Functionalized ionic liquid/S-C composite material and preparation method and composite cathode material thereof

An ionic liquid and composite material technology, which is applied in the fields of functionalized ionic liquid/S-C composite materials and their preparation, and composite cathode materials, can solve the problems of cycle capacity decay, high self-discharge, low Coulombic efficiency, etc. Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

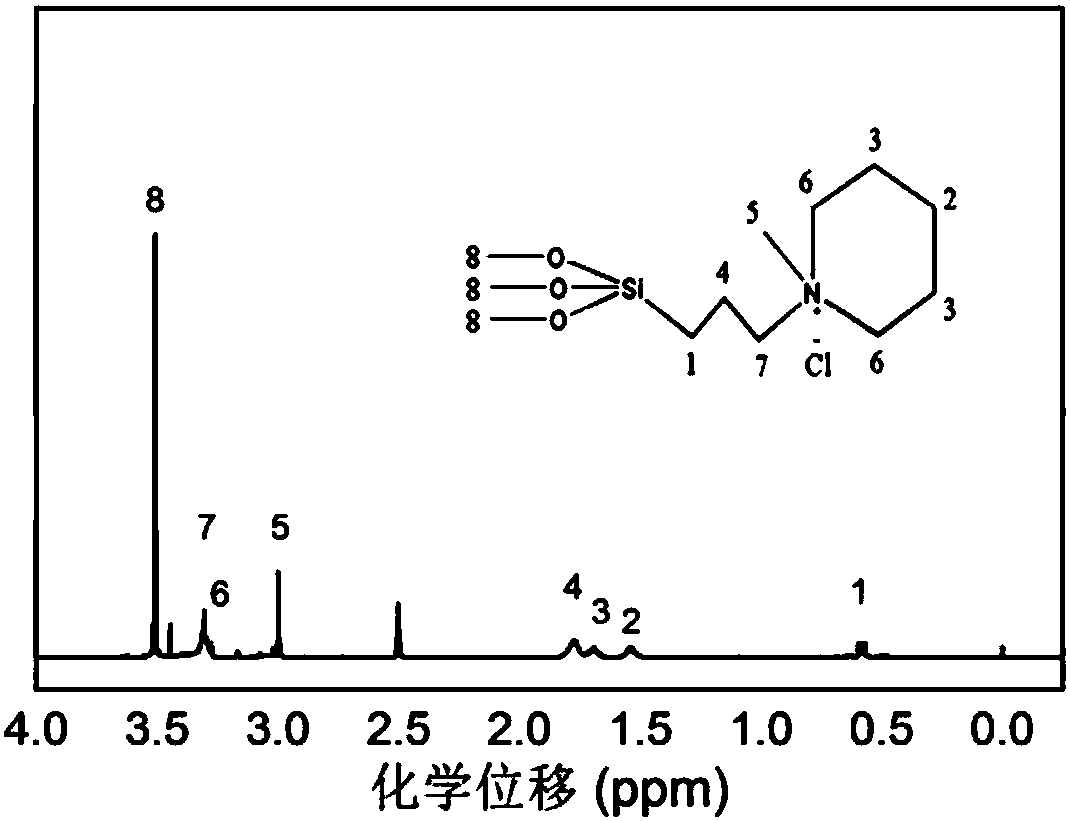

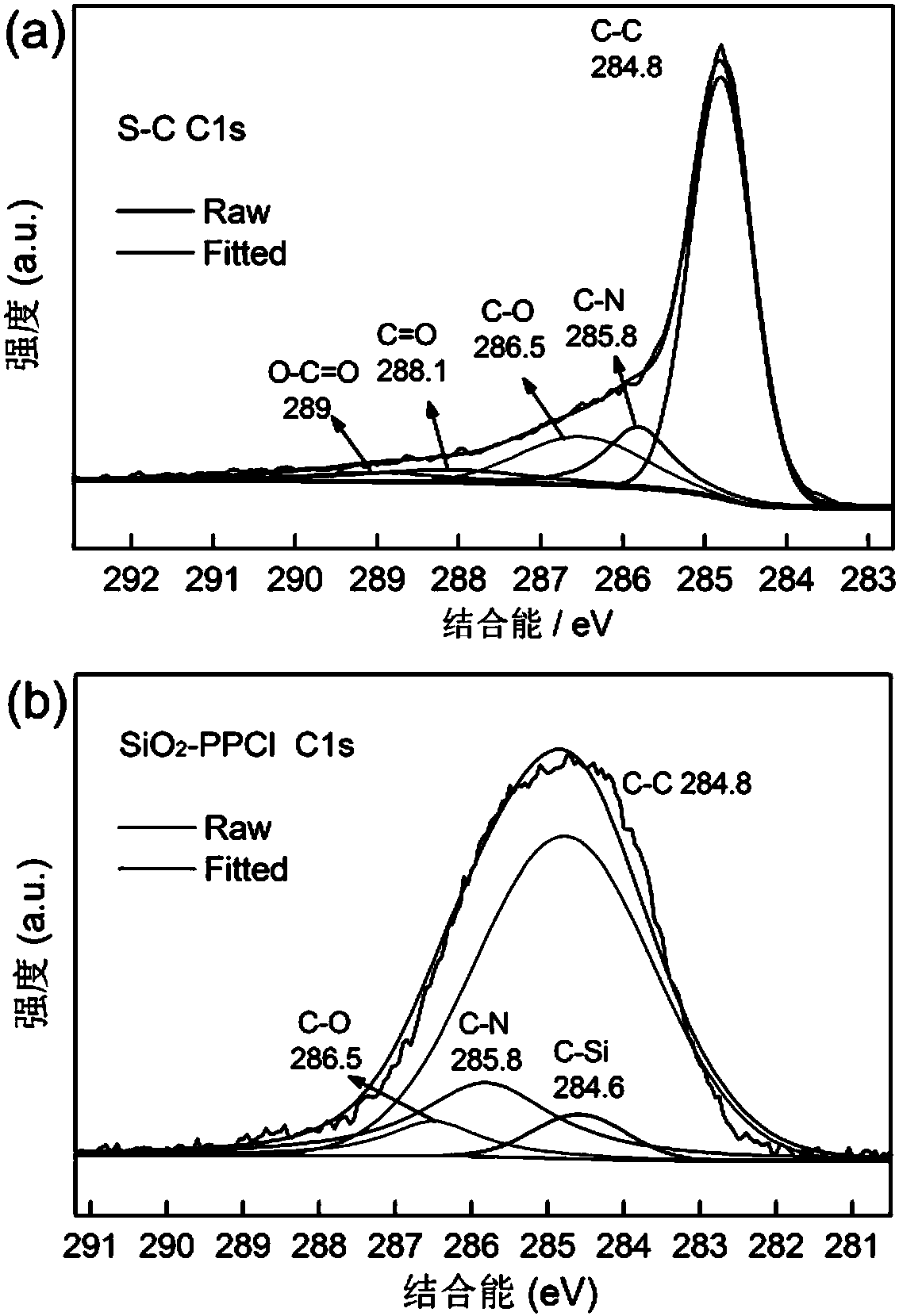

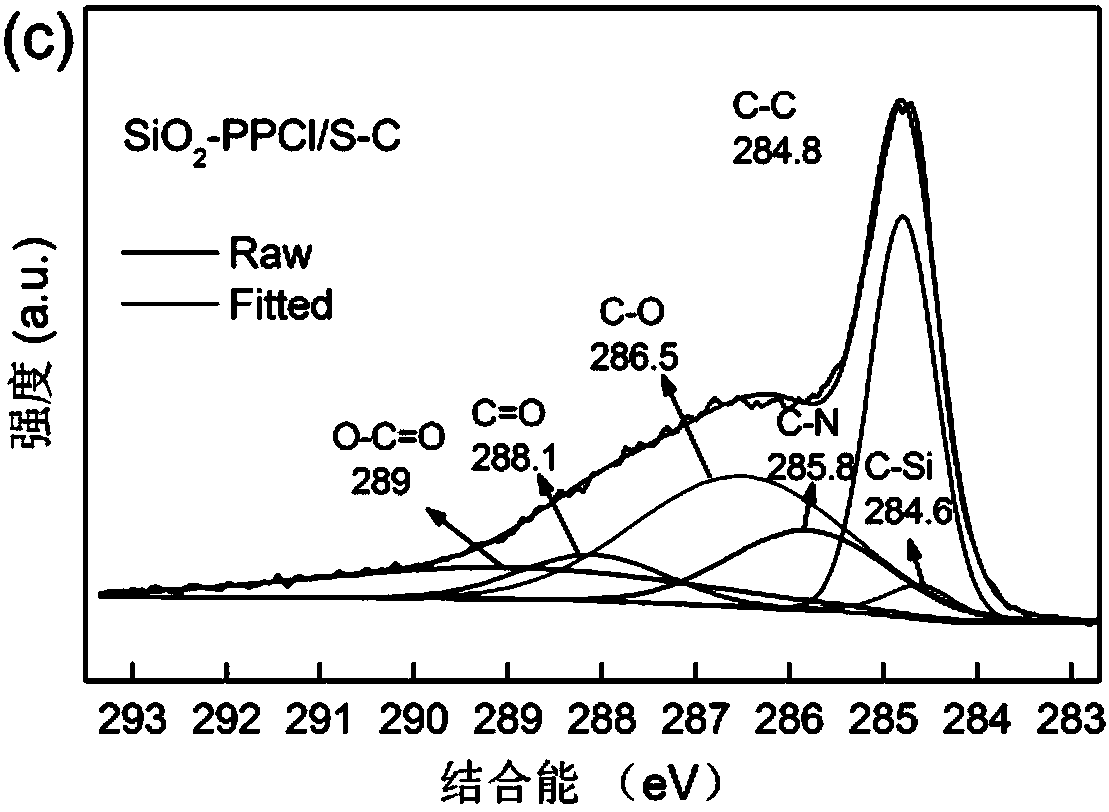

[0041] The functionalized ionic liquid of the present embodiment comprises ionic liquid and SiO 2 ; The ionic liquid is 1-methyl-1-propyl (trimethoxysilane) piperidinium chloride. Ionic Liquids and SiO 2 The mass ratio is 2:3. The functionalized ionic liquid is composed of the above-mentioned ionic liquid and SiO 2 Composite.

[0042] The preparation method of the functionalized ionic liquid of the present embodiment comprises the following steps:

