Patents

Literature

52 results about "Iron oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron forms two stable oxalates: Ferrous oxalate, Fe Ferric oxalate, Fe₂(C₂O₄)₃

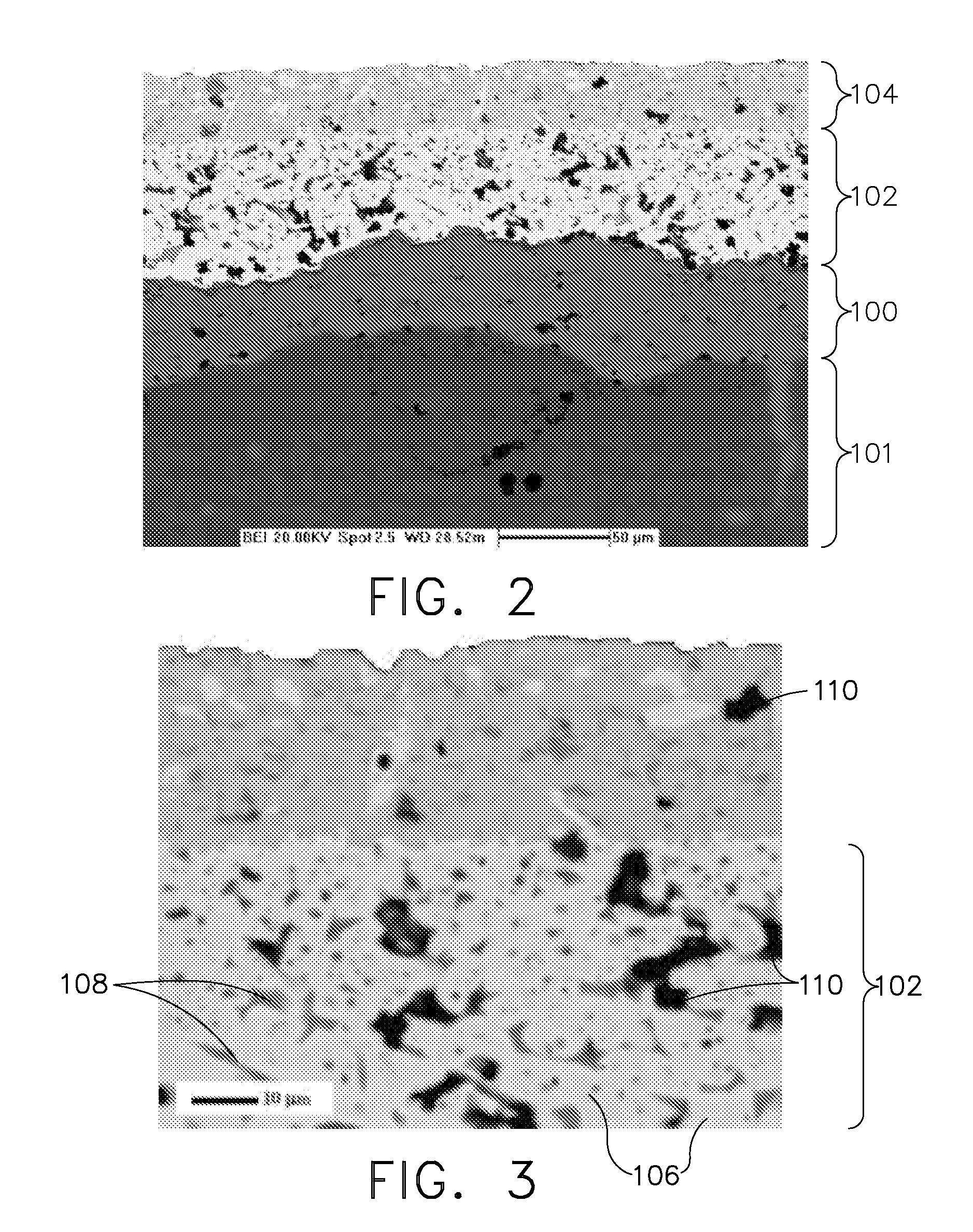

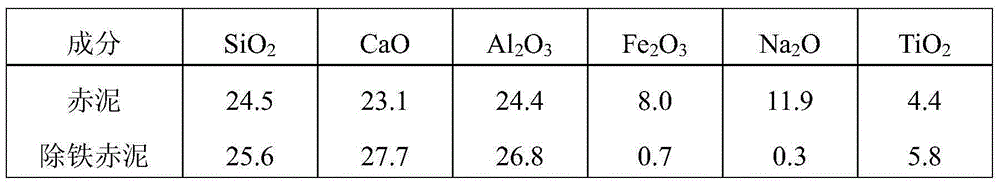

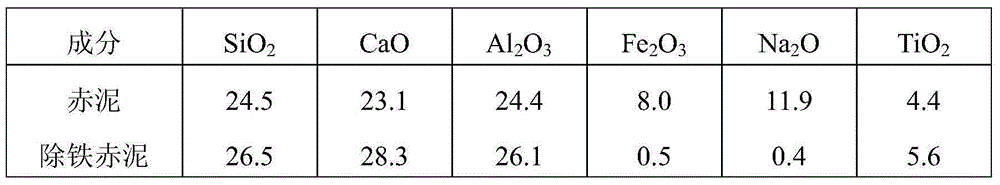

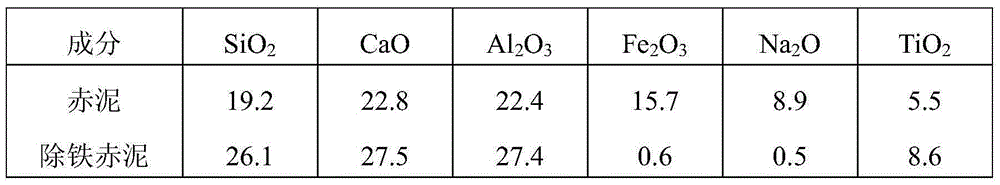

Method for separating and recovering iron from red mud

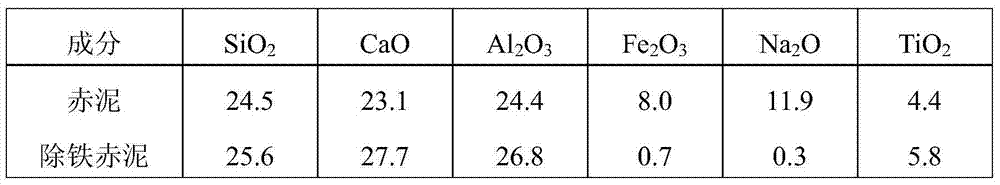

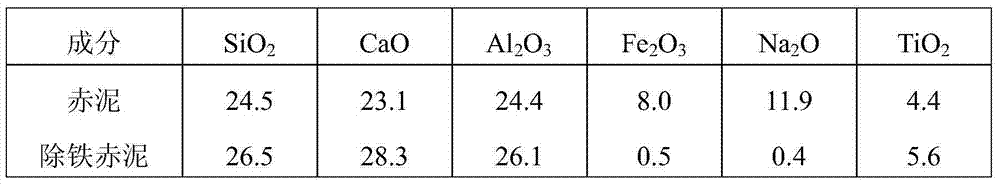

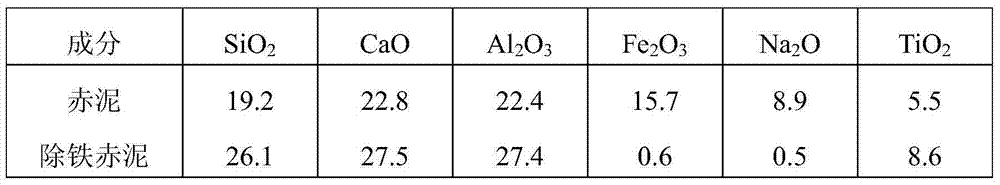

The invention relates to a method for separating and recovering iron from red mud. The method is characterized by comprising the steps: of leaching out and removing iron from the red mud by using an oxalic acid solution, and filtering to obtain iron-free red mud and an iron oxalate-containing leaching solution, wherein the obtained iron-free red mud can be used as a raw material for producing cement and fireproof bricks; iron oxalate in the obtained leaching solution is reduced to ferrous oxalate through membrane electrolysis or adding a reducing agent and ferrous oxalate is precipitated out, or iron in the solution is separated by directly neutralizing and precipitating an iron hydroxide and oxalate mixture; obtained ferrous oxalate is decomposed to obtain oxalic acid and an iron-containing compound; the obtained iron hydroxide and oxalate mixture is selectively leached out, separated and recovered to obtain oxalic acid and an iron-containing compound; the process of returning recovered oxalic acid to the red mud to leach out and remove iron is cyclically used. The method has the characteristics of short technological process, good iron separation effect, simplicity and convenience in operation, environmental friendliness and the like, and is suitable for large-scale industrialized application.

Owner:CENT SOUTH UNIV

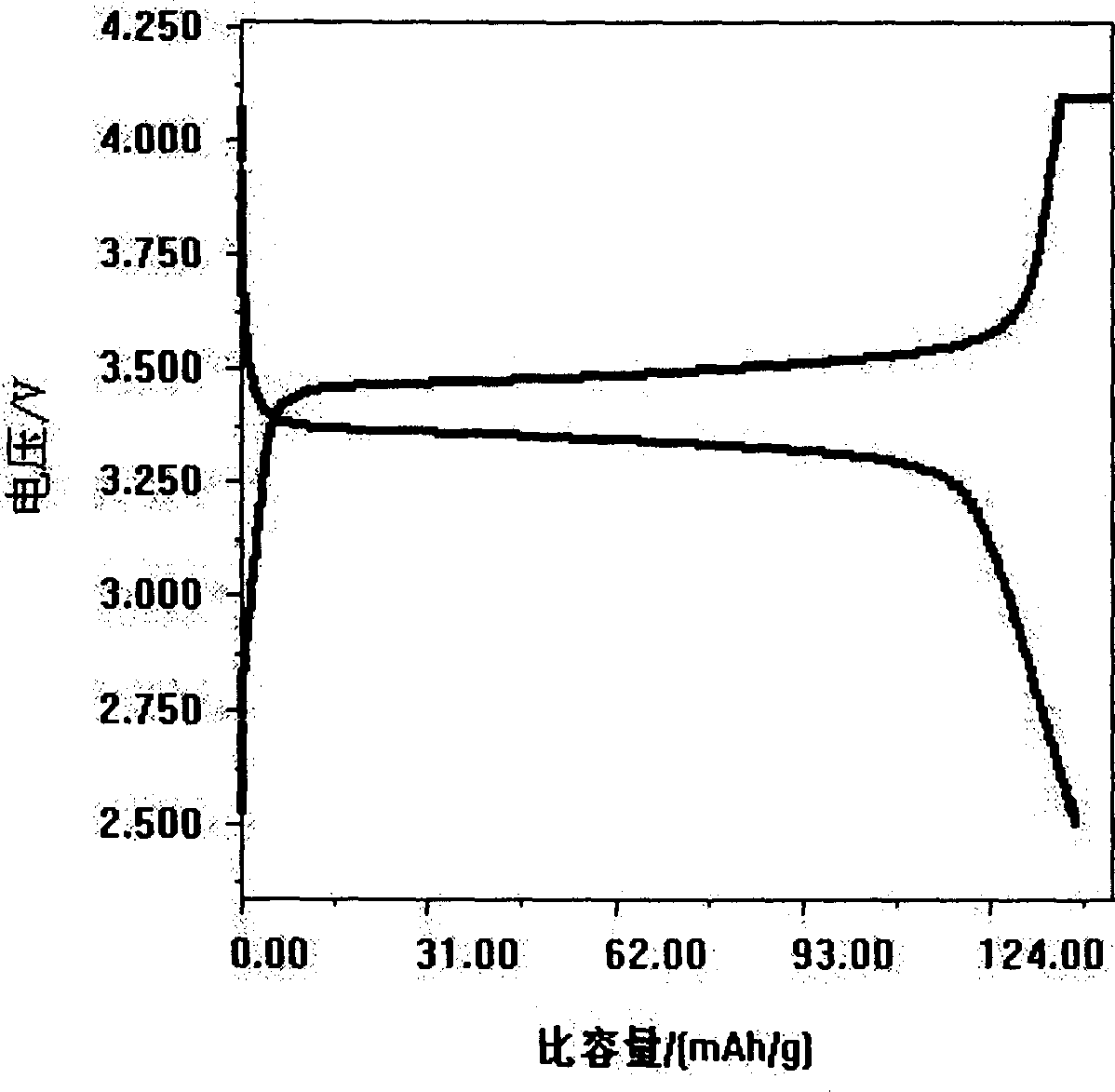

Method for synthesizing carbon-cladded ironic lithium phosphate

InactiveCN1775666AEasy to wrapHeating evenly inside and outsideCell electrodesPhosphorus compoundsPhosphateChemical measurement

The invention relates to a carbon coated lithium iron phosphate microwave-synthesizing method, relating to the preparation of anode material of a Li-ion battery. The invention weighs lithium carbonate, iron oxalate and ammonium diacid phosphate, proper amount of heat conduction agent and organic matter in chemical gauging ratio, using anhydrous alcohol as dispersant to fully grind and mix them, drying and pressing the mixture into blocks, placing the blocks in a pot holding activated carbon, and placing the pot in microwave field for irradiative heating so as to be able to make uniform- phase carbon coated lithium iron phosphate. The invention can realize carbon coating of lithium iron phosphate and more rapidly and uniformly heat the raw materials, beneficial to uniform and rapid reaction of massive raw materials. The method can shorten production cycle and reduce energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

