Method for preparing chromium-titanium-based lithium ion battery composite material

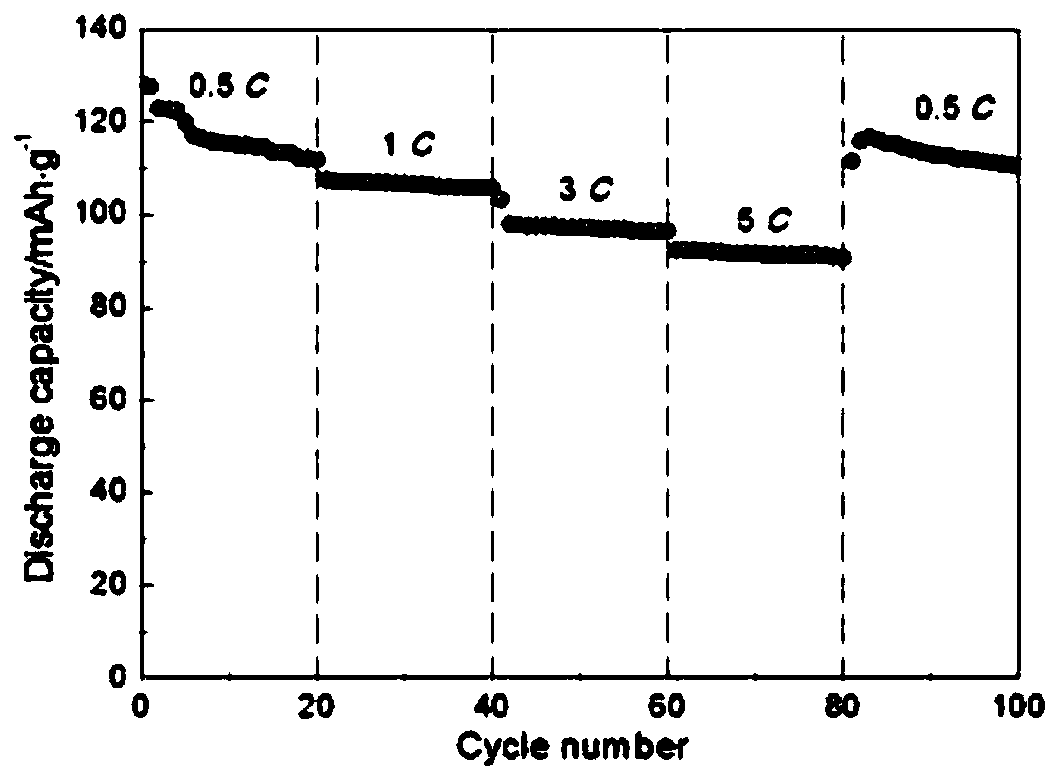

An ion battery and composite material technology is applied in the field of preparation of chromium-titanium-based lithium ion battery composite materials to achieve the effects of high use value, good reversible capacity with wide potential window and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