[0043] 1) Add 3.96g of N-Methyl piperidine and 8.73g of 3-chloropropyl trimethoxysilane to the organic solvent dimethylformamide (dimethylformamide) and mix reaction. Specifically, the reaction is to react at 80°C for 72h under the protection of an inert atmosphere; then the mixed system after the reaction is extracted with ethyl acetate, and the 1-methyl-1-propyl(trimethoxysilane)piperene produced by the reaction The pyridinium chloride precipitated in the mixed system; then the solvent and extractant were removed by evapora...

Embodiment 2

[0052] The functionalized ionic liquid of the present embodiment comprises ionic liquid and SiO 2 ; The ionic liquid is 1-methyl-1-propyl (trimethoxysilane) piperidinium chloride. Ionic Liquids and SiO 2 The mass ratio is 1:1. The functionalized ionic liquid is composed of the above-mentioned ionic liquid and SiO 2 Composite.

[0053] The preparation method of the functionalized ionic liquid of the present embodiment comprises the following steps:

[0054] 1) Add 3.5g of N-Methyl piperidine and 8g of 3-chloropropyl trimethoxysilane to the organic solvent dimethylformamide (dimethylformamide) for mixed reaction Specifically, the reaction is to react at 70°C for 48h under the protection of an inert atmosphere; then the mixed system after the reaction is extracted with ethyl acetate, and the 1-methyl-1-propyl (trimethoxysilane) produced by the reaction Piperidinium chloride precipitated in the mixed system; then evaporated with a rotary evaporator for 8h to remove the solven...

Embodiment 3

[0063] The functionalized ionic liquid of the present embodiment comprises ionic liquid and SiO 2 ; The ionic liquid is 1-methyl-1-propyl (trimethoxysilane) piperidinium chloride. Ionic Liquids and SiO 2 The mass ratio is 3.5:4. The functionalized ionic liquid is composed of the above-mentioned ionic liquid and SiO 2 Composite.

[0064] The preparation method of the functionalized ionic liquid of the present embodiment comprises the following steps:

[0065] 1) Add 4.8g of N-Methyl piperidine and 9.6g of 3-chloropropyl trimethoxysilane to the organic solvent dimethylformamide (dimethylformamide) and mix Reaction, specifically, the reaction is to react at 90°C for 60h under the protection of an inert atmosphere; then the mixed system after the reaction is extracted with ethyl acetate, and the 1-methyl-1-propyl (trimethoxysilane) produced by the reaction ) piperidinium chloride was precipitated in the mixed system; then the solvent and extractant were removed by evaporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com