Titanium dioxide nanobelt@MOF composite material and application thereof

A technology of titanium dioxide and composite materials, applied in the field of composite materials, can solve the problems of low photocatalytic activity and limited electron transport ability, and achieve the effects of inhibiting the recombination rate, enhancing the visible light absorption ability, and improving the photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

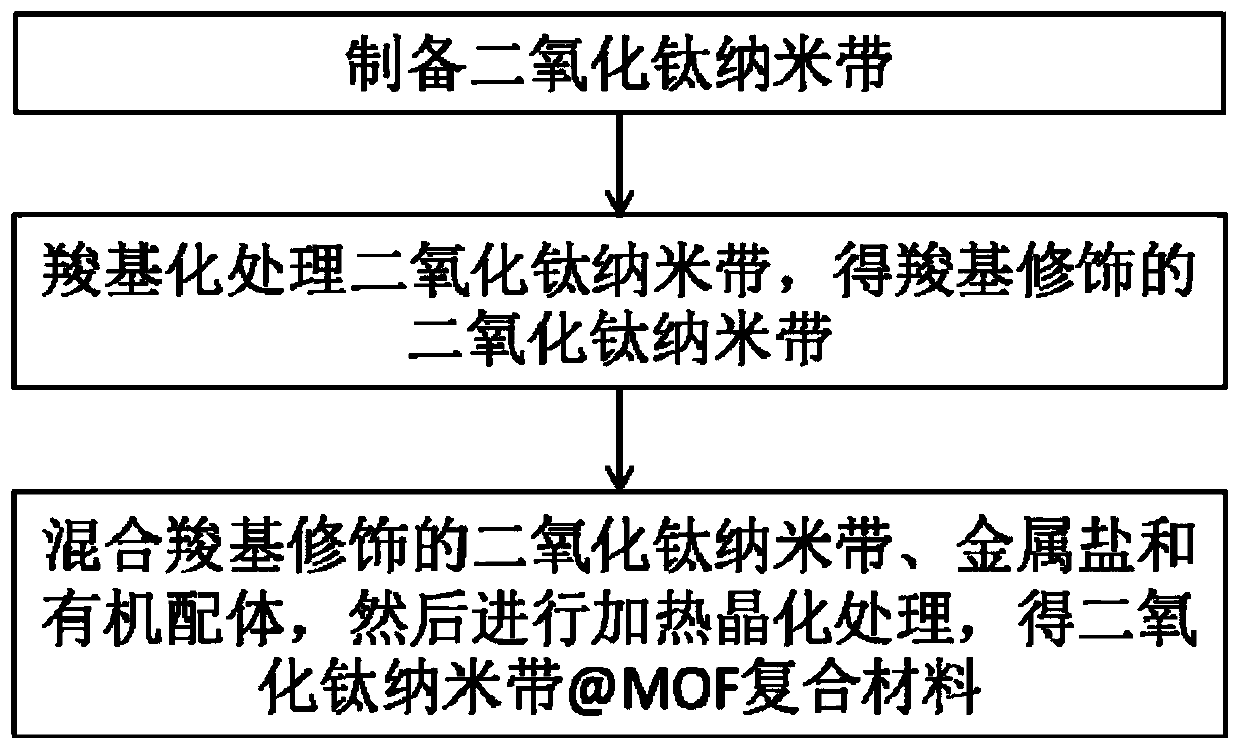

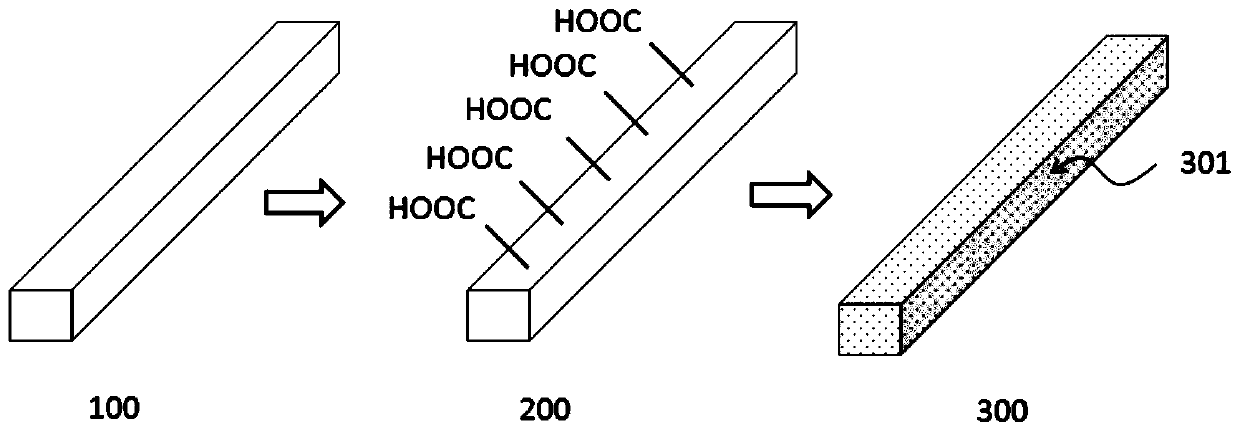

[0039] Another aspect of the present disclosure provides a method for preparing the above-mentioned titania nanobelt@MOF composite material, figure 1Shows a flow chart of the preparation process of the titanium dioxide nanoribbon @MOF composite material according to an embodiment of the present disclosure, figure 2 A schematic diagram of the synthesis mechanism of the titania nanobelt@MOF composite is shown. combine figure 1 with figure 2 As shown, the preparation method of the titanium dioxide nanobelt@MOF composite material includes: preparing titanium dioxide nanobelts; carboxylation treatment of titanium dioxide nanobelts to obtain carboxyl-modified titanium dioxide nanobelts; and mixing carboxyl-modified titanium dioxide nanobelts, metal salts and organic ligands. body, and then heated and crystallized to obtain a titanium dioxide nanoribbon@MOF composite material.

[0040] The preparation process of the titanium dioxide nanoribbon@MOF composite material is described...

Embodiment 1

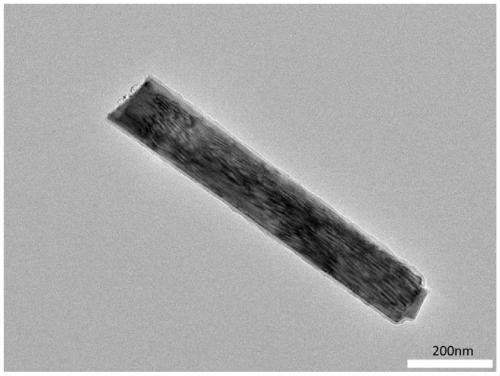

