Method for synthesizing carbon-cladded ironic lithium phosphate

A technology of carbon-coated lithium iron phosphate and microwave synthesis, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor thermal conductivity of raw materials, heterogeneous phases inside and outside materials, and affecting material control, etc., to achieve The effect of shortening the production cycle, heating quickly and evenly, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

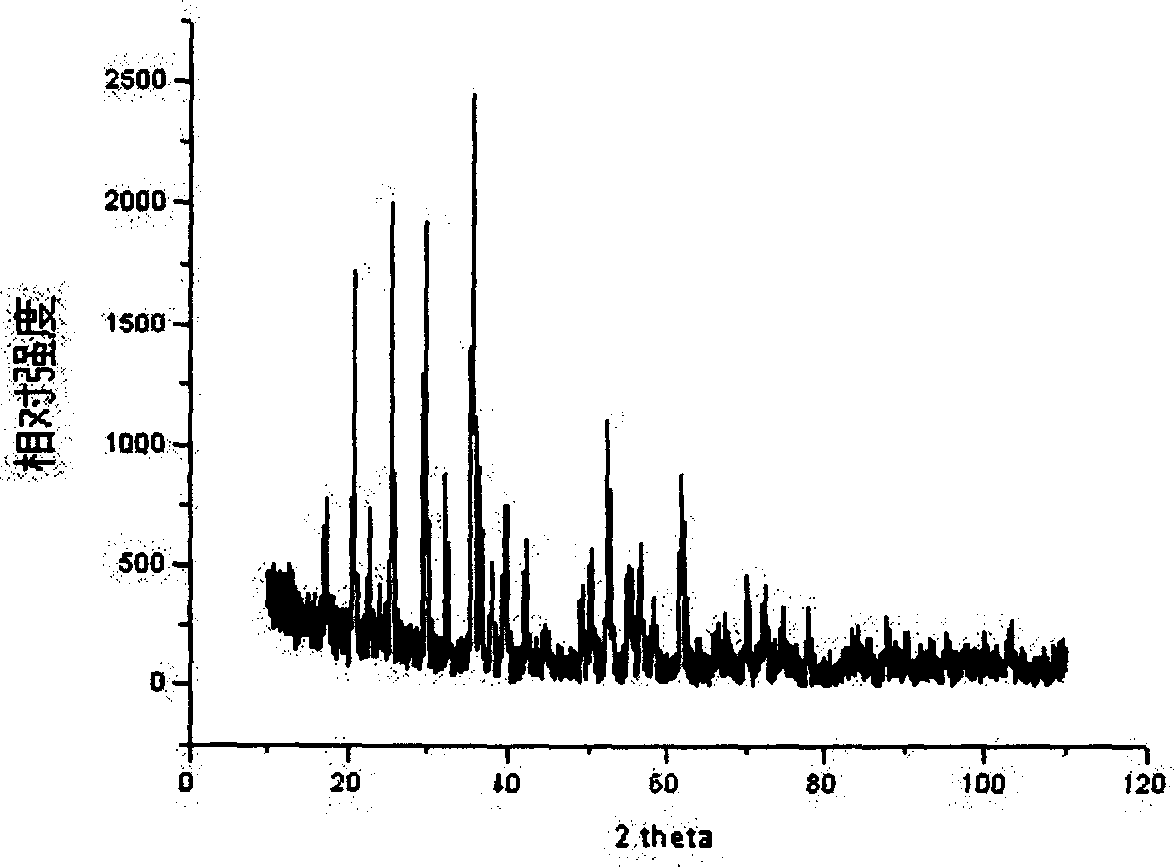

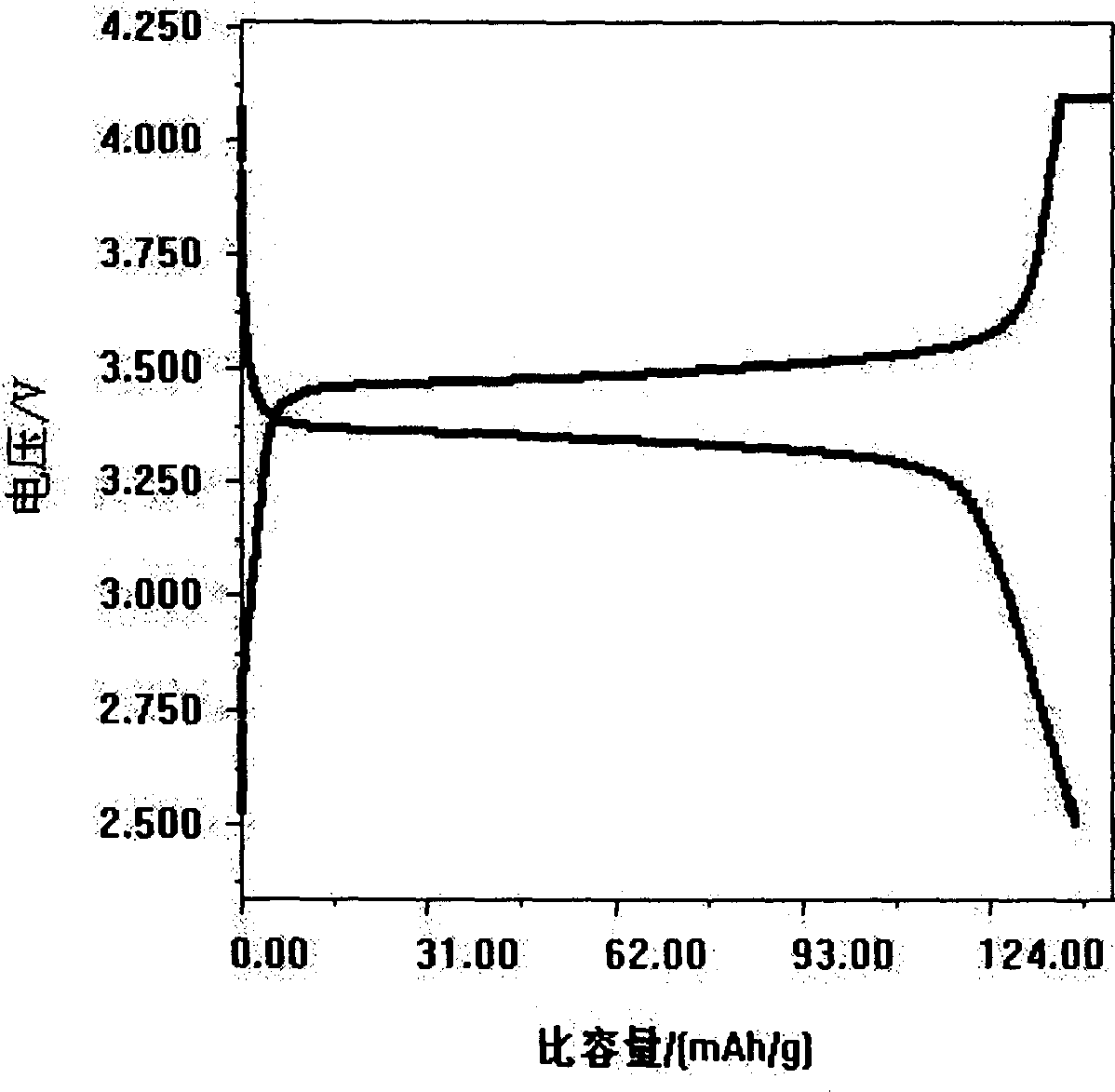

[0013] Example 1: Lithium carbonate, ferrous oxalate and ammonium dihydrogen phosphate were mixed according to the material ratio of 1:2:2 to obtain the basic raw materials. The above-mentioned basic raw materials, sucrose and heat-conducting agent acetylene black are mixed in a mass ratio of 10:1:0.5, fully ground and mixed with ethanol as a dispersant, and pressed into a block at 10Mpa after drying, with a block thickness of 1.4cm. In a crucible, place the crucible in a microwave oven and sinter on low heat for 5 min. Its XRD diagram is shown in figure 1 , see the second charge and discharge curve at 20mA / g current density figure 2 , the discharge capacity can reach 137mAh / g.

