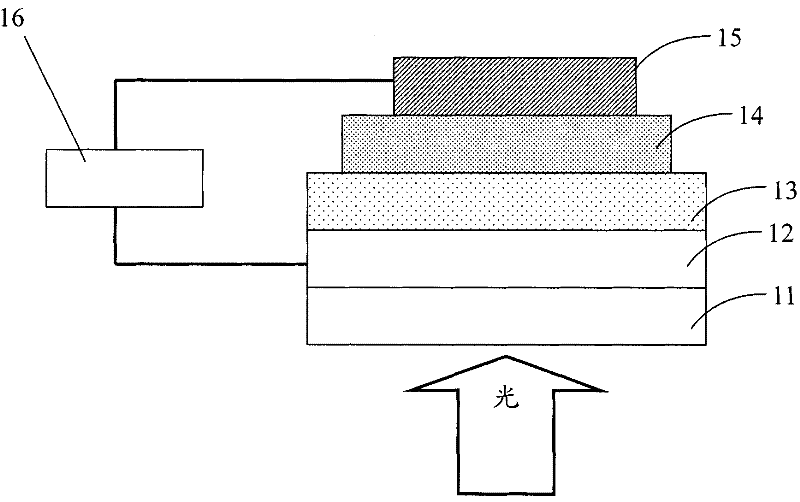

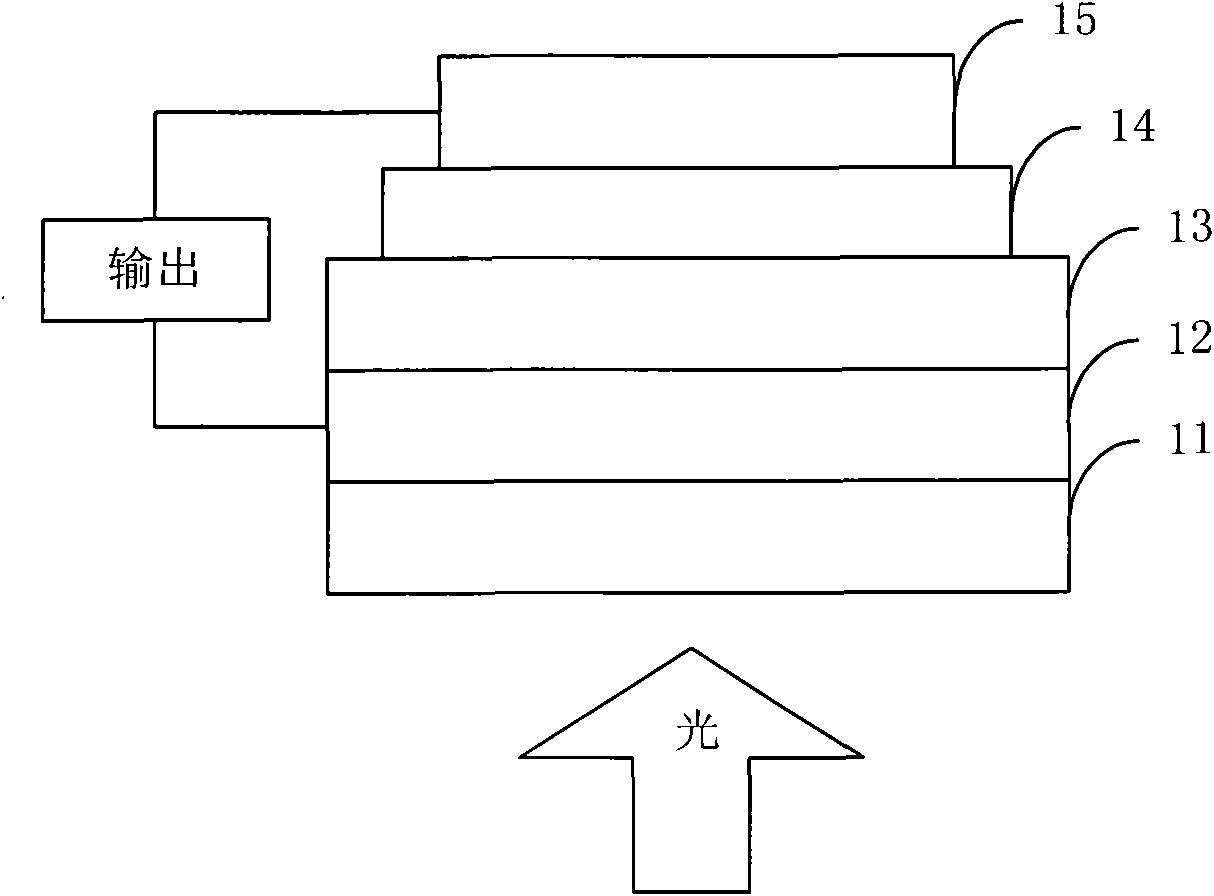

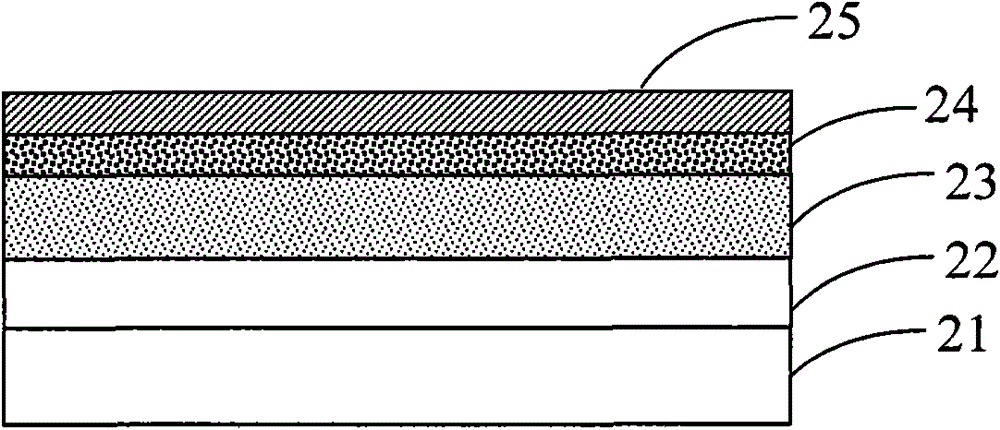

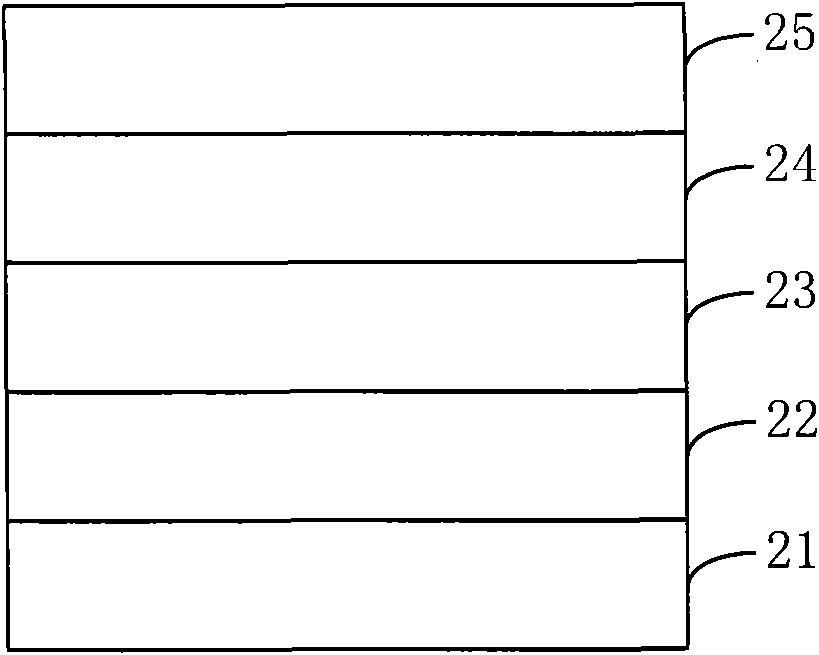

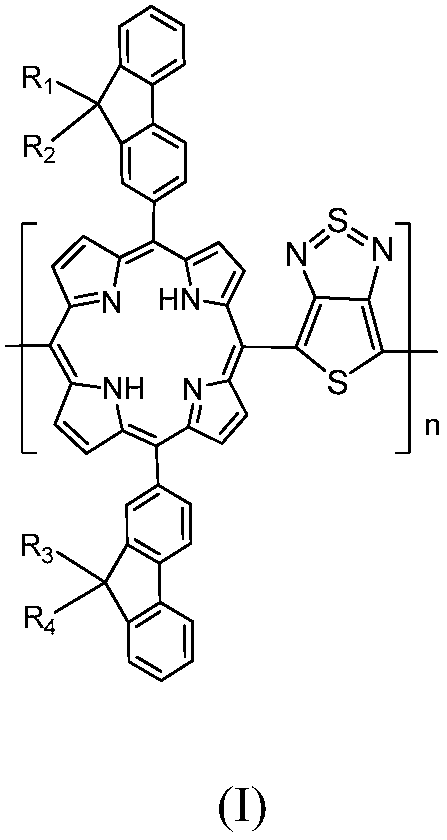

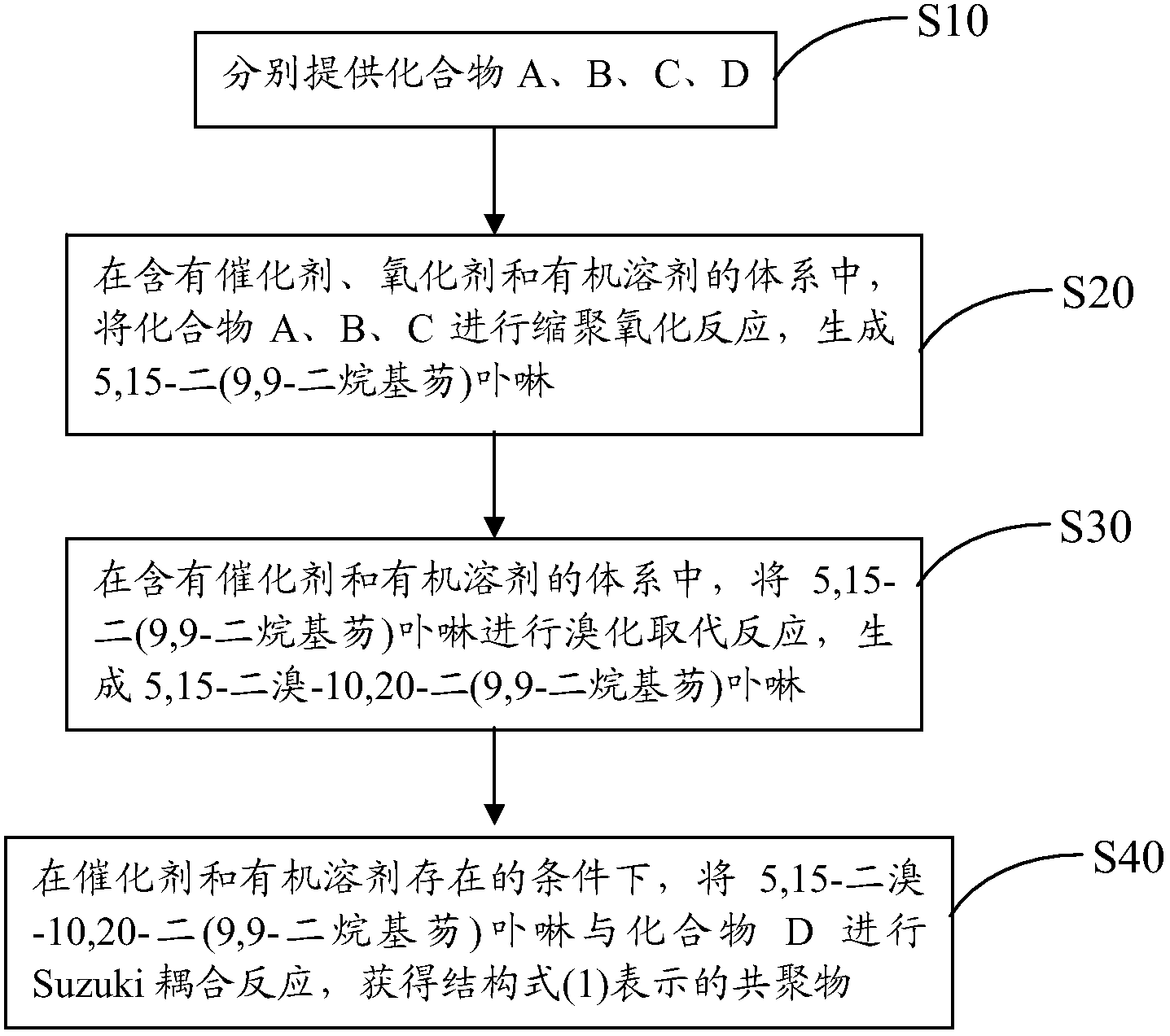

Porphyrin copolymer containing benzothiadiazole unit, its preparation method and application

InactiveCN102206328ALower energy gapBandgap narrowingSolid-state devicesSemiconductor/solid-state device manufacturingSpectral responsePorphyrin

The invention relates to the field of organic material technology, and provides a porphyrin copolymer containing benzothiadiazole unit, which is a copolymer expressed in a structural formula (1). Wherein R1, R2, R3, R4, R5, R6 are selected from alkyl of C1 to C32; n is an integer of 1 to 200. The invention also provides a method for preparing the porphyrin copolymer containing benzothiadiazole unit and an application. The porphyrin copolymer containing benzothiadiazole unit has excellent light stability and heat stability due to a fluorenes porphyrin structure and benzothiadiazole unit. And the benzothiadiazole unit is introduced in the polymer for widening a spectral response range of the polymer.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Metalloporphyrin-thienothiadiazole organic semiconductor material and preparation method and application thereof

ActiveCN102453234AExpand the scope of absorptionIncrease profitLaser active region structureSolid-state devicesSemiconductor materialsPorphyrin

The invention belongs to the field of optoelectronic materials and discloses a metalloporphyrin-thienothiadiazole organic semiconductor material and a preparation method and application thereof. The metalloporphyrin-thienothiadiazole organic semiconductor material has a structural formula (P) shown