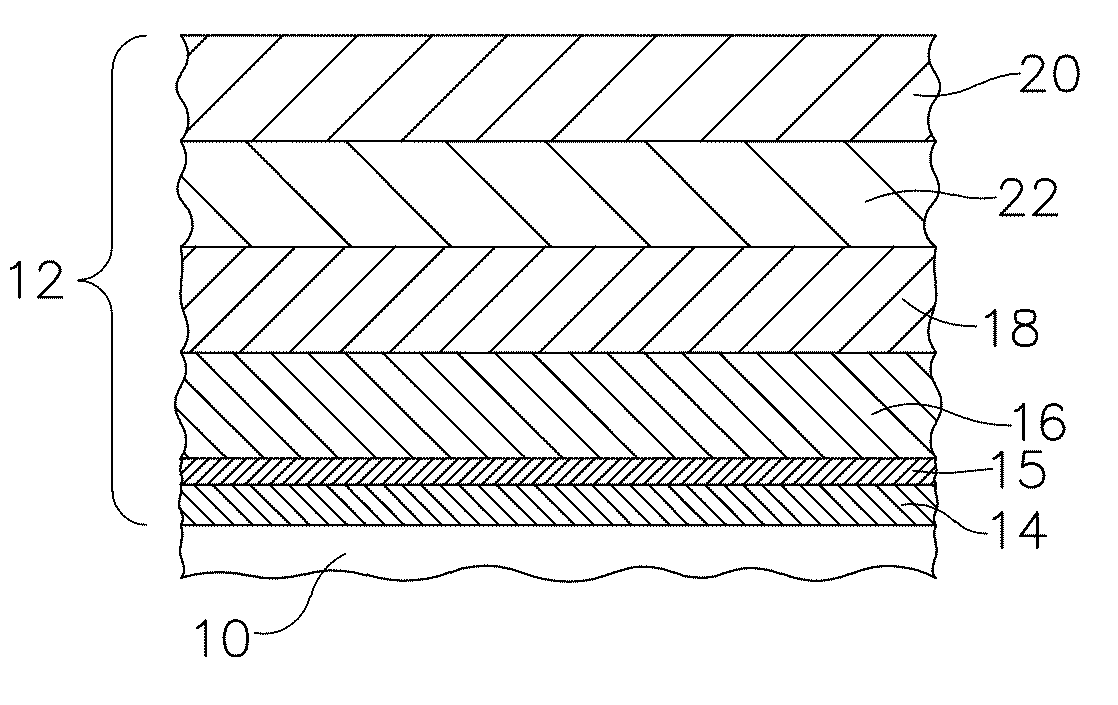

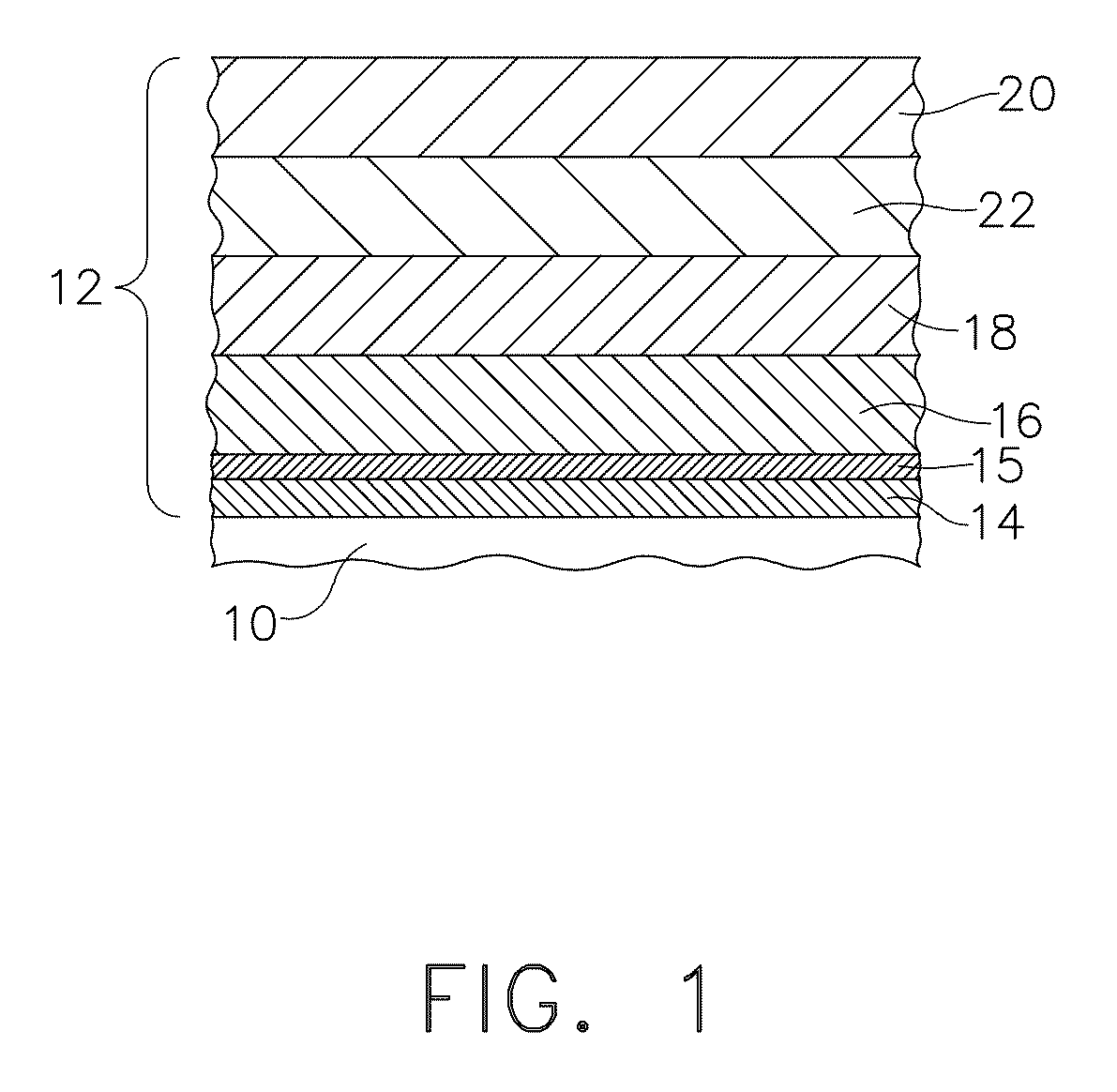

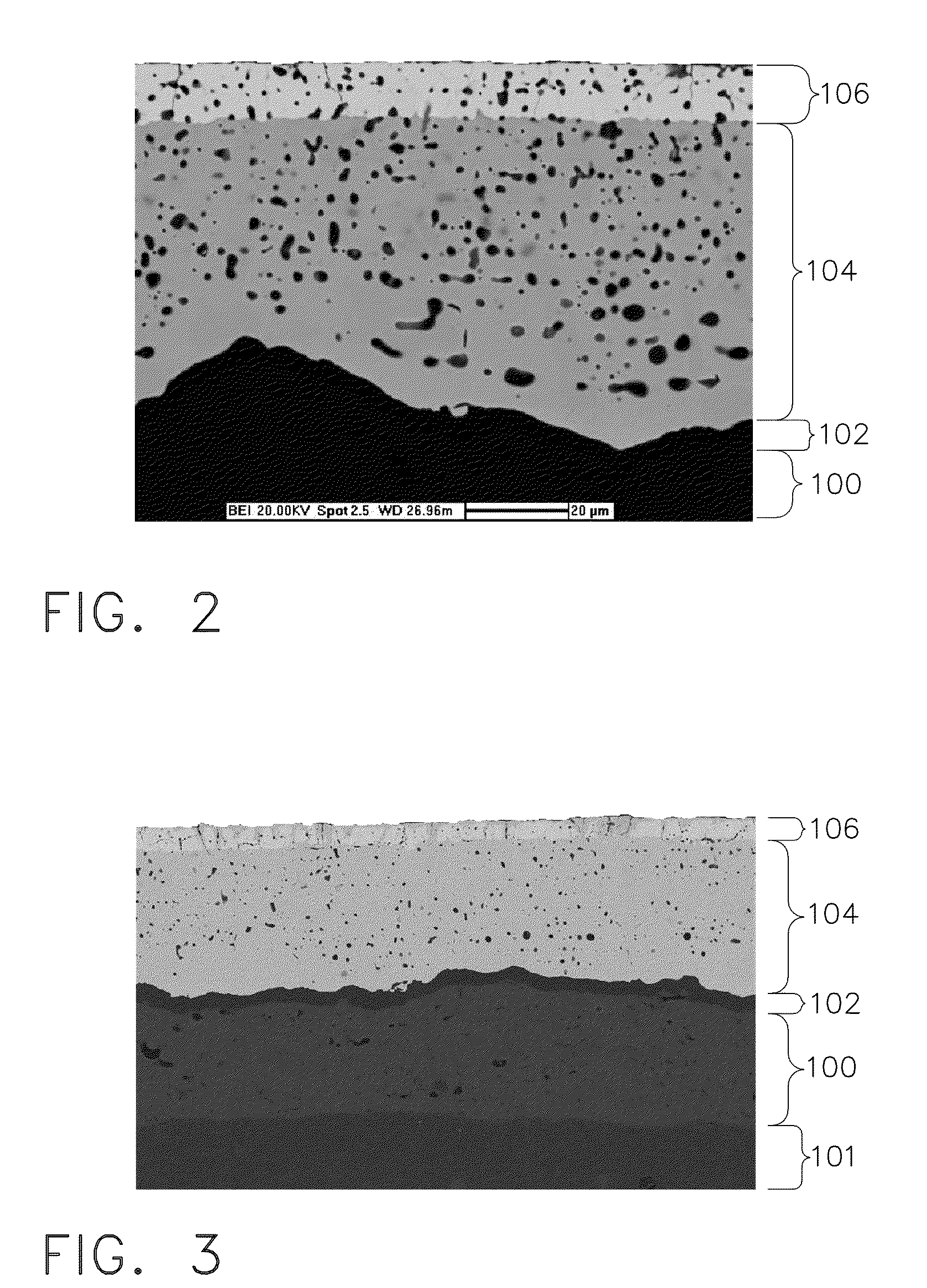

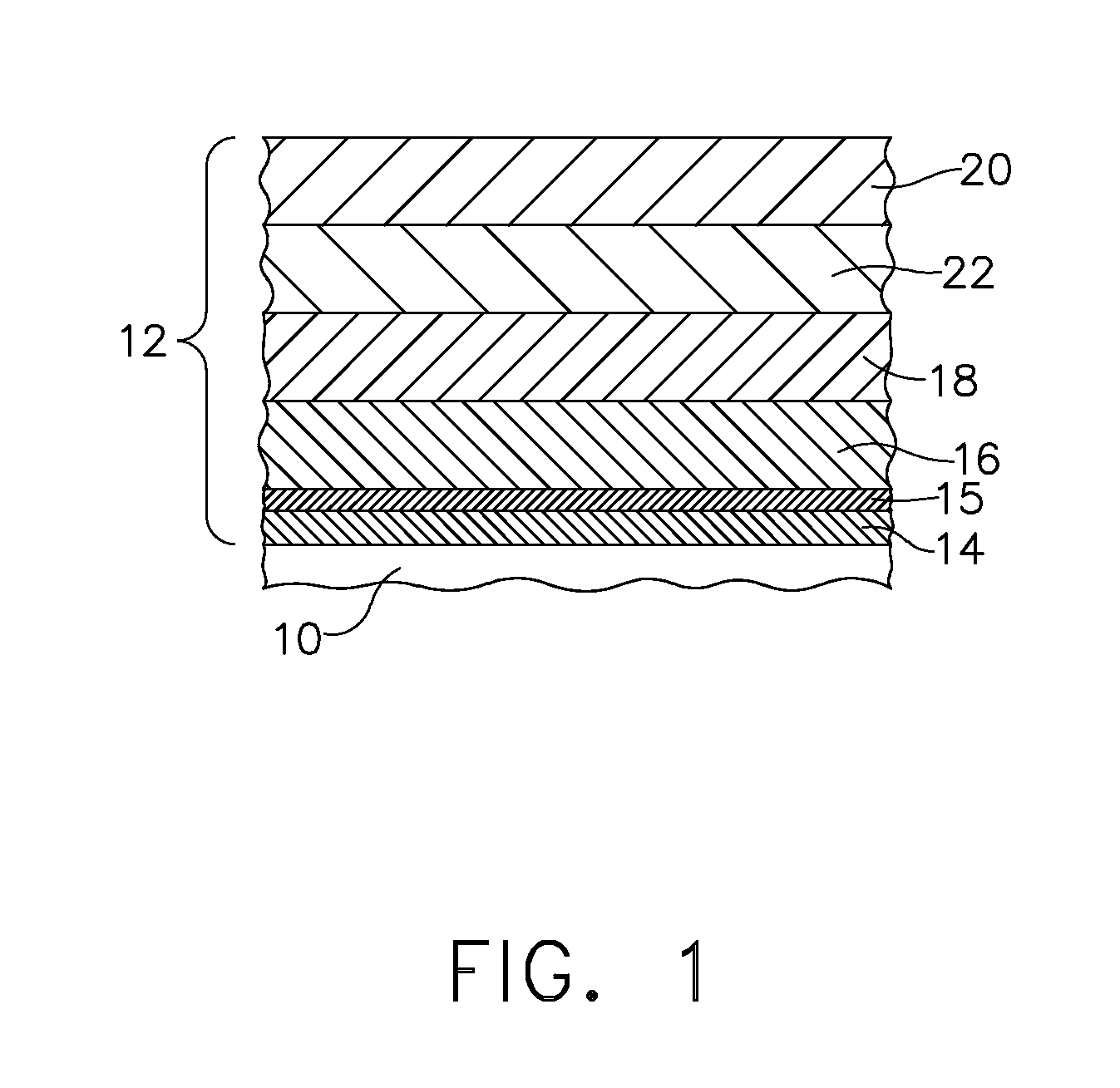

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

Polishing composition and method for producing a memory hard disk

InactiveUS6280490B1High cutting rateSmall surface roughnessPigmenting treatmentOther chemical processesIron sulfateEthylenediamine

A polishing composition for a memory hard disk, which comprises the following components (a) to (d):(a) from 0.1 to 50 wt %, based on the total amount of the polishing composition, of at least one abrasive selected from the group consisting of silicon dioxide, aluminum oxide, cerium oxide, zirconium oxide, titanium oxide, silicon nitride and manganese dioxide,(b) from 0.001 to 10 wt %, based on the total amount of the polishing composition, of at least one iron salt selected from the group consisting of iron nitrate, iron sulfate, ammonium iron sulfate, iron perchlorate, iron chloride, iron citrate, ammonium iron titrate, iron oxalate, ammonium iron oxalate and an iron chelate complex salt of ethylenediaminetetraacetic acid,(c) from 0.01 to 30 wt %, based on the total amount of the polishing composition, of at least one peroxydisulfate salt selected from the group consisting of ammonium peroxydisulfate, potassium peroxydisulfate and sodium peroxydisulfate, and(d) water.

