A laser ablation and oxidation in-situ preparation method of an integrated negative electrode of a lithium-ion battery

An in-situ preparation technology for lithium-ion batteries, which is applied in the field of laser ablation and oxidation in-situ preparation of lithium-ion battery integrated negative electrodes, can solve problems such as expensive equipment, high manufacturing costs, and complicated preparation processes, and achieve loose and porous structures. Relieves the effect of large volume change and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

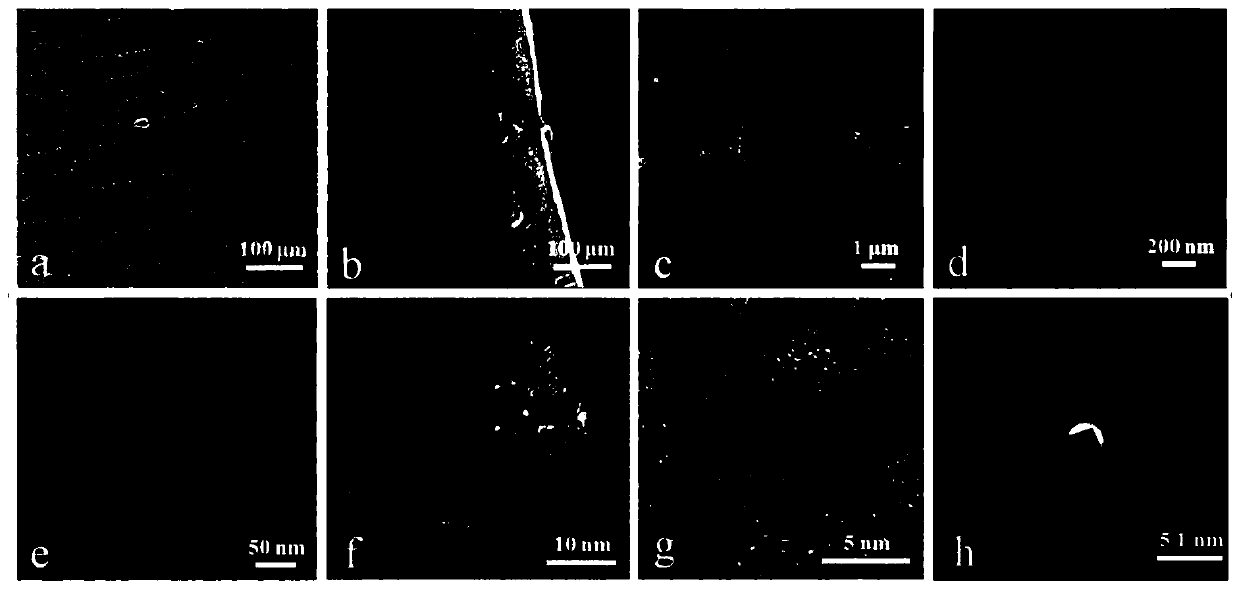

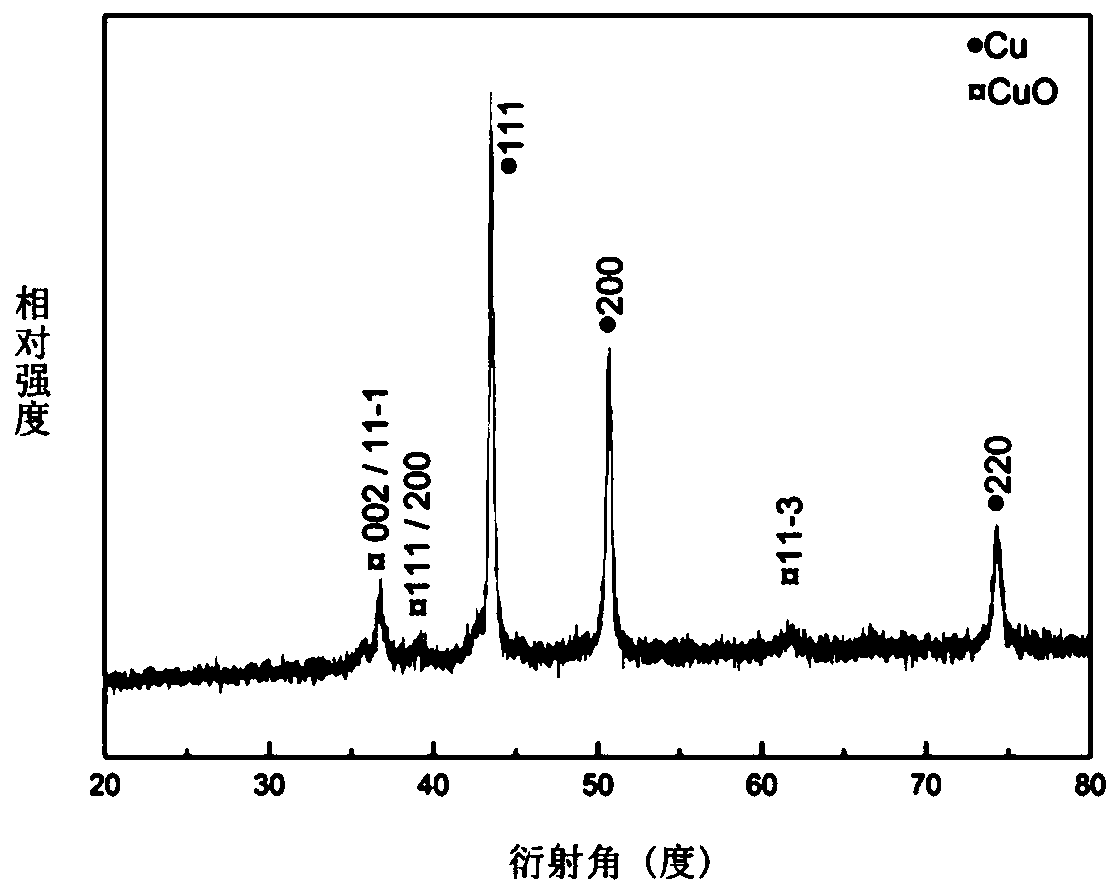

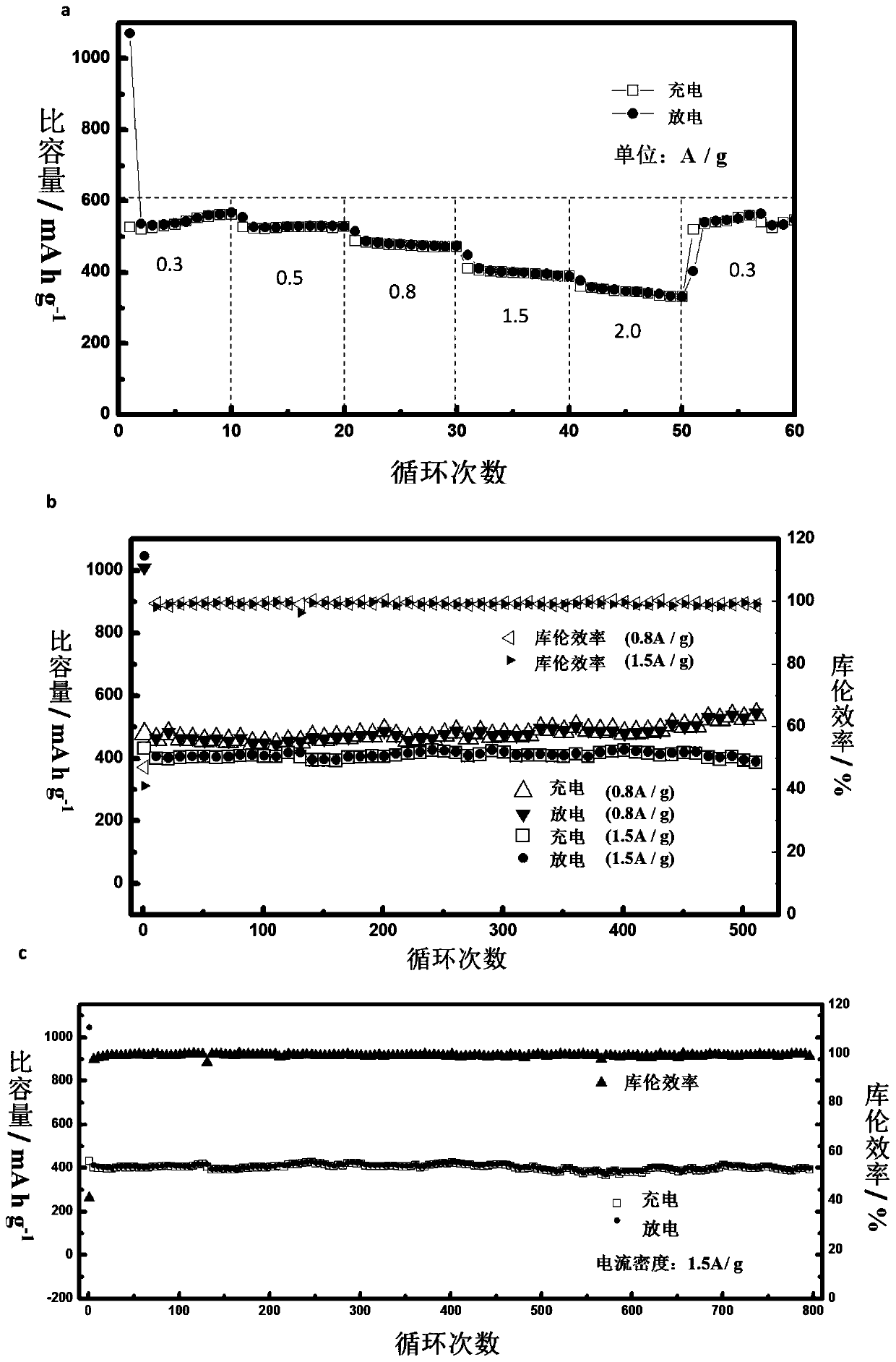

[0023] A laser ablation and oxidation in-situ preparation method for an integrated negative electrode of a lithium ion battery, comprising the following steps:

[0024] 1) Ultrasonic cleaning the metal foil with alcohol and deionized water for 30 minutes to remove impurities on the surface; the metal foil is made of copper with a purity of more than 99.99% and a thickness of 100 μm;