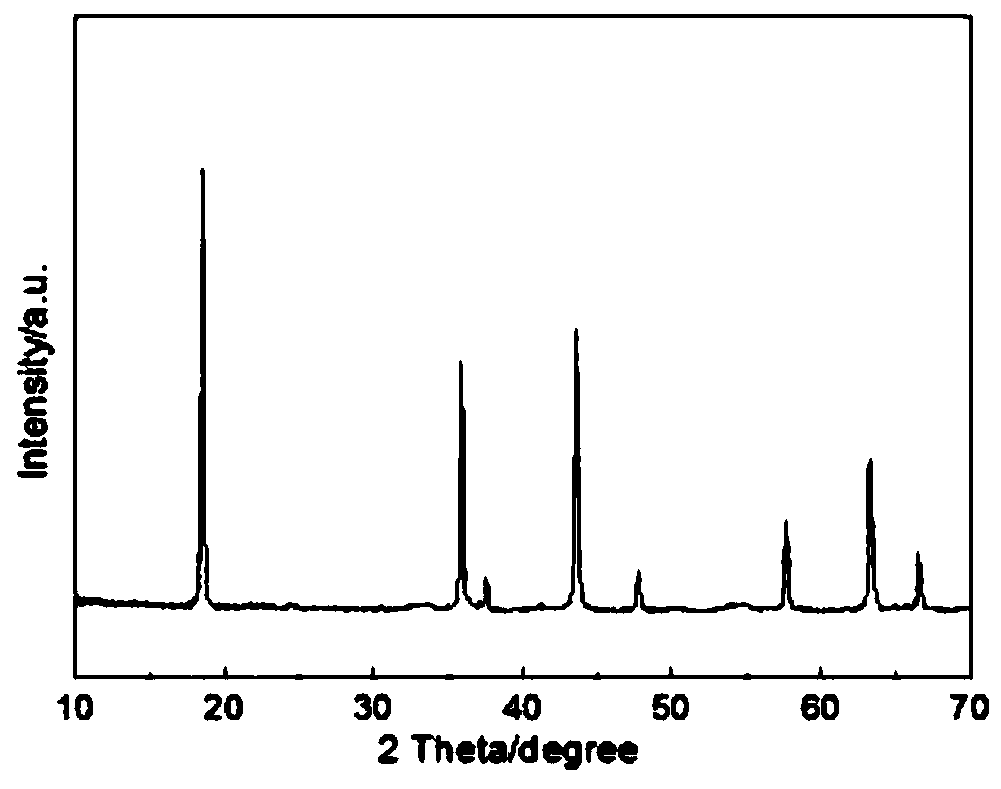

Image

Examples

Embodiment 1

[0030] A preparation method of a chromium-titanium-based lithium-ion battery composite material proposed by the present invention comprises the following steps:

[0031] S1. Weigh 12 mol of tetrabutyl titanate and 12 mol of chromium nitrate nonahydrate and dissolve them in an aqueous solution of absolute ethanol, add 15 mol of lithium hydroxide monohydrate in an aqueous ethanol solution under stirring, stir magnetically for 1 hour, and then add 2 mol of nickel nitrate and an aqueous solution of 2mol sodium molybdate, magnetically stirred for 1h, transferred the mixed solution to a stainless steel polytetrafluoroethylene reactor, put it into an oven and reacted at 160°C for 24h, cooled to room temperature, and filtered the mixed solution in the reactor get the precursor;

[0032] S2. Place the precursor in an oven, dry it at 80°C, grind it and place it in a muffle furnace for pre-calcination at 600°C for 6 hours, cool to room temperature, mill it in a ball mill for 3 hours, sie...

Embodiment 2

[0040] A preparation method of a chromium-titanium-based lithium-ion battery composite material proposed by the present invention comprises the following steps:

[0041] S1. Dissolve the titanium source and the chromium source in an aqueous solution of absolute ethanol, add the aqueous ethanol solution containing the lithium source, stir, then add the aqueous solution containing nickel nitrate and sodium molybdate, stir, react at 140°C for 26h, cool, and filter , to obtain the precursor;

[0042] S2, drying the precursor, pre-calcining, cooling, ball milling, sieving, then sintering, cooling to obtain LiCrTiO 4 -aNiMoO 4 Material;

[0043] S3, the LiCrTiO 4 -aNiMoO 4 The material is dissolved in deionized water, ultrasonically dispersed, a surfactant is added, stirred, and then pyrrole monomer, hydrochloric acid and ammonium persulfate aqueous solution are added, stirred, filtered, and dried to obtain a chromium-titanium-based lithium ion battery composite material.

Embodiment 3

[0045] A preparation method of a chromium-titanium-based lithium-ion battery composite material proposed by the present invention comprises the following steps:

[0046] S1. Dissolve tetrapropyl titanate and chromium acetate in an aqueous solution of absolute ethanol, add an aqueous ethanol solution containing lithium acetate dihydrate under stirring conditions, stir magnetically for 1.5 hours, and then add an aqueous solution containing nickel nitrate and sodium molybdate , magnetically stirred for 1.5h, then reacted at 140°C for 26h, cooled to room temperature, and filtered to obtain a precursor; wherein, the molar ratio of lithium acetate dihydrate, chromium acetate, and tetrapropyl titanate was 1:1:1, and nickel nitrate The molar ratio with sodium molybdate is 1:1;

[0047] S2. Place the precursor at 85°C to dry, after grinding, place it at 630°C for 5.5h, cool to room temperature, ball mill for 2.5h, sieve, then sinter at 840°C for 11h, cool to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com