in the specification, wherein in the formula, n is an integer from 1 to 100; R1, R2, R3 and R4 are H, C1-C32 alkyl, phenyl and alkylbenzene or alkoxy benzene containing one or more C1-C32; and M is a metal ion. The metalloporphyrin-thienothiadiazole organic semiconductor material has good film-forming property, strong absorbance and wide light absorption range, thus improving the sunlight use ratio of the material. The material also has better heat stability and environmental stability. Besides, the preparation method is simple in process and easy to operate and control.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Cutting-resistant glove processing technology

InactiveCN110644243ASimple processing technologyImprove cut resistanceWeft knittingGlovesPolyesterYarn

The invention provides a cutting-resistant glove processing technology, and relates to the field of labor protection gloves. The cutting-resistant glove processing technology includes the steps: glovecore preparation; glove core coating. Inner yarns and outer yarns are interwoven to form a glove core, polyethylene fibers with super-high relative molecule weight and bamboo-carbon modified polyester fibers wrap carbon fibers to form the outer yarns, and polyethylene fibers with super-high relative molecule weight and nylon fibers spirally wrap polyurethane filaments to form the inner yarns. A coating method of the glove core particularly includes the step: coating a composite material outside the woven glove core. The cutting-resistant glove processing technology is simple, large-scale automation production can be achieved, a processed cutting-resistant glove has excellent cutting resistance, comfortable and portable to wear and long in service life, hand flexibility is good, and replacing frequency is reduced.

