Lithium manganese phosphate composite material as well as preparation method and application thereof

A technology of lithium manganese iron phosphate and composite materials, which is applied in nanotechnology, electrical components, electrochemical generators, etc. for materials and surface science, and can solve the problem that the electrochemical properties of materials cannot be well exerted, and the electronic conductivity Problems such as low diffusion coefficient of lithium ions, achieve high practical use value, improve electrochemical performance, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

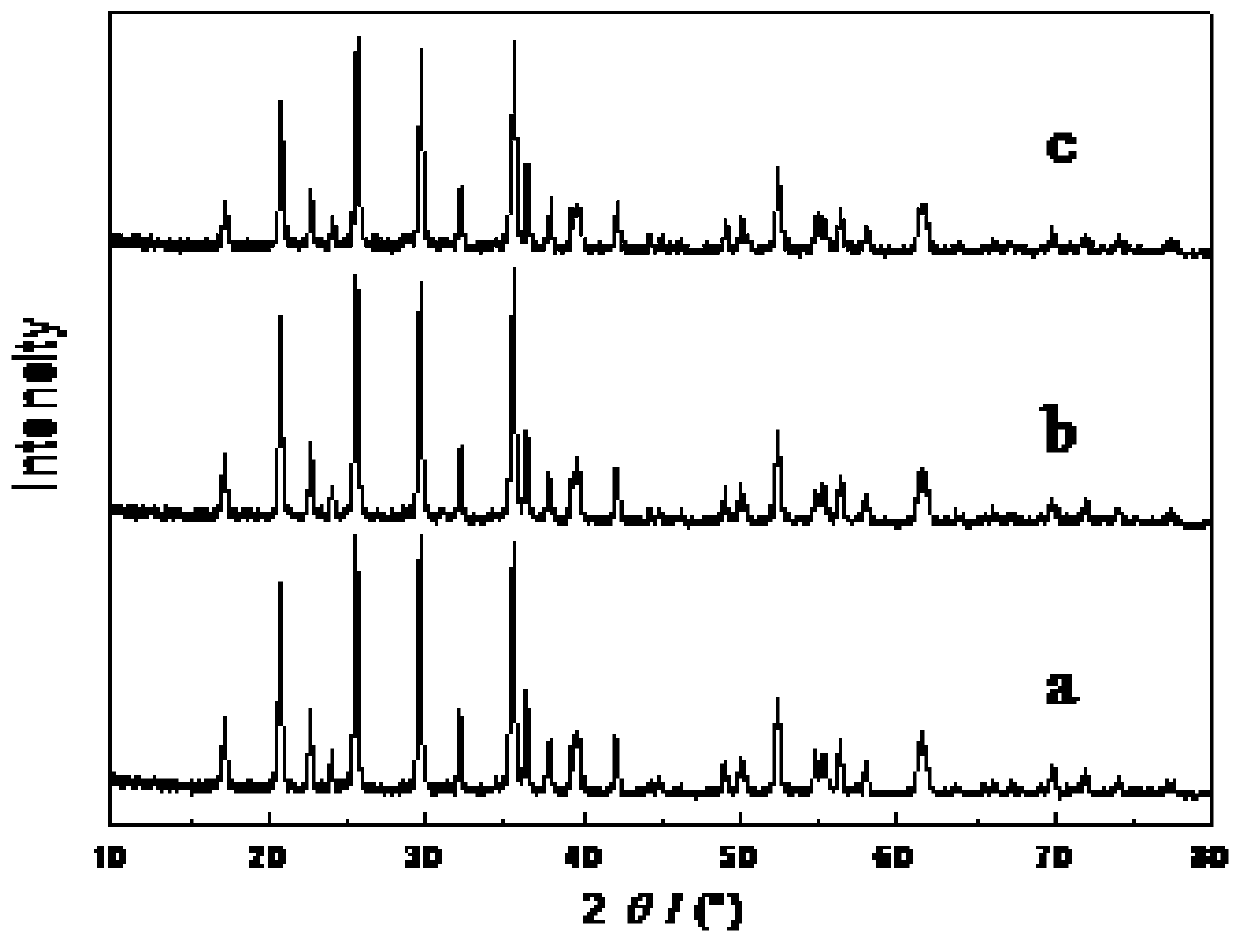

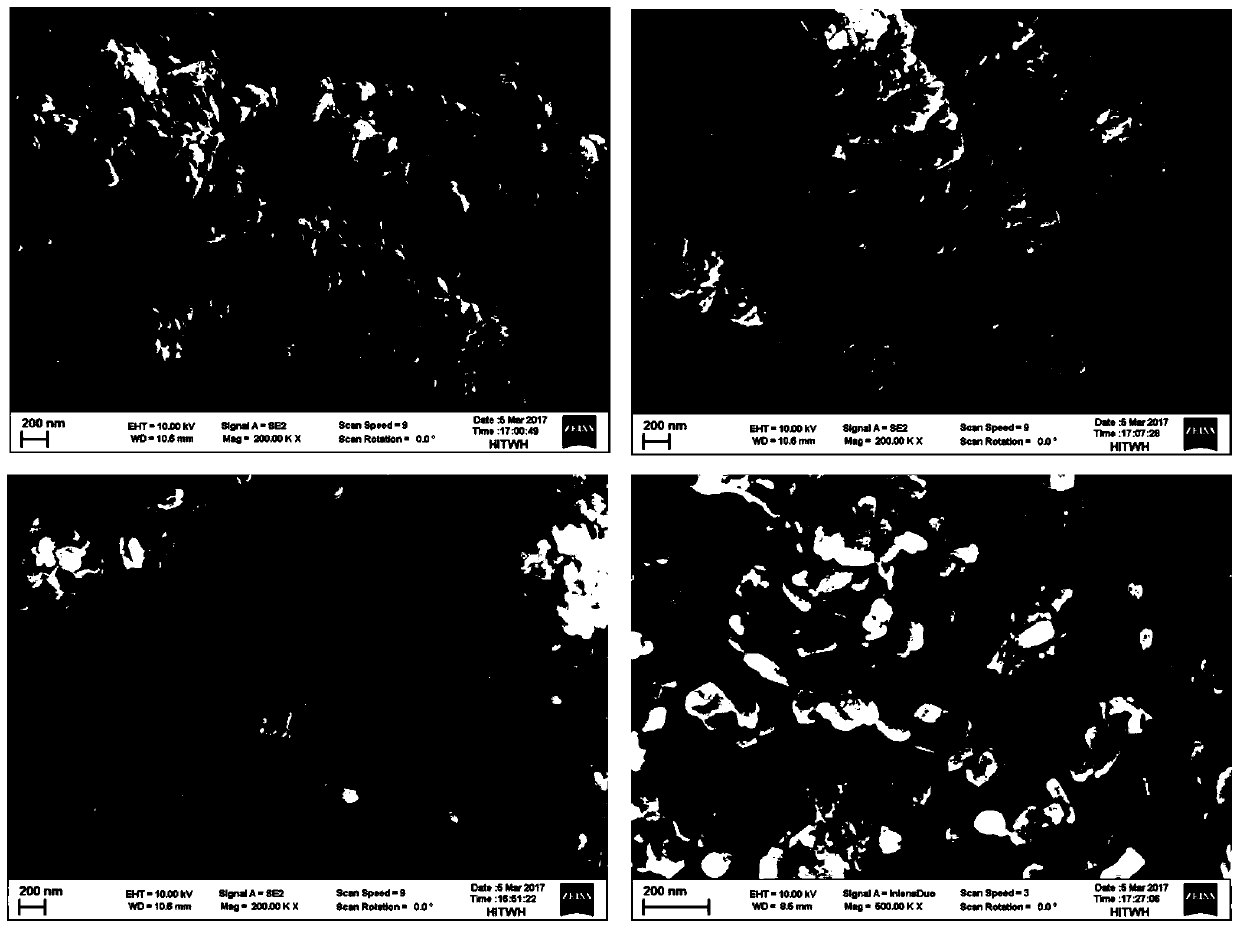

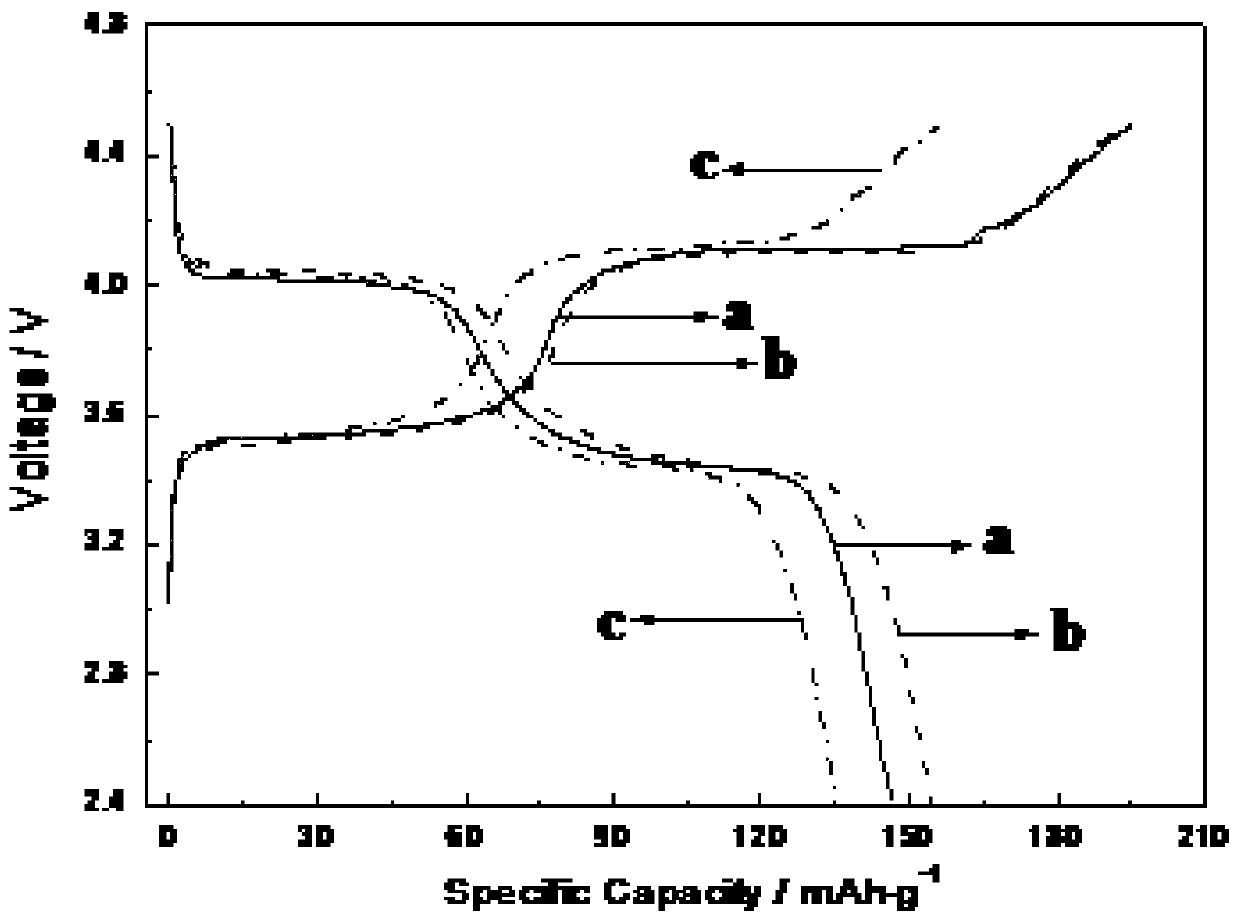

Embodiment 1

[0033] A preparation method of lithium manganese iron phosphate composite material, comprising the following steps:

[0034]S1, 0.06mol lithium hydroxide is dissolved in 60mL ethylene glycol to obtain lithium hydroxide ethylene glycol solution; 0.02mol phosphoric acid is dissolved in 30mL ethylene glycol to obtain phosphoric acid glycol solution; 0.01mol manganese sulfate monohydrate, Add 0.01mol of ferrous sulfate heptahydrate to 10mL of deionized water, then add 60mL of ethylene glycol and stir evenly to obtain