Owner:FUJIMI INCORPORATED

Gradient-doped manganese iron oxalate precursor and preparation method thereof

ActiveCN104710302AIncreasing concentration gradientImprove ionic conductivityCell electrodesCarboxylic acid salt preparationStructural formulaIron phosphate

The invention discloses a gradient-doped manganese iron oxalate precursor and a preparation method thereof. The chemical structural formula of the gradient-doped manganese iron oxalate precursor is Fe1-x-yMnx{M}yC2O4.2H2O, M is a doped element, the concentration of M outwardly increases from the center along the radium in a gradient manner, x is not lower than 0.4 and not greater than 0.9, and y is not lower than 0.02% and not greater than 5%. Gradient doping in a bulk phase in the invention realizes uniform mixing of iron and manganese atoms, and the concentration increasing gradient distribution of the doped element M from the core to the shell improves the ion conductivity, the electron conductivity, the cycle performances and the rate performance of the above material, and a new approach is provided for the large scale application of lithium manganese iron phosphate.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Method for preparing positive electrode material of LiFePO4 by phosphorous acid or salt thereof

InactiveCN101332987ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphorous acidPhosphate

The invention relates to a method for preparing lithium iron phosphate by phosphorous acid or phosphite; the preparation method is as follows: lithium salt, ferrous salt, phosphate and phosphorous acid or phosphite are blended, added with carbon-containing compound, and further added with wet milling liquid, processed by ball milling and mixing, and dried at normal atmosphere or vacuum; the dried powder is sintered to prepare lithium iron phosphate cathode material. The lithium is one of or the mixture of lithium carbonate, lithium hydroxide, lithium oxalate, lithium acetate, lithium nitrate, lithium fluoride and lithium phosphate; the ferrous salt is one of or the mixture of iron oxalate, iron acetate, iron dichloride, ferrous sulfate or ferrous carbonate; the phosphate is one of or the mixture of ammonium phosphate, diammonium phosphate of monoammonium phosphate; the molecular formula of phosphite is AH2PO3, A2HPO3, EHPO3, E(H2PO3)2 or G(H2PO3)3; the carbon-containing compound is one of or the mixture of polypropylene, polyacrylamide, polyvinyl alcohol, glucose, cane sugar or starch. The method of the invention has simple preparing process and short time consumed, and the materials have good cycling performance under the heavy current discharging condition.

Owner:FUJIAN NORMAL UNIV

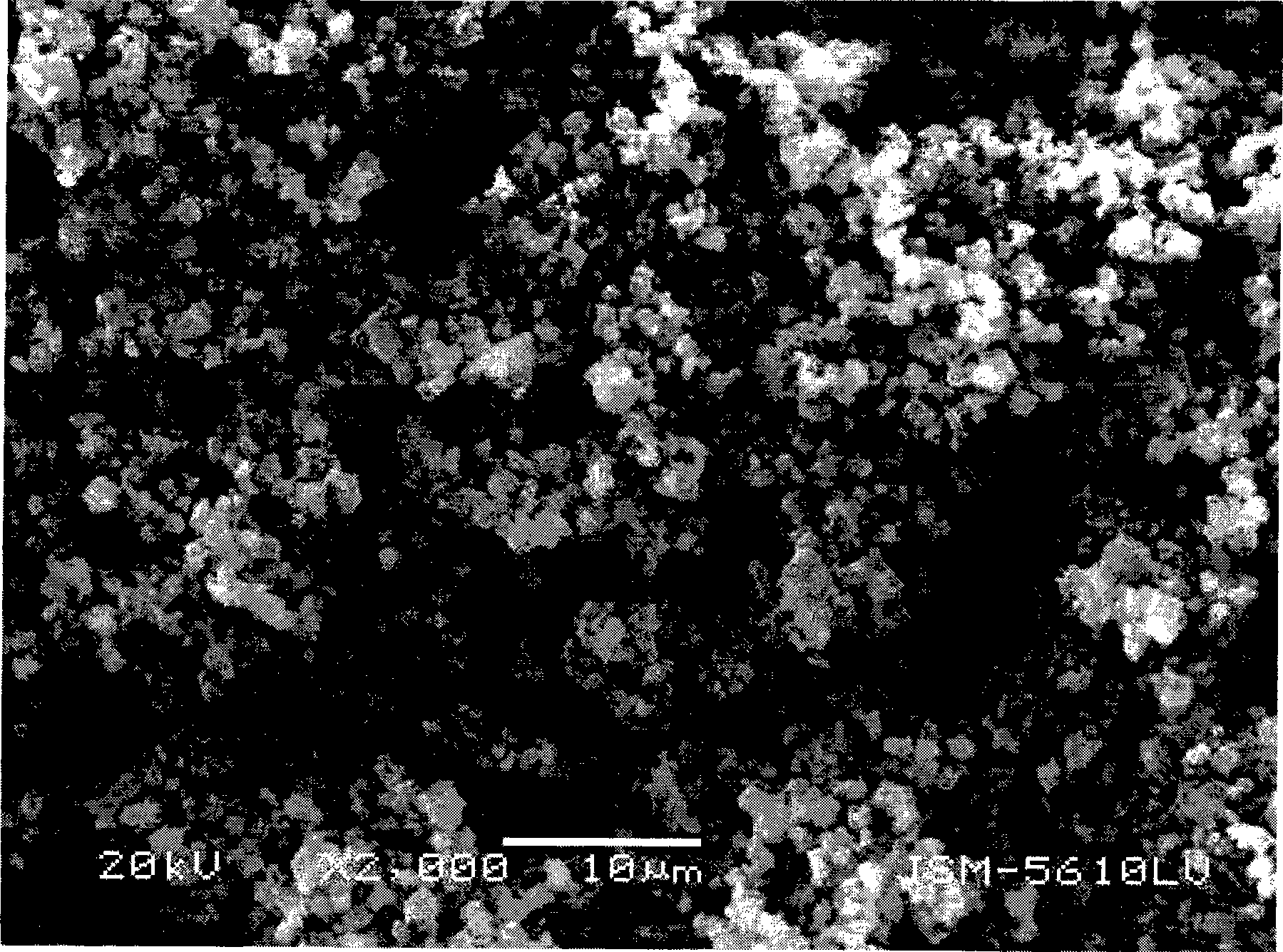

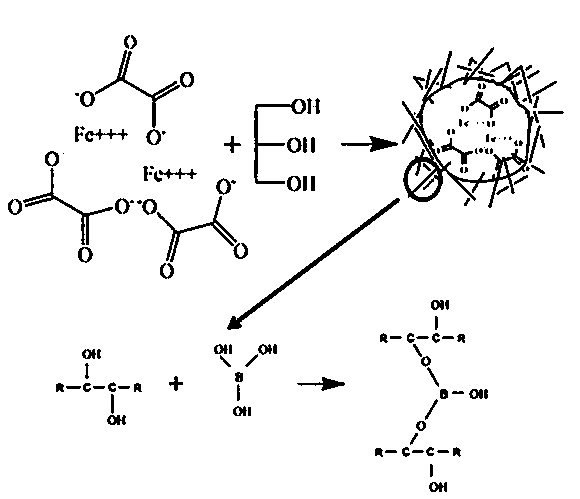

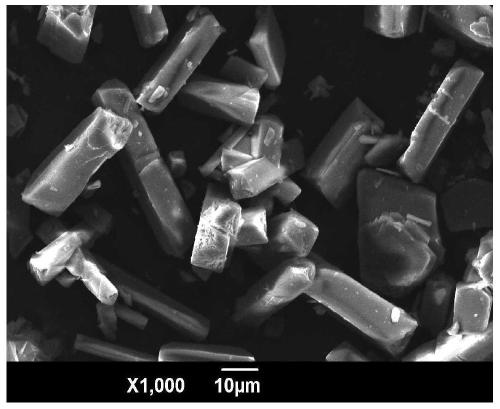

Method for preparing iron oxalate

InactiveCN101386575AMeet iron source requirementsImprove conductivityCarboxylic acid salt preparationPhosphateFiltration

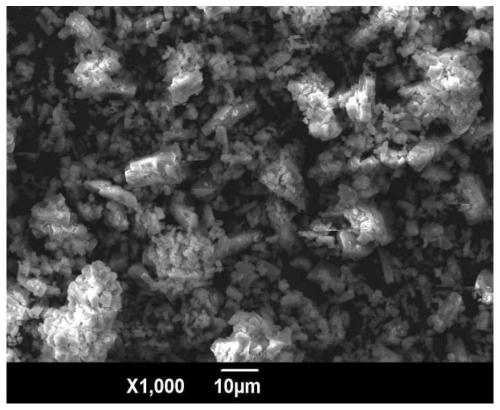

The present invention discloses a method for preparing ferrous oxalate, which belongs to the technical field of powdered material preparation. The aim of the invention is to provide a preparation method of ferrous oxalate which is high in purity, controllable in granularity, even in grain size, and high in conductivity. The method comprises the following steps of locating ferrous sulfate into dilute sulphuric acid, adding scrap iron with stirring, and obtaining a ferrous sulfate solution after suction filtration; dissolving oxalic acid or / and ammonium oxalate in distilled water with stirring and heating, and obtaining a mixed solution of oxalic acid or / and ammonium oxalate through suction filtration after dissolution; and, slowly adding the ferrous sulfate solution into oxalic acid solution, keeping the temperature, stirring, separating ferrous sulfate from the original synthetic solution after keeping stand, and obtaining ferrous oxalate powder through washing and drying. The ferrous oxalate prepared by the preparation method is a powder with a medium grain diameter of between 0.5 and 80 mu m. The granularity is completely controllable. The product purity is greater than 99.0 percent. The conductivity is high. The electrochemical performance of the ferrous phosphate salt composite material is largely improved. The conductivity of lithium iron phosphate is improved by 5 orders of magnitude.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