[0025] 2) At room temperature and air atmosphere, use nanosecond pulsed laser to scan and irradiate the metal foil respectively. The laser wavelength is 532nm, the pulse frequency is 30000Hz, the pulse width is 10ns, and the single pulse energy is 1.5×10 -4 J, laser scanning speed 25mm s -1 , the laser is perpendicular to the metal foil to obtain a metal oxide-metal integrated negative electrode;

[0026] 3) Put the metal oxide-metal integrated negative electrode into a vacuum oven and dry at 60°C for 6 hours;

[0027]4) Soak the dried metal oxide-metal integrated negative electrode in a mixed ...

Embodiment 2

[0035] A laser ablation and oxidation in-situ preparation method for an integrated negative electrode of a lithium ion battery, comprising the following steps:

[0036] 1) Ultrasonic cleaning the metal foil with acetone and deionized water for 30 minutes to remove impurities on the surface; the metal foil is made of iron with a purity of more than 99.99% and a thickness of 100 μm;

[0037] 2) At room temperature and air atmosphere, use nanosecond pulsed laser to scan and irradiate the metal foil respectively. The laser wavelength is 532nm, the pulse frequency is 20000Hz, the pulse width is 10ns, and the single pulse energy is 1.5×10 -4 J, laser scanning speed 15mm s -1 , the laser is perpendicular to the metal foil to obtain a metal oxide-metal integrated negative electrode;

[0038] 3) Put the metal oxide-metal integrated negative electrode into a vacuum drying oven for 8 hours at 90°C;

[0039] 4) Soak the dried metal oxide-metal integrated negative electrode in a mixed so...

Embodiment 3

[0043] A laser ablation and oxidation in-situ preparation method for an integrated negative electrode of a lithium ion battery, comprising the following steps:

[0044] 1) Ultrasonic cleaning the metal foil with alcohol and deionized water for 30 minutes to remove impurities on the surface; the metal foil is made of nickel with a purity of over 99.99% and a thickness of 100 μm;

[0045] 2) At room temperature and air atmosphere, use nanosecond pulse laser to scan and irradiate the metal foil respectively. The laser wavelength is 532nm, the pulse frequency is 10000Hz, the pulse width is 10ns, and the single pulse energy is 1.5×10 -4 J, laser scanning speed 20mm s -1 , the laser is perpendicular to the metal foil to obtain a metal oxide-metal integrated negative electrode;

[0046] 3) Put the metal oxide-metal integrated negative electrode into a vacuum drying oven to dry at 80°C for 10 hours;

[0047] 4) Soak the dried metal oxide-metal integrated negative electrode in a mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com