Grinding preparation method and application of polyoxometallate-metal organic framework material

A metal-organic framework and polyoxometalate technology, which is applied in the manufacture of hybrid/electric double-layer capacitors and hybrid capacitor electrodes, can solve the problems of repeated synthesis instability, small active area, and low production yield, and achieve stability Electrochemical performance, simple method, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

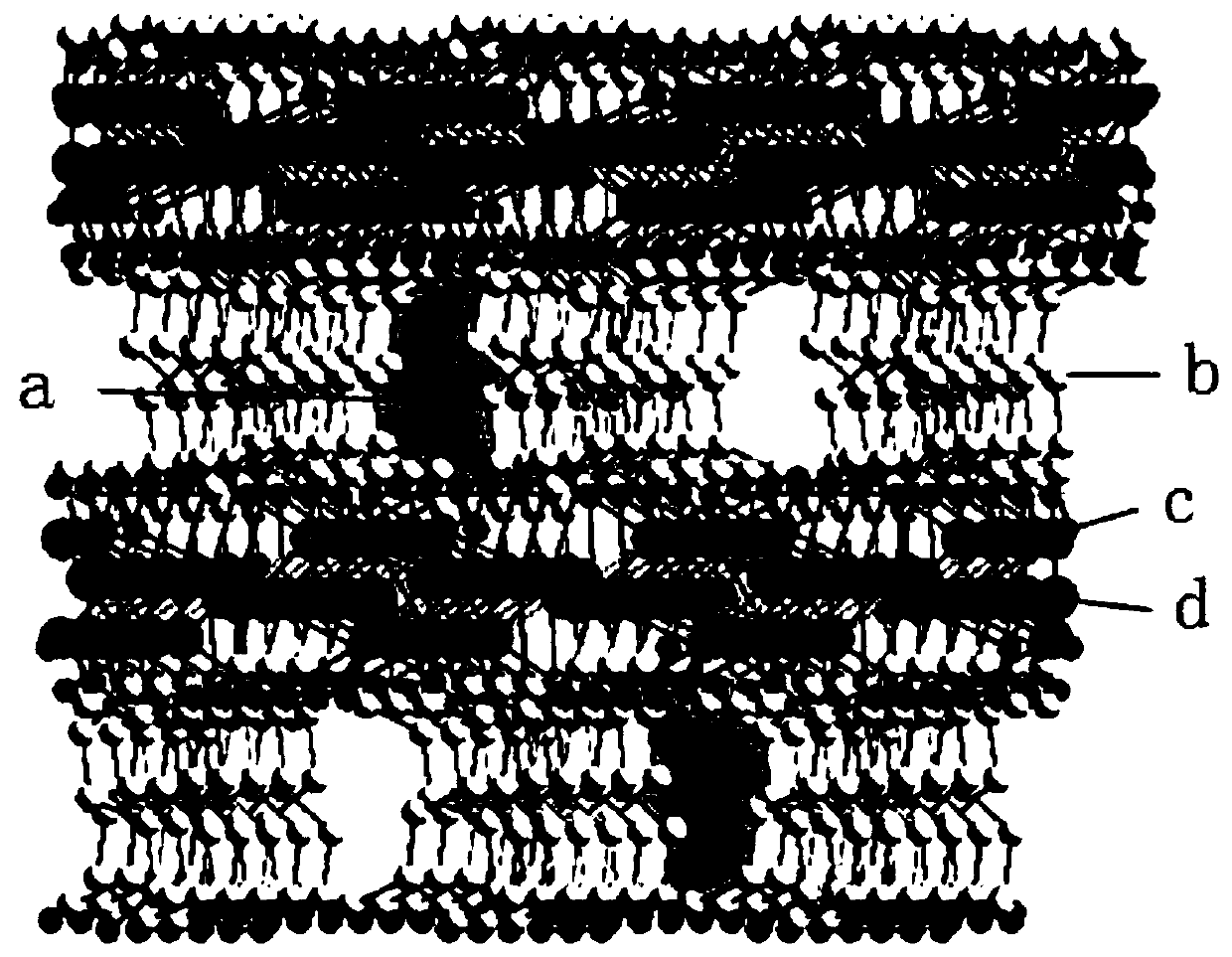

[0034] Specific embodiment 1: In this embodiment, a polyoxometalate-metal organic framework material, the molecular formula of the polyoxometalate-metal organic framework material is {Ag 6 Mo 7 o 24} @Ag-BTC.

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: a grinding preparation method of polyoxometalate-metal organic framework material, which is completed according to the following steps:

[0036] 1. Add AgNO sequentially in distilled water 3 and (NH 4 ) 6 Mo 7 o 24 4H 2 O, and stirred to dissolve to obtain product A; the AgNO 3 with (NH 4 ) 6 Mo 7 o 24 4H 2 The molar ratio of O is (5.5~7):(0.5~2);

[0037] 2. Adjust the pH of product A to 3.5-4.5 under stirring conditions, and continue stirring for 1h-2h to obtain product B;

[0038] 3. After the product B obtained in step 2 is completely evaporated, powder C is obtained, and powder C is mixed with trimesic acid, silver nitrate and absolute ethanol for 20min to 40min to obtain product D; The mol ratio of triformic acid is (1~2):(1.5~2.5), the mol ratio of described powder C and silver nitrate is (1~2):(0.5~2), the mol ratio of described powder C and dehydrated alcohol...

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the AgNO described in step one 3 with (NH 4 ) 6 Mo 7 o 24 4H 2 The molar ratio of O is 5.5:0.5.

[0048] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com