a mixed solution; add the phosphate glycol solution dropwise to the lithium hydroxide ethylene glycol solution at a rate of 1mL / min and stir evenly To obtain a white suspension, add dropwise to the mixed solution at a rate of 2 mL / min and stir evenly, then conduct a hydrothermal reaction for 10 h at a temperature of 180°C, cool, centrifuge, and wash 3 times with deionized water and absolute ethanol , dried for 10h to obtain LiMn 0.5 Fe 0.5 PO 4 Precursor;

[0035]...

Embodiment 2

[0041] A preparation method of lithium manganese iron phosphate composite material, comprising the following steps:

[0042] S1, 0.06mol lithium hydroxide is dissolved in 60mL ethylene glycol to obtain lithium hydroxide ethylene glycol solution; 0.02mol phosphoric acid is dissolved in 30mL ethylene glycol to obtain phosphoric acid glycol solution; 0.01mol manganese sulfate monohydrate, Add 0.01mol of ferrous sulfate heptahydrate to 10mL of deionized water, then add 60mL of ethylene glycol and stir evenly to obtain a mixed solution; add the phosphate glycol solution dropwise to the lithium hydroxide ethylene glycol solution at a rate of 1mL / min and stir evenly To obtain a white suspension, add dropwise to the mixed solution at a rate of 2 mL / min and stir evenly, then