Method for leaching gold hematite wrapped in second-stage calcine through using oxalic acid

A technology of encapsulating gold and hematite, which is applied in the direction of improving process efficiency, can solve problems such as complex operation process, high processing temperature, and large acid consumption, and achieve simple process flow, high iron leaching rate, and improved leaching rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

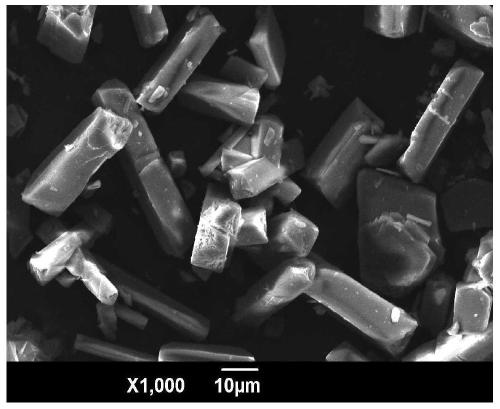

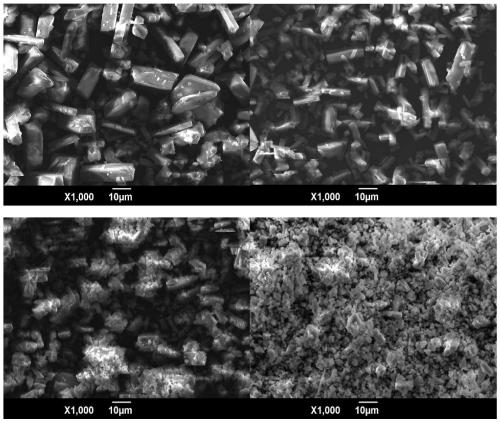

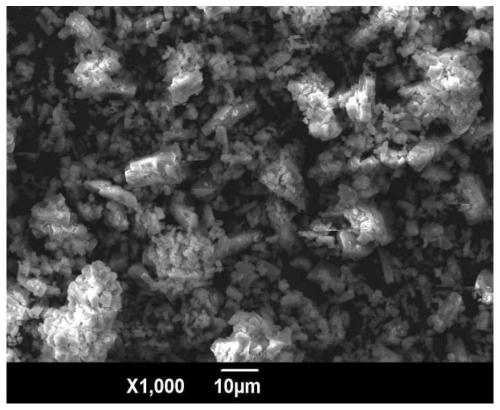

Image

Examples

Embodiment 1

[0033] Embodiment 1 provides a kind of method that utilizes oxalic acid to leach second-stage calcine and wrap gold hematite, comprise the following steps:

[0034] Step 1, adding oxalic acid in the leaching tank, the molar mass of oxalic acid added is 3.5 times of the total iron molar mass in the second stage calcine to be treated;

[0035] Step 2. Add the second-stage calcined sand and water into the leaching tank with oxalic acid at a liquid-solid ratio of 12mL / 1g, and stir and leaching at 70°C for 5 hours at a stirring speed of 500r / min. After the leaching process, carry out liquid-solid Separation to obtain leaching liquid and leaching slag, wherein, the gold content in the second-stage calcined sand is 57.50g / t, and the hematite content is 25.12%;

[0036] Step 3. Treat the leaching solution in step 2 with static sunlight for 10 hours. After the lighting process, solid-liquid separation is carried out to obtain light yellow solid precipitate and liquid after light. After...

Embodiment 2

[0041] Embodiment 2 provides a kind of method that utilizes oxalic acid to leach the gold-hematite wrapped in the second-stage calcine, comprising the following steps:

[0042] Step 1, adding oxalic acid in the leaching tank, the molar mass of oxalic acid added is 4.5 times of the total iron molar mass in the second-stage calcine to be treated;

[0043] Step 2. Add the second-stage calcined sand and water to the leaching tank with oxalic acid at a liquid-solid ratio of 15mL / 1g, and stir and leaching at 95°C for 3 hours at a stirring speed of 450r / min. After the leaching process, carry out liquid-solid Separation to obtain leaching solution and leaching residue. The weight of the second-stage calcine is 50g, the volume of water is 750mL, the gold content in the second-stage calcine is 47.49g / t, and the hematite content reaches 30.17%;

[0044] Step 3. Divide the leaching solution in step 3 into 6 parts on average, 1 part of the leaching solution is subjected to ultraviolet lig...

Embodiment 3

[0050] Embodiment 3 provides a kind of method that utilizes oxalic acid to leach second-stage calcine and wrap gold hematite, comprise the following steps:

[0051] Step 1, adding oxalic acid into the leaching tank, the molar mass of oxalic acid added is 4.02 times of the total iron molar mass in the second-stage calcine to be treated;

[0052] Step 2. Add the second-stage calcined sand and water into the leaching tank with oxalic acid at a liquid-solid ratio of 14mL / 1g, and stir and leaching at 80°C for 4 hours at a stirring speed of 450r / min. After the leaching process, carry out liquid-solid Separation to obtain leaching solution and leaching slag; among them, the gold content in the second-stage calcine is 50.33g / t, and the hematite content reaches 27.65%;

[0053] Step 3, the leaching solution in step 2 is treated with sunlight static light for 9 hours, and the liquid is subjected to solid-liquid separation after light, to obtain light yellow solid precipitation and liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com