Method for preparing fluorizated lithium vanadium phosphate as lithium-ion battery anode material by using spray pyrolysis method

A fluorinated lithium vanadium phosphate, lithium ion battery technology, applied in battery electrodes, circuits, phosphorus compounds, etc., can solve problems such as unfavorable industrial production, low material purity, poor electrochemical performance, etc., to shorten the synthesis cycle, simplify the Preparation process, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the implementation examples.

[0021] Implementation example 1

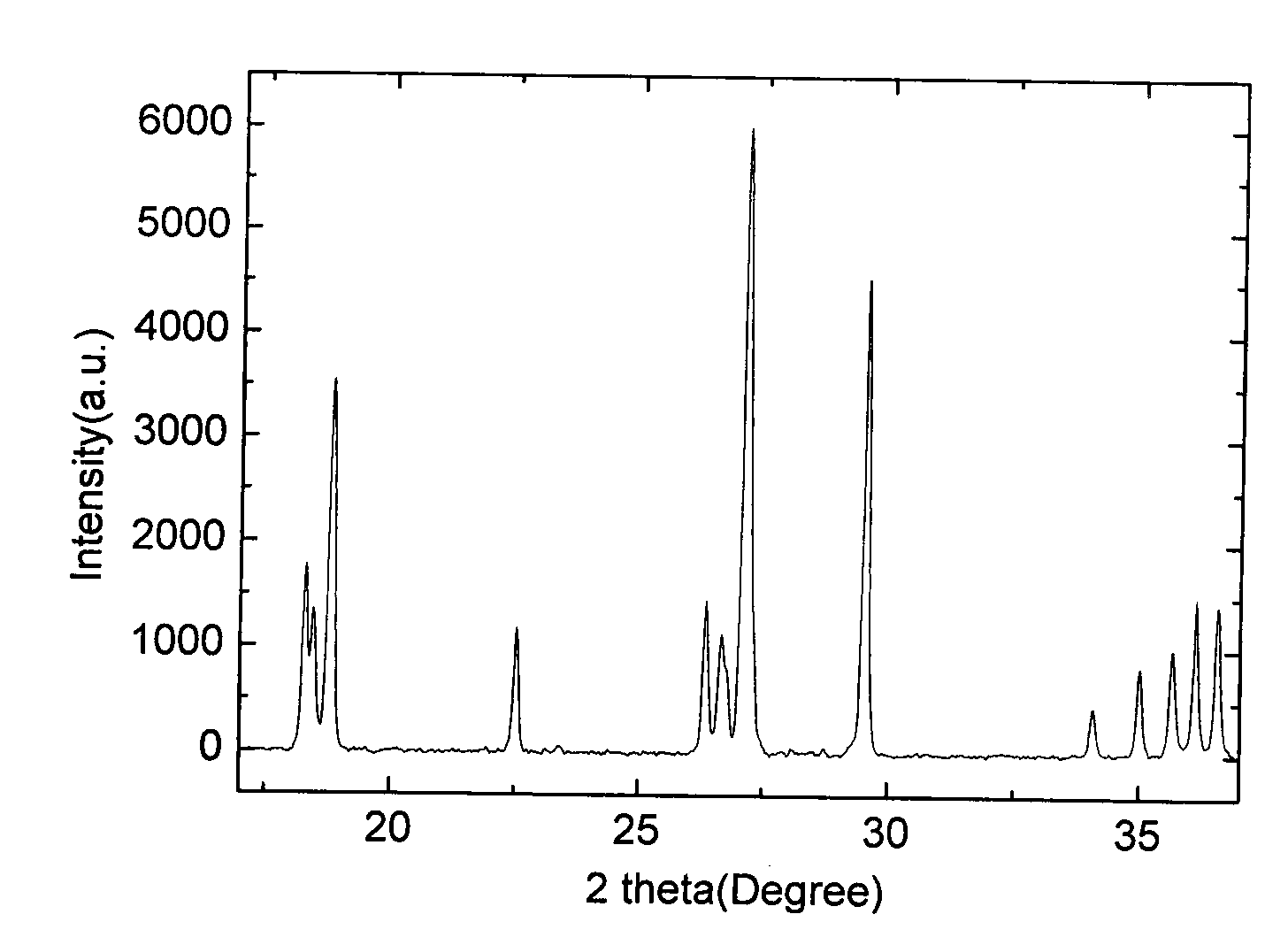

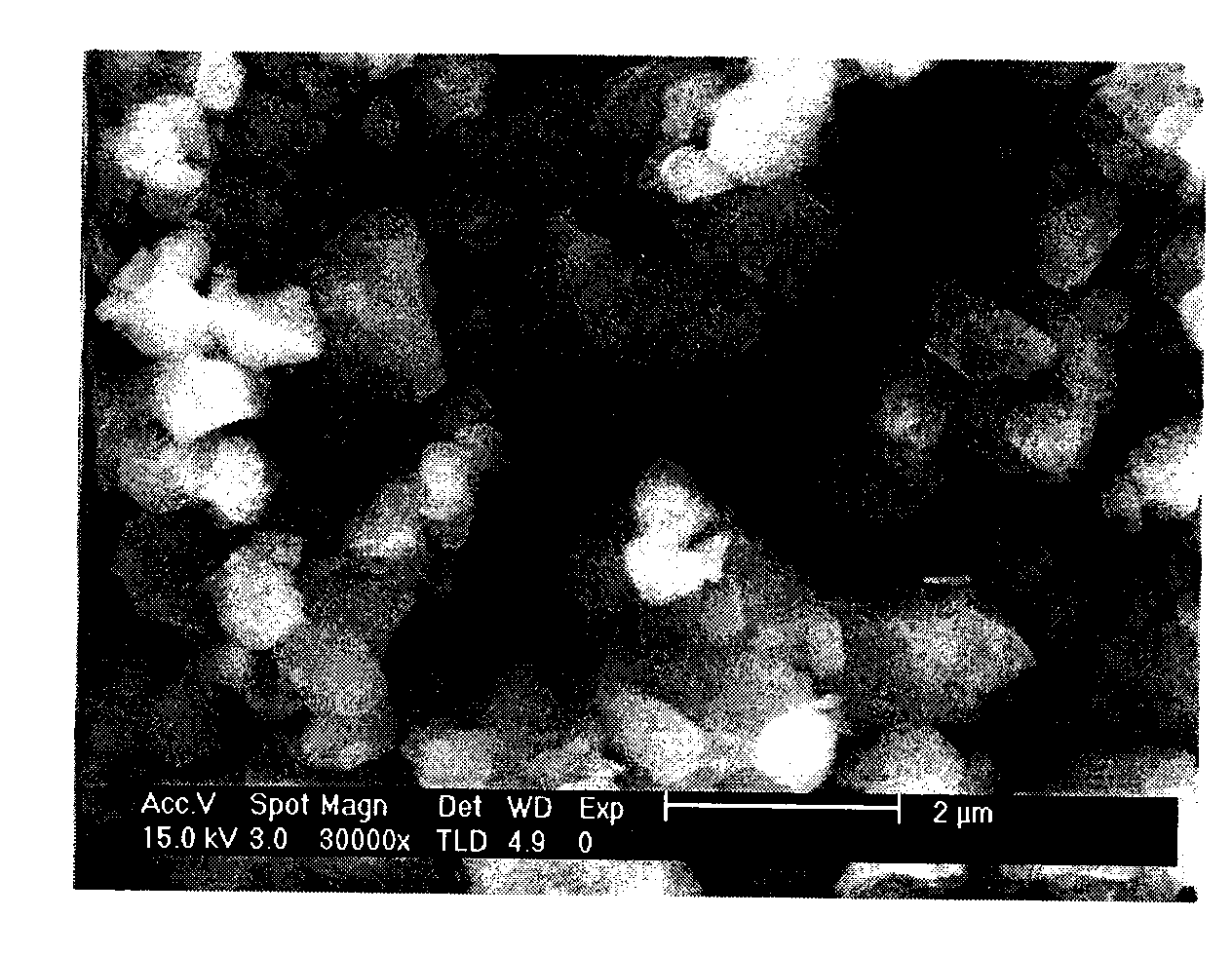

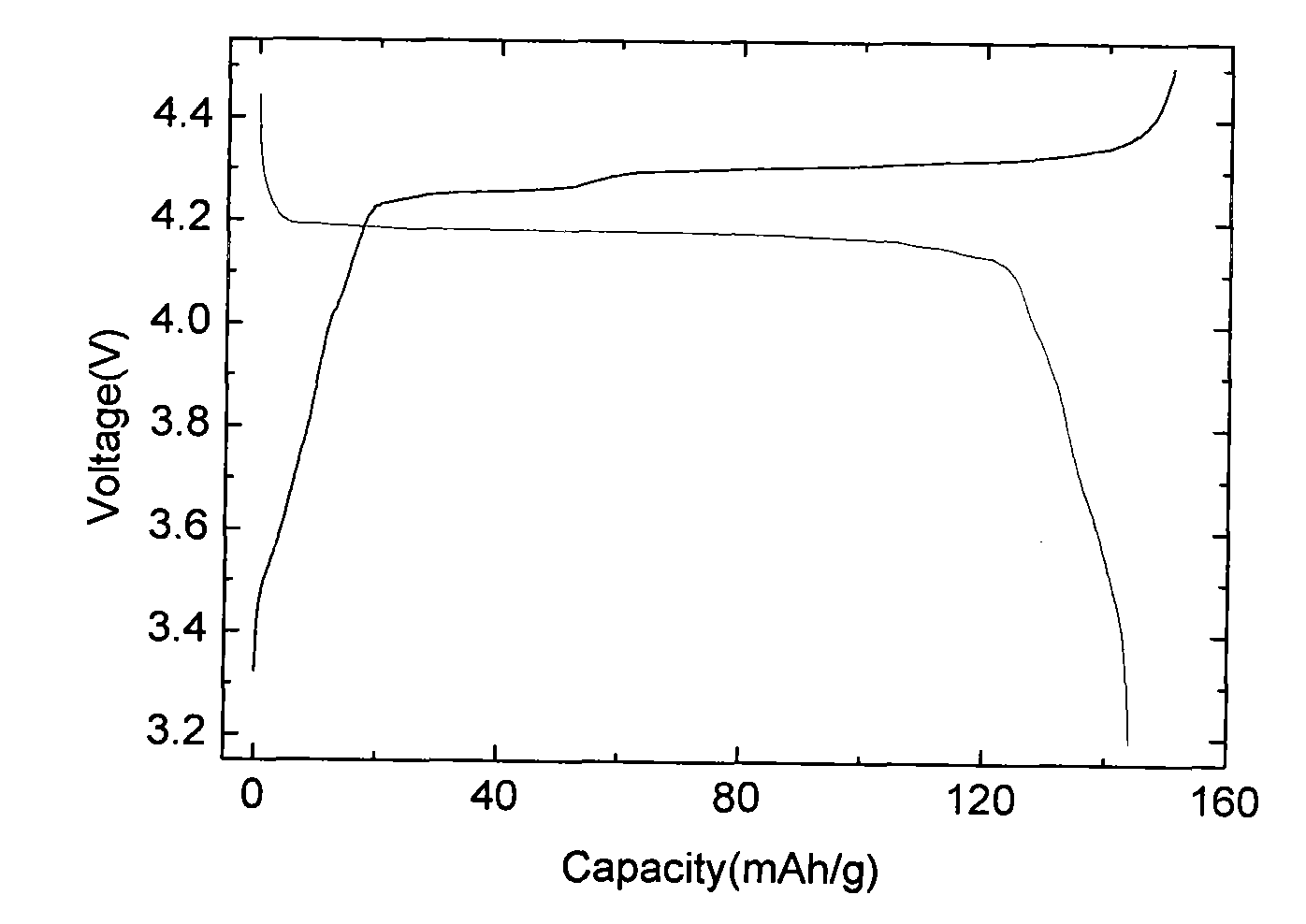

[0022] Add 0.4mol ammonium dihydrogen phosphate, 0.2mol ammonium metavanadate, 0.2mol lithium oxalate, 0.2mol ammonium fluoride, 0.2mol hydrazine hydrate, and 0.4mol maltose to water respectively, and stir with a mechanical stirrer after each substance is added After 30 minutes, make it evenly mixed, the total volume of the final mixed solution is 400mL, then put the mixed solution into an argon gas flow spray dryer, spray dry at 300°C, and collect the product to obtain the precursor powder. The resulting precursor powder was pressed into tablets under a pressure of 20 MPa, then sintered at 800 °C for 10 hours under the protection of argon, and then naturally cooled to room temperature to obtain LiVPO 4 F. X-ray powder diffraction analysis showed that the obtained product was pure LiVPO 4 F, there is no other impurity ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com