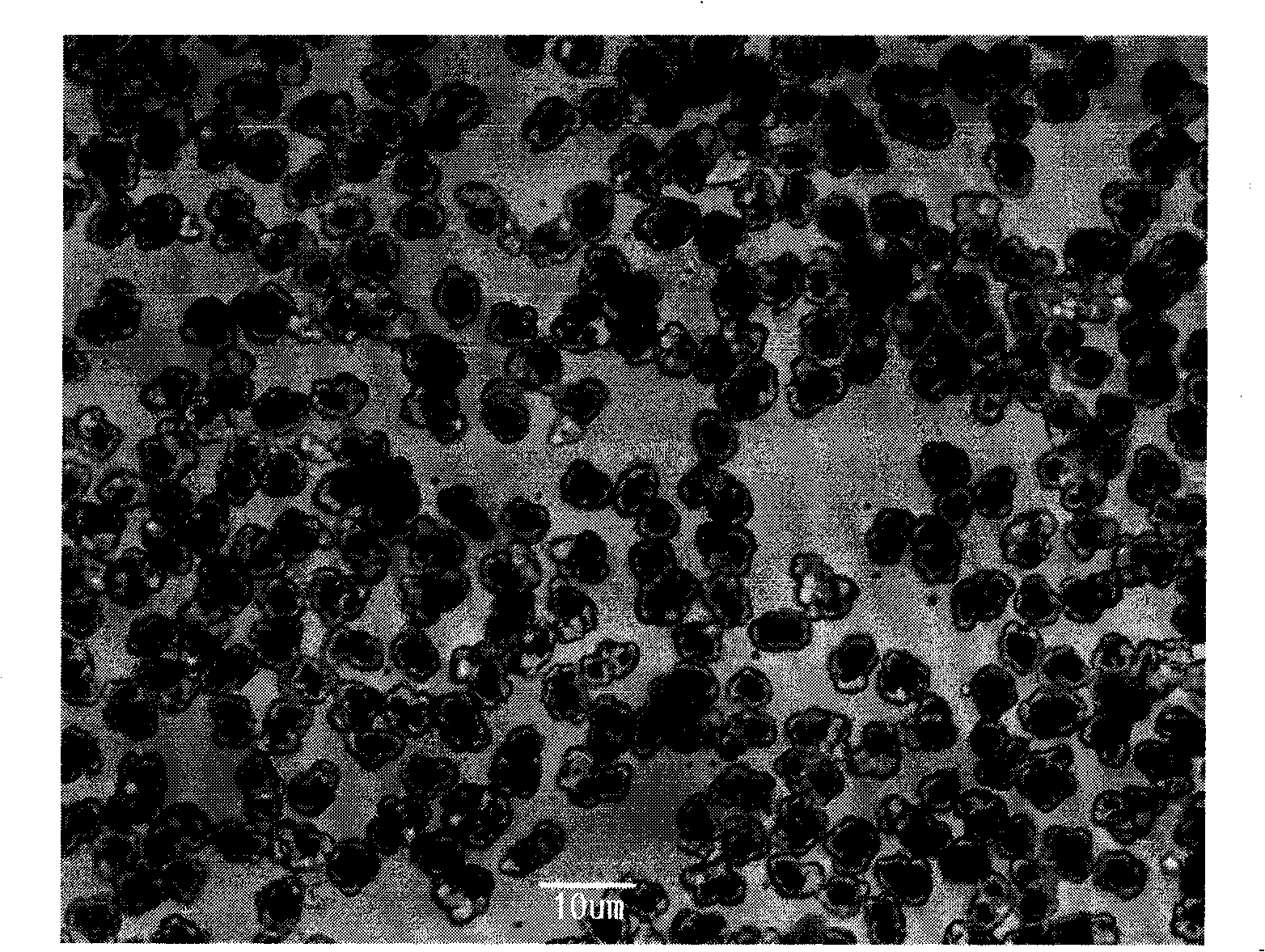

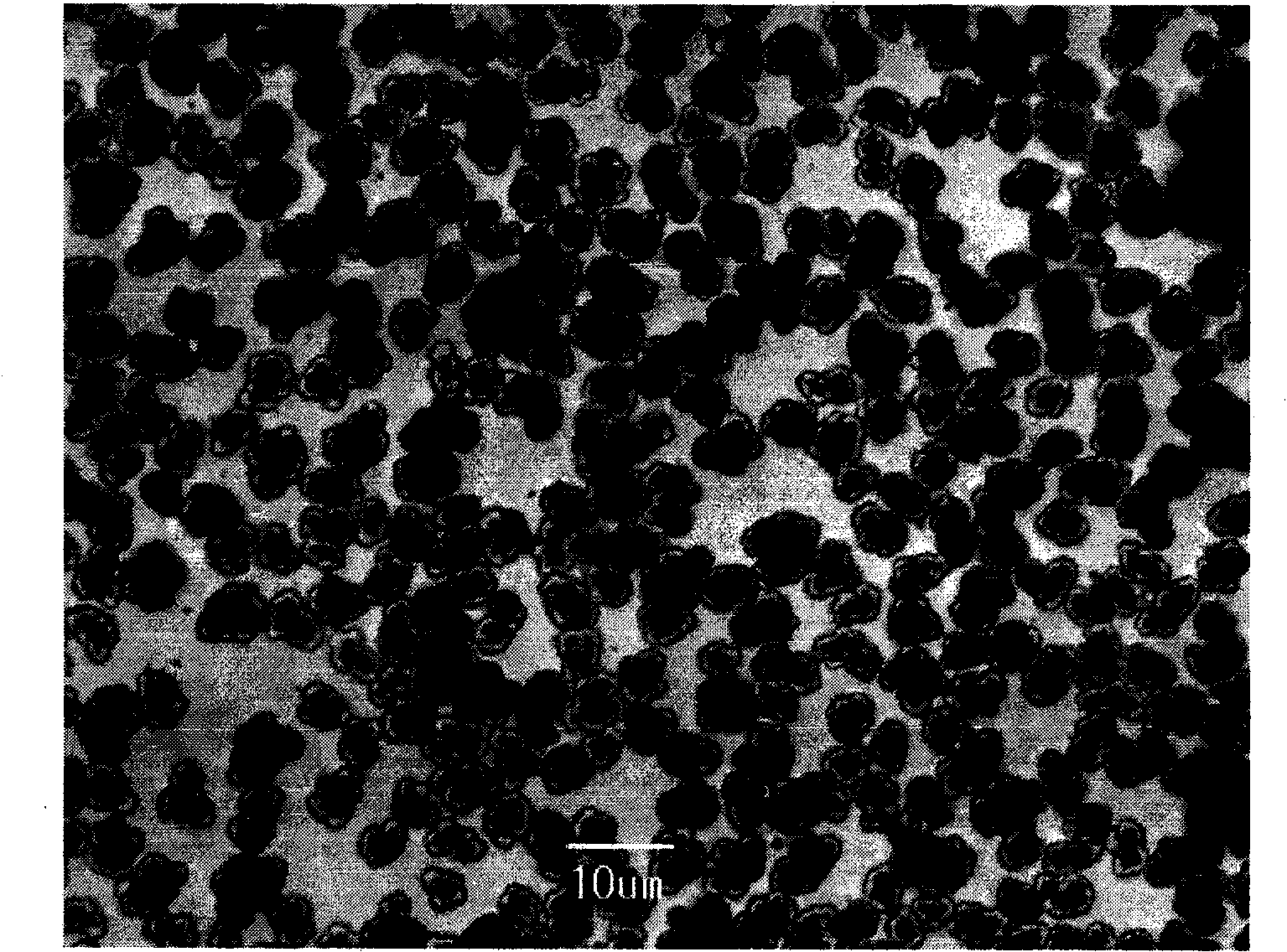

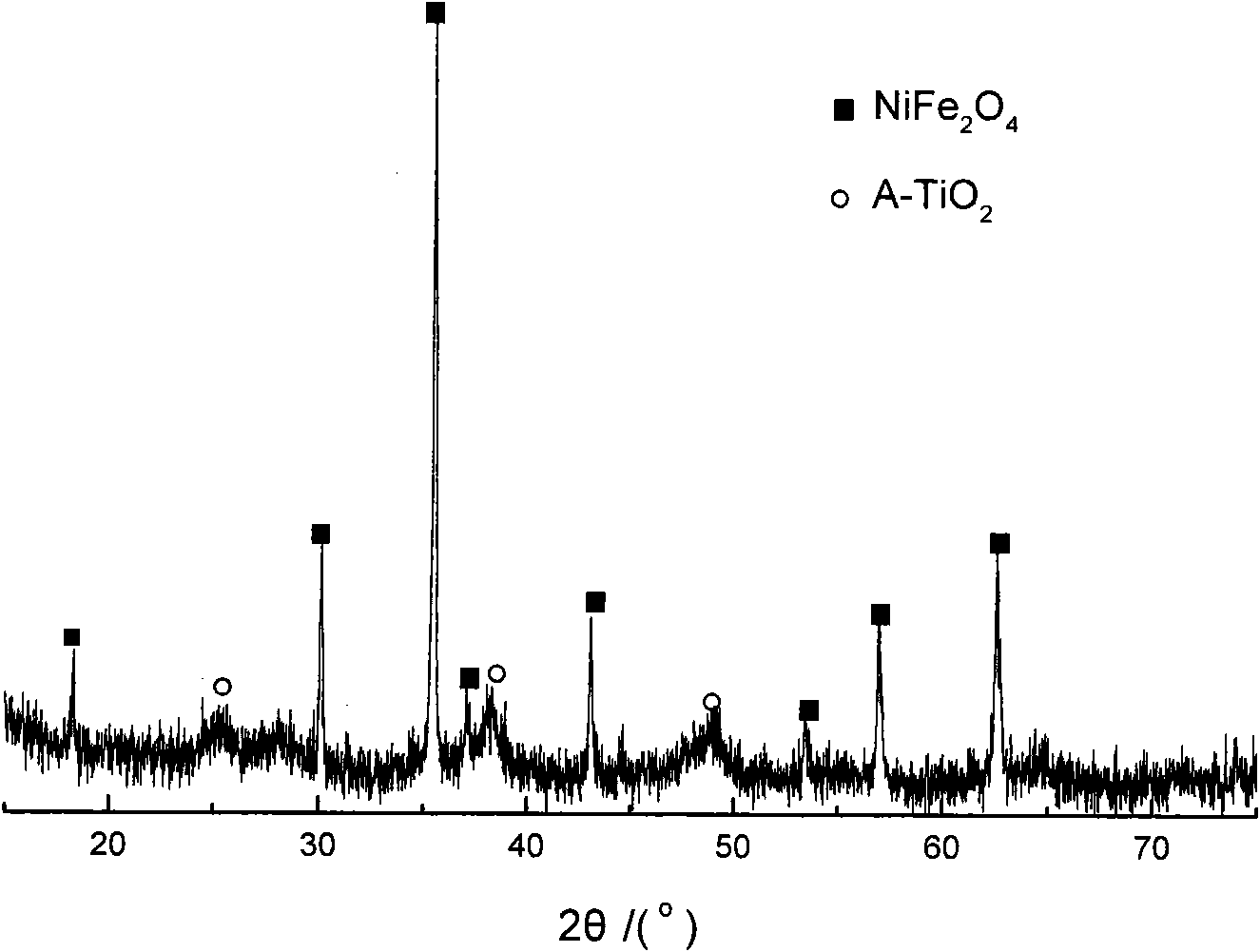

Preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst

ActiveCN101579628AGood dispersionLarge and adjustable package volumeWater/sewage treatment by irradiationWater contaminantsParticulatesNickel salt

The invention provides a preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst with micron grade micron order as carrier; the preparation process includes the following steps: adding green copperas solution and oxalic acid solution into the nickel salt solution for reaction to obtain the mixture precipitate of oxalate of nickel oxalate and iron oxalate; then baking to obtain the micron grade nickel ferrite powder; adding the titanic sulfate solution into the suspension of micron grade nickel ferrite powder so as to crystallize the titanium ions on the suspended particulates in the suspension to form a wrapping layer and obtain the nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst product. The magnetic loaded type titanium dioxide photo-catalyst prepared by the method of the invention has good dispersibility; and the particle diameter of the particles is about 5 mum; the titanium dioxide is obviously wrapping on the surface of the nickel ferrite to form a core / shell structure with large wrapping capacity as well as adjustable and homogenous distribution; the specific surface is 90-110 m / g; and the photo-catalyst has the feature of strong soft magnetism, can be rapidly recycled in aqueous solution and has higher catalytic activity, so that organic wastewater can be completely degraded. The preparation technology is simple, the cost is low, and large-scale production is easily realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

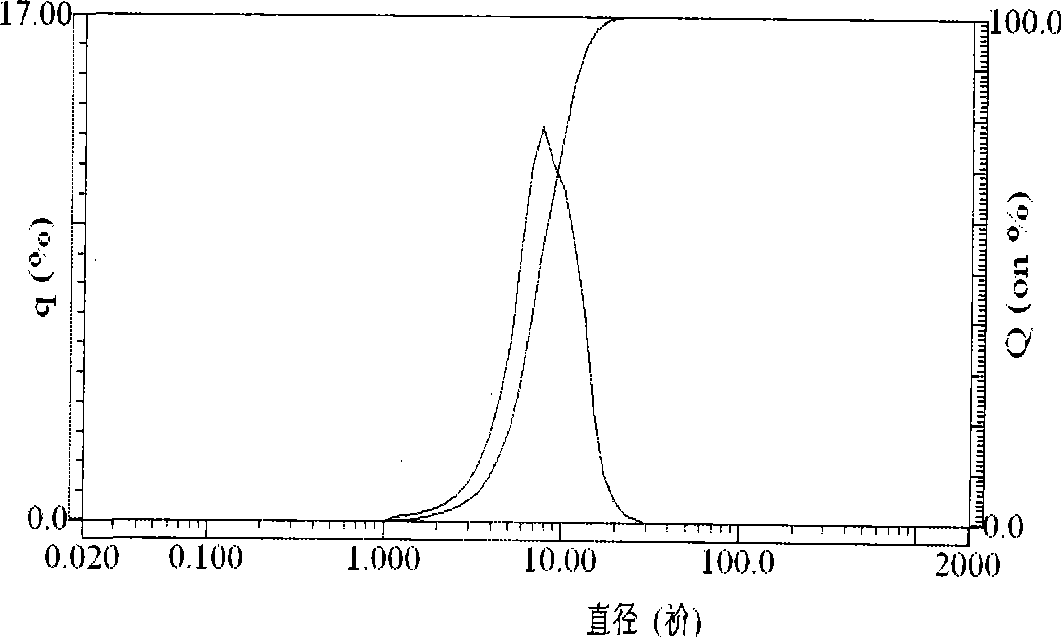

Method for producing high purity battery level iron oxalate from pickle liquor

The invention relates to a method for producing high-purity battery grade iron oxalate by utilizing pickle liquor, comprising the following steps: the pickle liquor is pre-treated for lowering spent acid content, thus leading the pickle liquor to generate ferrite solution with a certain concentration; then after strict filtering and magnetic separation, the ferrite solution is transported into a reaction kettle, then industry ammonia is added and the solution is stirred for reaction to generate ferrous hydroxide gelatin; the soluble oxalic acid solution is slowly added in and stirred, and then the mixture is stirred by a conversion reaction kettle and heat preservation is carried out, thus obtaining iron oxalate slurry after reaction; iron oxalate mother solution is separated in the iron oxalate slurry, and the separated iron oxalate is washed, dried and crashed for obtaining high-purity superfine iron oxalate products. The method has the beneficial effects that: the pickle liquor in industrial production is fully utilized; a two-step liquid phase method of oxidation and conversion is adopted for leading the reaction to be more fully, so that the reaction rate is greatly improved, the grain diameter of the finished products iron oxalate is fine and uniform, D50 is less than or equal to 5mum, and the content of the iron oxalate is more than or equal to 95.5 percent; furthermore, the pickle liquor is used as raw material, and cyclic utilization and environmental protection of the industrial waste are utilized, thus changing waste into valuable and greatly lowering the production cost.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Preparation method of multi-element doped lithium iron phosphate composite positive pole material

ActiveCN103346295AFast charge and discharge rateExtended service lifeCell electrodesCarbon layerHydrogen Sulfate

The invention relates to a preparation method of a multi-element doped lithium iron phosphate composite positive pole material. The chemical formula of the multi-element doped lithium iron phosphate is Li1-xKxFe1-yZnyP1-zSzO4, wherein x=0.1-0.2, y=0.2-0.3, and z=0.15-0.25. The method comprises the following steps: (1) weighing lithium acetate, iron oxalate, ammonium dihydrogen phosphate, ammonium hydrogen sulfate, zinc nitrate and potassium carbonate according to the molar weights of Li, K, Fe, Zn, P and S in the chemical formula, mixing, dissolving in deionized water to form a mixed solution, and performing nitrogen gas reduction reaction to obtain a mixture; (2) performing spray drying to obtain a spherical solid; and (3) presintering, adding starch accounting for 1-2wt% of the presintering product, uniformly grinding, and performing secondary sintering to obtain the multi-element doped lithium iron phosphate composite positive pole material. According to the prepared multi-element doped lithium iron phosphate composite positive pole material for a lithium ion battery, K, Zn and S are doped to modify the lithium iron phosphate to improve the ion diffusion performance and inhibit the aggregation phenomenon; and the surface of the lithium iron phosphate is coated with a carbon layer.

