A kind of preparation method of dyeable polyurethane film

A polyurethane film and polyurethane technology, applied in the field of polyurethane materials, can solve the problem of rare polyurethane dyeing effect, and achieve the effects of improving dye uptake and dyeing fastness, strong dyeing fastness, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

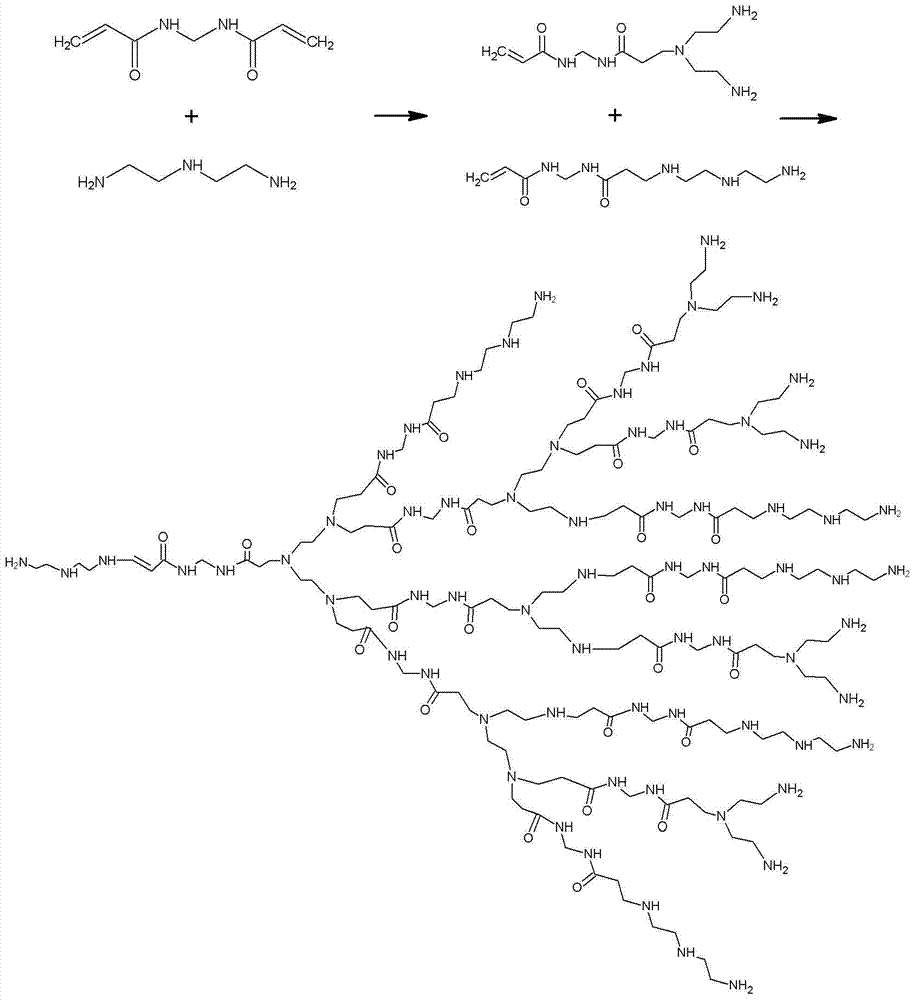

[0031] 1) Add N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) with a molar ratio of 1:1.1 to the solvent N,N-dimethylformamide (DMF), and add it at 40 After reacting at ℃ for 24h, a yellow-green amino-terminated hyperbranched polymer is obtained; the ratio of the total mass of N,N-methylenebisacrylamide and diethylenetriamine to the mass of N,N-dimethylformamide is 1 :1.1; The synthetic route and structural formula of amino-terminated hyperbranched polymer are as follows figure 1 Shown.

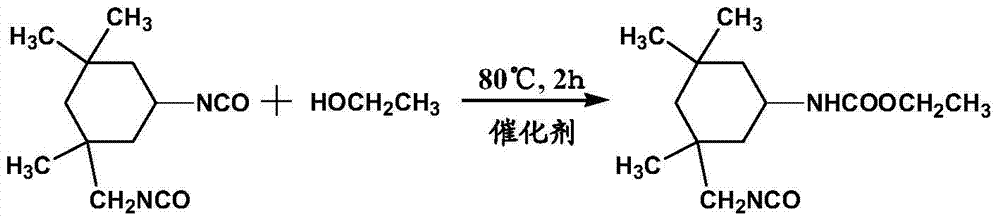

[0032] 2) Add isophorone diisocyanate with a molar ratio of 1:1.1 and absolute ethanol to the solvent N,N-dimethylformamide, and react at 0°C for 4 hours to obtain a blocking agent, wherein the isophorone The mass ratio of the total mass of ketone diisocyanate and absolute ethanol to the mass of N,N-dimethylformamide is 1:1.1; the synthetic route of the blocking agent is as follows figure 2 Shown.

