Method for preparing eggshell membrane/graphene/polymer composite flexible supercapacitor

A supercapacitor, graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of no eggshell film/graphene/polymer flexible supercapacitor preparation method, etc., and achieve the cost of raw materials Low cost, improved specific capacitance, small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

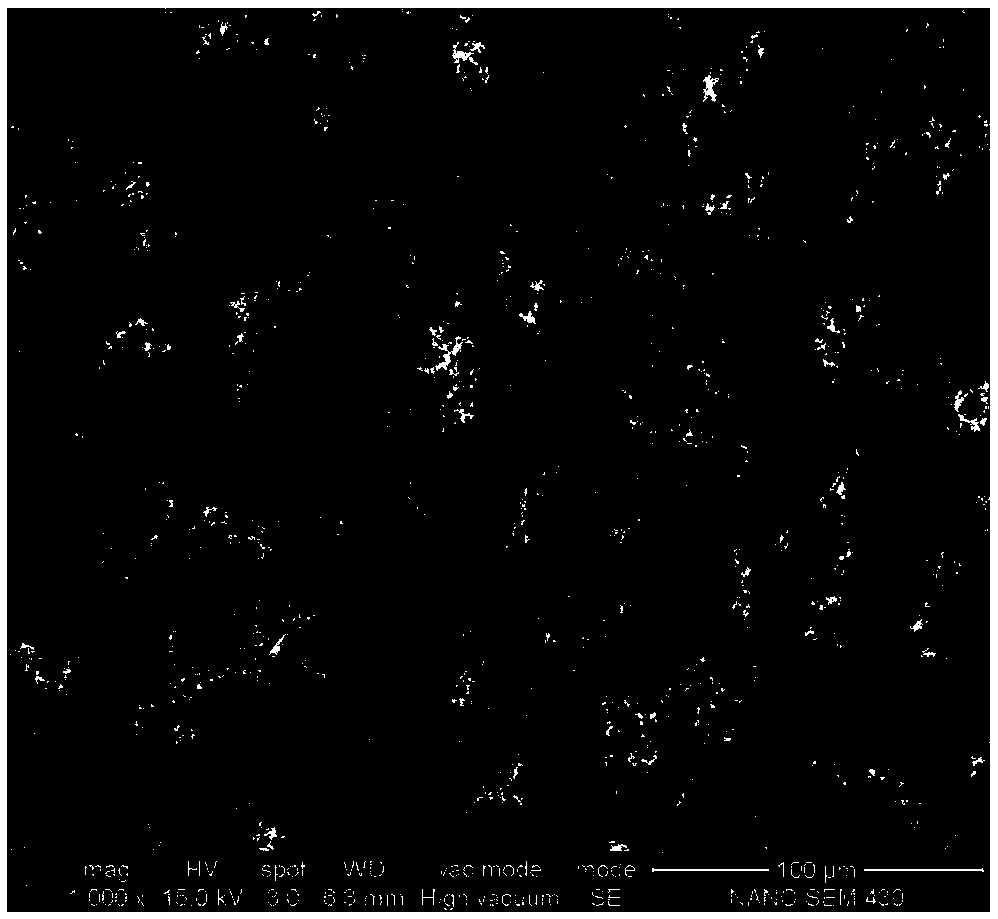

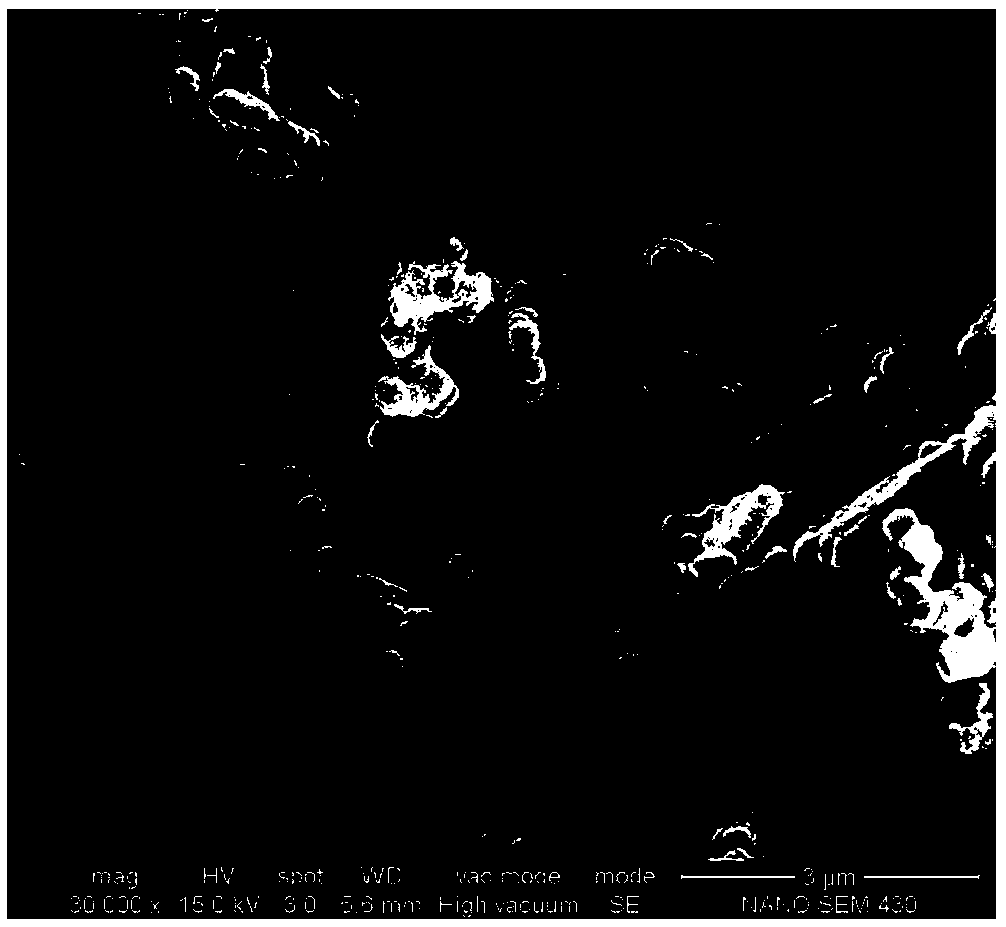

[0022] Place the eggshell in 1M hydrochloric acid to remove the outer layer of CaCO 3 , to obtain eggshell membranes, wash them with acetone-ethanol mixture, and dry them at 50°C. The purified eggshell membrane was placed in ferric chloride solution, and after 2 hours, the pyrrole monomer was added dropwise in an ice-water bath. After 6 hours of reaction, the eggshell membrane / polypyrrole composite electrode was obtained, and the single electrode was measured by an electrochemical workstation. The specific capacitance Cs is 110F / g.

Embodiment 2

[0024] The post-treated eggshell membrane was purified eggshell membrane (1 × 1cm 2 ) in a 0.4wt% graphene oxide solution for 30 minutes by a simple impregnation method, add an appropriate amount of hydrazine hydrate to the prepared eggshell membrane / graphene oxide, adjust the pH of the solution to about 10 with ammonia water, and react for 1-3 hours to obtain the eggshell membrane / graphene oxide Shell membrane / graphene. After drying, it was immersed