Owner:NINGBO SHENGTENG NEW MATERIALS

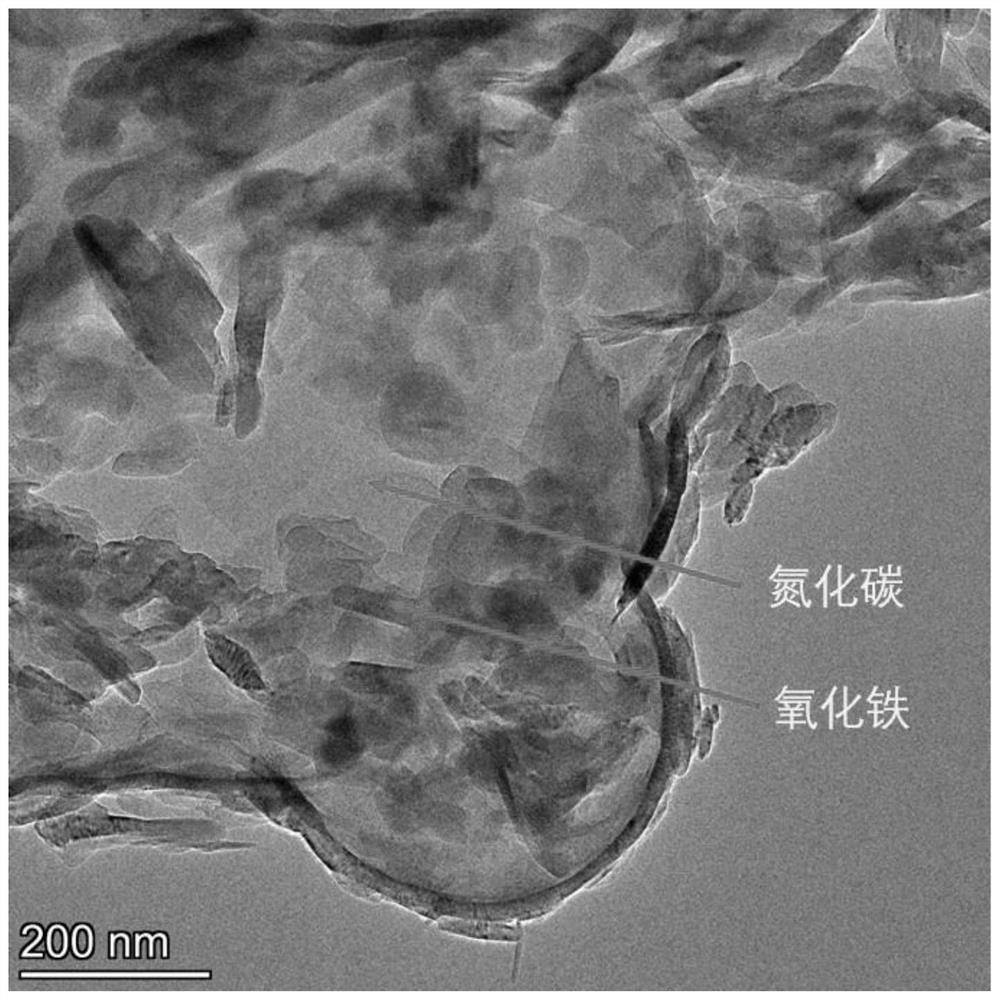

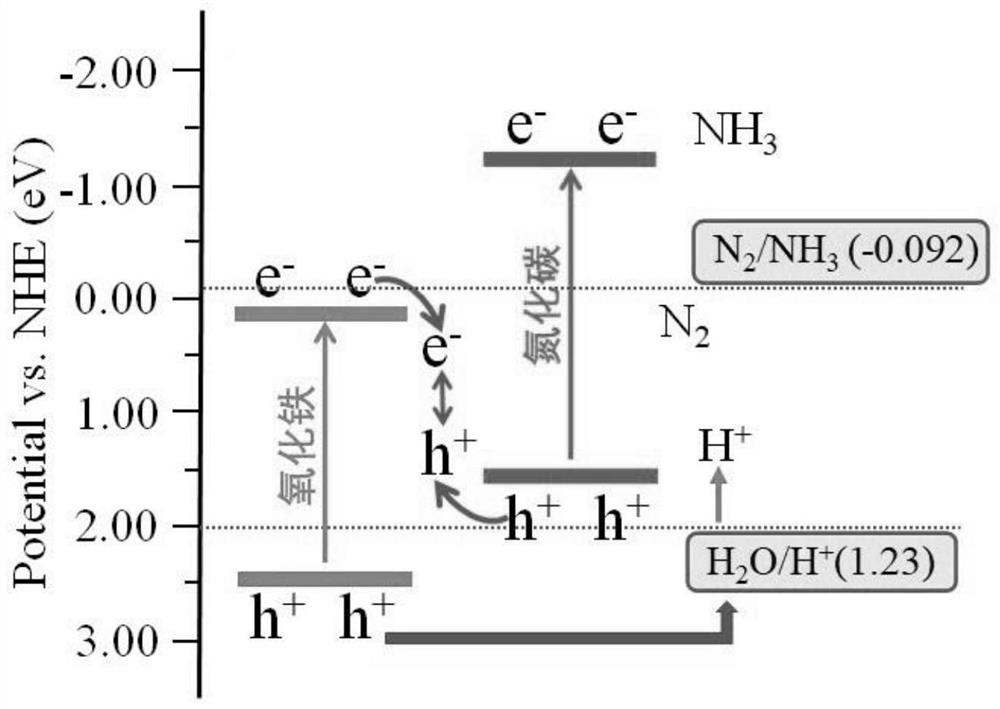

Preparation method and application of Z-type carbon nitride-iron oxide catalyst containing nitrogen defect structure

ActiveCN112371146APhotocatalytic nitrogen fixation and ammonia production performance is goodEasy to operatePhysical/chemical process catalystsBulk chemical productionPtru catalystThiourea

The invention discloses a preparation method and application of a Z-type carbon nitride-iron oxide catalyst containing a nitrogen defect structure, belongs to the technical field of photocatalytic material synthesis, and relates to modification of graphite-type carbon nitride (g-C3Nx) containing a nitrogen defect structure and preparation of the Z-type carbon nitride-iron oxide photocatalyst (g-C3Nx / Fe2O3) containing a nitrogen defect structure by compounding graphite-type carbon nitride with iron oxide (Fe2O3). The preparation method comprises the following steps of: taking urea, melamine orthiourea as a carbon nitride precursor; taking ammonia water, sodium hydroxide, potassium hydroxide or barium hydroxide and other alkalis as auxiliary materials; and taking iron oxalate, ferrous oxalate, ferrous sulfate and the like as iron sources, heating for 2-8 hours at 250-650 DEG C through a one-step roasting method, cooling to the room temperature through programmed cooling, grinding the reaction product into powder, washing the powder with water, and carrying out centrifuging and drying to obtain the catalyst. The preparation method is simple to operate, a nitrogen defect structure isintroduced into conventional g-C3N4 to prepare g-C3Nx, the g-C3Nx and ferric salt are synchronously roasted to compound Fe2O3, and the catalyst is applied to photocatalytic nitrogen fixation for ammonia production. Experimental results show that the prepared catalyst has good photocatalytic nitrogen fixation and ammonia production performance, has a popularization effect on photocatalytic green synthesis ammonia, and is energy-saving and environment-friendly.

Owner:JIANGSU UNIV

Hard anodizing coloring method of aluminum alloy surface

The invention relates to a hard anodizing coloring method of the aluminum alloy surface, belonging to the technical field of aluminum alloy surface treatment and aiming to solve the technical problems in the prior art that the process for treating the aluminum alloy surface has complicated steps and the treated aluminum alloy surface has a single color. The hard anodizing coloring method of the aluminum alloy surface comprises the following steps: a, hard anodizing: subjecting an cleaned aluminum alloy substrate to hard anodizing at 4-13 DEG C so that the a hard anodized film is formed on the aluminum alloy surface; and b, coloring: coloring the aluminum alloy under the condition of the existence of iron oxalate, and sealing to obtained the colored aluminum alloy. The hard anodizing coloring method of the aluminum alloy surface further comprises the step of treating the aluminum alloy at the high temperature of 380-450 DEG C. The hard anodizing coloring method of the aluminum alloy surface has a short technical process and a good coloring effect and ensures that the anodized film is not easy to fall and is colorful. The aluminum alloy surface has the high hardness value (HV) 0.05 of more than 400.

Owner:ZHEJIANG SUPOR CO LTD

Solar light catalytic bleaching agent and its dipping and bleaching method and rolling bleaching method

InactiveCN1749475AComposition is stableThe test data is accurate and reliableBleaching apparatusSolar lightBleach

The solar photocatalytic bleaching agent is re-compounded with iron oxalate and hydrogen peroxide solution, and is used in bleaching via the catalysis of sunlight or artificial light. The solar photocatalytic bleaching agent has stable components, easily controlled technological condition, simple compounding process, no influence on fiber and the post steps, and high bleaching quality. Its bleaching process is cold one in low power consumption and low comprehensive cost compared with hydrogen peroxide solution bleaching process. The present invention is suitable for use in various dyeing and finishing enterprises.

Owner:李春辉

Manufacturing method of a glass substrate for a magnetic disk

InactiveUS20130012104A1Reduce roughnessEfficient removalBase layer manufacturePlane surface grinding machinesSulfateSubstrate surface

Owner:HOYA CORP

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

ActiveUS20110217511A1Improve surface roughnessPretreated surfacesRecord information storageIron saltsNickel salt

Methods for improving surface roughness of an environmental barrier coating involving providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness wherein the slurry includes water; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, water soluble iron salts, water soluble gallium salts, water soluble aluminum salts, water soluble nickel salts, water titanium salts, water soluble boron salts, and water soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

A method for separating and recovering iron from red mud

Owner:CENT SOUTH UNIV

Thermoplastic moulding materials

Polyamide-based compositions may be heat stabilized by compositions of iron oxalate and diapentaerythritol. The heat stabilized polyamides may be used for production of moulding materials which may be injection moulded, blow-moulded, or extruded to provide articles of manufacture.

Owner:LANXESS DEUTDCHLAND GMBH

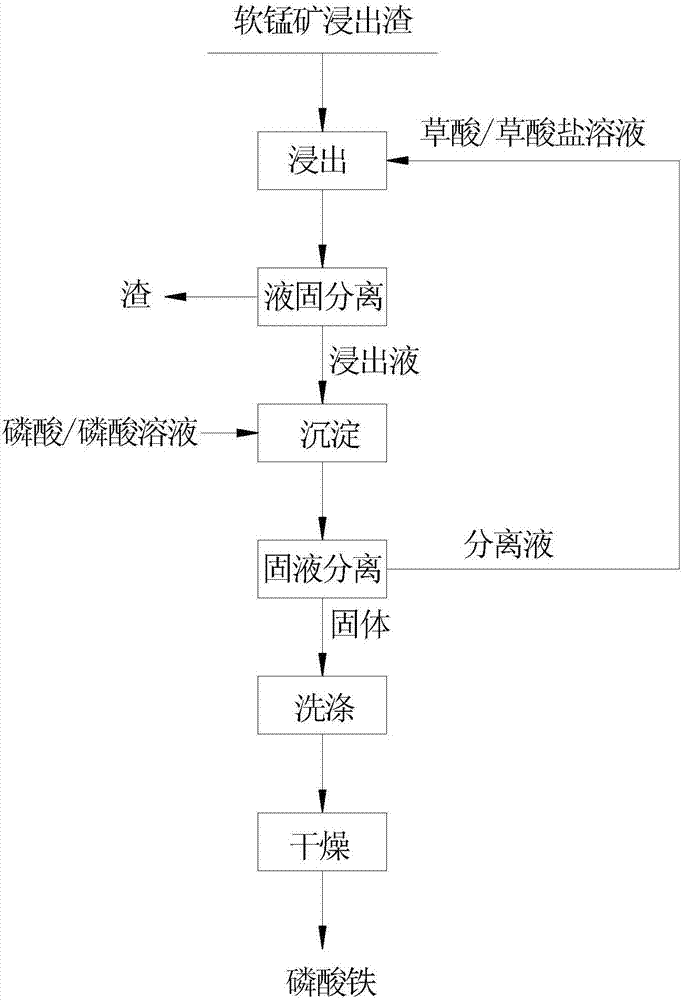

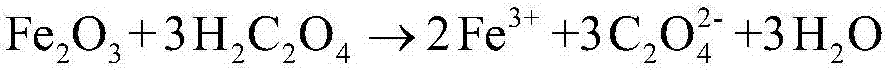

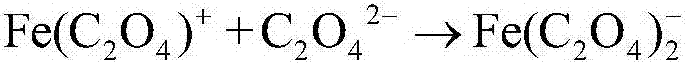

Method for recycling iron resource from soft manganese ore leaching slag

ActiveCN107502740ATake advantage ofAvoid wastingProcess efficiency improvementPregnant leach solutionPyrolusite

The invention provides a method for recycling iron resource from soft manganese ore leaching slag. The method comprises the following steps: (1) preparing pulp with soft manganese ore slag by taking a mixed solution of an oxalic acid solution or oxalic acid and an oxalate solution as a leaching agent, so that iron in the soft manganese ore leaching slag is converted into soluble iron oxalate; (2) performing liquid-solid separation to obtain waste slag and iron oxalate-containing leaching liquid; (3) adding phosphoric acid or a phosphoric acid solution into the iron oxalate-containing leaching liquid, converting the iron oxalate into iron phosphate precipitate, and performing solid-liquid separation to obtain iron phosphate and a separating liquid; (4) washing and drying the obtained iron phosphate to obtain an iron phosphate product; and (5) taking the separating liquid obtained in the step (3) as the leaching agent to continue leaching the iron in the soft manganese ore leaching slag, and forming a recycling process in such a manner. According to the method provided by the invention, the iron resource in the soft manganese ore leaching slag can be recycled and utilized, and meanwhile, environmental harm of the soft manganese ore leaching slag is reduced.