Owner:徐州华通手套有限公司

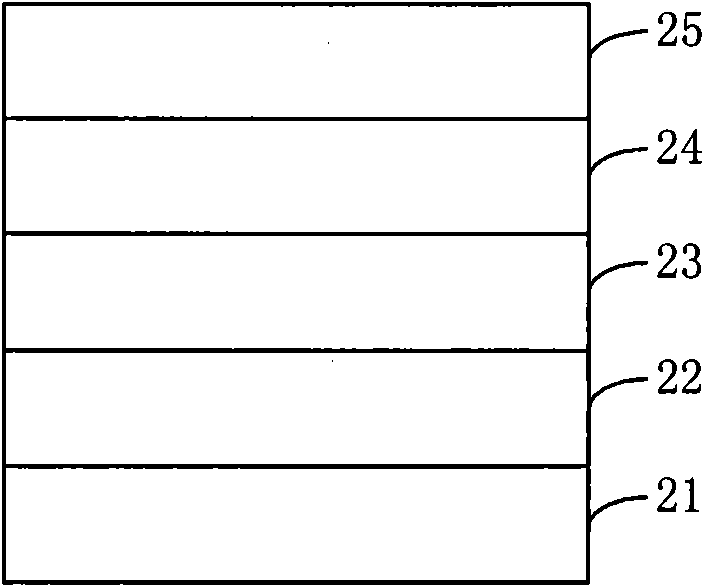

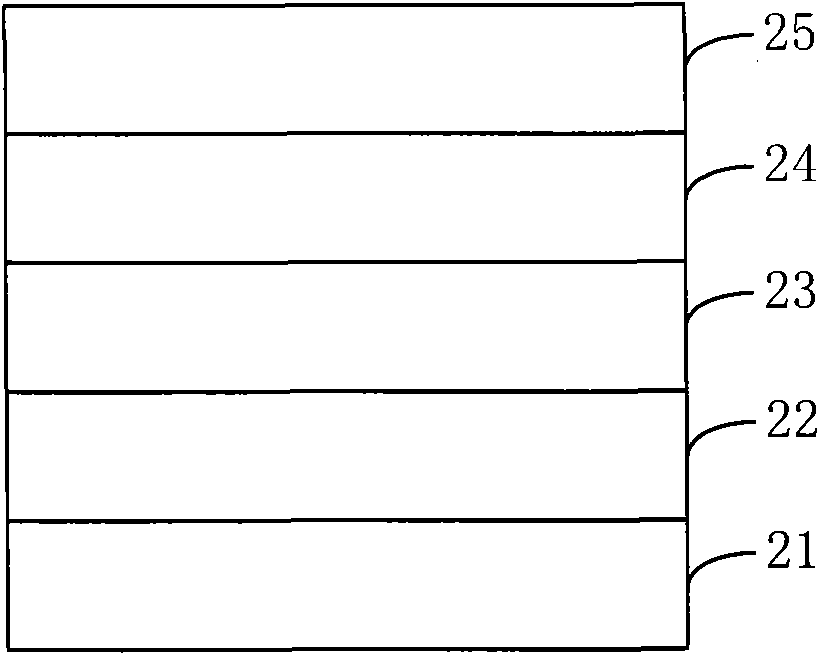

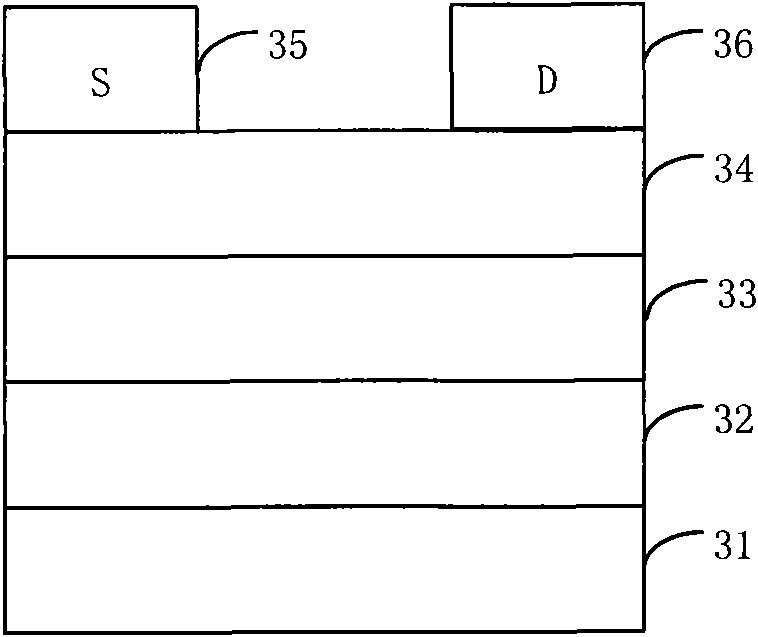

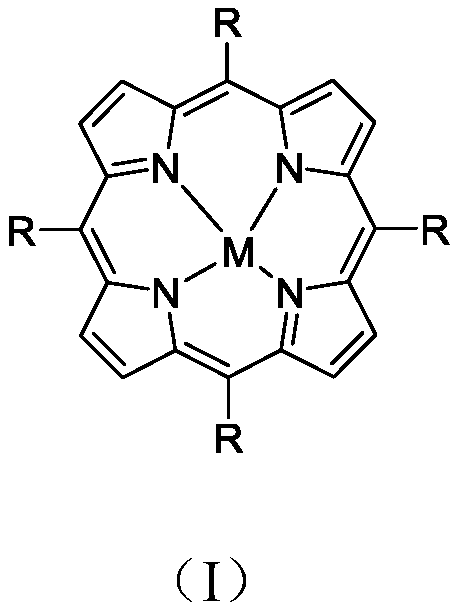

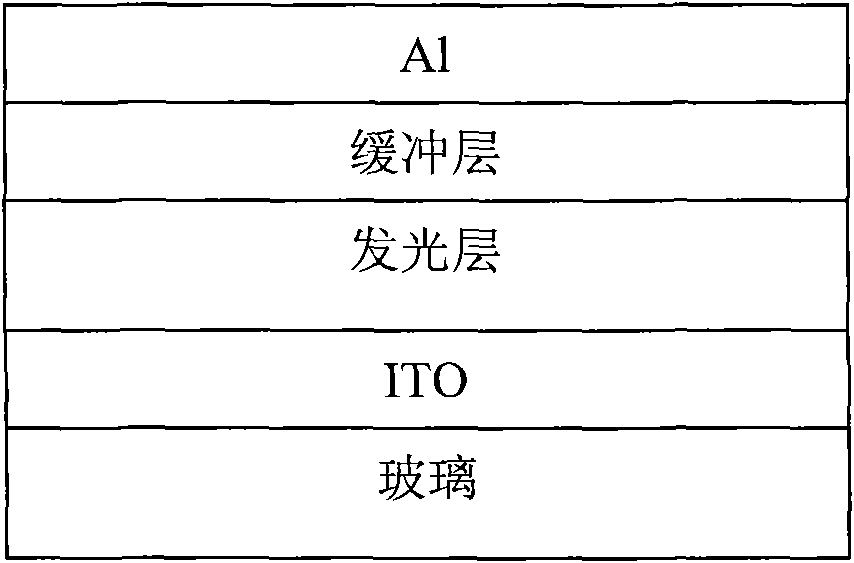

Metalloporphyrin complex and organic electroluminescent device thereof

InactiveCN110615793AReduce collisionOvercoming the roll-off of efficiency at high current densitiesOrganic chemistrySolid-state devicesHigh current densityPorphyrin

The invention provides a metalloporphyrin complex and an organic electroluminescent device thereof, and belongs to the technical field of organic photoelectric materials. The invention discloses a metalloporphyrin complex, which contains a porphyrin-containing unit and has a macrocyclic delocalized [pi] electron conjugated system with a planar structure. The quantum efficiency of charge transfer and energy transfer reactions is high, the quantum efficiency has good electron buffering performance and photoelectric magnetism, good rigidity and flexibility and good thermal stability and environmental stability, collision between triplet excitons is reduced, and the problem of roll-off of the efficiency of the device under high current density is solved. The organic light-emitting device prepared by using the complex as an object doping material has the advantages of low driving voltage and high light-emitting efficiency, and is an organic light-emitting material with excellent performance.