in ferric chloride solution for 24 hours, then pyrrole monomer was added dropwise, and reacted in an ice-water bath for 6 hours to obtain eggshell membrane / graphene / polypyrrole composite material. Take two electrode materials of equal mass, use PVA-phosphoric acid as the electrolyte, and assemble them into a "sandwich" solid supercapacitor. The specific capacitance Cs of the single electrode is 152F / g measured by an electrochemical workstation.

Embodiment 3

[0026] The post-treated eggshell membrane was purified eggshell membrane (1 × 1cm 2 ) was immersed in 0.4wt% graphene oxide solution for 60 minutes by a simple impregnation method, and an appropriate amount of hydrazine hydrate was added to the prepared eggshell membrane / graphene oxide, and the pH of the solution was adjusted to about 10 with ammonia water, and the reaction was carried out for 1-3 hours to obtain eggshell membrane / graphene oxide. Shell membrane / graphene. After drying, it was immersed in ferric chloride solution for 24 hours, then pyrrole monomer was added dropwise, and reacted in an ice-water bath for 6 hours to obtain eggshell membrane / graphene / polypyrrole composite material. Take two electrode materials of equal mass, use PVA-phosphoric acid as the electrolyte, and assemble them into a "sandwich" solid supercapacitor. The specific capacitance Cs of the single electrode measured by the electrochemical workstation is 196F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com