Miniature puncture-type camera power supply connecting line

A piercing, connecting wire technology, applied in the field of connecting wires, can solve the problems of connecting wire pollution, high cost and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

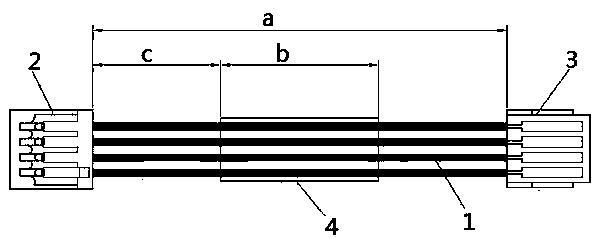

[0015] see figure 1 , the fine and small piercing type camera power supply connecting wire of the present invention comprises: a plurality of copper alloy wires 1 arranged side by side at equal intervals, and the two ends of the copper alloy wires 1 are pierced into the first miniature piercing connector 2 and the second micro piercing connector 2 respectively. In the second micro piercing connector 3, the number and position of the connectors of the first micro piercer and the second micro piercer correspond to the number and position of the copper alloy wire 1, and most copper alloy wires 1 use acetate tape 4 Carry out package fixation.

[0016] As a specific structure, such as figure 1 As shown, the number of copper alloy wires 1 is four, and the distance between them is 0.8 mm. Preferably, the copper alloy wire 1 is a halogen-free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com