conduct a hydrothermal reaction for 10 h at a temperature of 180°C, cool, centrifuge, and wash 3 times with deionized water and absolute ethanol , dried for 10h to obtain LiMn 0.5 Fe 0.5 PO 4 Precursor;

[0043...

Embodiment 3

[0049] A preparation method of lithium manganese iron phosphate composite material, comprising the following steps:

[0050] S1, 0.06mol lithium hydroxide is dissolved in 60mL ethylene glycol to obtain lithium hydroxide ethylene glycol solution; 0.02mol phosphoric acid is dissolved in 30mL ethylene glycol to obtain phosphoric acid glycol solution; 0.01mol manganese sulfate monohydrate, Add 0.01mol of ferrous sulfate heptahydrate to 10mL of deionized water, then add 60mL of ethylene glycol and stir evenly to obtain a mixed solution; add the phosphate glycol solution dropwise to the lithium hydroxide ethylene glycol solution at a rate of 1mL / min and stir evenly To obtain a white suspension, add dropwise to the mixed solution at a rate of 2 mL / min and stir evenly, then conduct a hydrothermal reaction for 10 h at a temperature of 180°C, cool, centrifuge, and wash 3 times with deionized water and absolute ethanol , dried for 10h to obtain LiMn 0.5 Fe 0.5 PO 4 Precursor;

[0051...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com