Thin-coating heavy-duty anticorrosive coating and preparation method thereof

A heavy-duty anti-corrosion and coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high local stress of the substrate coating, high film thickness coating cracking, coating failure, etc., to improve glass Transition temperature, reduce corrosion rate, increase the effect of hydrophobic interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

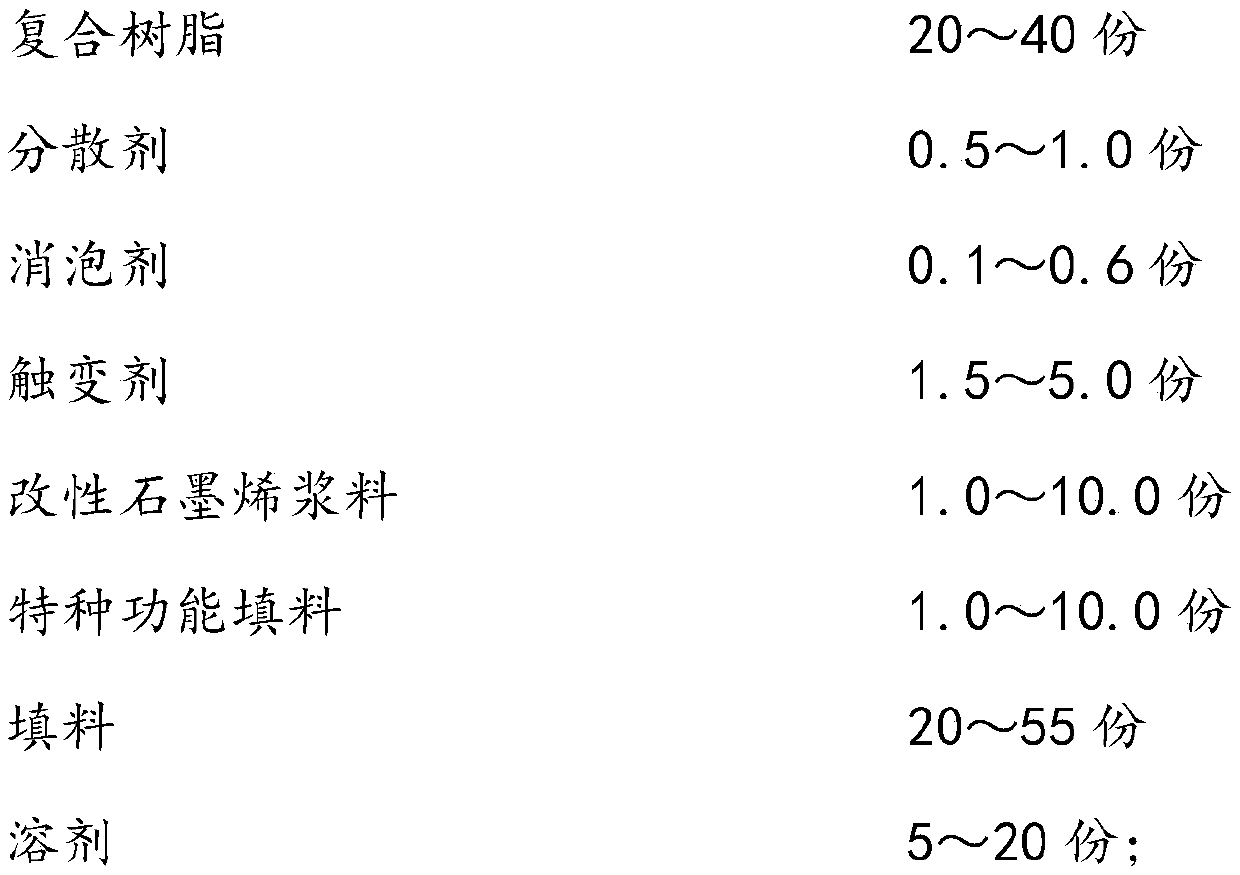

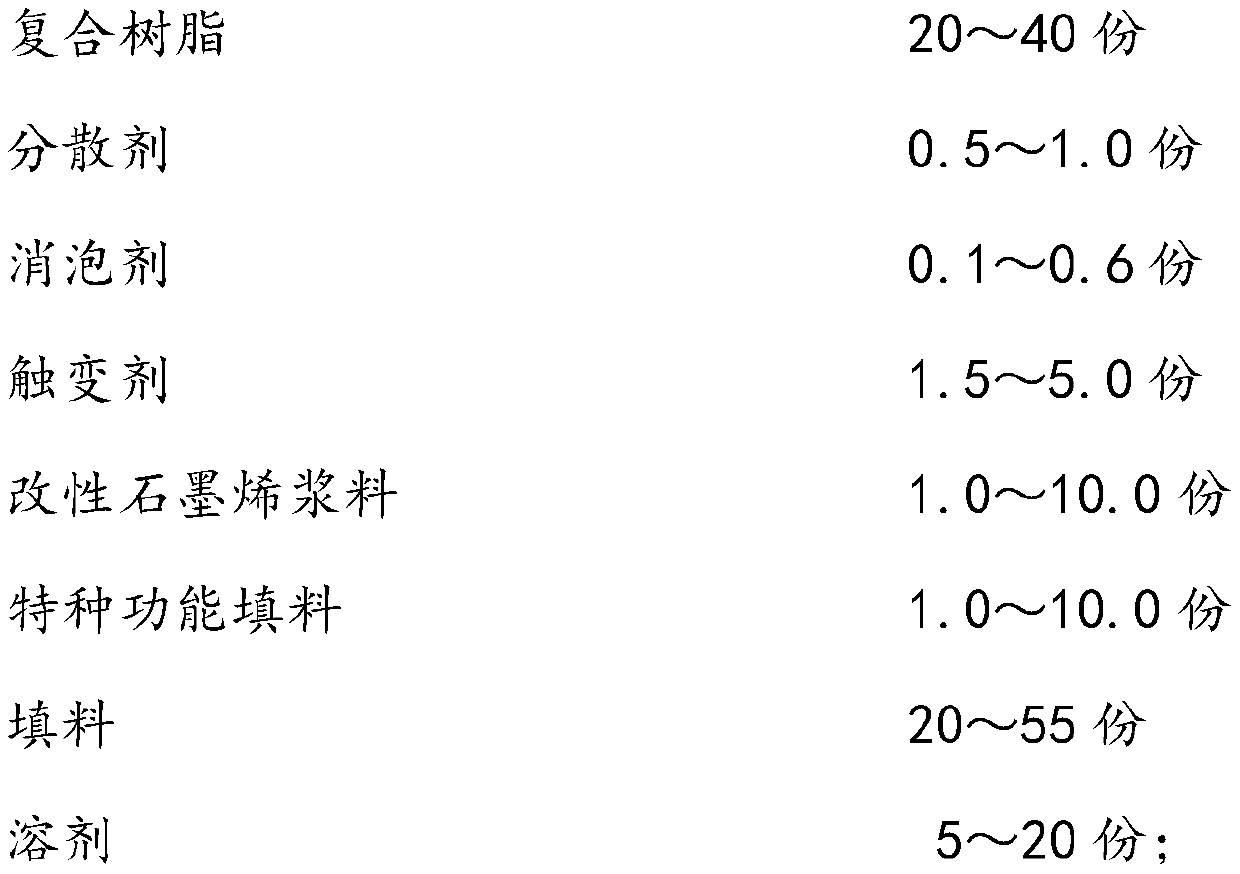

Method used

Image

Examples

Embodiment 2

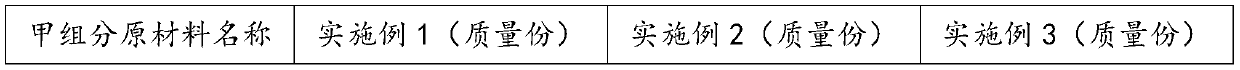

[0041] The composite resin used in Example 2 is bisphenol A epoxy resin and epoxy modified silicone resin, the mass ratio of bisphenol A epoxy resin to epoxy modified silicone resin is 3:1, the dispersant is BYK110, and the defoaming agent The agent is BYK A530, the thixotropic agent is organic bentonite, the size of the graphene material in the modified graphene slurry is 50 μm, and the specific surface area is 210m 2 / g, the single layer thickness is 60nm, the mass solid content is 8%, the special functional filler is nano-silica, the filler is talcum powder and feldspar powder; the solvent is xylene, and the composite curing agent is Parkson Bs8636 and Parkson Bs805;

Embodiment 3

[0042]The composite resin used in Example 3 is bisphenol A epoxy resin and epoxy modified silicone resin, the mass ratio of bisphenol A epoxy resin to epoxy modified silicone resin is 4:1, the dispersant is BYK110, and the defoaming agent is BYK110. The agent is BYK A530, the thixotropic agent is organic bentonite, the size of the graphene material in the modified graphene slurry is 50 μm, and the specific surface area is 210m 2 / g, the single layer thickness is 60nm, the mass solid content is 8%, the special functional filler is nano-silica, the filler is talc powder and feldspar powder; the solvent is xylene, and the composite curing agent is bs8519 and Bs8003;

[0043] Thin coating type heavy-duty anticorrosion coating main performance index of the present invention is as shown in table 2:

[0044] Table 2 The main performance indicators of thin-coated heavy-duty anti-corrosion coatings

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com