Owner:SICHUAN UNIV

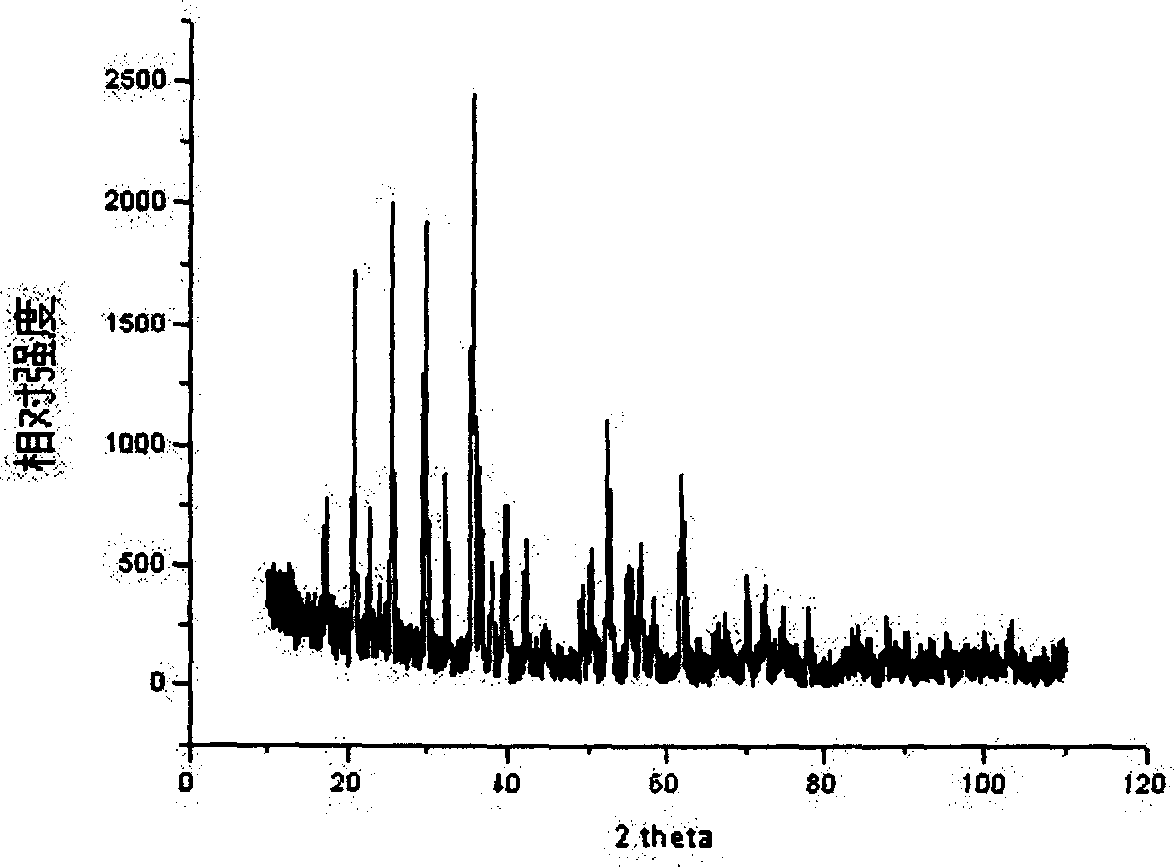

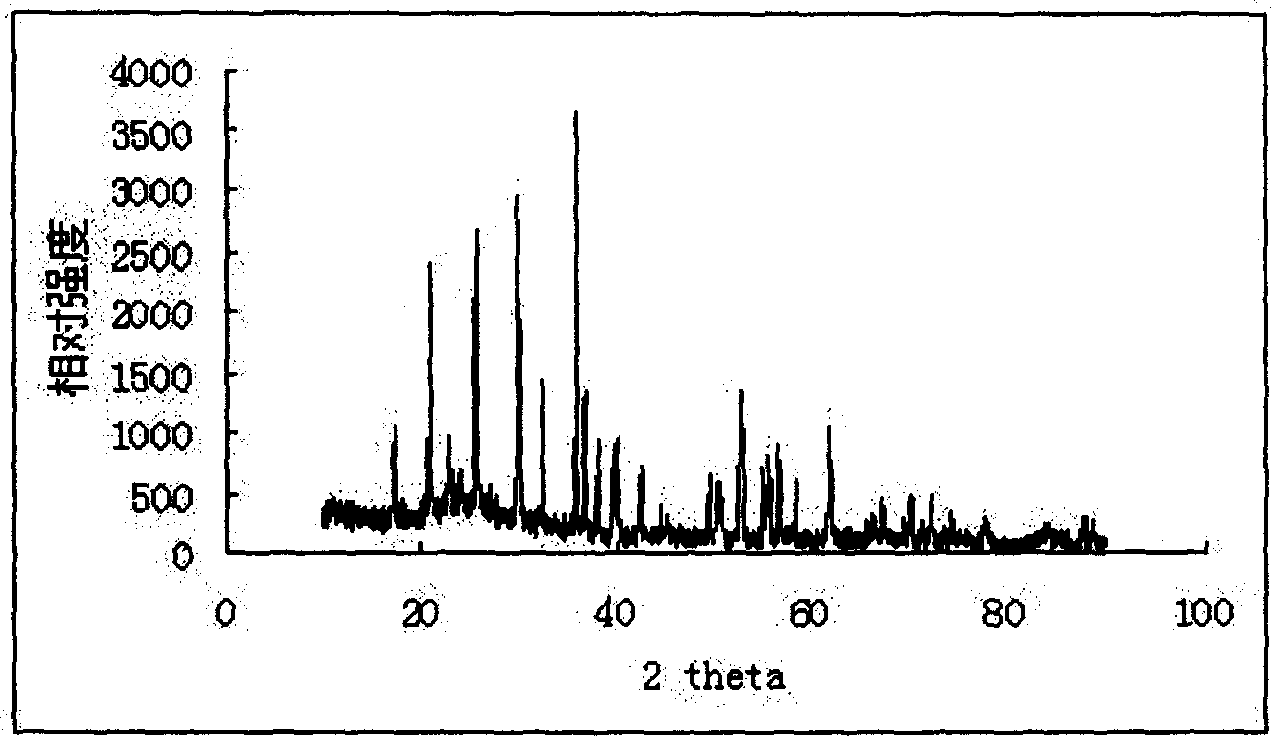

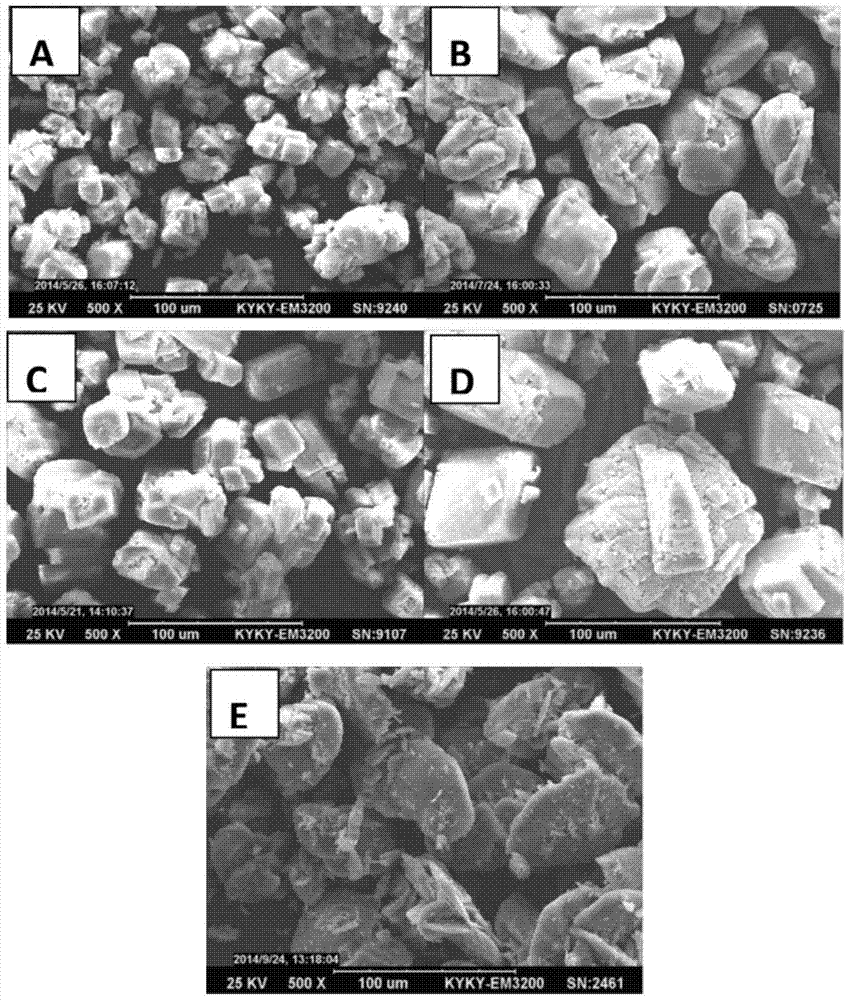

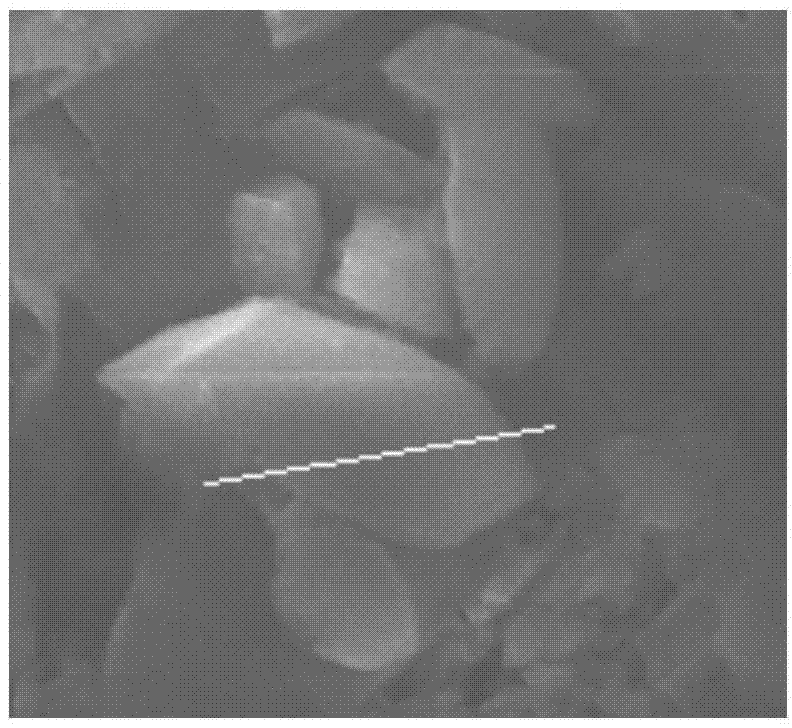

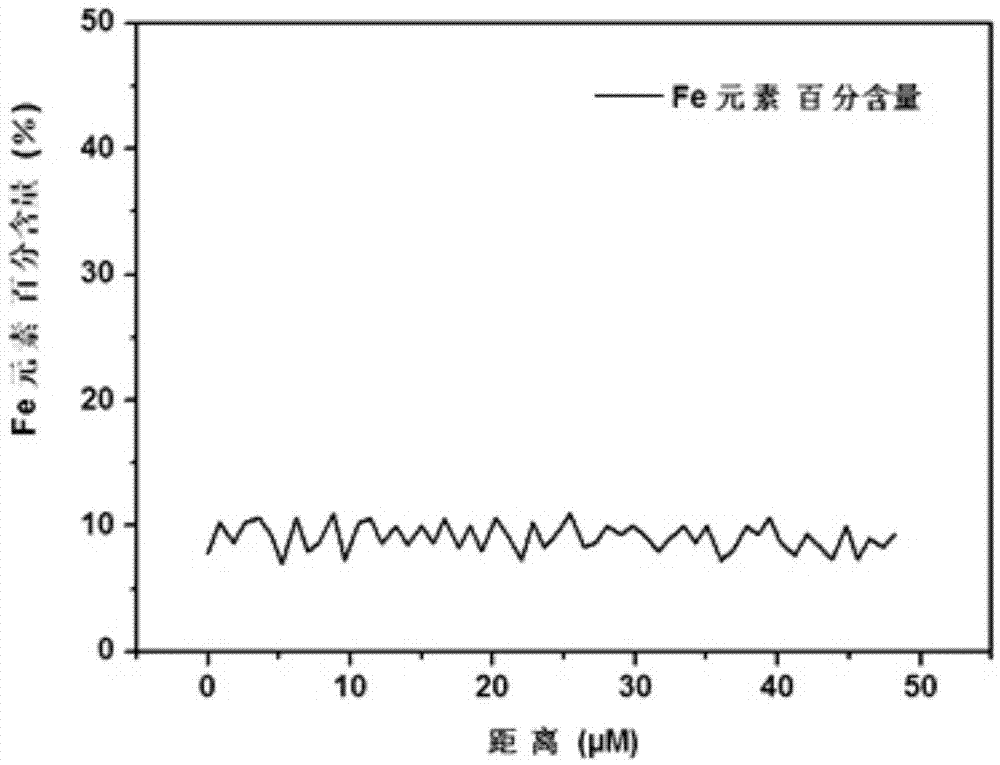

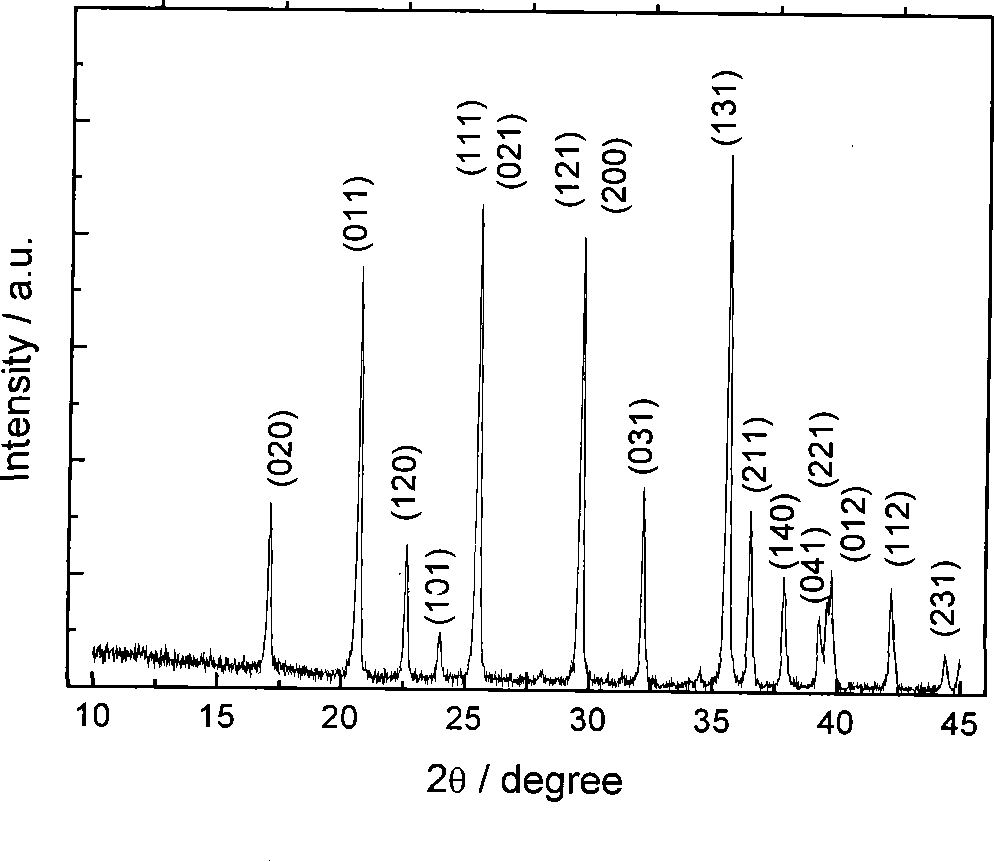

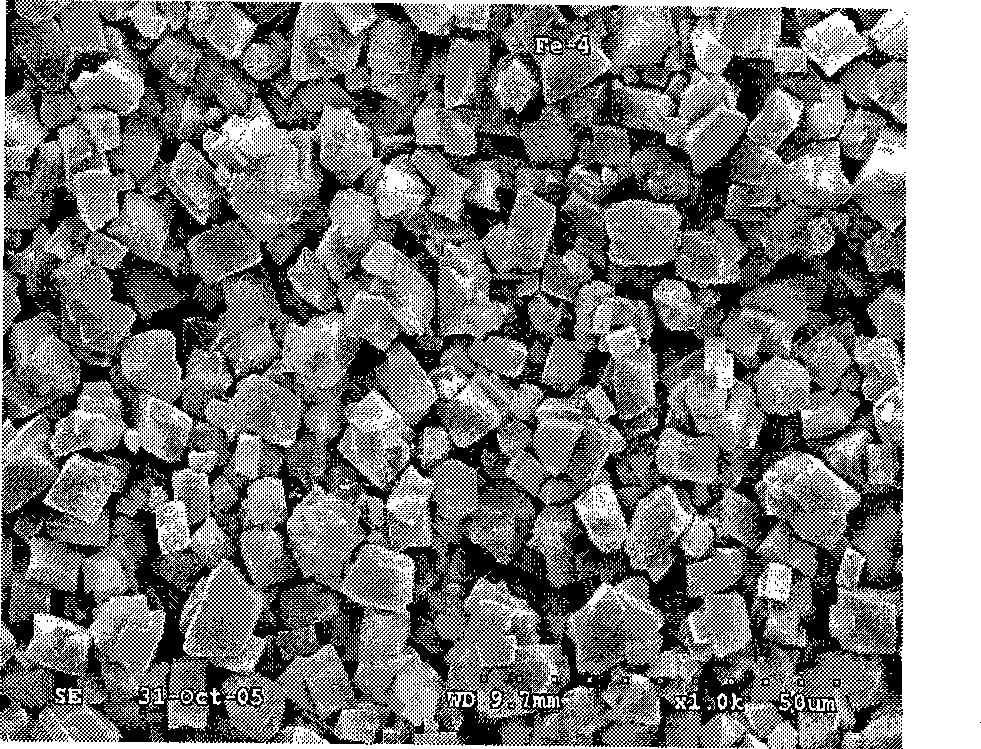

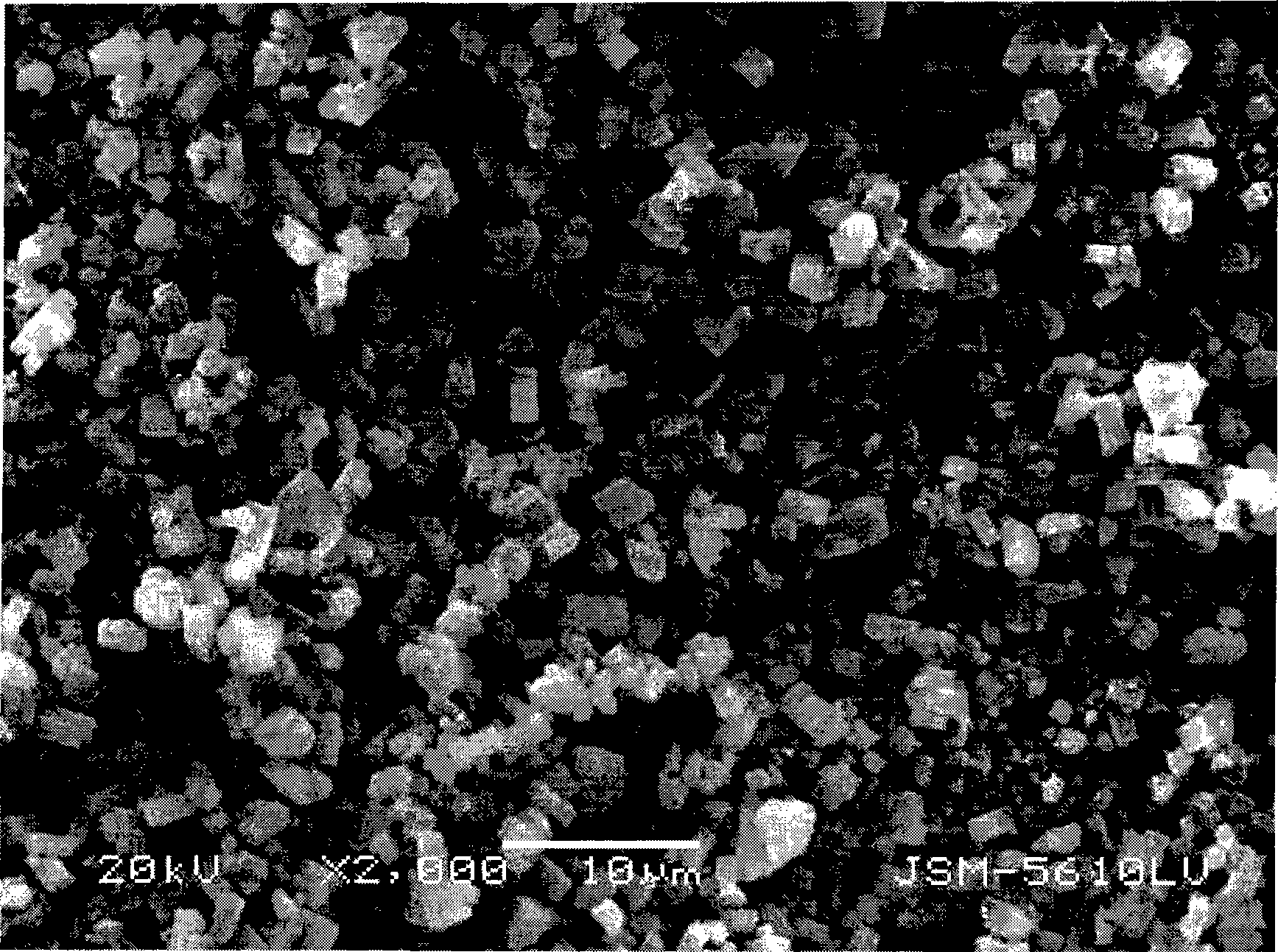

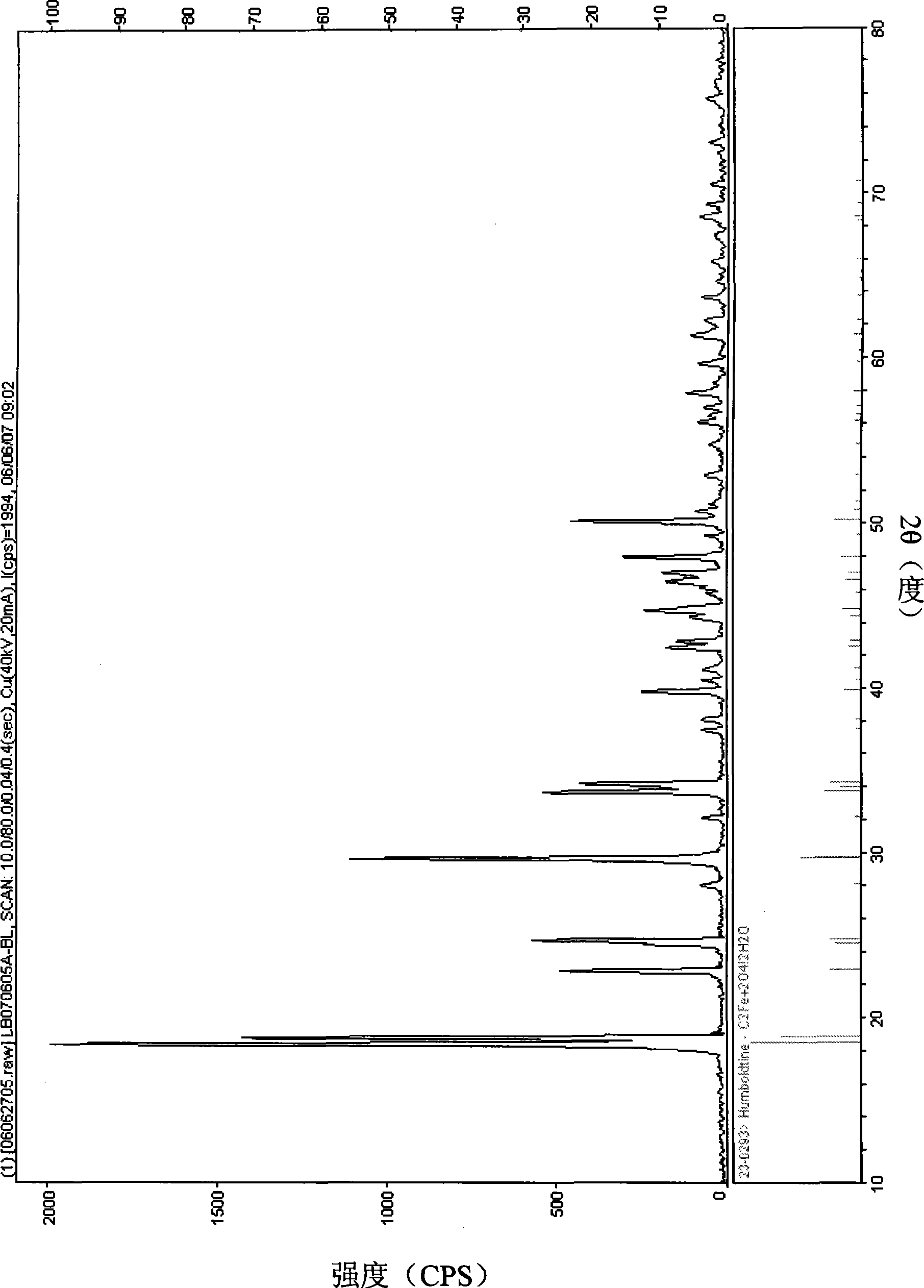

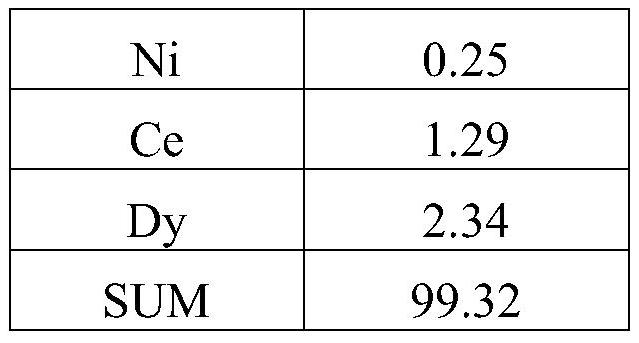

Iron oxalate crystal and preparation thereof

InactiveCN101462944APolycrystalline material growthCarboxylic acid salt preparationFerrous saltsOxalate crystals

The invention relates to a preparation method of monoclinic ferrous oxalate crystal (FeC2O4.2H2O) with particlesize less than 3mum and the monoclinic ferrous oxalate crystal with particlesize less than 3mum obtained by adopting the method. A solid-liquid two-phase method is adopted and the reaction is controlled by controlling the feeding speed of solid oxalate and the temperature and concentration of bivalence ferrous salt solution, thus achieving the purpose of generating the ferrous oxalate crystals with specific crystal formation and particlesize. The method is characterized in that: the solid oxalate is added into the bivalence ferrous salt water solution with concentration of Fe2+ being 0.5-1.7mol / l at the temperature of 40-80 DEG C at the feeding speed of more than 500g / min for reaction by temperature preservation. The method has simple process and high yield. The ferrous oxalate crystal with particlesize less than 3mum is obtained by the method, and the crystal formation is the monoclinic crystal.

Owner:海宁市盐官工业投资有限公司

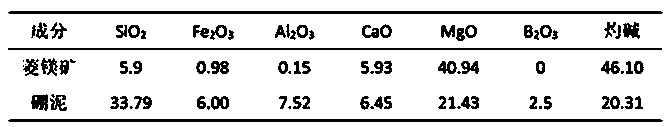

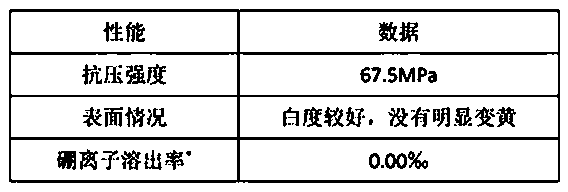

Comprehensive utilization method for high-iron high-calcium high-silicon waste magnesite and boron mud

ActiveCN111153610AImprove reaction efficiencySimple processOrganic compound preparationSolid waste managementOXALIC ACID DIHYDRATEGlycerol

The invention discloses a comprehensive utilization method of high-iron high-calcium high-silicon waste magnesite and boron mud, which comprises the following steps: calcining waste magnesite in a rotary kiln, pulverizing light calcined magnesia powder, and leaching iron and calcium with an oxalic acid and glycerol alcohol solution to obtain calcium oxalate and complex iron oxalate; and adding magnesium sulfate and boric sludge, and carrying out stirring to prepare a magnesium building material product. According to the invention, high-iron high-calcium high-silicon waste magnesite and boron mud are used as raw materials, iron and calcium impurities are leached out through oxalic acid, glycerol alcohol and oxalic acid are subjected to graft polymerization under the hydration heat release condition of magnesium oxysulfate cement, hydroxyl in a formed polymer reacts with boron to solidify boron, then the boron is further solidified through a magnesian cementing material, secondary utilization of solid waste is achieved, and the method is environmentally friendly. The preparation method is simple, the light calcined magnesia powder prepared by using the rotary kiln is small in grain size, high in activity, relatively low in cost, safe, non-toxic, low in leaching harmful impurities and large in dosage, and is used for building material products, and the prepared building material product is relatively high in whiteness and good in performance.