[0055] 1) Dissolve 0.4g of P25 titanium dioxide in 10M aqueous sodium hydroxide solution, stir for 1h to mix evenly, transfer to a 100mL polytetrafluoroethylene reactor and heat at 180°C for 72h, wash the product several times with deionized water, soak Stand in dilute hydrochloric acid solution for 24 hours to replace sodium ions, then hydrothermally treat with dilute sulfuric acid solution at 100°C for 12h, wash the product with deionized water and ethanol several times and dry it, then treat it in air atmosphere at 600°C for 2h to obtain TiO 2 nanobelt.

[0056] 2) 1g prepared TiO 2 Nanobelts and 3g of terephthalic acid were dissolved in a mixed solution containing 45ml of deionized water and 5ml of ethanol, heated at 100°C for 12h after ultrasonication for 1h, the product was washed with deionized water and ethanol in turn, centrifuged, and vacuum-dried at 80°C to obtain carboxyl modification TiO 2 nanobelt;

[0057] 3) Add 0.2g of carboxy-modified TiO 2 Dissolve the n...

Embodiment 2

[0060] 1) Dissolve 0.2g of P25 titanium dioxide in 8M aqueous sodium hydroxide solution, stir for 2 hours to mix evenly, transfer to a 100ml polytetrafluoroethylene reactor and heat at 160°C for 72 hours, wash the product several times with deionized water, soak Stand in dilute hydrochloric acid solution for 36 hours to replace sodium ions, then hydrothermally treat with dilute sulfuric acid solution at 100°C for 24h, wash the product with deionized water and ethanol several times and dry it, then treat it in air atmosphere at 650°C for 3h to obtain TiO 2 nanobelt.

[0061] 2) 2g prepared TiO 2 Dissolve nanobelts and 4g of trimesic acid in a mixed solution containing 52ml of deionized water and 3ml of ethanol, heat at 100°C for 12h after ultrasonication for 2h, wash and centrifuge the product in turn with deionized water and ethanol, and vacuum-dry at 80°C to obtain carboxyl modification TiO 2 nanobelt;

[0062] 3) 0.15g of carboxy-modified TiO 2 Dissolve the nanoribbons i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com