Preparation method and application of two-dimensional porous few-layer g-C3N4 nanosheet photocatalyst

A photocatalyst, g-c3n4 technology, used in physical/chemical process catalysts, catalysts, carbon compound catalysts, etc., can solve the problems of economy and resource waste, and achieve the effect of strong adsorption capacity, high visible light response capacity, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

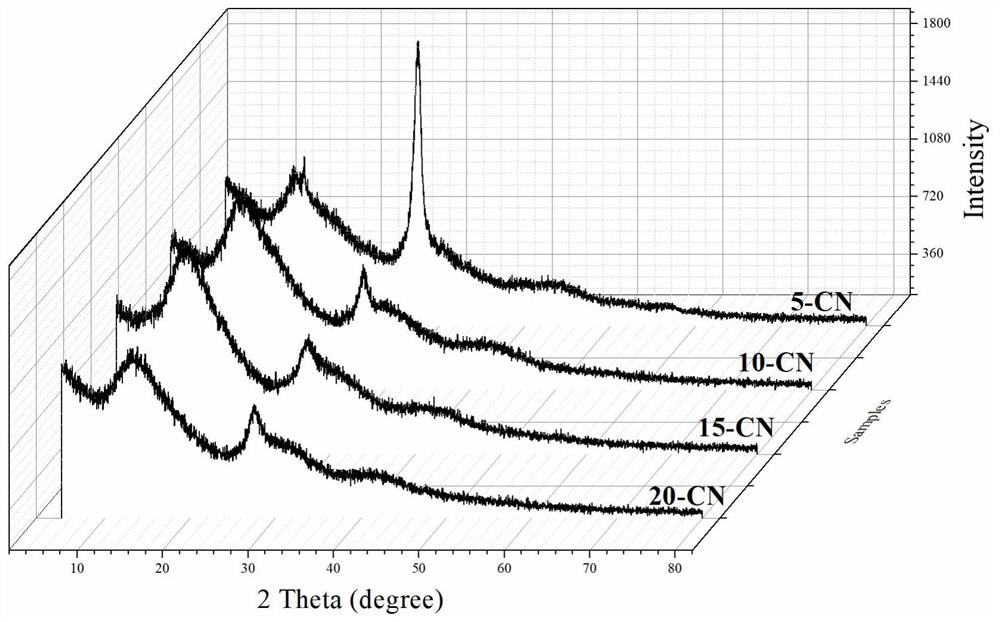

Embodiment 1

[0033] (1) Two-dimensional porous few-layer g-C 3 N 4 Precursor preparation:

[0034] Put 10g of urea into an alumina crucible, heat it in a muffle furnace at a temperature of 550°C, and heat up at a rate of 5°C / min, and calcine it for 4 hours;

[0035] (2) Two-dimensional porous few-layer g-C 3 N 4 Preparation of intermediates:

[0036] A certain amount of g-C3 N 4 The precursor was ultrasonically dispersed in water for 10 minutes, and quickly placed in a liquid nitrogen environment for 30 seconds of freezing treatment, which was recorded as 1 ultrasonic-freezing cycle, and this cycle was repeated 5 times;

[0037] (3) Two-dimensional porous few-layer g-C 3 N 4 Preparation of nanosheet photocatalyst:

[0038] Put the frozen-treated intermediate obtained in step (2) into an alumina crucible, heat it in a muffle furnace at a high temperature of 500°C, and heat up at a rate of 5°C / min, and calcinate it for 2 hours, and name it 5-CN;

[0039] (4) Take the two-dimensional...

Embodiment 2

[0041] (1) Two-dimensional porous few-layer g-C 3 N 4 Precursor preparation:

[0042] Put 10g of urea into an alumina crucible, heat it in a muffle furnace at a temperature of 550°C, and heat up at a rate of 5°C / min, and calcine it for 4 hours;

[0043] (2) Two-dimensional porous few-layer g-C 3 N 4 Preparation of intermediates:

[0044] A certain amount of g-C 3 N 4 The precursor was ultrasonically dispersed in water for 10 minutes, quickly placed in a liquid nitrogen environment and frozen for 30 seconds, recorded as 1 ultrasonic-freezing cycle and repeated this cycle 10 times;

[0045] (3) Two-dimensional porous few-layer g-C 3 N 4 Preparation of nanosheet photocatalyst:

[0046] Put the frozen-treated intermediate obtained in step (2) into an alumina crucible, heat it in a muffle furnace at a high temperature of 500°C, and heat up at a rate of 5°C / min, and calcinate it for 2 hours, and name it 10-CN; (4) Take the two-dimensional porous few-layer g-C in step (3) ...

Embodiment 3

[0048] (1) Two-dimensional porous few-layer g-C 3 N 4 Precursor preparation:

[0049] Put 10g of urea into an alumina crucible, heat it in a muffle furnace at a temperature of 550°C, and heat up at a rate of 5°C / min, and calcine it for 4 hours;

[0050] (2) Two-dimensional porous few-layer g-C 3 N 4 Preparation of intermediates:

[0051] A certain amount of g-C 3 N 4 The precursor was ultrasonically dispersed in water for 10 minutes, quickly placed in a liquid nitrogen environment and frozen for 30 seconds, and underwent 15 ultrasonic-freezing cycles;

[0052] (3) Two-dimensional porous few-layer g-C 3 N 4 Preparation of nanosheet photocatalyst:

[0053] Put the frozen-treated intermediate obtained in step (2) into an alumina crucible, heat it in a muffle furnace at a high temperature of 500°C, and heat up at a rate of 5°C / min, and calcinate it for 2 hours, and name it 15-CN;

[0054] (4) Take the two-dimensional porous few-layer g-C in step (3) 3 N 4 0.03 g and 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com