Owner:辽宁科大中驰镁建材科技有限公司 +1

Method for producing high purity battery level iron oxalate from pickle liquor

ActiveCN101462942BHigh puritySmall particle sizeCarboxylic acid salt preparationOXALIC ACID DIHYDRATEFerrous salts

The invention relates to a method for producing high-purity battery grade iron oxalate by utilizing pickle liquor, comprising the following steps: the pickle liquor is pre-treated for lowering spent acid content, thus leading the pickle liquor to generate ferrite solution with a certain concentration; then after strict filtering and magnetic separation, the ferrite solution is transported into a reaction kettle, then industry ammonia is added and the solution is stirred for reaction to generate ferrous hydroxide gelatin; the soluble oxalic acid solution is slowly added in and stirred, and then the mixture is stirred by a conversion reaction kettle and heat preservation is carried out, thus obtaining iron oxalate slurry after reaction; iron oxalate mother solution is separated in the iron oxalate slurry, and the separated iron oxalate is washed, dried and crashed for obtaining high-purity superfine iron oxalate products. The method has the beneficial effects that: the pickle liquor in industrial production is fully utilized; a two-step liquid phase method of oxidation and conversion is adopted for leading the reaction to be more fully, so that the reaction rate is greatly improved,the grain diameter of the finished products iron oxalate is fine and uniform, D50 is less than or equal to 5mum, and the content of the iron oxalate is more than or equal to 95.5 percent; furthermore, the pickle liquor is used as raw material, and cyclic utilization and environmental protection of the industrial waste are utilized, thus changing waste into valuable and greatly lowering the production cost.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

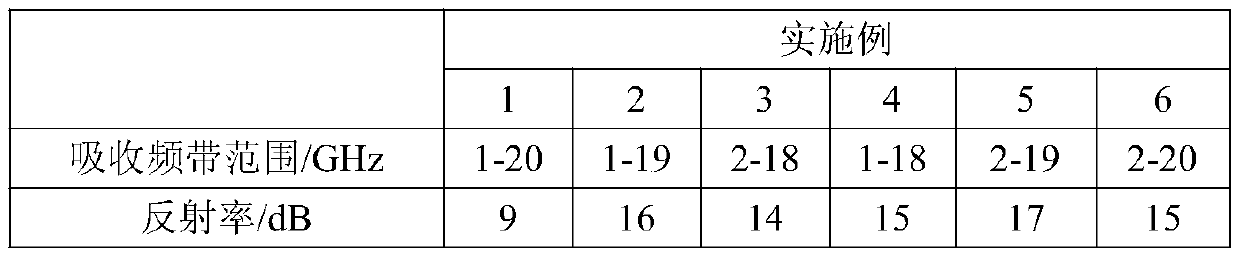

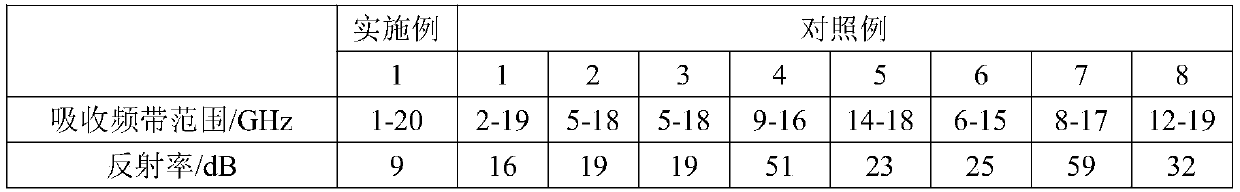

Preparation method for carbon wave-absorbing material

The invention provides a preparation method for a carbon wave-absorbing material. The carbon wave-absorbing material is composed of a carbon matrix material, a heat conduction carbon fiber, butyl acrylate and a 819 photo-initiator, the carbon matrix material is prepared from a reaction of activated carbon sponge, mesoporous carbon, a heat conduction carbon fiber, a nano carbon material and ferrite, the heat conduction carbon fiber is prepared by reacting a carbon fiber, copper acetate, Sr-10 emulsifiers, thiourea, water, ethanol, glucose and ammonia water, and the ferrite is prepared by reacting iron oxalate, cobalt oxalate, nickel oxalate, nano copper powder, acrylic acid, methoxy polyethylene glycol 550 monomethacrylate, and the 819 photo-initiator. The carbon wave-absorbing material prepared by the method of the invention has excellent wave-absorbing properties.

