Preparation method and application of Z-type carbon nitride-iron oxide catalyst containing nitrogen defect structure

A defect structure, catalyst technology, applied in physical/chemical process catalysts, ammonia preparation/separation, chemical instruments and methods, etc., to achieve the effect of good photocatalytic nitrogen fixation and ammonia production and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

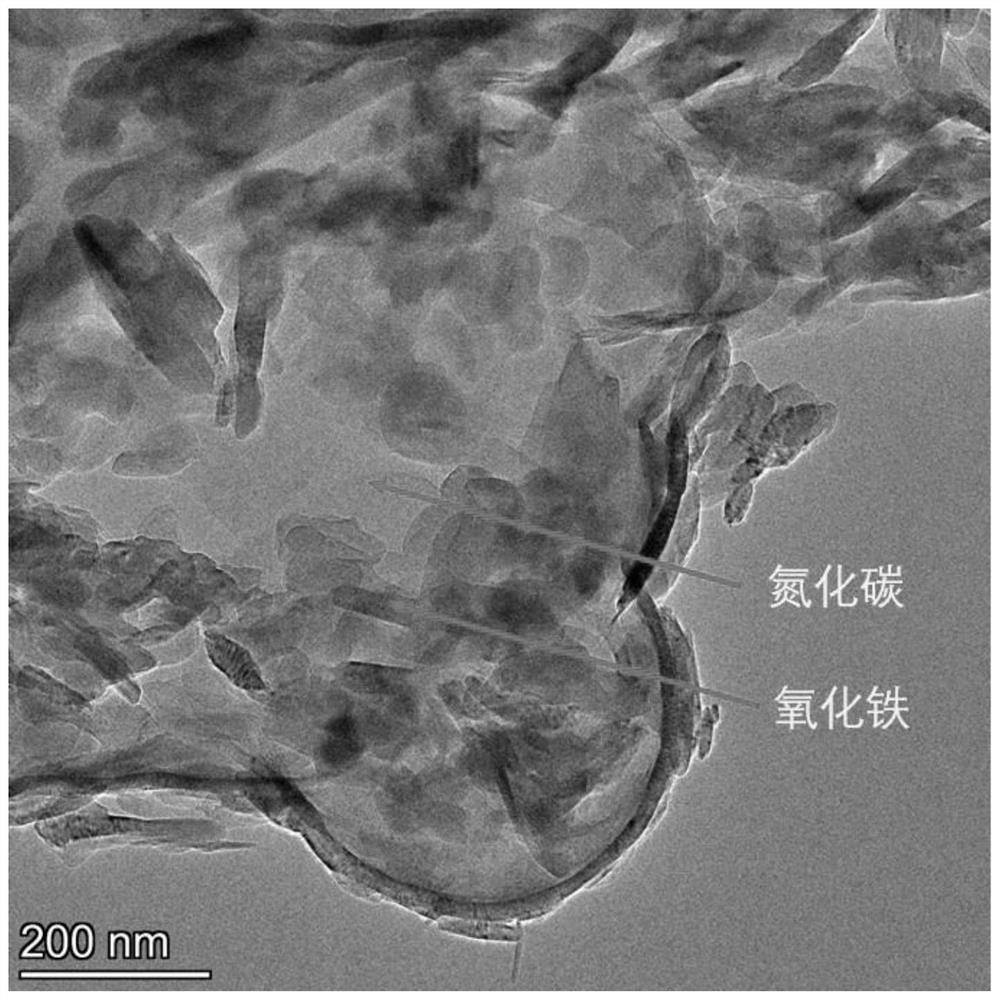

[0031] A nitrogen-containing defect structure Z-type g-C 3 N x / Fe 2 o 3 The preparation method of catalyst, comprises the steps:

[0032] (1) Disperse 5 g of urea in 50 mL of sodium hydroxide solution (0.5 mol / L), stir for 30 min, dry at 60°C for 12 h, then cool to room temperature, grind into powder and collect for later use.

[0033] (2) Mix and grind 5g of the above-mentioned urea / sodium hydroxide mixture with 0.5g ferric oxalate, add it into the crucible, put it into the muffle furnace, and heat it at 10 ℃·min -1 Raise the temperature to 150 °C, after heating for 1 h, at 10 °C min -1 Raise the temperature to 450 °C, heat for 1 hour, then cool down to room temperature, grind into powder, wash with water, centrifuge and dry to prepare the nitrogen-containing defect structure Z-type photocatalyst g-C 3 N x -0.1 / Fe 2 o 3 -0.1.

[0034] Under normal temperature and pressure conditions, add 50 mg of g-C to 500 mL methanol aqueous solution (0.001 mol / L) 3 N x -0.1 / Fe ...

Embodiment 2

[0036] A nitrogen-containing defect structure Z-type g-C 3 N x / Fe 2 o 3 The preparation method of catalyst, comprises the steps:

[0037] (1) Disperse 10 g of melamine in 50 mL of potassium hydroxide solution (0.5 mol / L), stir for 30 min, dry at 60°C for 12 h, then cool to room temperature, grind into powder and collect for later use.

[0038] (2) Mix and grind 5g of the above-mentioned melamine / potassium hydroxide mixture and 1g of ferrous oxalate, add it into the crucible, put it into the muffle furnace, and heat it at 10 ℃·min -1 Raise the temperature to 200 °C, after heating for 2 h, at 10 °C min -1 The temperature was raised to 500 °C, heated for 2 h, then cooled to room temperature by program cooling, ground into powder, washed with water, centrifuged and dried to prepare the nitrogen-containing defect structure Z-type photocatalyst g-C 3 N x -0.2 / Fe 2 o 3 -0.2.

[0039] Under normal temperature and pressure conditions, add 100 mg of g-C to 500 mL methanol aque...

Embodiment 3

[0041] A nitrogen-containing defect structure Z-type g-C 3 N x / Fe 2 o 3 The preparation method of catalyst, comprises the steps:

[0042] (1) Disperse 25g of melamine in 50mL of ammonia solution (0.5 mol / L), stir for 30min, dry at 60°C for 12h, then cool to room temperature, grind into powder and collect for later use.

[0043] (2) Mix and grind 5g of the above-mentioned melamine / ammonia water mixture and 1.5g of ferrous oxalate into the crucible, put it into the muffle furnace, and heat it at 10 ℃·min -1 Raise the temperature to 350 °C, after heating for 2 h, at 10 °C min -1 The temperature was raised to 530 °C, heated for 3 h, then cooled to room temperature by program cooling, ground into powder, washed with water, centrifuged and dried to prepare the nitrogen-containing defect structure Z-type photocatalyst g-C 3 N x -0.5 / Fe 2 o 3 -0.3.

[0044] Under normal temperature and pressure conditions, add 100 mg of g-C to 500 mL methanol aqueous solution (0.001 mol / L) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com