Biomass carbon-loaded nano zero-valent iron material as well as preparation method and application thereof

A nano-zero-valent iron and biomass carbon technology, applied in the field of nano-materials, can solve problems such as difficulty in recycling, and achieve the effects of not easy to agglomerate, mild reaction, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

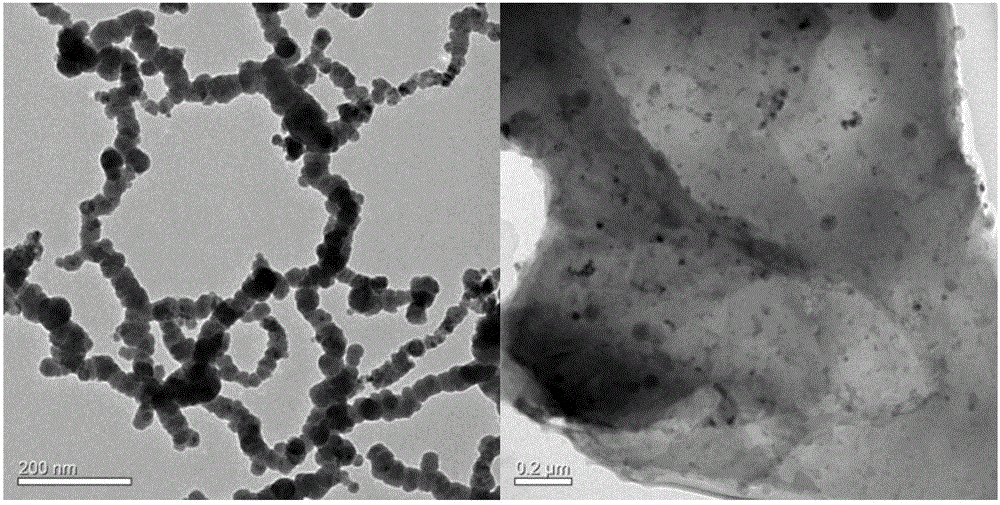

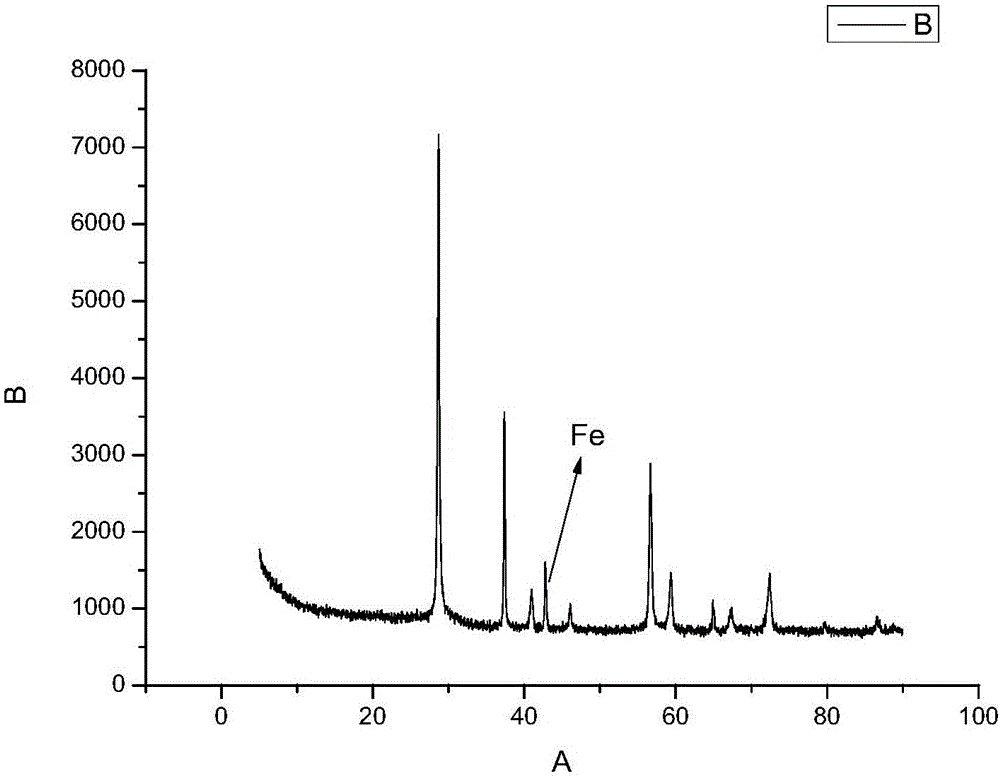

[0025] Example 1 Preparation of Biomass Carbon-Loaded Nano Zero-Valent Iron Material

[0026] 1. Crush clean walnut shells through a 100-mesh fine sieve, wash with water, centrifuge until the supernatant is colorless, wash with organic solvent and deionized water, and dry overnight in a blast dryer at 65°C.

[0027] 2. Weigh 10 g of walnut shell powder dried in step 1 into a crucible with a lid, cover it, and carbonize it in a muffle furnace at 600°C at a high temperature, and the residence time at 600°C is 4h.