Owner:JILIN TEACHERS INST OF ENG & TECH

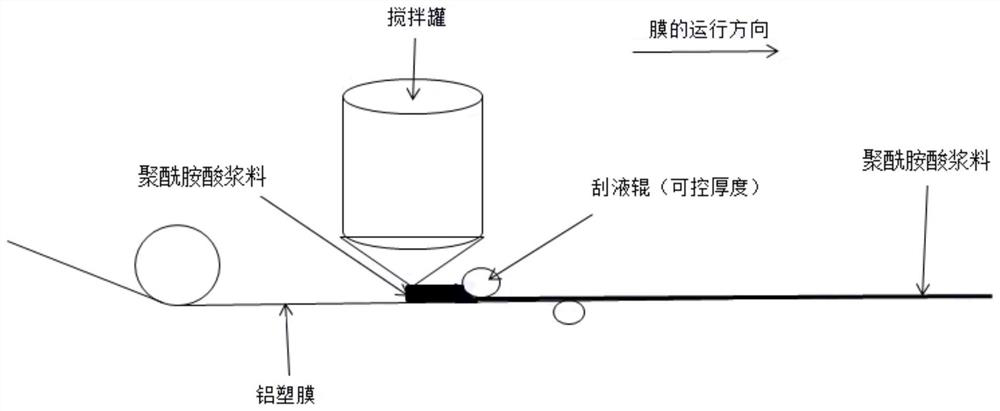

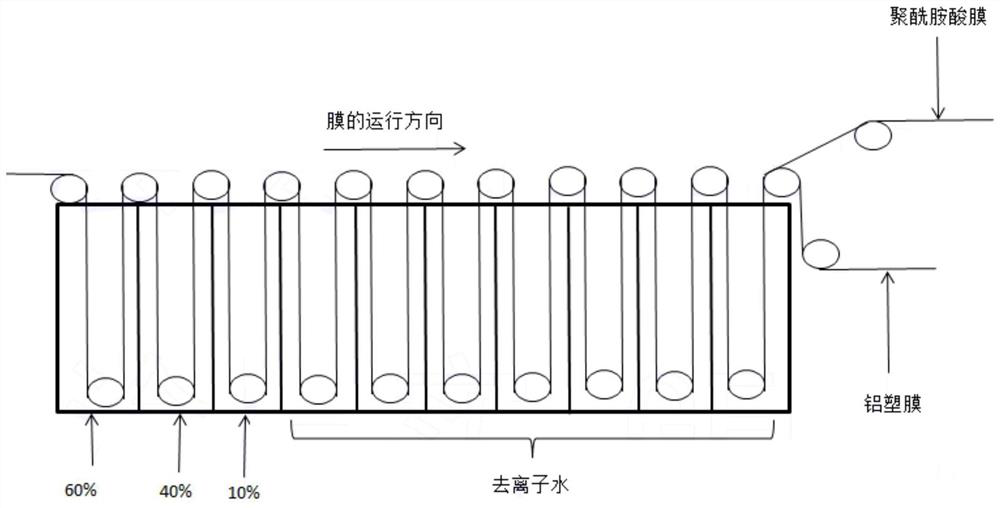

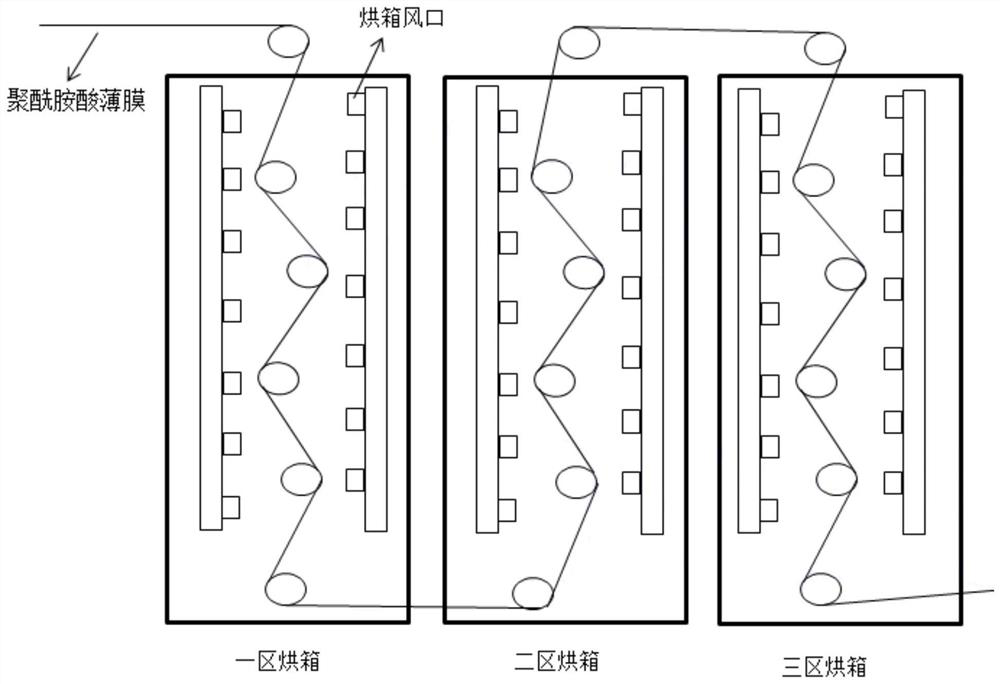

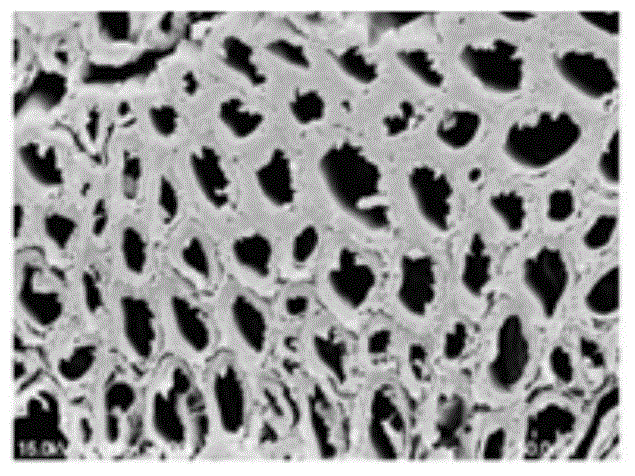

Polyimide diaphragm and preparation method thereof

ActiveCN111875797AGood rigidity and flexibilityImprove thermal stabilityLi-accumulatorsCell component detailsPolymer sciencePyrrolidinones

