Method for preparing lithium iron borate serving as positive material of lithium ion battery by sol-gel technology

A sol-gel technology and lithium-ion battery technology, applied in the field of preparation of lithium-ion battery cathode materials, can solve the problems of unfavorable large-scale industrial production, poor electrochemical performance, complex and changeable process, etc., to shorten the preparation cycle and reduce synthesis Temperature, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the implementation examples.

[0018] Implementation Example 1

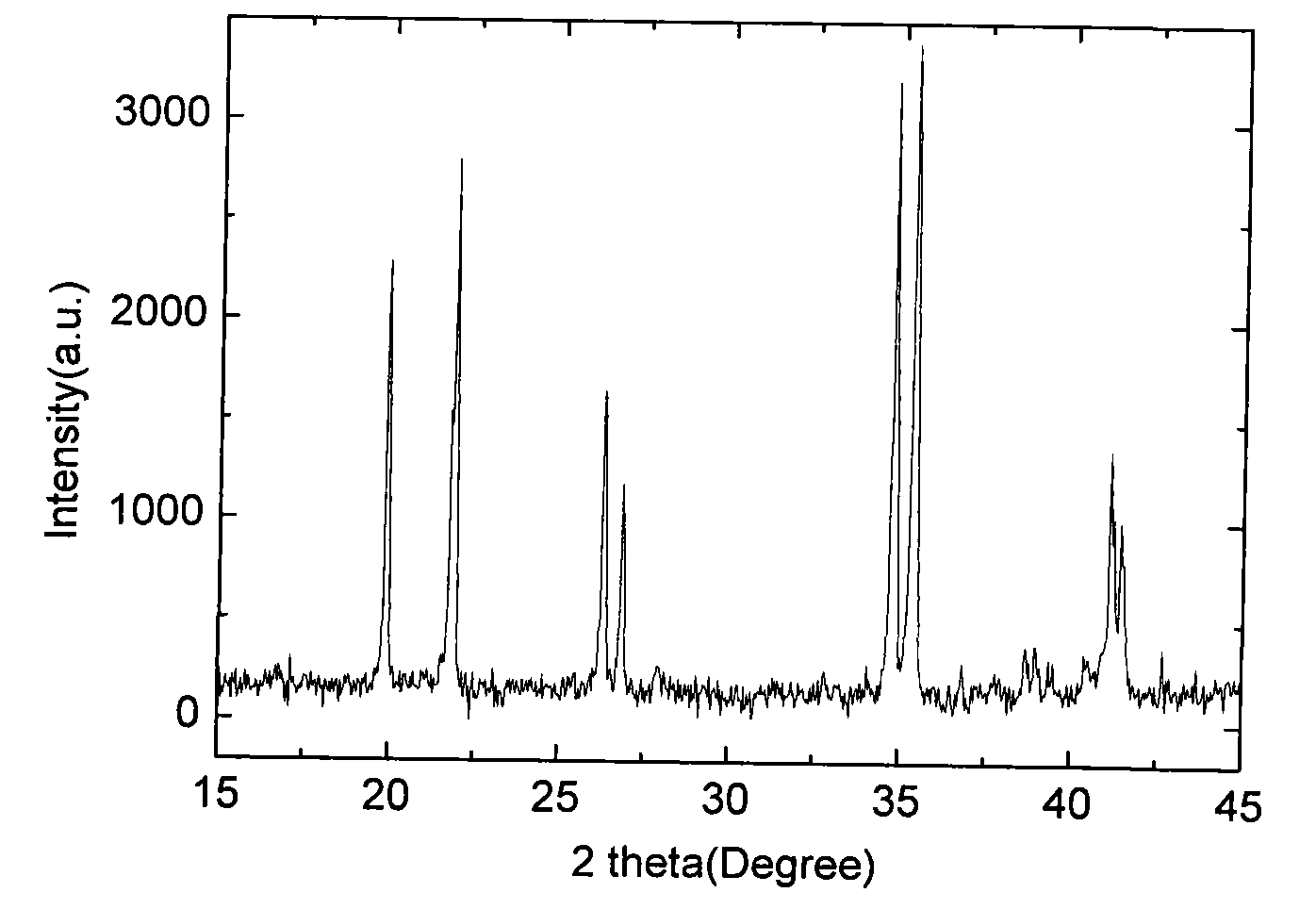

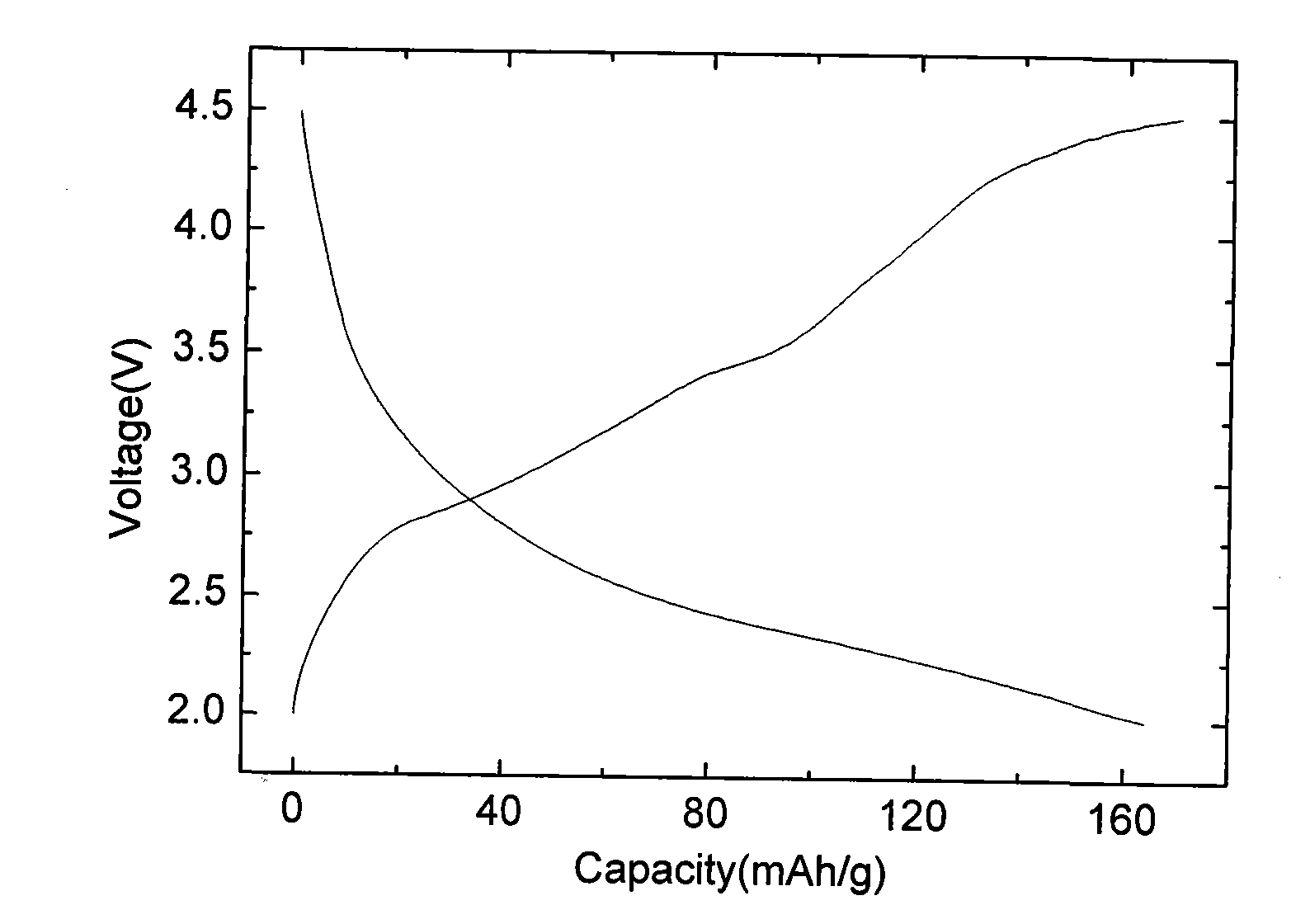

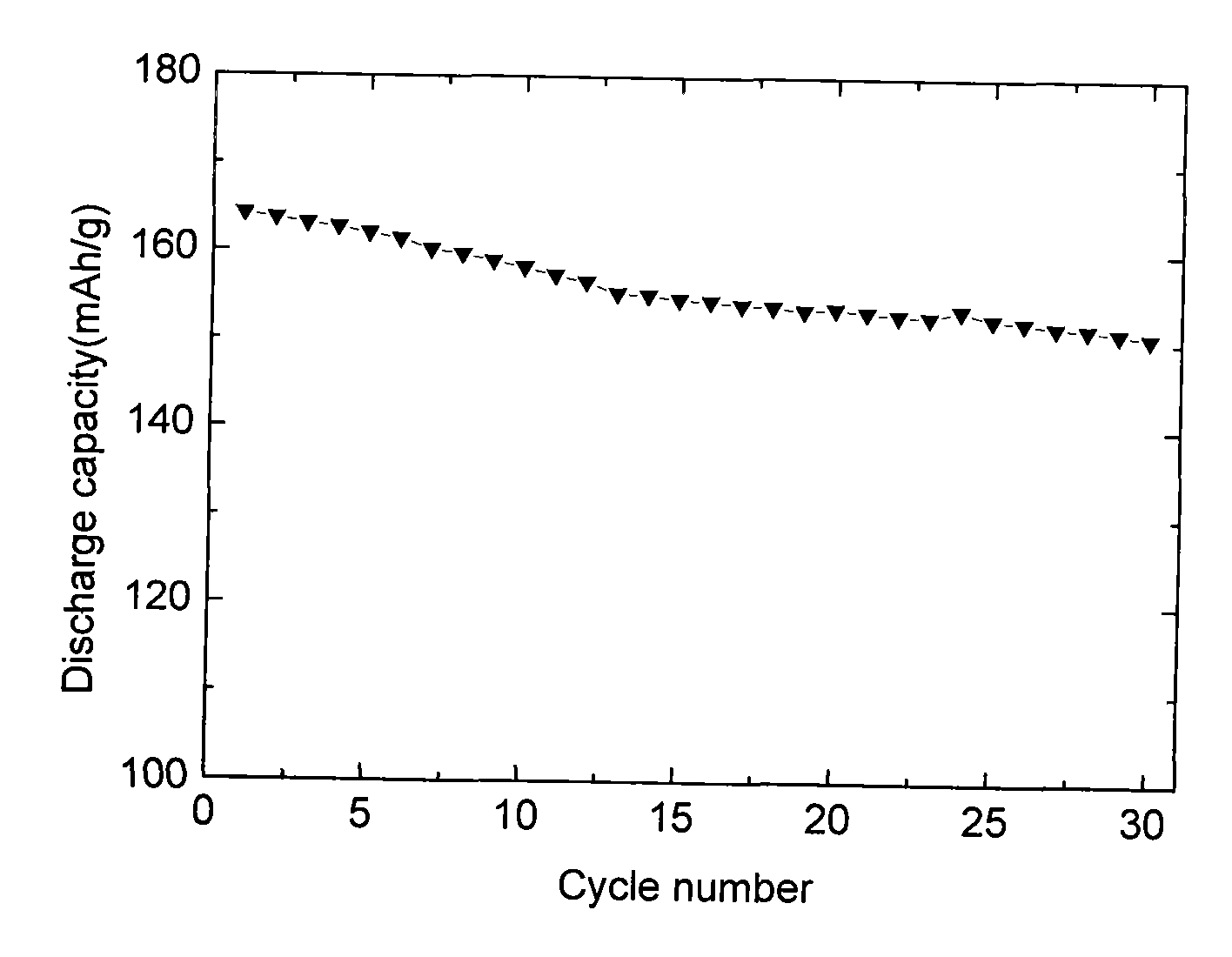

[0019] Dissolve 0.1mol lithium hydroxide, 0.1mol iron oxalate, 0.1mol boric acid and 0.2mol tartaric acid in 2000mL water, stir at room temperature for 30 minutes to obtain a sol, then raise the temperature to 80°C and keep this temperature for 24h to form a gel, Then the gel was dried at 120°C and ball-milled for 2 hours, then pressed into a tablet under a pressure of 20 MPa, then sintered at 600°C for 10 hours under the protection of argon, and naturally cooled to room temperature to obtain LiFeBO. 3 . X-ray powder diffraction analysis indicated that the obtained product was pure LiFeBO 3 , without any other impurity phase, high crystallinity; from scanning electron microscope analysis, it is known that the particle dispersibility of the obtained product is good, and the particle size is 60nm. The resulting product was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com