Antibacterial bamboo fiber and recycle polyester blended sock

A fiber regeneration and recycled polyester technology, applied in the field of textiles, can solve the problems of antibacterial, sweat absorption, poor comfort and warmth retention, unable to absorb sweat in time, unable to drain in time, etc., and achieve high application value and theoretical significance, moisture absorption Highly breathable and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

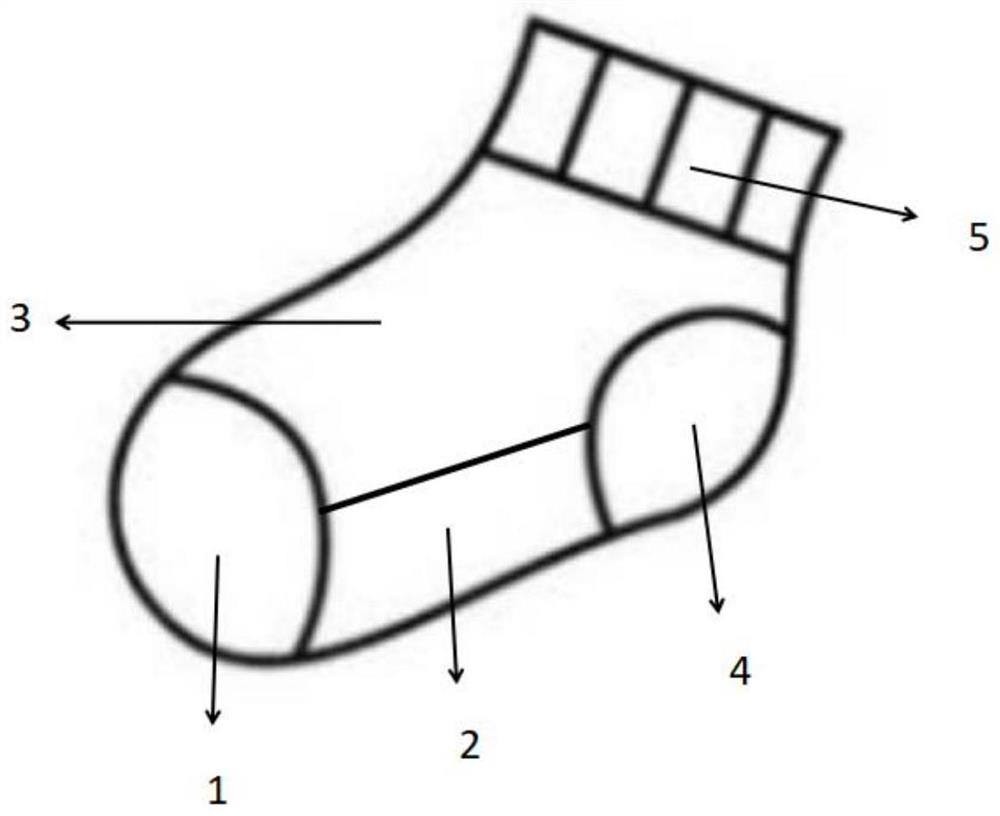

Image

Examples

preparation example Construction

[0030] A kind of preparation method of antibacterial bamboo fiber, comprises the following steps:

[0031] Step 1: irradiate bamboo fibers with 60Coγ-rays or accelerator electron beams, the irradiation dose is 0-10kGy, and modify them in vacuum at room temperature for 4h;

[0032] Step 2: Nano-silver grafted bamboo fiber: Add the nano-particles and irradiated bamboo fiber into a three-necked flask with a condenser and an electric stirring device, add silver nitrate solution and 2 mL of catalyst CuBr 2 , the temperature is controlled at 20-60°C and the reaction is stirred for 2h;

[0033] Step 3: Take out the nano-silver grafted bamboo fiber in the above step 2, wash it with ethanol three times, then centrifuge it on a centrifuge, then dry it at 25°C and put it into a sample bag for later use.

[0034] Wherein the silver ion concentration in the silver nitrate solution is 0.05-0.1mol / L; the mass ratio of the silver ion in the added silver nitrate solution to the cellulose in t...

Embodiment 1

[0036] Step 1: the preparation method of antibacterial bamboo fiber

[0037] Bamboo fibers were irradiated with 60Coγ-rays or accelerator electron beams at a dose of 2kGy, and modified in vacuum at room temperature for 4h.

[0038] Nano-silver grafted bamboo fiber: add nano-particles and irradiated bamboo fiber into a three-necked flask with a condenser and an electric stirring device, add silver nitrate solution (0.05mol / L) and 2mL of catalyst CuBr 2 , the temperature was controlled at 20°C and the reaction was stirred for 2h.

[0039] The nano-silver grafted jute fiber was taken out and washed three times with ethanol, then centrifuged in a centrifuge, dried at 25°C and put into a sample bag for later use.

[0040] Step 2: Bamboo fiber and recycled polyester fiber blend

[0041] Modified bamboo fiber and hollow regenerated polyester fiber are used for blending, and the blending ratio is 1:9.

[0042] Step 3: Cotton fiber and recycled polyester fiber blend

[0043] It is ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 lies in that the irradiation dose is different, and other contents are the same as in Embodiment 1. The irradiation dose in this embodiment is 3kGy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com