Preparation method and application of two-dimensional ZnO/g-C3N4 composite photocatalyst

A technology of g-c3n4 and compound light, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high compounding efficiency and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

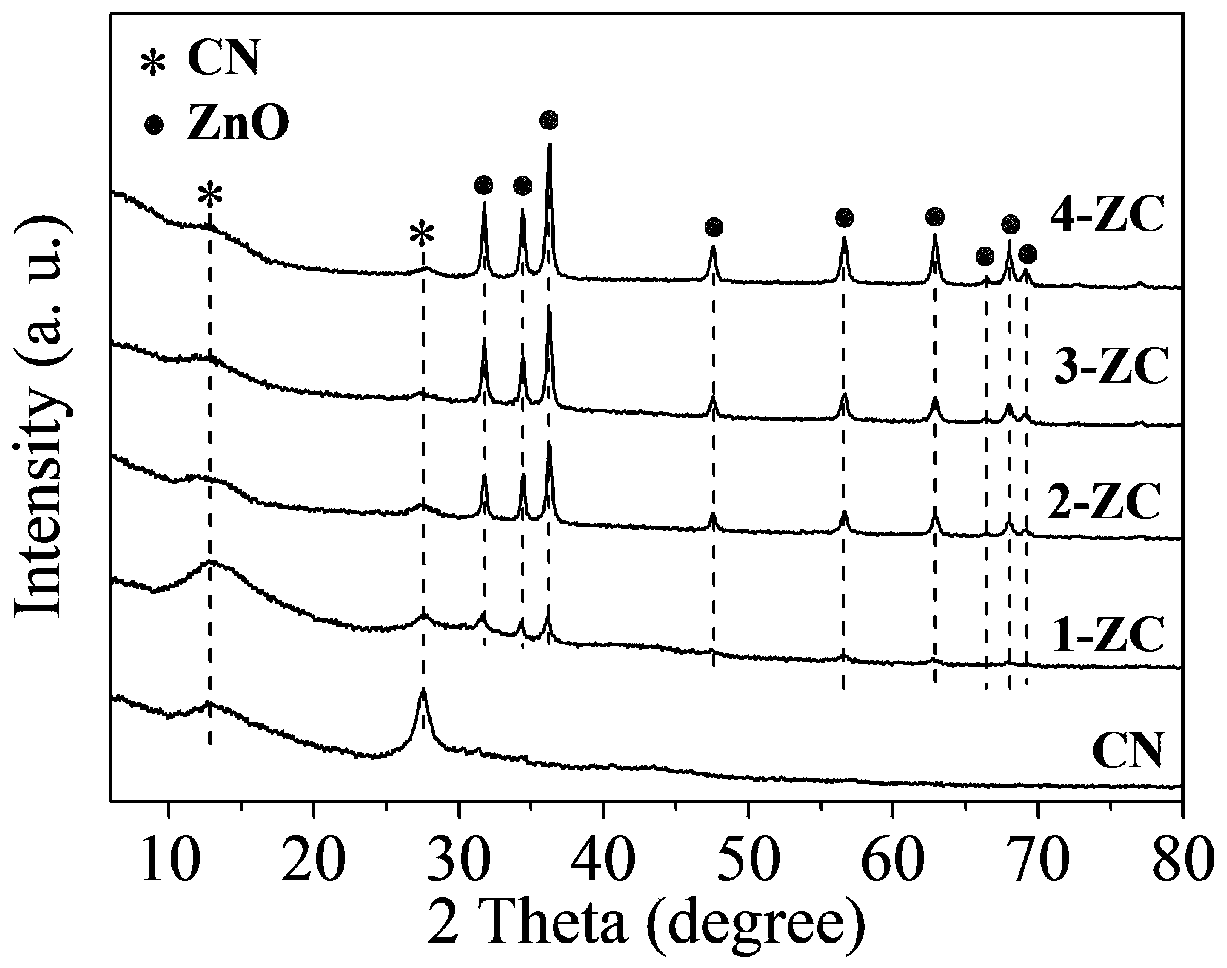

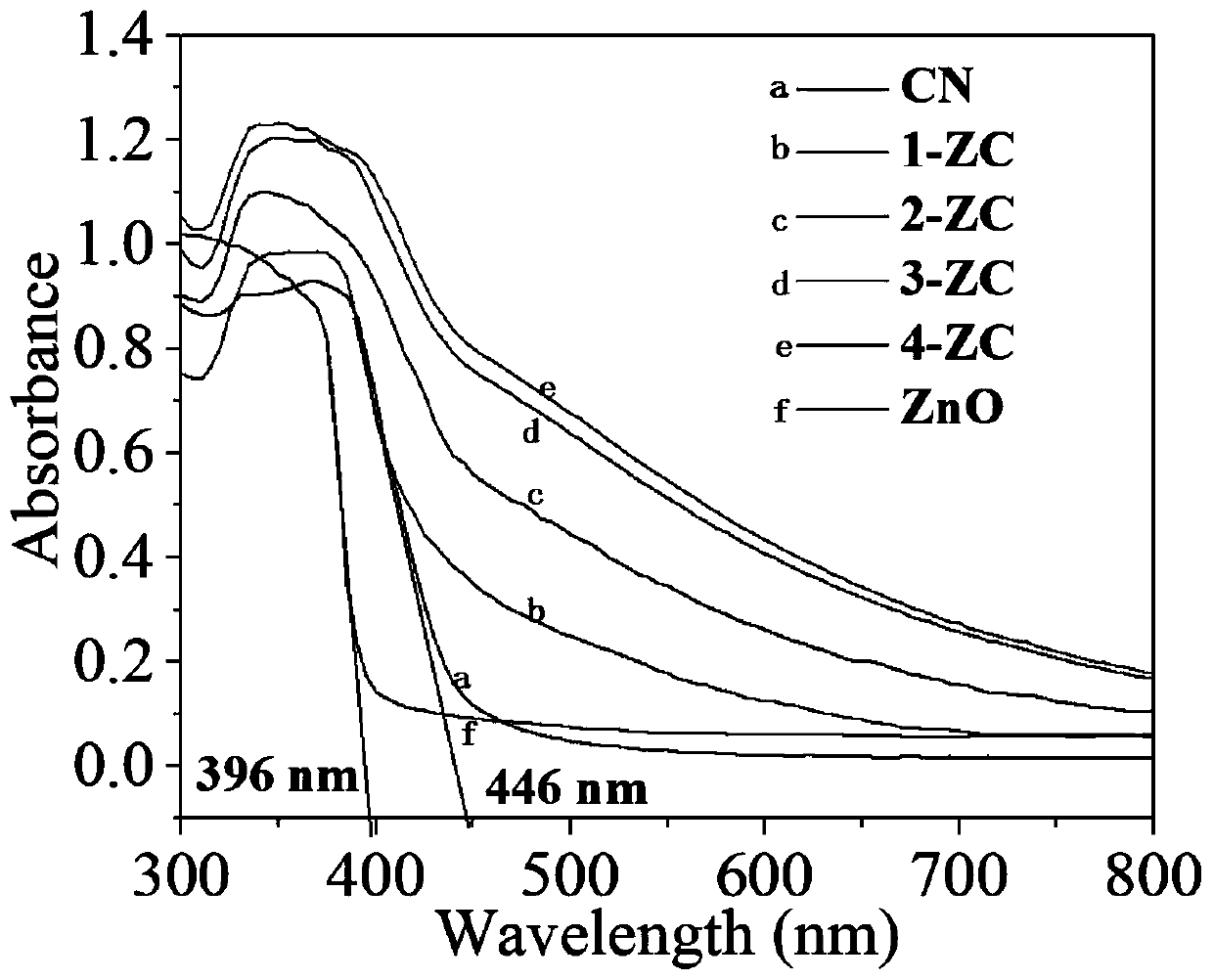

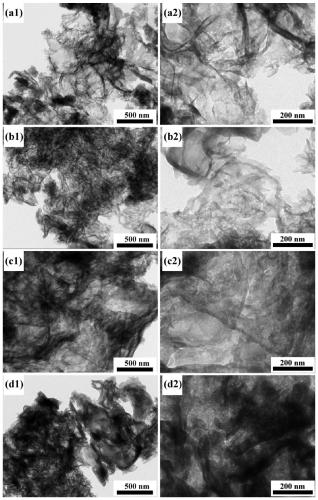

Method used

Image

Examples

Embodiment 1

[0029] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0030] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0031] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0032] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed with water several times (to neutral), dried in vacuum at 60°C, and then calcined for 2 hours at 500°C. After cooling to room temperature, the two-dimensional thin layer g-C can be obtained by grinding 3 N 4 Nanosheets.

[0033] (3) Two-dimensional ZnO / g-C 3 N 4 Preparation of composite photocatalyst:

[0034] The Zn (AC 2 ) in the solution and ultrasonically mixed for 30min until completely dispersed, and 50ml of C with a concentration of 0.8mol / ...

Embodiment 2

[0037] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0038] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0039] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0040] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed with water several times, dried in vacuum at 60°C, and then calcined for 2 hours at 500°C (the heating rate was 5°C / min), after being cooled to room temperature, the two-dimensional thin layer g-C can be obtained by grinding 3 N 4 Nanosheets.

[0041] (3) Two-dimensional ZnO / g-C 3 N 4 Preparation of composite photocatalyst:

[0042] It is the Zn(AC) of 0.6mol / L that the sample gained in 200mg (2) is added to 50ml concentration 2 The solution was ...

Embodiment 3

[0045] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0046] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0047] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0048] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed with water for several times, dried in vacuum at 60°C, and then calcined for a second time at 500°C for 2 hours, and then cooled to room temperature , Grinding to get two-dimensional thin layer g-C 3 N 4 Nanosheets.

[0049] (3) Two-dimensional ZnO / g-C 3 N 4 Preparation of composite photocatalyst:

[0050] It is the Zn(AC) of 0.8mol / L that the sample gained in 200mg (2) is added to 50ml concentration 2 The solution was mixed and ultrasonicated for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com