The invention discloses a preparation method of a polyimide diaphragm, which comprises the following steps: reacting p-phenylenediamine or 4,4-diaminodimethyl ether with pyromellitic dianhydride or 3,3,4,4-biphenyl tetracarboxylic dianhydride in N-methyl pyrrolidone to obtain a polyamide acid solution; uniformly mixing the polyamic acid solution with dimethyl carbonate to obtain polyamic acid slurry; spreading the polyamide acid slurry uniformly on the horizontal conveying film by controlling the thickness of the polyamide acid slurry, wherein the polyamide acid slurry uniformly adheres to thehorizontal conveying film, and a polyamide acid film is obtained; and extracting the polyamide acid film, removing the horizontal transfer film, drying the film to obtain a diaphragm precursor, and dehydrating the film at high temperature to obtain the polyimide diaphragm. According to the invention, the molecular structure is designed, so that the prepared polyimide diaphragm has better rigidityand flexibility; in addition, a large number of hydrogen bonds appear among polyimide molecules, and the interaction among the polyimide molecules is improved, so that the prepared polyimide diaphragm has relatively good thermal stability.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

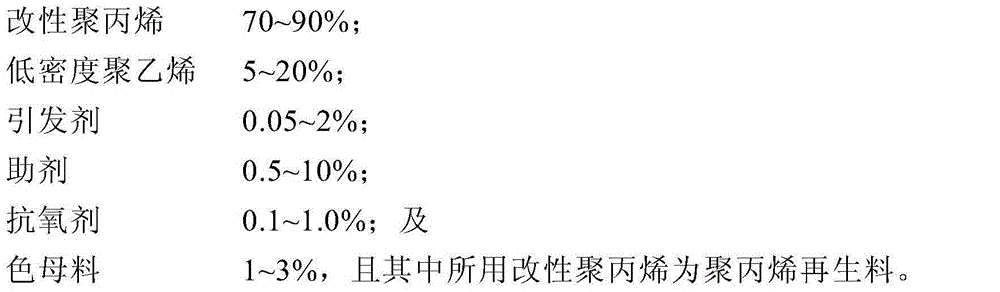

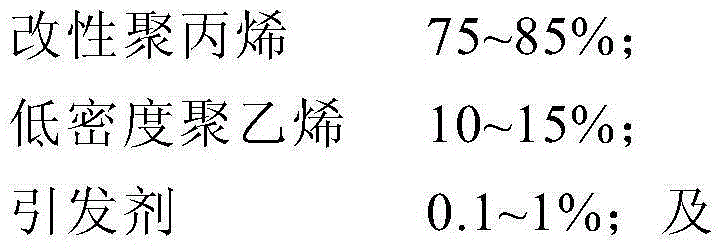

Materials for non-excavation cable protection pipes and cable protection pipes

InactiveCN103497289BIn line with the development policy of environmental protection and recycling industrySave resourcesLow-density polyethyleneMasterbatch

Owner:EAST CHINA UNIV OF SCI & TECH

Radiation protection mortar used for isolating nuclear leak

ActiveCN106782723AReduce the hazards of nuclear radiationGood rigidity and flexibilityMaterial nanotechnologyShieldingGamma rayGraphite particle

The invention discloses a radiation protection mortar used for isolating nuclear leak. The radiation protection mortar comprises the following ingredients in parts by weight: 10-20 parts of cement, 6-10 parts of mineral powder, 25-40 parts of river sand, 8-10 parts of a dispersed latex powder, 8-15 parts of barite particles, 6-10 parts of polyphenyl ether, 8-12 parts of nano-lead particles, 8-12 parts of polyvinylidene fluoride, and 10-15 parts of graphite particles. The invention aims at providing the radiation protection mortar used for isolating nuclear leak, the radiation protection mortar used for isolating nuclear leak has the characteristics of excellent rigidity and flexibility, good structure stability at high temperature state, corrosion resistance and wear resistance, is not layered, does not segregate, and does not sagging; a wall body built from the radiation protection mortar can isolate and shield alpha rays, beta rays and gamma rays in nuclear radiation, and the harm of the nuclear radiation on people or materials on the other side of the wall body is greatly reduced.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

Metal porphyrin-diazosulfide organic semiconductor material as well as preparation method and application thereof

InactiveCN102417586BHigh affinityEasy injectionGroup 4/14 element organic compoundsLaser active region structureSemiconductor materialsPorphyrin

The invention belongs to the field of photoelectron materials, which discloses a metal porphyrin-diazosulfide organic semiconductor material as well as a preparation method and application thereof. The metal porphyrin-diazosulfide organic semiconductor material has a structural formula (P), wherein n is an integer from 1-100, R1, R2, R3 and R4 is H, the alkyl of C1-C32, phenyl and alkylbenzene oralkoxy benzene containing one or a plurality of C1-C32, and M is a metal ion. The metal porphyrin-diazosulfide organic semiconductor material provided by the invention has the advantages of good filmforming property, strong absorbance and wide light absorption range, and the use ratio of the metal porphyrin-diazosulfide organic semiconductor material on sunlight is improved. The metal porphyrin-diazosulfide organic semiconductor material has better thermal stability and environment stability. In addition, the preparation method has a simple technology and is easy to operate and control.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

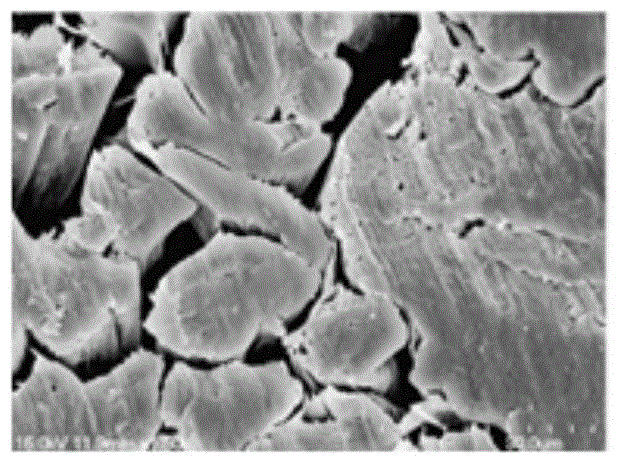

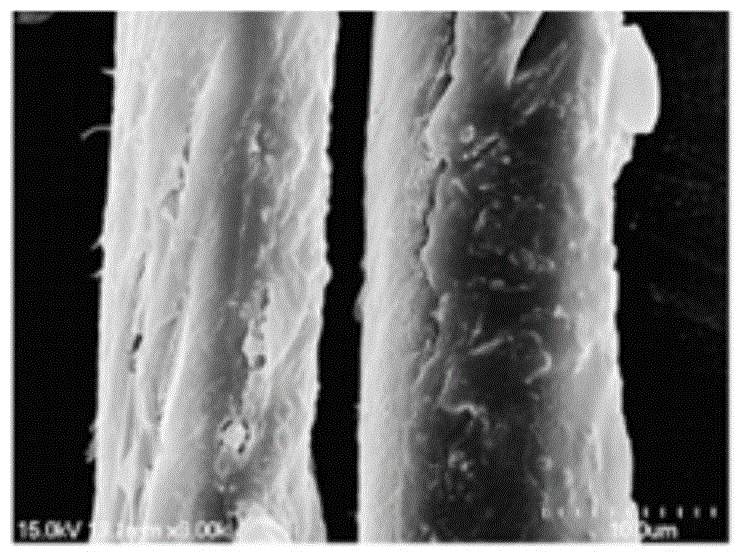

Preparation process of environment-friendly sugarcane peel fibers

InactiveCN105803537AStrong moisture absorption and breathabilityGood rigidity and flexibilityVegetable materialSingle fiberMoisture absorption

The invention discloses a preparation process of environment-friendly sugarcane peel fibers. The preparation process comprises the following steps of: (1), firstly, removing sugarcane peels and transversely cutting the sugarcane peels into small sections with the length of 50mm-75mm; putting the sugarcane peels into clean water and washing; then putting the sugarcane peels into a water batch at the bath ratio of 1 to 30, and boiling for 1-2 hours; replacing the clean water and repeatedly boiling for 1-3 times, and drying; (2) putting the dried sugarcane peels into a mixed solution of hydrochloric acid and formic acid under a stirring condition that the temperature is 80-90 DEG C at the bath ratio of 1 to (20-35), and extracting the sugarcane peel fibers; (3) washing the obtained sugarcane peel fibers with water, and putting the sugarcane peel fibers into an alkaline solution under a stirring condition that the temperature is 75-80 DEG C at the bath ratio of 1 to (20-35) and carrying out alkali boiling treatment; and (4) putting the sugarcane peel fibers subjected to the alkali boiling treatment into a weak acid solution and carrying out neutralizing treatment, and washing with the water and drying to obtain 50%-70% of sugarcane peel single fibers, with the residue of bundle fibers. The sugarcane fibers prepared by the invention have strong moisture absorption and air permeability, good rigidness and softness and strength elongation property, and are environmentally friendly and biodegradable.

