Pre-lithiated lithium ion secondary battery negative electrode material and mechanical pre-lithiation method thereof

A technology for secondary batteries and negative electrode materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve the problems of high price, high energy consumption, flammability and explosion of inert lithium powder, and achieve high first coulomb. Efficiency and stable cycle life, avoiding lithium dendrite problems, and the effect of short fabrication times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

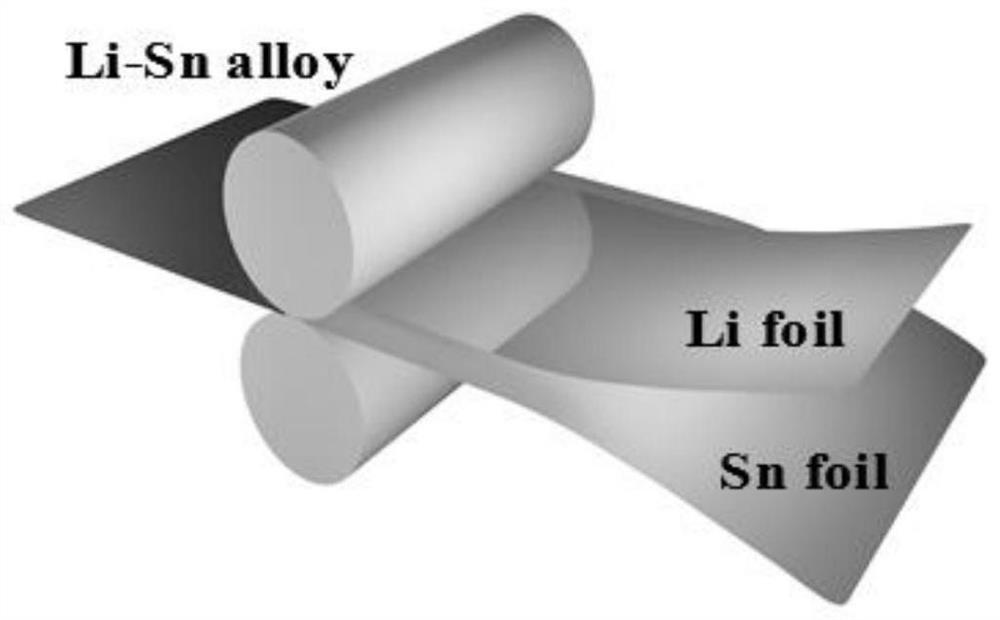

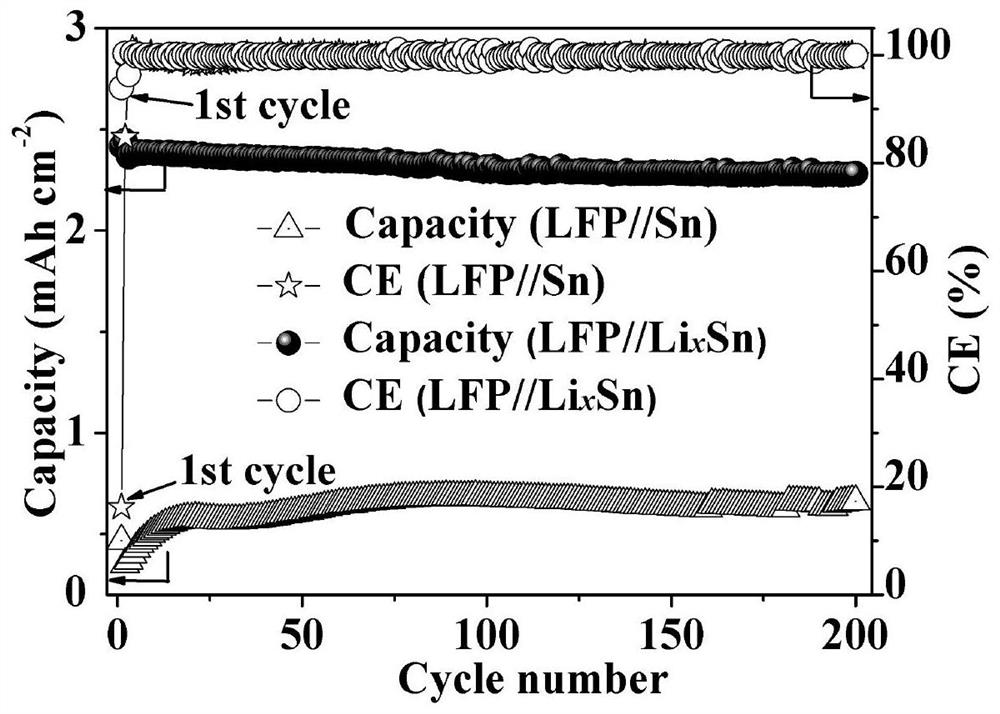

[0032] figure 1 It is a schematic diagram of mechanical pre-lithiation preparation by stacking tin foil and lithium tape in Example 1 of the present invention.

