Ultrathin moisture-absorbing and breathable high-stitch-length weft-knitted double-sided fabric and production process

A moisture-absorbing, breathable, double-sided fabric technology, which is applied in weft knitting, knitting, textiles and papermaking, can solve the problems of poor moisture absorption and breathability, inability to cut at will, poor UV resistance, etc., and achieve strong moisture absorption and breathability. Lightweight, good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

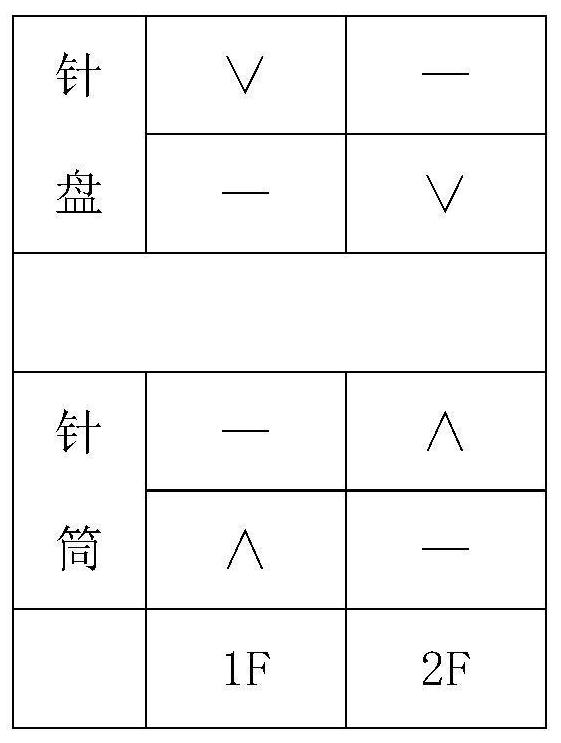

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] refer to figure 1 . An ultra-thin, moisture-absorbing, breathable, high-gauge weft-knitted double-sided fabric, including the fabric body, which is woven by a 50-needle, 34-inch, 84-way weft-knitted double-sided circular machine, and the fabric body is composed of 2 knitting needles and 2 lines of yarn. Complete cycle double rib structure, the yarn arrangement of the fabric body is two routes and one cycle, both routes use 15D / 12F low-elastic semi-gloss polyester DTY (Draw Texturing Yarn, stretch textured yarn) as the veil, and 20D spandex as the lining yarn. Among them, the tissue structure of the fabric is realized by using 2 knitting needles and 2 yarns to form a complete cycle of double rib structure. For details, see figure 1 Triangular diagram of weaving process.

[0018] During the knitting process of a 50-needle, 34-inch, 84-way weft-knitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com