Owner:SHANGHAI SHUIXING HOME TEXTILE

A rigid and flexible protective mortar for nuclear power plants

The invention discloses rigid-flexible protecting mortar for nuclear power plants and a preparation method of the rigid-flexible protecting mortar and belongs to the technical field of anti-radiation mortar. The rigid-flexible protecting mortar is prepared from the following components in parts by weight: 5-15 parts of cement, 6-10 parts of mineral powder, 30-50 parts of river sand, 3-5 parts of dispersed latex powder, 6-10 parts of wood fiber powder, 8-12 parts of nano-lead particles and 4-8 parts of epoxy resin powder. The invention aims at providing the rigid-flexible protecting mortar for the nuclear power plants and the preparation method of the rigid-flexible protecting mortar. The rigid-flexible protecting mortar has the characteristics of being long in service life, good in rigid-flexible property, high-temperature structure stability, and anti-radiation property, corrosion-resistant, wear-resistant and capable of avoiding layering, segregation and sagging and preventing nuclear leakage, thereby improving the security level of the nuclear power plants.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

Metal porphyrin-anthracene organic semiconductor material as well as preparation method and application thereof

InactiveCN102417584BHigh affinityEasy injectionGroup 4/14 element organic compoundsLaser active region structureSemiconductor materialsCharge carrier mobility