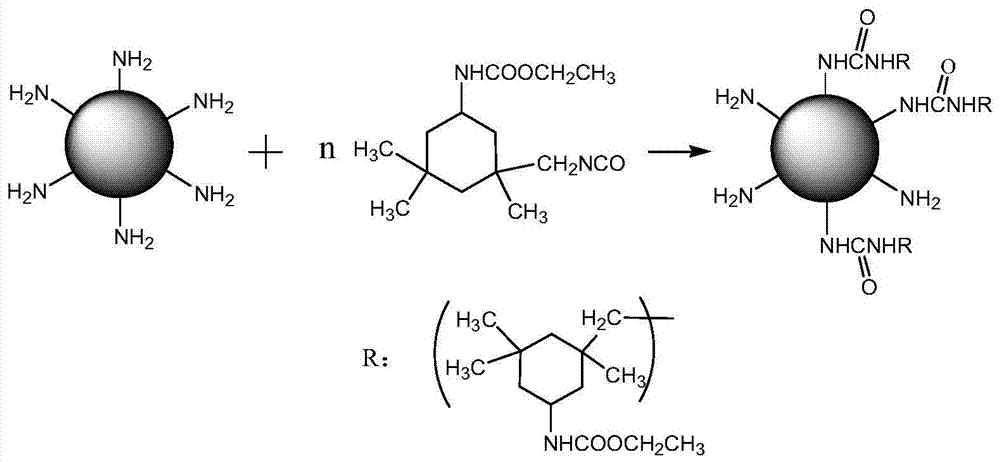

[0033] 3) Mix the amino-terminated hyperbranched polymer with a mass ratio of 3:0....

Embodiment 2

[0037] 1) Add N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) with a molar ratio of 1:1.2 into the solvent N,N-dimethylformamide (DMF), and add it to the solvent at 80 After 8 hours of reaction at ℃, a yellow-green amino-terminated hyperbranched polymer is obtained; the ratio of the total mass of N,N-methylenebisacrylamide and diethylenetriamine to the mass of N,N-dimethylformamide is 1 :1.2;

[0038] 2) Add isophorone diisocyanate with a molar ratio of 1:1.2 and anhydrous ethanol to the solvent N,N-dimethylformamide, and react at 10°C for 2.5 hours to obtain a blocking agent. The mass ratio of the total mass of ketone diisocyanate and absolute ethanol to the mass of N,N-dimethylformamide is 1:1.2;

[0039] 3) Mix the amino-terminated hyperbranched polymer with a mass ratio of 3:1 and the end-capping agent, and react at 65°C for 3h to obtain the end-capped hyperbranched polymer.

[0040] 4) Add the solvent N,N-dimethylformamide to the polyurethane raw material, stir ...

Embodiment 3

[0043] 1) Add N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) with a molar ratio of 1:1.3 to the solvent N,N-dimethylformamide (DMF), and add it at 60 After reacting at ℃ for 20h, a yellow-green amino-terminated hyperbranched polymer is obtained; the ratio of the total mass of N,N-methylenebisacrylamide and diethylenetriamine to the mass of N,N-dimethylformamide is 1 :1.4;

[0044] 2) Add isophorone diisocyanate with a molar ratio of 1:1.3 and absolute ethanol to the solvent N,N-dimethylformamide, and react at 15°C for 2 hours to obtain a blocking agent, in which isophorone The mass ratio of the total mass of ketone diisocyanate and absolute ethanol to the mass of N,N-dimethylformamide is 1:1.3;

[0045] 3) Mix the amino-terminated hyperbranched polymer with a mass ratio of 3:1.5 and the end-capping agent, and react at 70° C. for 2 hours to obtain the end-capped hyperbranched polymer.

[0046] 4) Add the solvent N,N-dimethylformamide to the polyurethane raw material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com