[0033] like figure 1 As shown, the mechanical pre-lithiation method based on the negative electrode material of the lithium ion secondary battery in this embodiment includes the following steps:

[0034] Step 1, prepare 50μm tin foil.

[0035] Step 2, in the drying room, the lithium tape with a thickness of 25 μm and the tin foil are flatly bonded together to obtain a bonding material.

[0036] Step 3, the distance between the two rollers of the roller press is set to be smaller than the total thickness of the laminated material, the laminated material is rolled 5-10 times by the roller press, and the two rollers are rolled after each rolling. The distance before each roller is adjusted to be small, and the pre-lithiated tin negative electrode material of 50 μm-60 μm is obtained after the rolling is completed.

[...

Embodiment 2

[0042] The mechanical pre-lithiation method based on the negative electrode material of the lithium ion secondary battery in this embodiment includes the following steps:

[0043]Step 1, prepare 15μm-100μm tin-based alloy foil, the tin-based alloy foil can be Cu-Sn, Co-Sn, Ag-Sn, Cu-Ag-Sn, Zn-Sn, Sb-Sn, Bi-Sn, In-Sn, In-Bi-Sn and other tin alloys;

[0044] Step 2, in the drying room, flatly attach a lithium tape with a thickness of 1 / 10 to 1 of the thickness of the tin-based alloy foil to the tin-based alloy foil to obtain a bonding material;

[0045] Step 3, press the laminated material in step 2 for 15min-2h under the pressure of 5MPa-30MPa by a tablet machine, so that the lithium ribbon is completely embedded in the tin-based alloy foil to obtain a pre-lithiated lithium ion secondary battery negative electrode material.

Embodiment 3

[0047] The mechanical pre-lithiation method based on the negative electrode material of the lithium ion secondary battery in this embodiment includes the following steps:

[0048] Step 1, prepare 15μm-100μm aluminum metal foil or aluminum-based alloy foil as a self-supporting battery negative pole piece;

[0049] Step 2, in the drying room, flatly attach a lithium tape with a thickness of 1 / 10 to 1 of the thickness of the self-supporting battery negative pole piece to the battery negative electrode material to obtain a bonding material;

[0050] In step 3, the laminated material obtained in step 2 is pressed for 15min-2h by a tablet press under a pressure of 5MPa-30MPa to obtain a pre-lithiated aluminum negative electrode material.

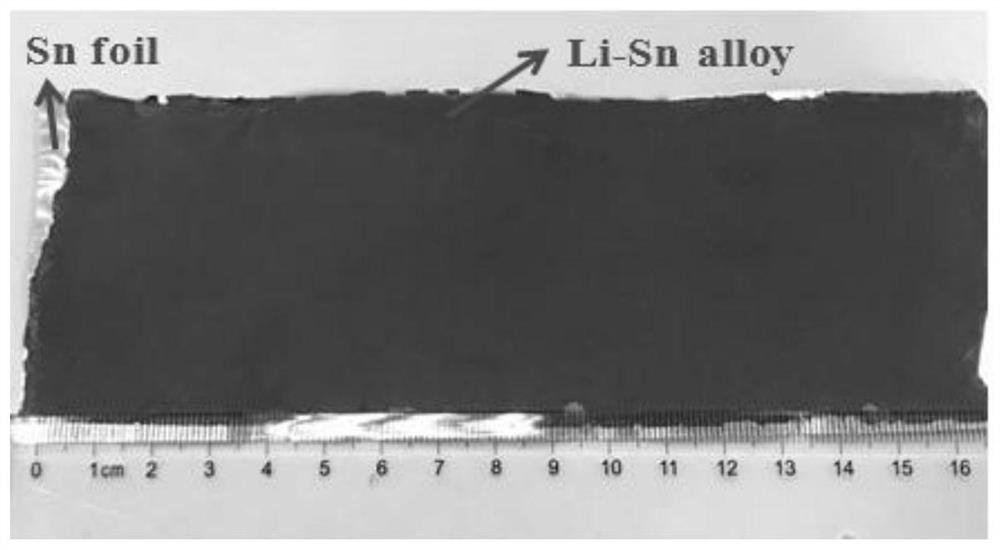

[0051] Figure 4 This is a physical diagram of the pre-lithiated aluminum negative electrode material in Example 3 of the present invention.

[0052] like Figure 4 As shown, lithium metal can be embedded in the aluminum-based alloy foil, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com