CdS/MIL-101 (Cr) photocatalyst modified PVDF ultrafiltration membrane, preparation method and applications thereof

A photocatalyst and ultrafiltration membrane technology, applied in the field of membrane separation, to achieve the effects of reducing energy consumption and cost, easy operation and avoiding photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

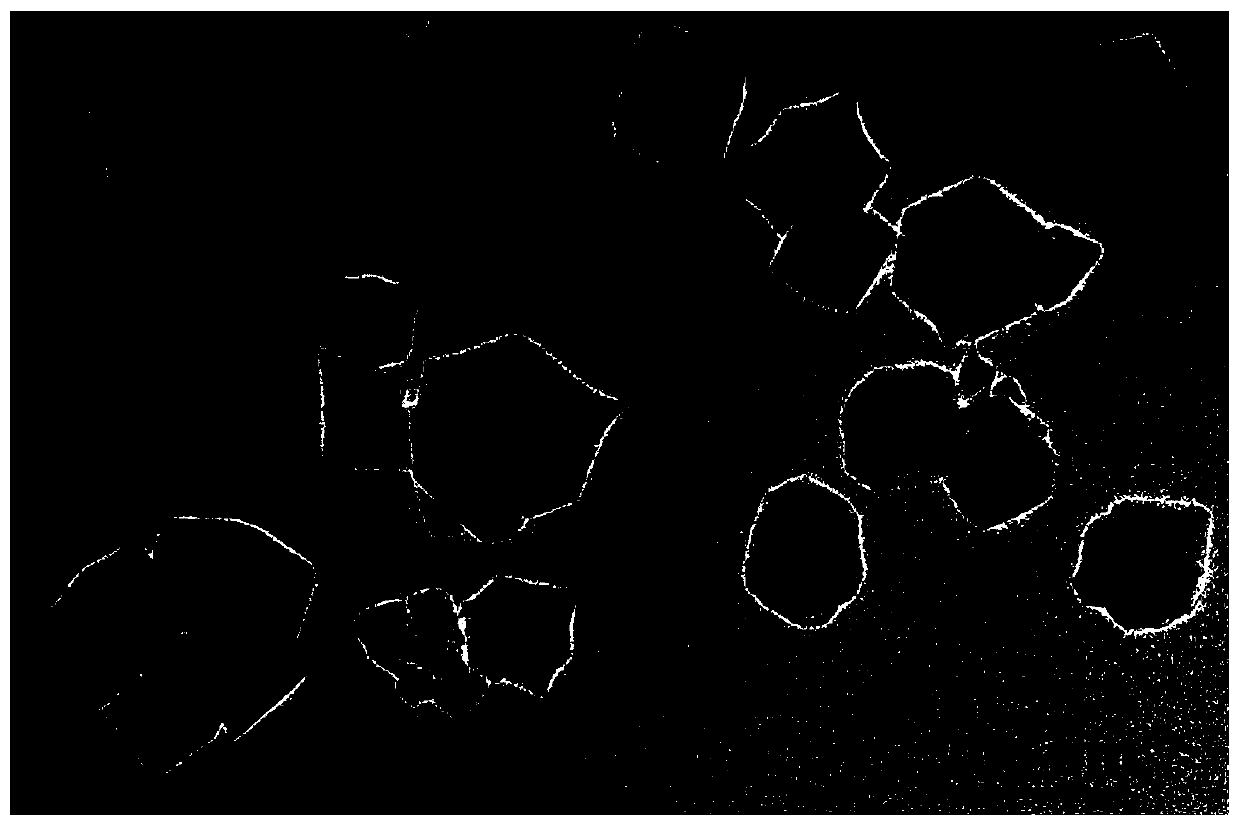

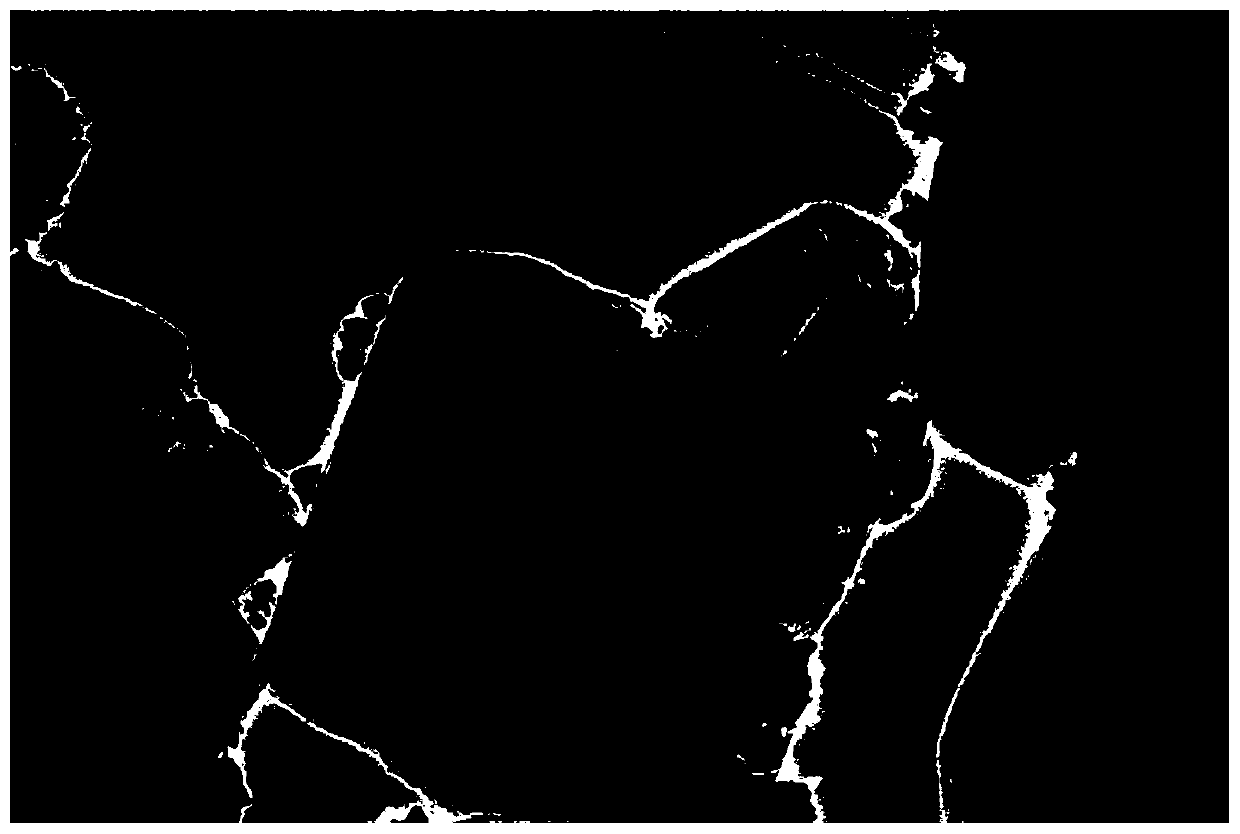

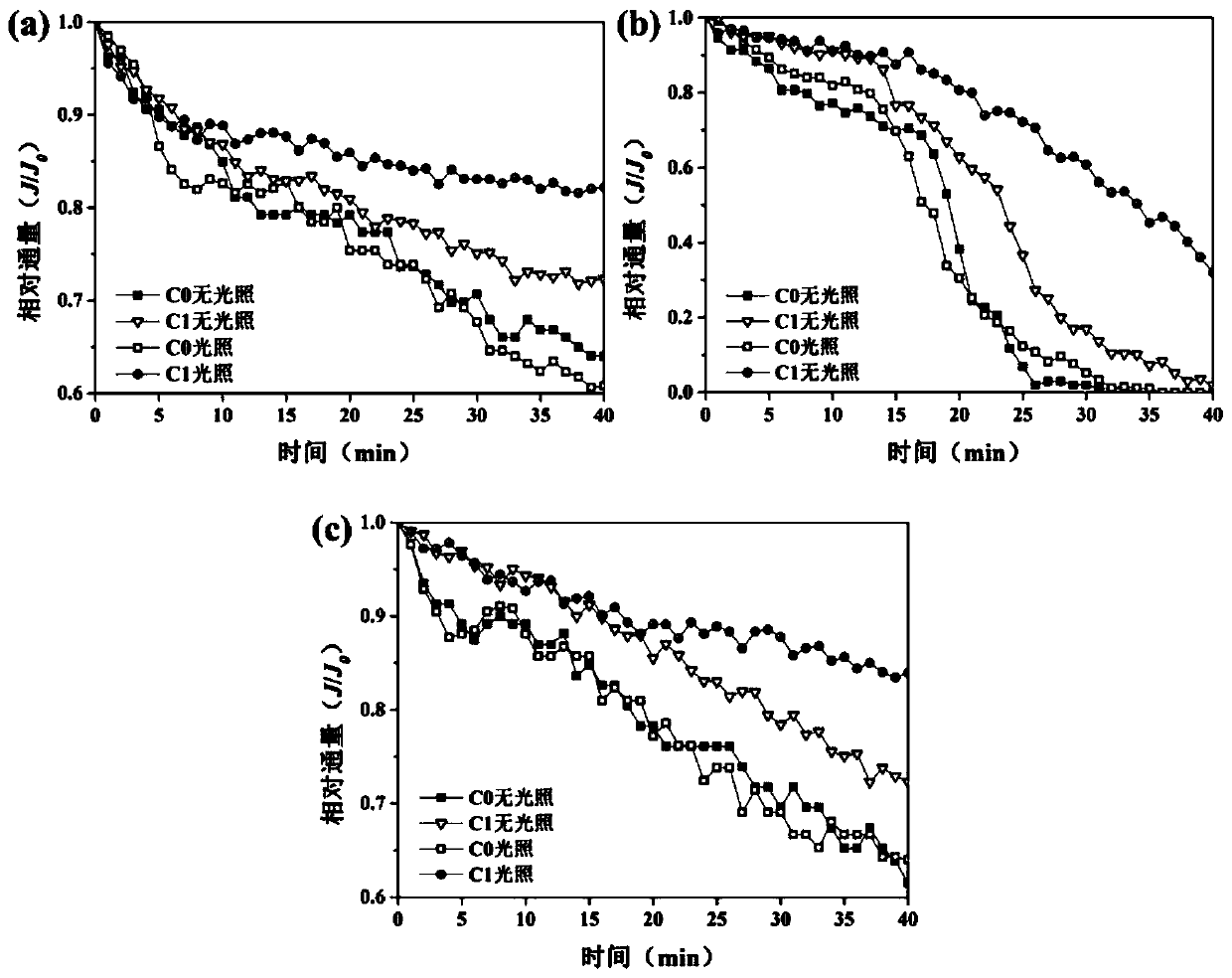

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of MIL-101(Cr) nanoparticles

[0047] Take 5g Cr(NO 3 ) 3 9H 2 O, 2g of terephthalic acid (BDC), 0.8mL of hydrofluoric acid (HF) and 70mL of deionized water were mixed and transferred to a high-temperature and high-pressure reactor for hydrothermal reaction at 210°C for 5h; after natural cooling, the mixture was heated at 8000rpm Centrifuge for 10 min, wash the obtained solid material three times with water and ethanol respectively; the washed product is redispersed in 100 mL of N,N-dimethylformamide and stirred for 12 h for purification, and the purified solid is transferred to 100 mL of ethanol , treated at 100° C. for 10 h; finally, the product was washed three times with ethanol and dried in a vacuum oven at 100° C. to obtain purified MIL-101 (Cr) nanoparticles.

