Preparation method of zinc-based negative electrode material, prepared negative electrode material, negative-electrode plate and lithium battery

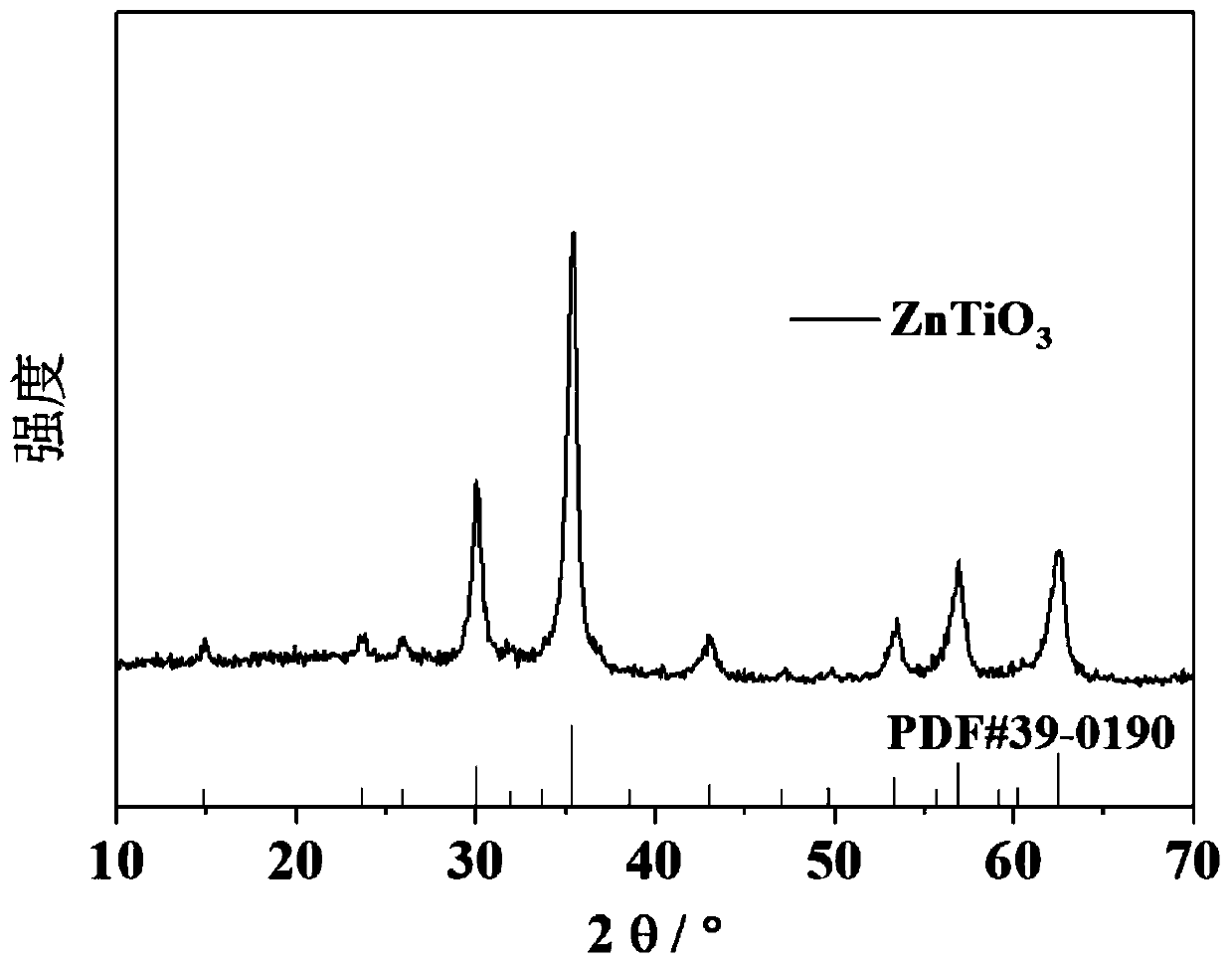

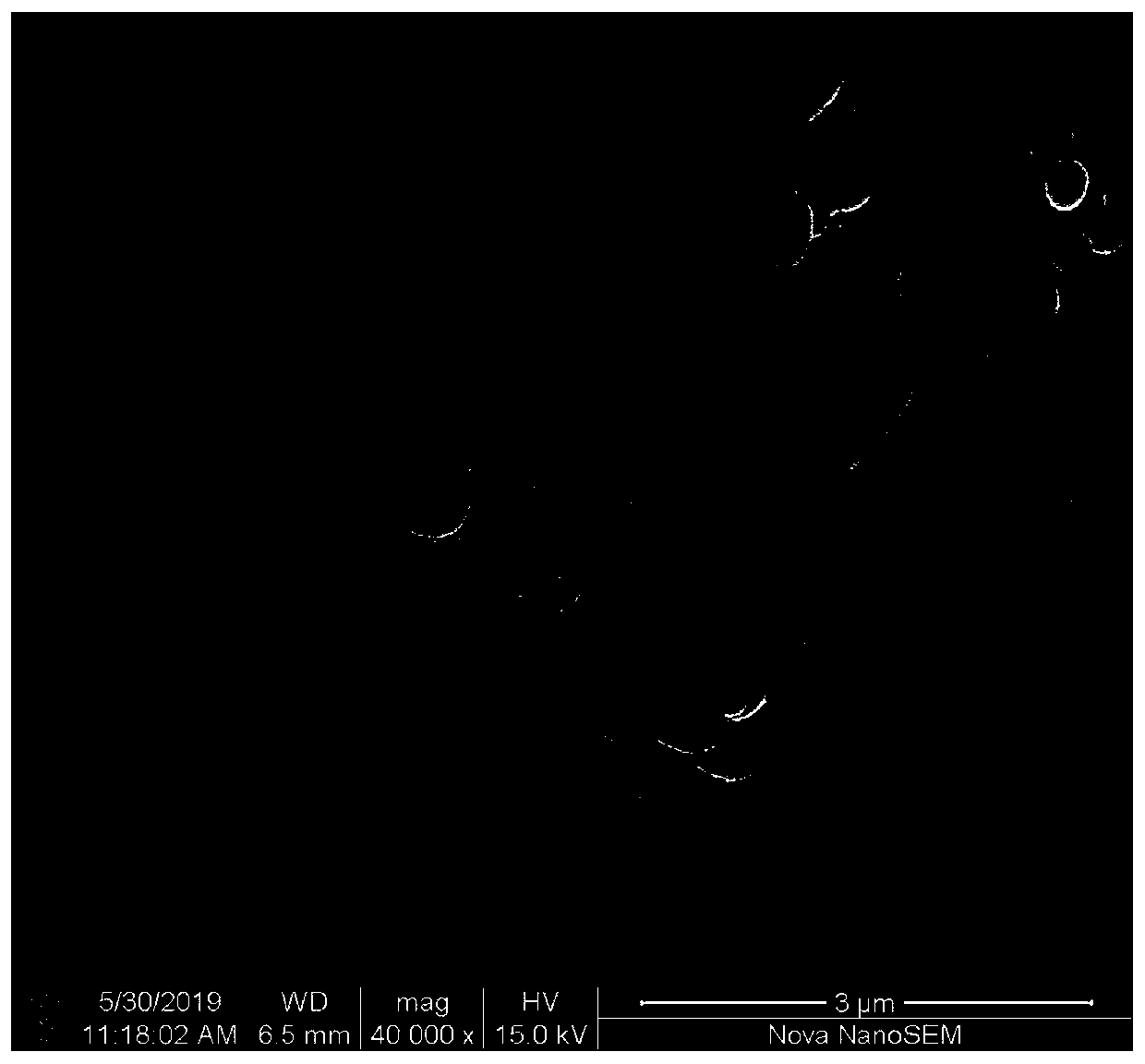

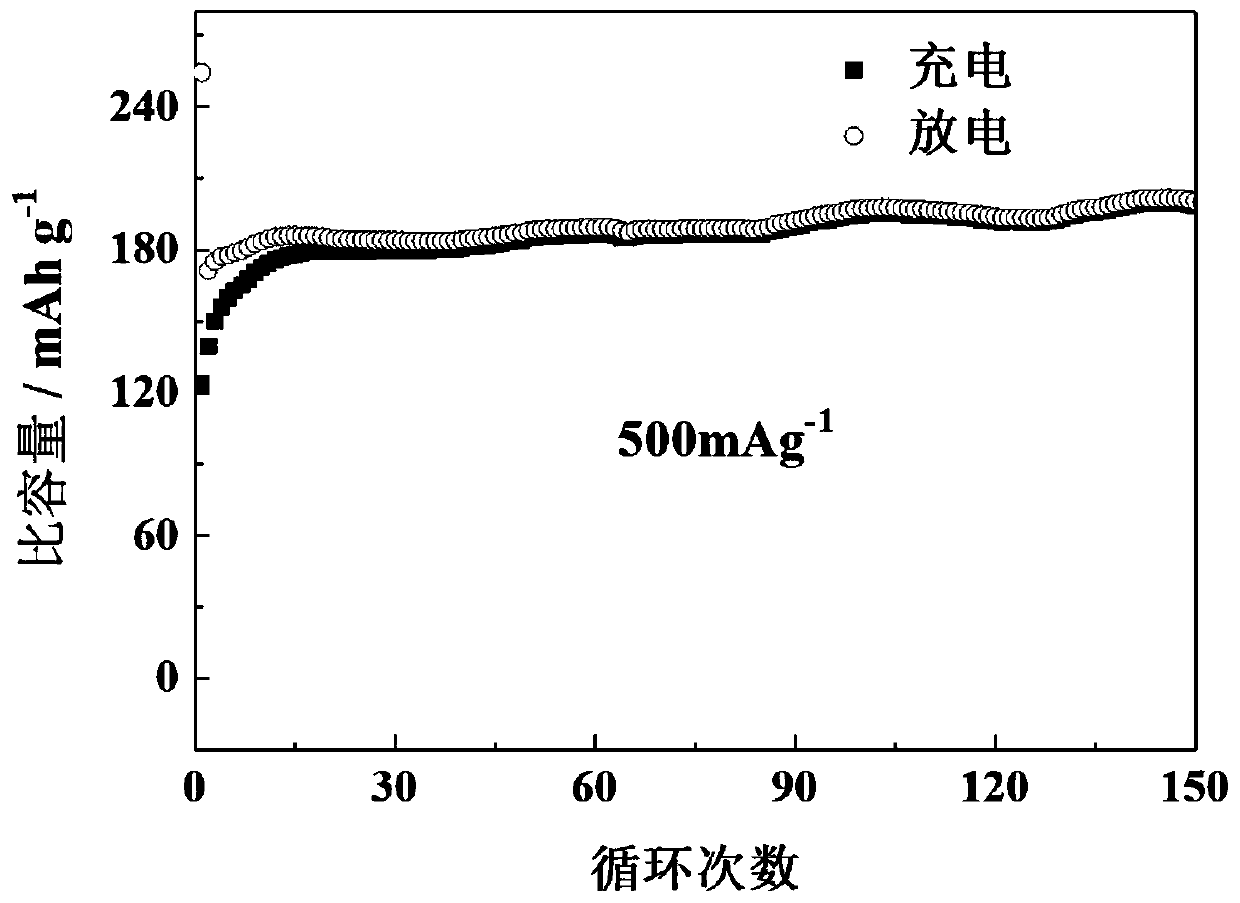

A technology of negative electrode material and negative electrode sheet is applied in the field of preparation of zinc-based negative electrode material, which can solve the problems of low lithium ion diffusion rate, restrict the application of lithium titanate, and wide range of powder particle size, and achieve uniform distribution of titanium source, Improved reproducibility and controllability, particle size and composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] This embodiment provides a method for preparing a zinc-based negative electrode material, the method comprising the following steps:

[0099] (1) Add 0.01mol of zinc citrate under stirring conditions to 110mL mixed solution composed of ethanol, ethylene glycol, formamide and acetonitrile in a volume ratio of 10:10:1:1 to obtain solution A; Tetrabutyl titanate was added to a 30mL mixed solution composed of ethanol and benzyl alcohol in a volume ratio of 2:1 to obtain solution B;

