W18O49/ZnTiO3 nitrogen fixation photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and nitrogen fixation, which is applied in the field of photocatalytic materials to achieve strong photocatalytic reduction ability, mild conditions and favorable effects for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Blue tungsten oxide photocatalyst (W 18 O 49 ) is prepared as follows:

[0026] Dissolve 0.01 mol of tungsten hexachloride in 15 mL of absolute ethanol, stir until blue, put it in a hydrothermal kettle for hydrothermal reaction at 160 °C for 6 h, naturally cool to room temperature, wash with water, dry at 70 °C, and grind to obtain blue Color tungsten oxide powder, namely blue tungsten oxide photocatalyst.

Embodiment 2

[0028] Zinc titanate photocatalyst (ZnTiO 3 ) is prepared as follows:

[0029] Dissolve 0.01mol of zinc acetate in absolute ethanol, add 3mL of concentrated nitric acid, stir for 30min, add 0.01mol of tetra-n-butyl titanate dropwise to the resulting mixed solution, continue stirring for 30min, and put the resulting solution into a hydrothermal kettle Hydrothermal reaction at 160 °C for 6 h, naturally cooled to room temperature, washed with water, dried at 105 °C, and ground to obtain an intermediate product; the intermediate product was placed in a muffle furnace, and heated to 500 °C at a heating rate of 5 °C / min. Calcined in air for 2 hours, cooled to room temperature naturally, and ground to obtain zinc titanate powder, that is, zinc titanate photocatalyst.

Embodiment 3

[0031] W 18 O 49 / ZnTiO 3 The preparation method of nitrogen-fixing photocatalyst is as follows:

[0032] Add 0.0005mol of tungsten hexachloride to absolute ethanol, stir until blue, add 0.0005mol of zinc titanate powder prepared in Example 2, continue to stir for 1 hour, and put the mixed solution into a hydrothermal kettle for hydrothermal reaction at 160°C for 6 hours , to be naturally cooled to room temperature, washed with water, dried at 70 °C, and ground to obtain W 18 O 49 / ZnTiO 3 Nitrogen fixation photocatalyst.

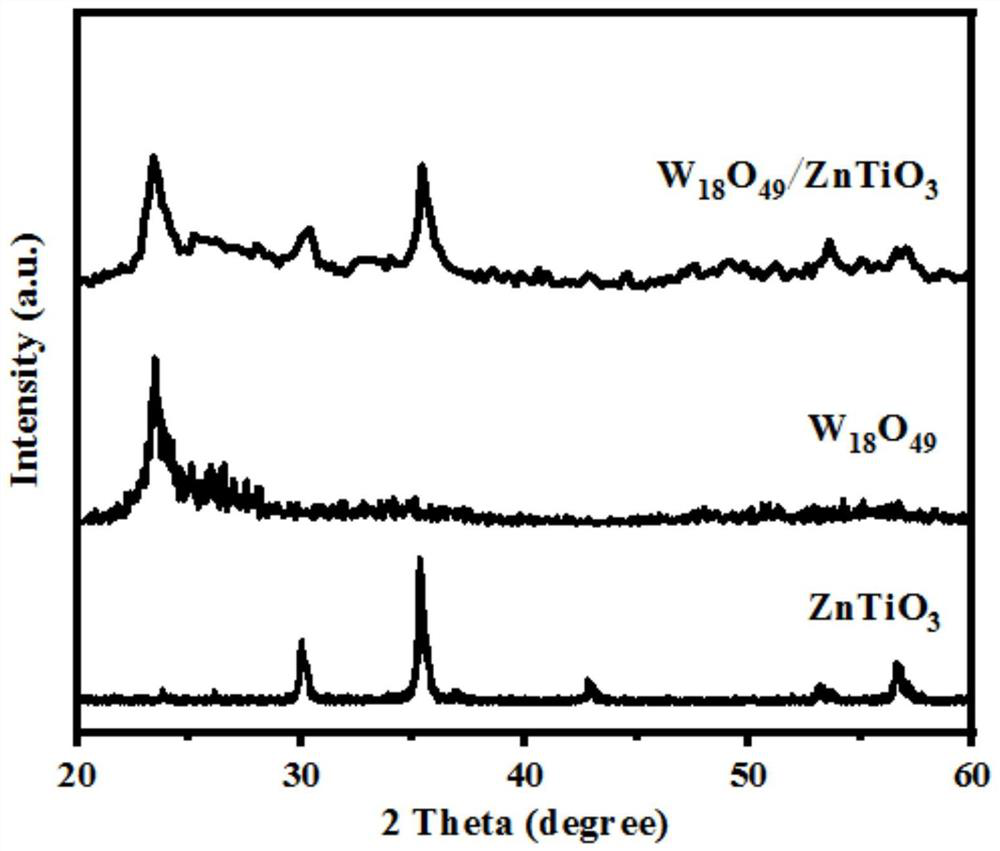

[0033] figure 1 W prepared for Example 1 18 O 49 , the ZnTiO prepared in Example 2 3 and the W prepared in Example 3 18 O 49 / ZnTiO 3 XRD patterns of nitrogen-fixing photocatalysts. from figure 1 It can be seen that ZnTiO 3Corresponding to 5 visible peaks, corresponding to XRD standard card JCPDSNO.39-0190, W 18 O 49 There is only one obvious diffraction peak, and the other small peaks are almost unobservable, which corresponds to the XRD s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com