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

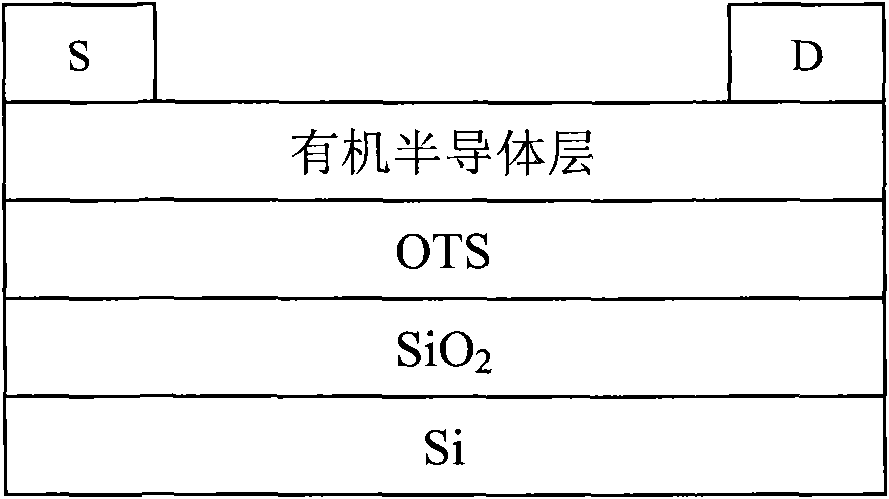

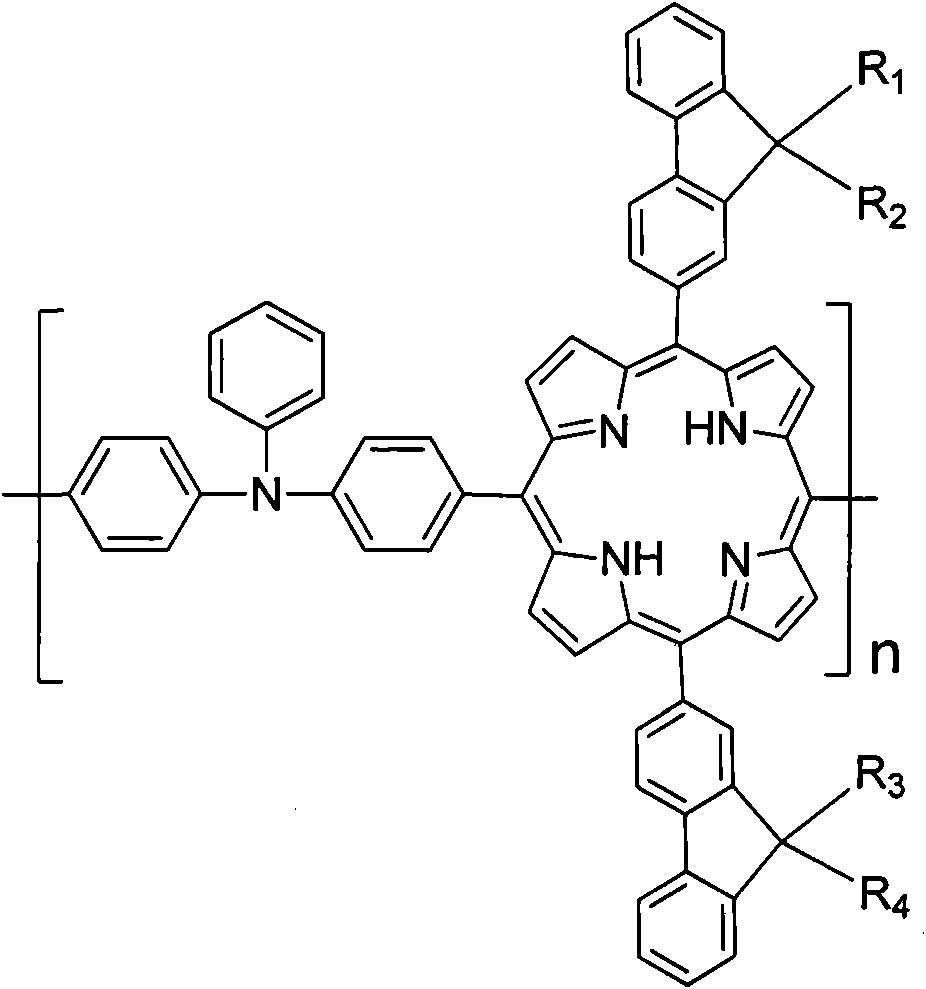

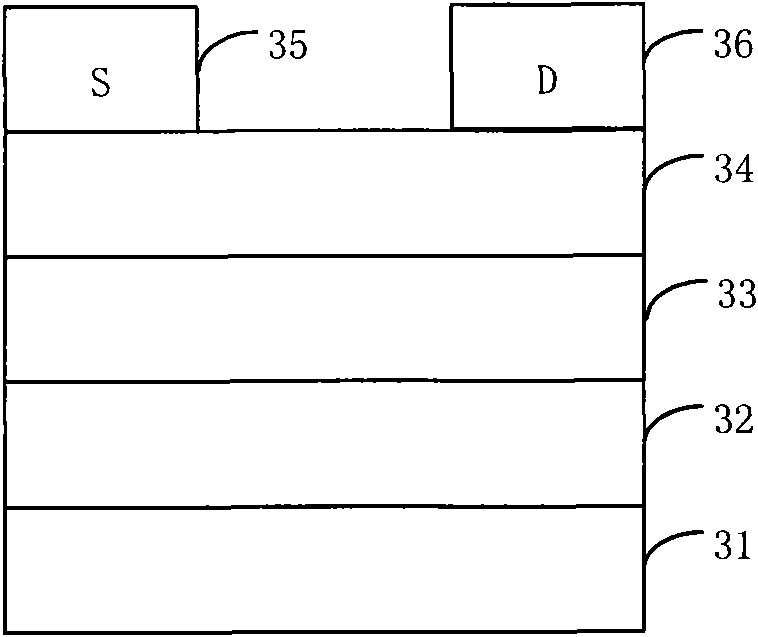

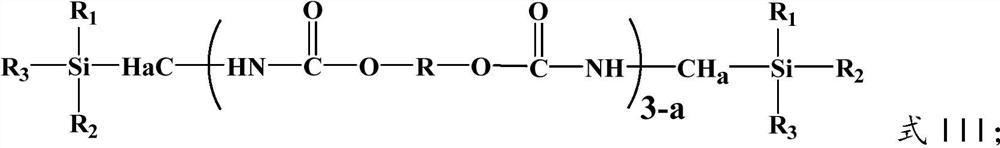

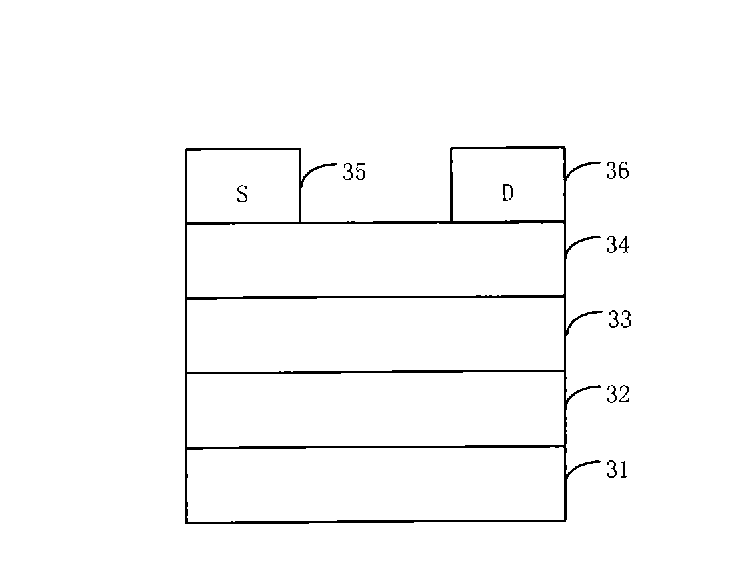

Copolymer material containing carbazole porphyrin-triphenylamine and preparation method and application thereof

InactiveCN102311538BImprove quantum efficiencyHigh hole mobilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorHigh energy

The invention relates to a copolymer material containing carbazole porphyrin-triphenylamine and a preparation method and application thereof. The copolymer material has a structural formula (III) shown in the specification, wherein n is an integral number of between 1 and 100; R1 and R2 are H or alkyl groups having 1 to 32 carbon atoms. In the copolymer material with the structural formula, the advantages of carbazole, porphyrin and triphenylamine compounds are fully utilized, so the copolymer material has the high energy conversion efficiency, and can be widely applied to fields of organic semiconductor materials, polymer solar cells, organic electrofluorescence, organic field effect transistors, organic laser storage, organic non-linear materials, organic laser and the like.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of thermosetting resin composition and prepreg and laminate made by using the same

ActiveCN106243626BGood compatibilityImprove interface performanceSynthetic resin layered productsElectrical equipmentEpoxyImide

The present invention discloses a thermosetting resin composition, which comprises (calculated as the solid weight): (a) 10-80 parts of a hydrocarbon resin, (b) 20-100 parts of maleimide ester, (c) 0.1-8 parts of an initiator, and (d) 5-100 parts of an epoxy resin. According to the present invention, the maleimide ester having the polyfunctional long-chain structure and the rigid imide ring is used and is matched with the hydrocarbon resin having the flexibility to form the thermosetting composition, such that the thermosetting resin composition and the prepared printed circuit prepreg and laminated plate produced by using thermosetting resin composition have characteristics of excellent dielectric property, excellent heat resistance, excellent adhesion, excellent flame retardancy, excellent flexural strength, excellent toughness, high peel strength, low water absorption, excellent processability and the like through the interaction between the hydrocarbon resin and the maleimide ester.