[0028] 3. Dissolve the biomass carbon obtained in step 2 in 100 mL of 1 mol / L hydrochloric acid, boil for 30 min, and remove the inorganic salt and ash therein.

[0029] 4. Filter the mixed liquid obtained in step 3, wash with organic solvents such as absolute ethanol and DMF, and deionized water three times, and dry overnight in a blast dryer.

[0030] 5. Weigh 1.6218g ferric chloride hexahydrate and dissolve it in 100mL alcohol:water=4:1 mixture.

[0031] 6. Weigh...

Embodiment 2

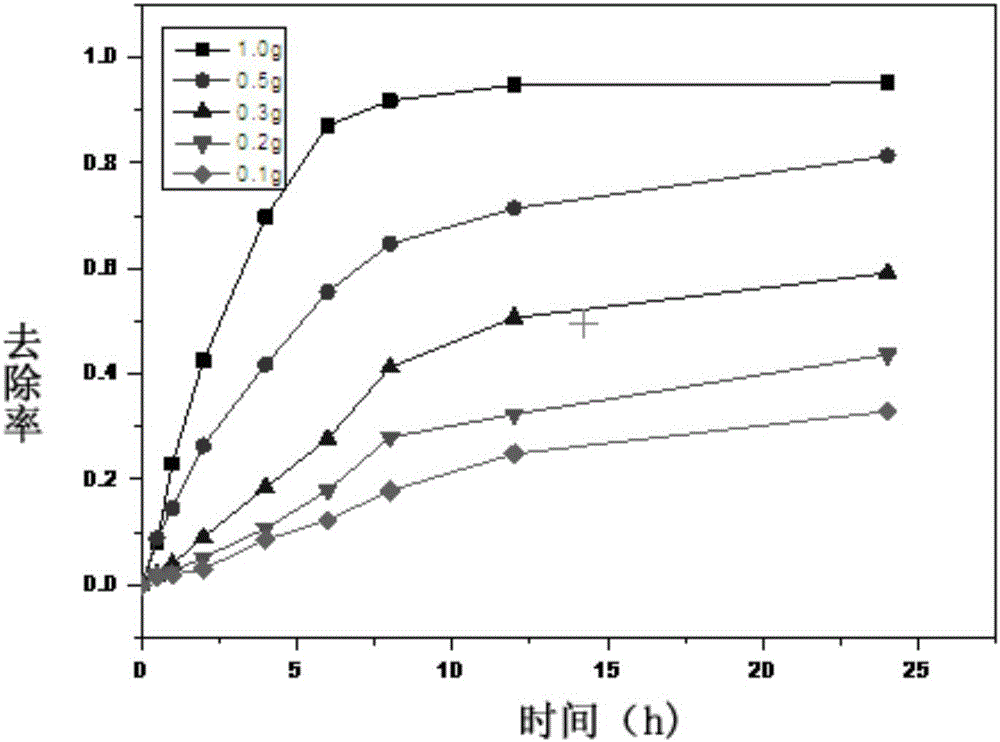

[0036] Example 2 Research on the degradation of bromophenol blue by biomass carbon loaded nanometer zero-valent iron material

[0037] 1. Prepare 5 parts of the same bromophenol blue solution 100mL in a 150mL Erlenmeyer flask, the concentration is 10mg / L, and the solvent is water.

[0038] 2. Take respectively 0.01g, 0.05g, 0.1g, 0.15g and 0.2g of the biomass carbon-loaded nano-zero-valent iron material (named as C-NZVI) obtained in Example 1 and throw them into five different Erlenmeyer flasks in step 1 in solution.

[0039] 3. Start timing immediately after the feeding is completed, and take samples at the specified time. The sampling time is 0min, 30min, 1h, 2h, 4h, 6h, 8h, 12h, 24h.

[0040] 4. Use the ultraviolet spectrophotometer to test the sample, the specific results are as follows image 3 .

[0041] From image 3 It can be seen that when other conditions are the same, with the increase of C-NZVI dosage, the reaction becomes faster and faster. The dosage range o...

Embodiment 3

[0042] Example 3 Comparison of the dispersibility of carbon microsphere-supported nanometer zero-valent iron (named as C-NZVI) and other materials

[0043] 1. The biomass carbon-loaded nano-zero-valent iron material C-NZVI (two parts), C (biomass carbon) and NZVI (traditional nano-zero-valent iron) obtained in Example 1 that weighed 0.05 g were placed in 4 identical In the 50mL colorimetric tube.

[0044] 2. Add 0.05g of CMC to one of the colorimetric tubes added with C-NZVI.

[0045] 3. Add 50mL deionized water to the four colorimetric tubes, shake well, and put them on the test bench.

[0046] 4. Collect photos of the samples at 15min, 1.0h and 2h respectively.

[0047] Such as Figure 4As shown, from left to right are photos after standing for 15min, 1h and 3h respectively. When standing for 15 minutes, the materials can still maintain good dispersion; when standing for 1 hour, there is no big change compared with before, only a small part of C-NZVI is agglomerated; aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com