Modified carbon nitride and tungsten oxide coupled p-n type heterojunction composite material and preparation method and application thereof

A technology of composite materials and carbon nitride, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems that the photocatalytic performance needs to be greatly improved, achieve excellent photocatalytic bactericidal activity, reduce The effect of reaction energy consumption and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ordinary carbon nitride (g-C 3 N 4 ) preparation method:

[0034] Grind 4g of melamine, raise the temperature to 520°C in a tube furnace fed with nitrogen for 100min, then calcinate at 520°C for 2h, raise the temperature to 540°C for 20min and keep it for 2h, and finally cool down to room temperature for 100min.

[0035] Modified carbon nitride (g-C 3 N 4 -m) preparation method:

[0036] Mix 1g of melamine and 3g of triaminopyrimidine in a mortar and grind them evenly, raise the temperature from 100°C to 520°C in a tube furnace fed with nitrogen, keep the temperature at 520°C for 2 hours, raise the temperature to 540°C for 20 minutes and keep it for 2 hours, and finally 100 minutes Bring to room temperature.

[0037] WO 3 The preparation method:

[0038] 4gH 2 WO 4 It was calcined in a muffle furnace at 520°C for 2h, and the heating time was 100min, then it was raised to 540°C for 2h in 20min, and then cooled to room temperature for 100min.

[0039] g-C 3 N 4 ...

Embodiment 2

[0045] Each g-C synthesized by calcining in embodiment 1 3 N 4 -m / WO 3 The practical application effect of visible light photocatalytic bactericidal active materials was tested. The concentration in E.Coil is 2×10 7 Add 50mg of the target photocatalytic fungicide to 50mL of CFU / mL physiological saline solution. 2 Irradiate under visible light for 2 hours to kill the bacteria and then take samples. Spread the diluted bacterial solution on the solid medium and put it in a constant temperature incubator for 24 hours. The temperature in the constant temperature incubator is kept at 37°C. Counted by plate counting method.

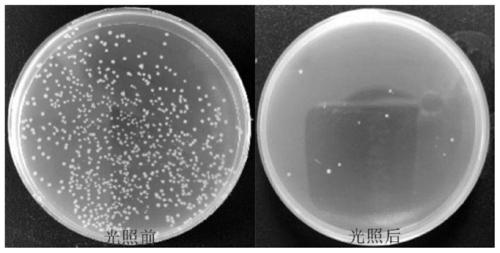

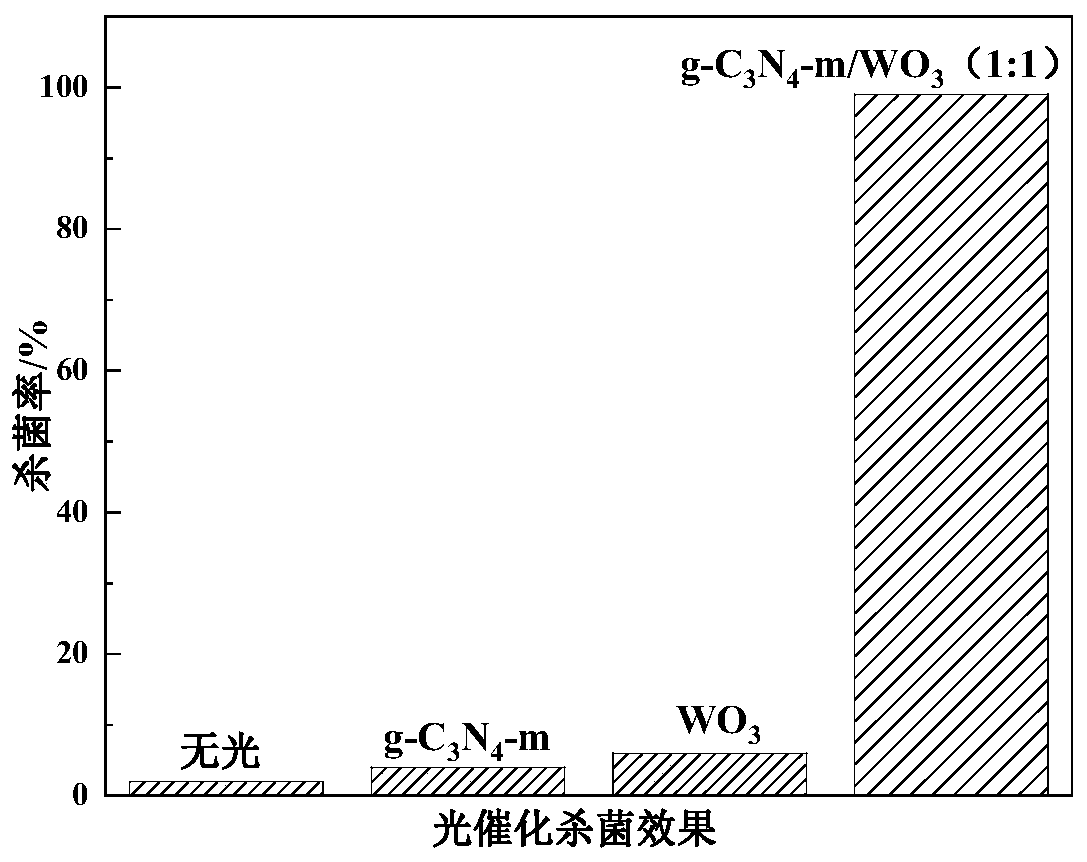

[0046] figure 1 After culturing for 24 hours, add g-C 3 N 4 -m / WO 3 (1:1) The growth of bacteria in the composite material group before and after light, it can be seen that g-C 3 N 4 -m / WO 3 (1:1) is a visible light catalyzed fungicide, which can kill Escherichia coli well after being exposed to light. figure 2 g-C prepared for Example 1 3 N 4 -m / ...