Owner:SHENGYI TECH SUZHOU

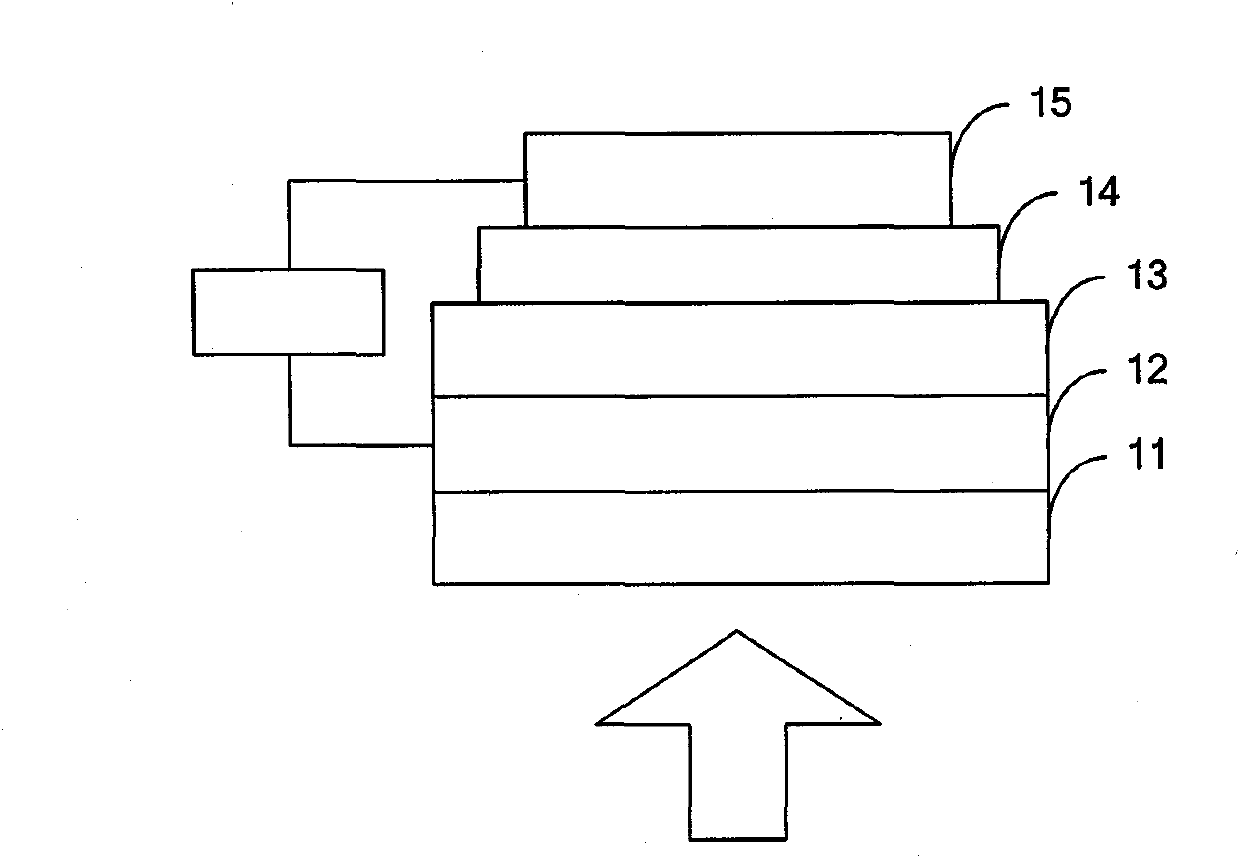

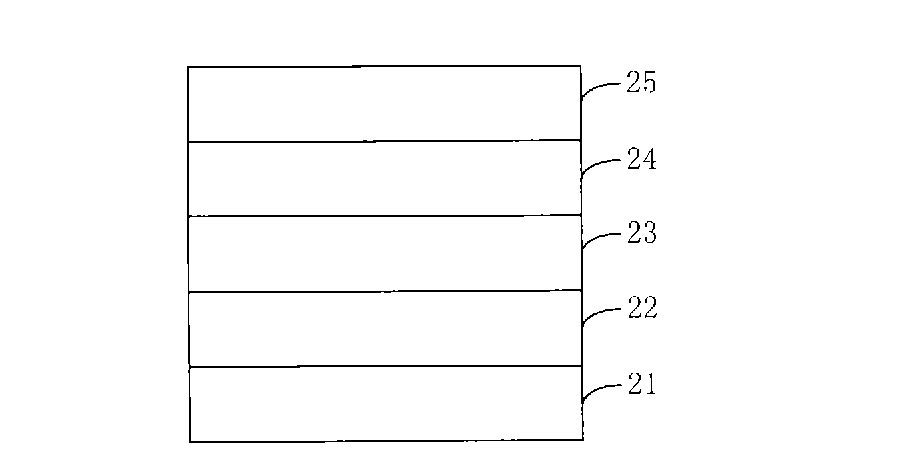

Triphenylamine unit porphyrin copolymer as well as preparation method and application thereof

InactiveCN102276800BImprove quantum efficiencyGood electronic cushioningOrganic chemistrySolid-state devicesPolymer scienceElectrical battery

The invention discloses a triphenylamine unit porphyrin copolymer with a molecular structural general formula (I) in the specification as well as a preparation method and application thereof. In the formula (I), R1, R2, R3 and R4 are selected from alkyls of C1-C32; and n is an integer ranging from 1 to 100. The triphenylamine unit porphyrin copolymer has the advantages of favorable electronic buffer property, photoelectric magnetism, rigidity and flexibility as well as better heat stability, environment stability, dissolution performance and film forming processing property. The preparation method of the triphenylamine unit porphyrin copolymer has the advantages of simplicity, mild reaction conditions, high yield and easiness for operation and control, and is suitable for the field such as solar cells and the like.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Metalloporphyrin-thienothiadiazole organic semiconductor material and preparation method and application thereof

ActiveCN102453234BHigh affinityEasy injectionLaser active region structureSolid-state devicesSemiconductor materialsPorphyrin

The invention belongs to the field of optoelectronic materials and discloses a metalloporphyrin-thienothiadiazole organic semiconductor material and a preparation method and application thereof. The metalloporphyrin-thienothiadiazole organic semiconductor material has a structural formula (P) shown in the specification, wherein in the formula, n is an integer from 1 to 100; R1, R2, R3 and R4 are H, C1-C32 alkyl, phenyl and alkylbenzene or alkoxy benzene containing one or more C1-C32; and M is a metal ion. The metalloporphyrin-thienothiadiazole organic semiconductor material has good film-forming property, strong absorbance and wide light absorption range, thus improving the sunlight use ratio of the material. The material also has better heat stability and environmental stability. Besides, the preparation method is simple in process and easy to operate and control.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Porphyrin copolymer containing thienothiadiazole units, preparation method and uses thereof

InactiveCN102834430BLower energy gapIncreased energy gapFinal product manufactureSolid-state devicesBand gapFluorene

A porphyrin copolymer containing thienothiadiazole units, preparation method and uses thereof are disclosed. The copolymer has the structural formula (I), wherein: R 1 , R 2 , R 3 , R 4 are same or different and each represents a C 1 -C 32 alkyl; n is an integer of 1-100. The copolymer comprises fluorene units, thienothiadiazole units and porphyrin units, which enhance the density of electron cloud in copolymer skeleton, make the band-gap of the copolymer become narrow, thereby broaden the spectral response range of the copolymer, and improve the photoelectric transformation efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

A siloxane-terminated polyether lithium battery adhesive and preparation method thereof

ActiveCN110746922BIncreased ion mobilityImprove charge and discharge efficiencyPolyether adhesivesPtru catalystPhase-transfer catalyst

The invention discloses a preparation method of a siloxane-terminated polyether-type lithium battery adhesive, which comprises the following steps: 1) adding a solvent and a cyanate to a reaction bottle for stirring and mixing, then adding a phase transfer catalyst, and raising the temperature to 70-100°C, constant temperature for 30 minutes to activate and disperse evenly; 2) respectively add metered chlorosilane and polyether-based alcohol or chlorosilane and polyester-based alcohol to the activation reaction solution in step 1), due to the exothermic The reaction temperature is raised to 90-120° C., and the temperature range is maintained for 6-8 hours. After the reaction, the filtrate is obtained by cooling down to room temperature and filtered; the solvent is removed to obtain the siloxane-terminated polyether lithium battery adhesive. The siloxane-terminated polyether lithium battery adhesive of the invention has simple preparation method, low cost, high efficiency and fast adhesion, and is easy to be industrialized. The prepared siloxane-terminated polyether for lithium battery electrode bonding can improve the high efficiency, high and low temperature resistance, stable charge and discharge efficiency and adhesion of lithium batteries.

Owner:HUBEI UNIV

A radiation-proof mortar for isolating nuclear leaks

ActiveCN106782723BReduce the hazards of nuclear radiationGood rigidity and flexibilityMaterial nanotechnologyShieldingAdditive ingredientGamma ray

The invention discloses a radiation protection mortar used for isolating nuclear leak. The radiation protection mortar comprises the following ingredients in parts by weight: 10-20 parts of cement, 6-10 parts of mineral powder, 25-40 parts of river sand, 8-10 parts of a dispersed latex powder, 8-15 parts of barite particles, 6-10 parts of polyphenyl ether, 8-12 parts of nano-lead particles, 8-12 parts of polyvinylidene fluoride, and 10-15 parts of graphite particles. The invention aims at providing the radiation protection mortar used for isolating nuclear leak, the radiation protection mortar used for isolating nuclear leak has the characteristics of excellent rigidity and flexibility, good structure stability at high temperature state, corrosion resistance and wear resistance, is not layered, does not segregate, and does not sagging; a wall body built from the radiation protection mortar can isolate and shield alpha rays, beta rays and gamma rays in nuclear radiation, and the harm of the nuclear radiation on people or materials on the other side of the wall body is greatly reduced.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

A kind of thermosetting resin composition and prepreg and laminated board prepared by using it

ActiveCN109810468BImprove heat resistanceHigh mechanical strengthMetal layered productsPolyesterImide

The invention discloses a thermosetting resin composition, which, in parts by weight, comprises: (a) epoxy resin: 100 parts; (b) unsaturated polyester active ester resin represented by structural formula (1): 50-200 parts (c) Resin containing both maleimide group and vinyl group as shown in structural formula (2): 10-200 parts by weight; (d) Cyanate resin: 10-200 parts; (e) Acceleration Dosage: 0.05~4 servings. The present invention combines epoxy resin, maleimide resin, cyanide resin through the reactivity of unsaturated bond between unsaturated polyester active ester, resin containing maleimide group and vinyl group at the same time, and cyanate ester. The ester resin is effectively combined in a resin system, so that the resin composition has excellent dielectric properties, heat resistance, strength, rigidity and flexibility, high peel strength, low water absorption, and small thermal shrinkage after curing. For high-speed, high-frequency printed circuit boards.

Owner:常熟生益科技有限公司

Metalloporphyrin-thienopyrazine organic semiconductor material, preparation method thereof and application thereof

ActiveCN102453229BHigh affinityEasy injectionLaser active region structureSolid-state devicesSemiconductor materialsPorphyrin

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com