[0048] (2) Preparation of CdS / MIL-101(Cr) nano photocatalyst

[0049] Weigh 5g MIL-101(Cr) and 2.5g Cd(AC) 2 2H 2 O was dispersed in 50mL dimethyl sulfoxide (DMSO), and the suspension...

Embodiment 2

[0060] (1) Preparation of MIL-101(Cr) nanoparticles

[0061] Take 4.8g Cr(NO 3 ) 3 9H 2 O, 1.9g of terephthalic acid (BDC), 0.6mL of hydrofluoric acid (HF) and 60mL of deionized water were mixed and transferred to a high-temperature and high-pressure reactor for hydrothermal reaction at 205°C for 6h; after natural cooling, the mixture was Centrifuge at 7500rpm for 15min, wash the obtained solid material three times with water and ethanol respectively; redisperse the washed product in 90mL N,N-dimethylformamide and stir for 11h for purification, and transfer the purified solid to 90mL ethanol , treated at 90°C for 11 h; finally, the product was washed three times with ethanol and dried in a vacuum oven at 90°C to obtain purified MIL-101(Cr) nanoparticles.

[0062] (2) Preparation of CdS / MIL-101(Cr) nano photocatalyst

[0063] Weigh 4.5g MIL-101(Cr) and 2g Cd(AC) 2 2H 2 O was dispersed in 45mL dimethyl sulfoxide (DMSO), and the suspension was transferred to a high-temperat...

Embodiment 3

[0071] (1) Preparation of MIL-101(Cr) nanoparticles

[0072] Take 4.5g Cr(NO 3 ) 3 9H 2 O, 1.8g terephthalic acid (BDC), 0.5mL hydrofluoric acid (HF) and 50mL deionized water were mixed and transferred to a high-temperature and high-pressure reactor, and hydrothermally reacted at 200°C for 7h; after natural cooling, the mixture was Centrifuge at 7000rpm for 20min, wash the obtained solid material three times with water and ethanol respectively; redisperse the washed product in 80mL N,N-dimethylformamide and stir for 10h for purification, and transfer the purified solid to 80mL ethanol at 80°C for 12h; finally, the product was washed three times with ethanol and dried in a vacuum oven at 80°C to obtain purified MIL-101(Cr) nanoparticles.

[0073] (2) Preparation of CdS / MIL-101(Cr) nano photocatalyst

[0074] Weigh 4g MIL-101(Cr) and 1.3g Cd(AC) 2 2H 2 O was dispersed in 40mL dimethyl sulfoxide (DMSO), and the suspension was transferred to a high-temperature and high-press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com