High-grade elastic silk anti-wrinkle fabric and its preparation method

A technology of real silk and fabrics, applied in the field of textile weaving, can solve problems such as friction and poor softness of silk fabrics, and achieve the effects of improved resistance, hydrophilicity, antibacterial properties and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

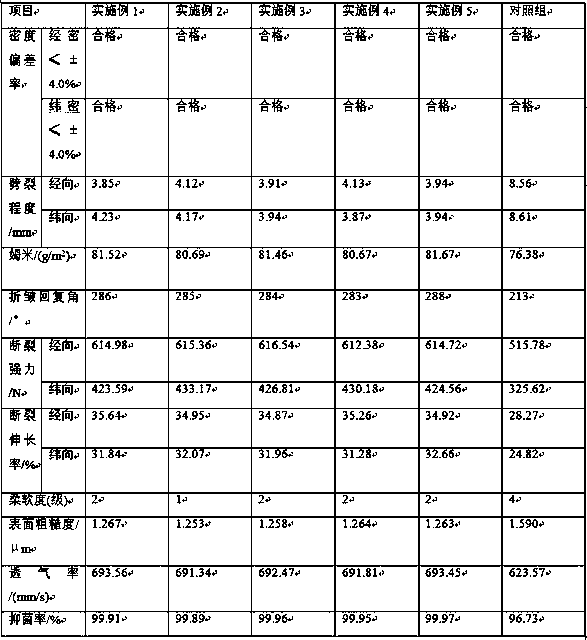

Examples

Embodiment 1

[0030] The components of the finishing liquid raw materials are: 7.5 parts of silkworm chrysalis chitosan, 2 parts of citric acid, 3.5 parts of alkylamide betaine, 3 parts of morning glory extract, 3.2 parts of sorrel extract, dioctyl sulfosuccinate 1.5 parts of ester sodium salt;

[0031] Preparation of modified resin cotton: take 40 parts of resin cotton washed with acetone, ethanol and deionized water, and then dry at 55°C to remove impurities in the resin cotton to obtain dried resin cotton; 30 parts of acid anhydride, 18 parts of polyethylene glycol, and 9 parts of 1,2,3,4-butane tetracarboxylic acid were placed in the reaction kettle, and then dried resin cotton was added for impregnation and grafting for 2 hours, and then plasma irradiation , set the irradiation time to 4.5min, shake and wash the grafted resin cotton after plasma irradiation with deionized water at 78°C for 60min, and then repeatedly wash with clean deionized water to completely remove the monomer attac...

Embodiment 2

[0037] The components of the finishing liquid raw materials are: 6 parts of silkworm chrysalis chitosan, 1.5 parts of citric acid, 5 parts of alkylamide betaine, 4 parts of morning glory extract, 3.5 parts of sorrel extract, dioctyl sulfosuccinate 1.8 parts of ester sodium salt;

[0038] Preparation of modified resin cotton: take 42 parts of resin cotton, wash them with acetone, ethanol and deionized water, and then dry them at 60°C to remove impurities in the resin cotton to obtain dried resin cotton; 38 parts of acid anhydride, 16 parts of polyethylene glycol, and 10 parts of 1,2,3,4-butane tetracarboxylic acid were placed in the reaction kettle, and then dried resin cotton was added for impregnation and grafting for 1.9h, and then plasma Irradiate, set the irradiation time to 5min, shake and wash the grafted resin cotton after plasma irradiation with 80°C deionized water for 52min, and then repeatedly shake and wash with clean deionized water to completely remove the monome...

Embodiment 3

[0044] The components of the raw materials of the finishing solution are: 8 parts of silkworm chrysalis chitosan, 1 part of citric acid, 3 parts of alkylamide betaine, 5 parts of morning glory extract, 4 parts of sorrel extract, dioctyl sulfosuccinate 1 part sodium ester;

[0045] Preparation of modified resin cotton: Take 50 parts of resin cotton, wash them with acetone, ethanol and deionized water, and then dry them at 58°C to remove impurities in the resin cotton to obtain dried resin cotton; 35 parts of acid anhydride, 16 parts of polyethylene glycol, and 8.5 parts of 1,2,3,4-butane tetracarboxylic acid were placed in the reaction kettle, and then dried resin cotton was added for impregnation and grafting for 1.8 hours, and then plasma Irradiate, set the irradiation time to 3.5min, shake and wash the grafted resin cotton after plasma irradiation with deionized water at 75°C for 50min, and then repeatedly wash with clean deionized water to completely remove the monolayers a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com