Diamond polishing film production method

A polishing film and diamond technology, applied in the field of abrasives, can solve the problems of huge particles, difficulty in maintaining processing force, and small number of devices, and achieve the effects of increasing specific surface area, prolonging service life, and improving chip force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Investigate the dispersion effect of different media on diamond micropowder

[0033] Take diamond powder (ordinary single crystal diamond, specification: D9μm, nominal size range 8-12μm, equivalent to M8 / 12 in JB / T7990-1998) and divide it into 4 parts, 2g each, add to 10ml methyl ethyl ketone and toluene respectively , xylene and cyclohexane, which are marked as samples 1, 2, 3, and 4 in turn; put samples 1-4 on an ultrasonic disperser for ultrasonic treatment for 20 minutes, and observe the dispersion state of each sample 5 minutes after taking it out. Such as figure 1 As shown, it is found that even through ultrasonic dispersion treatment, the diamond powder in methyl ethyl ketone will immediately settle down, and then the diamond powder in toluene and xylene will also gradually settle, and only the diamond powder in cyclohexane still maintains a uniform Dispersed state, no sedimentation phenomenon.

[0034] The above experiments show that diamond microp...

Embodiment 2

[0035] Example 2 Effect of washing pH value on polishing film quality

[0036] Synthetic diamond powder usually needs to be chemically treated with acidic substances such as hydrochloric acid, sulfuric acid, and nitric acid during purification. After the treatment, there will be more acidic substances on the surface of the diamond, so the PH value of the diamond soaked in pure water often shows strong acidity. For example, take 4g of ordinary single crystal diamond with a specification of D1μm and put it into 20ml of pure water, and the measured pH value is 4.93, showing strong acidity.

[0037] In order to investigate the effect of different washing pH values on the quality of the polishing film, the diamond micropowder with different washing pH values is used as raw material, and the polishing film samples are prepared according to the same method, and the processing force and durability of the samples are investigated.

[0038] 2.1 Sample preparation

[0039] Take or...

Embodiment 3

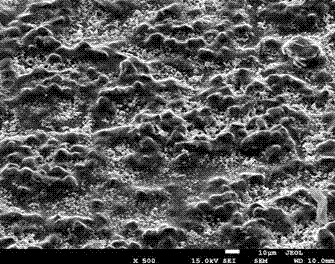

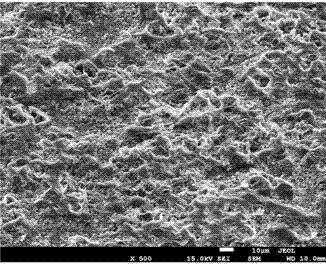

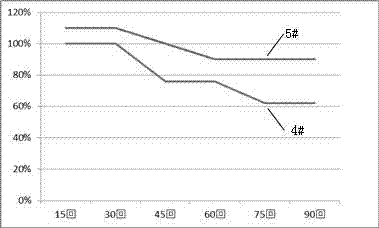

[0055] Embodiment 3 The impact of etching treatment on the quality of diamond polishing film

[0056] 3.1 Sample preparation

[0057] Take D9μm ordinary standard single crystal diamond powder and D9μm etched diamond powder as raw materials, and prepare two kinds of polishing film samples according to the following method: weigh unsaturated polyester, polyvinyl chloride and polyacrylic resin, add organic The solvent dissolves the resin, adding a curing agent to form a binder; adding the diamond powder into cyclohexane and ultrasonically dispersing it evenly, then adding it into the binder and stirring evenly to make a coating solution; coating the above coating solution on the base film The surface can be cured by heating.

[0058] The prepared polishing film samples are marked as 4# (D9μm, ordinary standard single crystal diamond) and 5# (D9μm, etched diamond).

[0059] Base film: biaxially stretched PET (polyethylene terephthalate) film, thickness 75 μm, produced by Japan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com