Preparation method of hexagonal-prism-shaped iron-cobalt double-metal selenide

A bimetal and selenide technology, applied in the field of inorganic materials, can solve the problems of agglomeration or uneven composition, irregular material morphology, etc., and achieve the effects of small distance, uniform particle size distribution, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

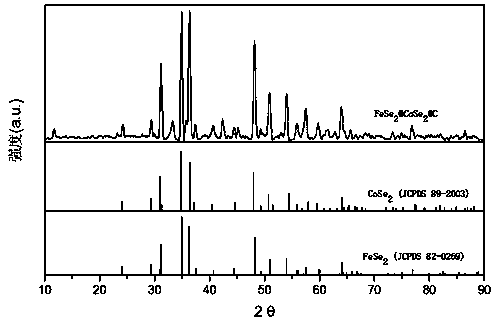

Image

Examples

Embodiment 1

[0035] A preparation method with hexagonal iron-cobalt double metal selenide, comprising the following steps:

[0036] S1. Take 0.4040g Fe(NO 3 ) 3 •9H 2 O and 0.2911g Co(NO 3 ) 2 •6H 2 O was dissolved in 50mL of isopropanol, which was designated as solution A;

[0037] S2. Dissolve 1.0g of PVP (Mw=10000) in 50mL of isopropanol, and record it as solution B;

[0038] S3. Take 1.6802g NaHCO 3 Dissolve in 100mL deionized water, and record it as solution C;

[0039] S4. After mixing solution B and solution A, sonicate for 15 minutes, add solution C dropwise under magnetic stirring in an oil bath; keep the temperature of the oil bath at 40°C for 12 hours, and wash with ethanol and deionized water for several times after the reaction. The precipitate was collected by vacuum drying at ℃ for 24 h;

[0040] S6. The prepared iron-cobalt precursor and selenium powder are respectively placed on both ends of a porcelain boat and evenly paved, and the mass ratio is 1:2;

[0041] S7 ...

Embodiment 2

[0043] Repeat the steps of Example 1, and adjust the oil bath in S4 to an ice bath at 0°C.

Embodiment 3

[0045] The steps of Example 1 were repeated, and the temperature of the oil bath in S4 was adjusted to 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com