[0100] (2) Add the solution B to the continuously stirring solution A, and simultaneously add 0.01 g of a mixture of sodium stearate and sodium dodecylsulfonate in a mass ratio of 1:8 and 0.01 g of 1-ene Propyl-3-methylimidazolium chloride salt to obtain solution C, and continue to stir vigorously for 10 minutes to make the solution C mix uniformly;

[0101] (3) Heat the solution C in a polytetrafluoroethylene reactor at 180° C. for 6 hours to obtain a mixed solution. The mixed solution is coo...

Embodiment 2

[0108] This embodiment provides a method for preparing a zinc-based negative electrode material, the method comprising the following steps:

[0109] (1) Add 0.01mol zinc citrate to a 110mL mixed solution composed of ethanol and ethylene glycol at a volume ratio of 1:1 under stirring conditions to obtain solution A; add 0.01mol tetrabutyl titanate to ethanol and ethylene glycol Benzyl alcohol is in the 30mL mixed solution that forms by volume ratio 2:1, obtains solution B;

[0110] (2) Add the solution B to the continuously stirring solution A, and simultaneously add 0.01 g of a mixture of sodium stearate and sodium dodecylsulfonate in a mass ratio of 1:8 and 0.01 g of 1-ene Propyl-3-methylimidazolium chloride salt to obtain solution C, and continue to stir vigorously for 10 minutes to make the solution C mix uniformly;

[0111] (3) Heat the solution C in a polytetrafluoroethylene reactor at 180° C. for 6 hours to obtain a mixed solution. The mixed solution is cooled to room t...

Embodiment 3

[0115] This embodiment provides a method for preparing a zinc-based negative electrode material, the method comprising the following steps:

[0116] (1) Add 0.01mol of zinc citrate under stirring conditions to 110mL mixed solution composed of ethanol, ethylene glycol, formamide and acetonitrile in a volume ratio of 10:10:1:1 to obtain solution A; Tetrabutyl titanate was added to 30 mL of benzyl alcohol solution to obtain solution B;

[0117] (2) Add the solution B to the continuously stirring solution A, and simultaneously add 0.01 g of a mixture of sodium stearate and sodium dodecylsulfonate in a mass ratio of 1:8 and 0.01 g of 1-ene Propyl-3-methylimidazolium chloride salt to obtain solution C, and continue to stir vigorously for 10 minutes to make the solution C mix uniformly;

[0118] (3) Heat the solution C in a polytetrafluoroethylene reactor at 180° C. for 6 hours to obtain a mixed solution. The mixed solution is cooled to room temperature and then filtered to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com