Owner:长沙凯泽工程设计有限公司

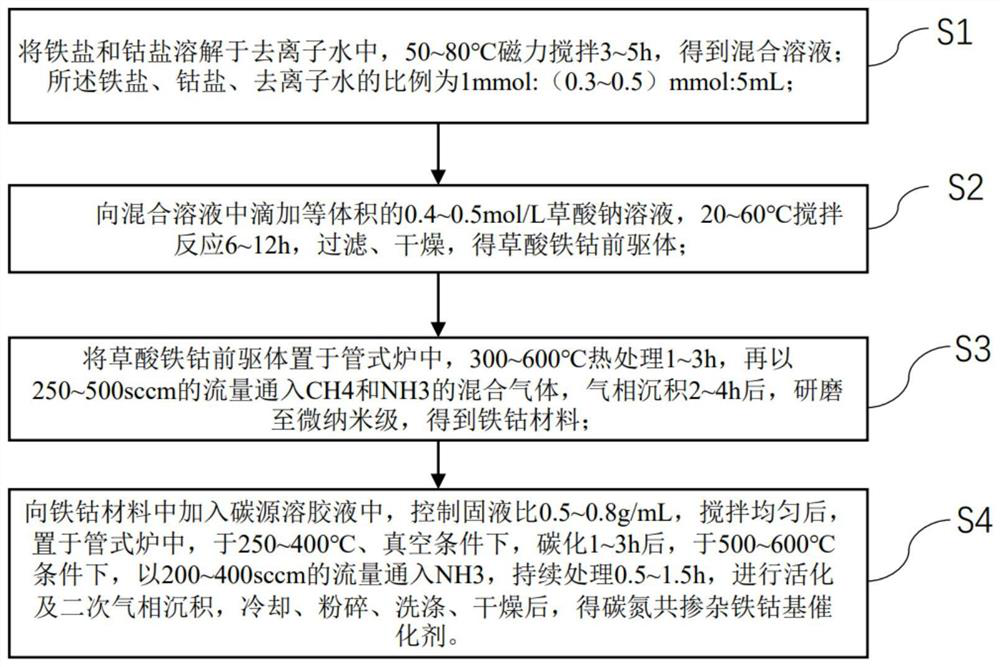

Preparation method and application of carbon-nitrogen co-doped iron-cobalt-based catalyst

InactiveCN113522333AImmobilizationAchieve targeted conversionsCatalyst activation/preparationEther preparationPtru catalystIron salts

The invention discloses a preparation method and application of a carbon-nitrogen co-doped iron-cobalt-based catalyst, and the preparation method comprises the following steps: S1, dissolving an iron salt and a cobalt salt in deionized water, and magnetically stirring at 50-80 DEG C for 3-5 hours to obtain a mixed solution; S2, dropwise adding an isometric 0.4-0.5 mol / L sodium oxalate solution into the mixed solution, stirring and reacting at 20-60 DEG C for 6-12 hours, filtering and drying; S3, placing the obtained cobalt iron oxalate precursor in a tubular furnace, carrying out heat treatment at 300-600 DEG C for 1-3 hours, introducing a mixed gas of CH4 and NH3 at a flow rate of 250-500 sccm, carrying out vapor deposition for 2-4 hours, and grinding to a micro-nano level; and S4, adding a carbon source sol solution into the obtained iron-cobalt material, carbonizing for 1-3 hours, introducing NH3 at the flow rate of 200-400 sccm under the condition of 500-600 DEG C, continuously treating for 0.5-1.5 hours, activating, carrying out secondary vapor deposition, cooling, crushing, washing and drying. The metal elements Fe and Co and oxides thereof form a defect energy state between a valence band and a conduction band by doping non-metal elements carbon and nitrogen, so that lattice distortion is caused, and the catalytic activity and directional selectivity of the catalyst are improved.

Owner:哈尔滨领昇生物医药科技有限公司

Vanadium cell electrolyte

The invention relates to the technical field of cell electrolyte, and in particular relates to a vanadium cell electrolyte. The vanadium cell electrolyte is characterized in that at least one of inorganic molybdate, phosphate and oxalate is selected as an ionic liquid additive, wherein the inorganic molybdate is selected from at least one of sodium molybdate, ammonium molybdate, potassium molybdate, magnesium molybdate, zinc molybdate, iron molybdate, manganese molybdate and calcium molybdate; oxalate is selected from at least one of sodium oxalate, ammonium oxalate, potassium oxalate, lithiumoxalate, magnesium oxalate, zinc oxalate, iron oxalate, manganese oxalate and calcium oxalate. According to the vanadium cell electrolyte, the additive is capable of increasing the dissolvability ofthe electrolyte, inhibiting the hydrolyzing of pentavalent vanadium ions, and greatly improving the stability of cathode electrolyzing; inorganic molybdate is treated as the cathode electrolyte additive through which the stability of the cathode electrolyte is improved, and the running temperature range of a vanadium cell is expanded. The vanadium cell electrolyte is simple in preparation processand operation, and low in cost; the vanadium cell can easily stably run under high temperature.

Owner:杨昌恩

Carbon nanotube modified silicone rubber material

The invention discloses a carbon nanotube modified silicone rubber material. The carbon nanotube modified silicone rubber material comprises the following raw materials: silicone rubber, polyasparticacid ester, ethylene-acrylate rubber, silicon dioxide aerogel, carbon nanotubes, iron oxalate, montmorillonite, halloysite, polyvinyl alcohol fiber, glass fiber, zinc oxide, a silane coupling agent, 2,5-dimethyl-2,5-di(tert-butylperoxyl)hexane, benzoperoxide, an accelerator DM, N,N'-bis(salicylidene)-1,2-propanediamine and N-hydroxymethyl-3-(dimethoxyphosphonyl)propionamide. The carbon nanotube modified silicone rubber material provided by the invention has the advantages of good heat resistance, excellent aging resistance and flame retardancy and high strength.

Owner:天长市荣盛有机硅科技有限公司

Preparation of iron oxalate hydrous salt crystal

The invention provides a method for preparing ferrous oxalate hydrated salt crystals. The method comprises the following steps: carrying out the contact reaction between a solution A and a solution B. The contact manner and condition of the solution A and the solution B are provided to allow the produced ferrous oxalate hydrated salt to be supersaturated in the reaction mixed solution of the solution A and the solution B. By adopting the method, the prepared ferrous oxalate hydrated salt crystals have smaller average particle size and higher purity.

Owner:海门市创豪工业设计有限公司

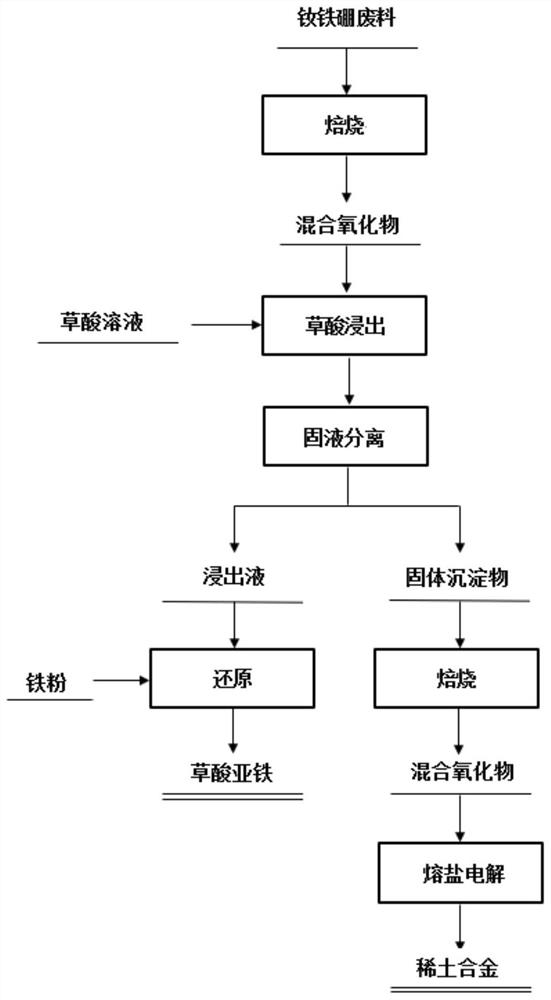

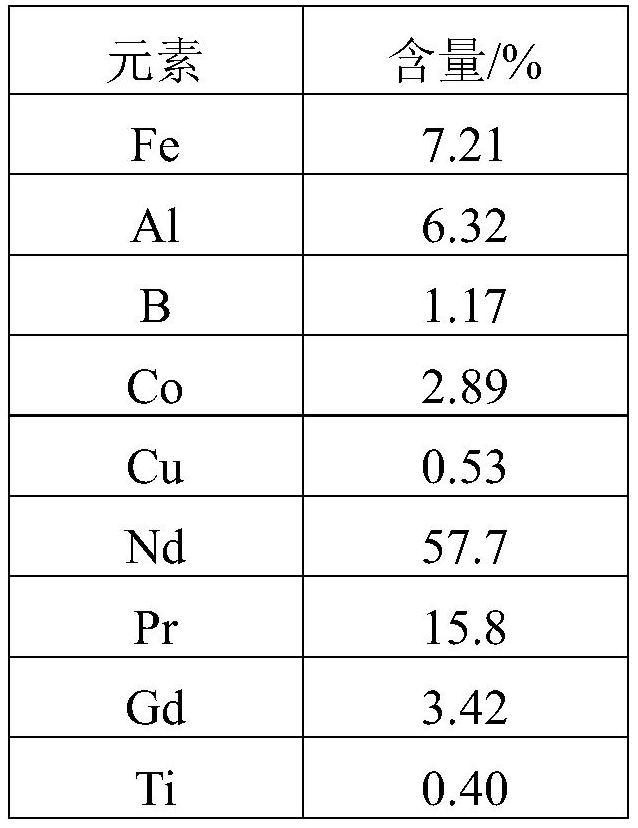

A method for synchronously and efficiently extracting rare earth and iron from high-value recycled NdFeB waste

ActiveCN110607537BEasy to operateEfficient extraction and high process operabilityOrganic compound preparationCarboxylic acid salt preparationOXALIC ACID DIHYDRATEElectrolysis

The invention belongs to the technical field of industrial waste recycling and specifically relates to a method for synchronously and efficiently extracting high-value rare earth and iron from NdFeB waste for reuse. The method of the present invention reacts the oxidation product obtained after oxidizing and roasting the NdFeB waste with the oxalic acid solution to obtain the leach solution containing iron oxalate and the solid precipitate mainly composed of rare earth oxalate, and then only the leach solution and the precipitate Iron reduction and molten salt electrolysis treatment can be carried out respectively to obtain rare earth alloys for the production of NdFeB materials and ferrous oxalate for the production of lithium battery materials. The method only uses oxalic acid solution as a leaching agent and a precipitating agent, and can complete the leaching of iron and the transformation of rare earths in one step, thereby achieving the purpose of simultaneously realizing the efficient extraction and high-value recycling of iron and rare earths. The method of the invention has a short extraction process, is environmentally friendly, can effectively recover and obtain high-value products, and has extremely high process operability.

Owner:赣州稀土友力科技开发有限公司

Method for leaching gold hematite wrapped in second-stage calcine through using oxalic acid

InactiveCN111394577AAchieve reuseImprove leaching rateProcess efficiency improvementOXALIC ACID DIHYDRATEPregnant leach solution

The invention discloses a method for leaching gold hematite wrapped in second-stage calcine through using oxalic acid. The method comprises the steps that firstly, the oxalic acid is added into a leaching tank; the second-stage calcine and water are added into the leaching tank added with the oxalic acid, agitation leaching is carried out, and liquid-solid separation is carried out after the leaching process is ended so as to obtain a leachate and leaching residues; illumination treatment is carried out on the leachate to obtain a faint yellow precipitate and an illuminated solution; and cyaniding leaching is conducted on the leaching residues, liquid-solid separation is conducted after the leaching process is finished, and accordingly gold-containing pregnant solution is obtained. According to the method, the oxalic acid is added, the strong complexing effect of C2O4<2-> on Fe<3+> is utilized, the hematite in the second-stage calcine is leached in the form of an iron oxalate complex,the iron leaching speed is high, the iron leaching rate is high, the energy consumption in the leaching process is low, and industrialization is easy; the leachate is subjected to illumination treatment to obtain ferrous oxalate, part of the oxalic acid is re-used, and recovering of iron, recycling of part of leaching agent oxalic acid and re-using of the system water are achieved; and cyaniding is conducted on iron removal slag for gold extraction, and the leaching rate of gold is effectively increased.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Seal rubber mat capable of preventing salt corrosion and preparation method thereof

The invention provides a seal rubber mat capable of preventing salt corrosion. The seal rubber mat is made from silicone rubber, fluororubber, an anti-aging agent DNP, an anti-aging agent CMA, white carbon black, calcium carbonate, iron oxalate, an accelerator NOBS, an accelerator DPTH, t-butyl perbenzoate, benzoyl peroxide and epoxy resin. The preparation method comprises the steps that (1) the fluororubber is subjected to plastication; (2) after the plastication, the fluororubber is mixed with the silicone rubber and other components in an open mill for mixing; (3) the rubber compound is subjected to remilling; (4) extrusion forming and vulcanization are carried out, and the seal rubber mat is obtained. The seal rubber mat has the advantages of smooth surfaces, strong resistance to corrosion and long service life, simple preparation process, reasonable components and safe production during the preparing process.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Method for preparing iron oxalate

InactiveCN101717331ASolve intractableHigh economic valueCarboxylic acid salt preparationSulfateDissolution

The invention relates to a method for preparing iron oxalate, belonging to the field of chemical engineering. The method for preparing iron oxalate can recycle by-product of copperas generated when preparing titanium pigment with titanium concentrate. The method for preparing iron oxalate takes the by-product of copperas generated when preparing the titanium pigment with the titanium concentrate as raw materials, and comprises the following steps of: a. adding water to the copperas for dissolution to obtain a ferrous sulfate solution, adjusting pH value to be 5.6 to 6.5 by utilizing ammonia, filtering the solution; b. extracting the filtrate by utilizing P2O4, separating the filtrate to obtain an organic phase and a water phase; c. and adding a solution containing F to the water phase so as to deposit Mg<2+>, filtering the solution, adding an oxalic acid solution to the filtrate, and filtering the solution to obtain iron oxalate crystallization. The invention not only solves the problem of stacking the copperas, but also enhances the economic value of the copperas, provides a new choice for treating the by-product of copperas generated when preparing titanium pigment with a sulfuric acid method, and has wide application prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com