Embodiment 3

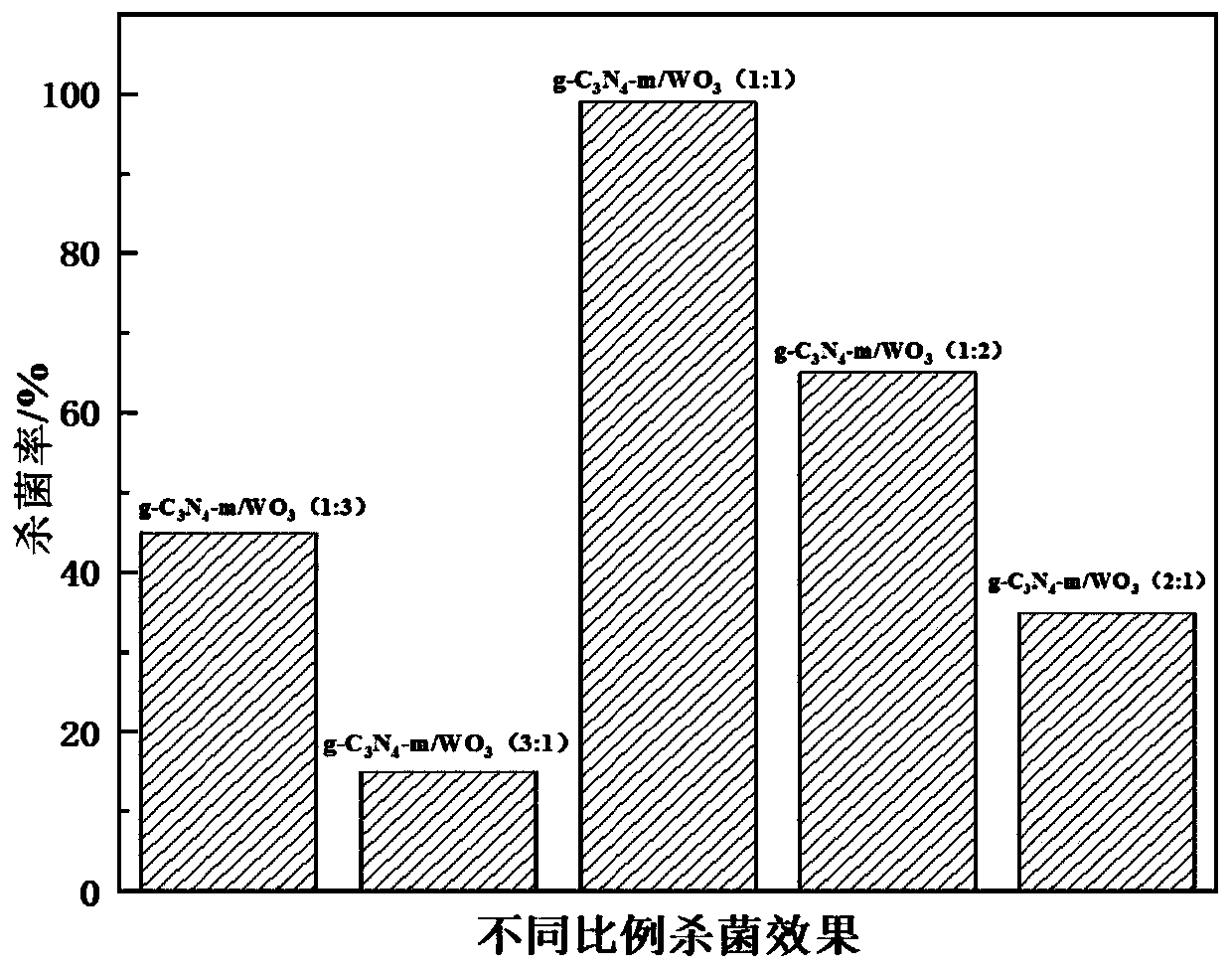

[0048] Modified Carbon Nitride and WO 3 Different ratios of different ratios can adjust the efficiency of sterilization, and different ratios affect the rate of electron separation. Adjusting the different ratios between the two and optimizing the performance of the composite material has an important impact on improving the sterilization efficiency. Very important effect, the present invention is by adjusting the ratio of the two, and adopts the sterilization method of embodiment 2 to test the bactericidal performance.

[0049] image 3 For different g-C in embodiment 1 3 N 4 -m, WO 3 g-C in mass proportion 3 N 4 -m / WO 3 The killing effect of photocatalytic fungicides on Escherichia coli can be seen that g-C 3 N 4 -m / WO 3 (1:1) has the best bactericidal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com