example 2

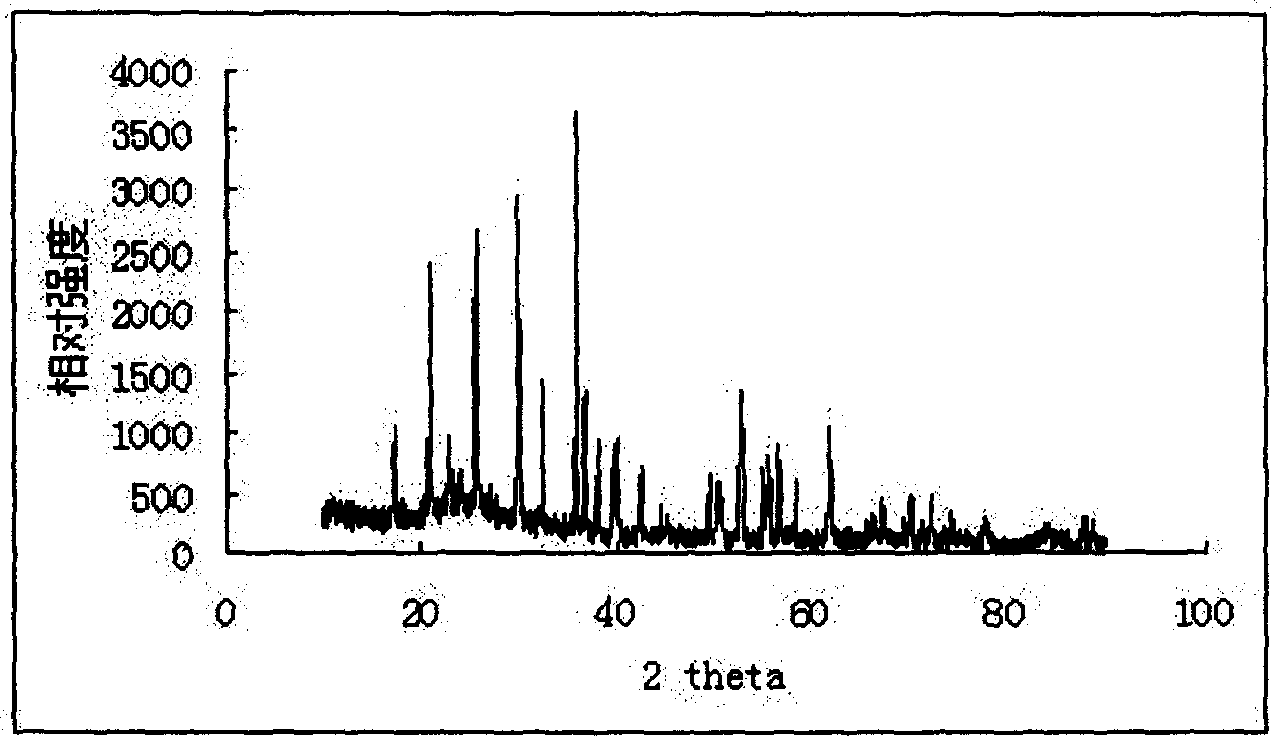

[0014] Example 2: Lithium carbonate, ferrous lactate and ammonium dihydrogen phosphate were mixed according to the material ratio of 1:2:2 to obtain basic raw materials. The above-mentioned basic raw materials, sucrose and heat-conducting agent acetylene black are mixed in a mass ratio of 10:0.3:1, fully ground and mixed with ethanol as a dispersant, and pressed into a block at 10Mpa after drying. In a crucible, place the crucible in a microwave oven and sinter on low heat for 3 minutes. Its XRD diagram is shown in image 3 , see the second charge and discharge curve at 200mA / g current density Figure 4 , the discharge capacity can reach 111mAh / g.

example 3

[0015] Example 3: Lithium hydroxide, ferrous oxalate and ammonium dihydrogen phosphate were mixed according to the material ratio of 1:1:1 to obtain the basic raw material. Mix the above-mentioned basic raw materials, starch, and activated carbon in a mass ratio of 10:0.3:1.5, use ethanol as a dispersant to fully grind and mix, and after drying, press it into a block at 10Mpa with a thickness of 2.2cm, and place it in a crucible with activated carbon , and then put the crucible in a microwave oven and sinter on low heat for 8 minutes. The fifth charge and discharge curve at 30mA / g current density is shown in Figure 5 , the discharge capacity can reach 144mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com