4-phenoxyphenol doped carbon nitride photocatalyst and preparation method and application thereof

A phenoxyphenol, carbon nitride light technology, applied in the field of photocatalysis, can solve problems such as unfavorable industrial large-scale production, cumbersome preparation process, long preparation time, etc., and achieves improved photocatalytic performance, simple synthesis method, and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation of 4-phenoxyphenol doped carbon nitride photocatalyst comprises the following specific steps:

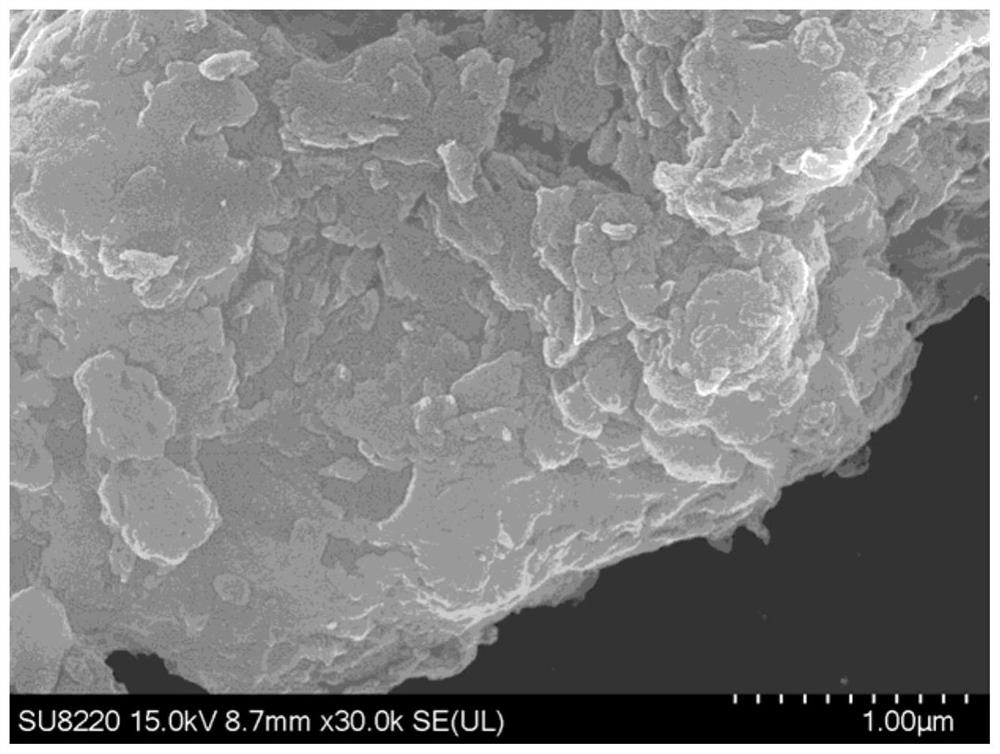

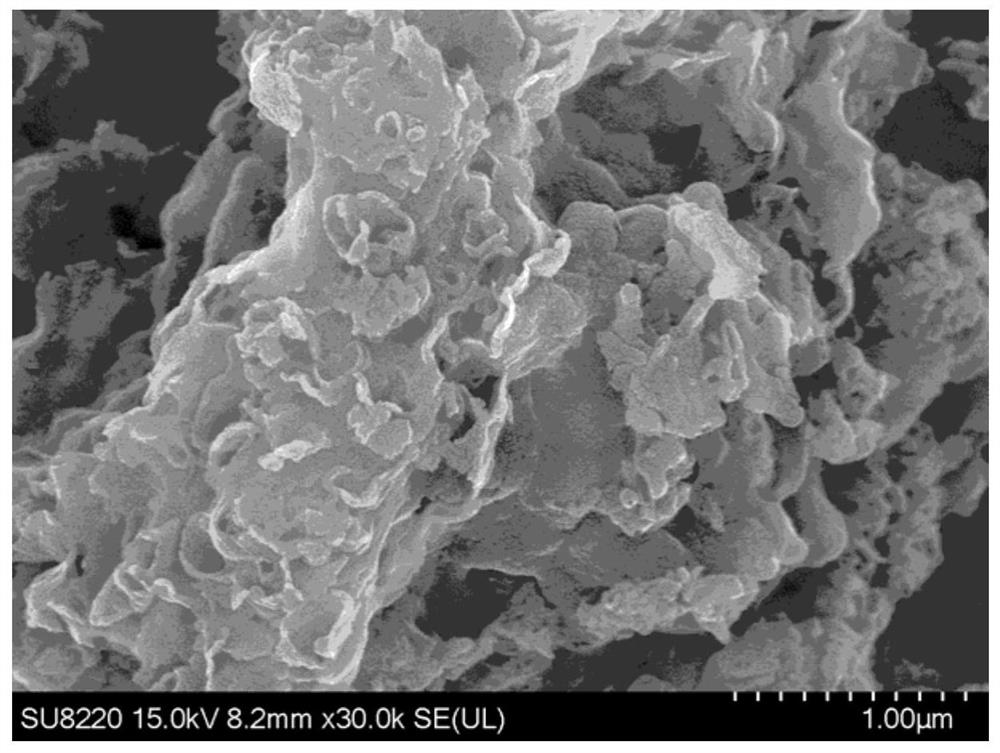

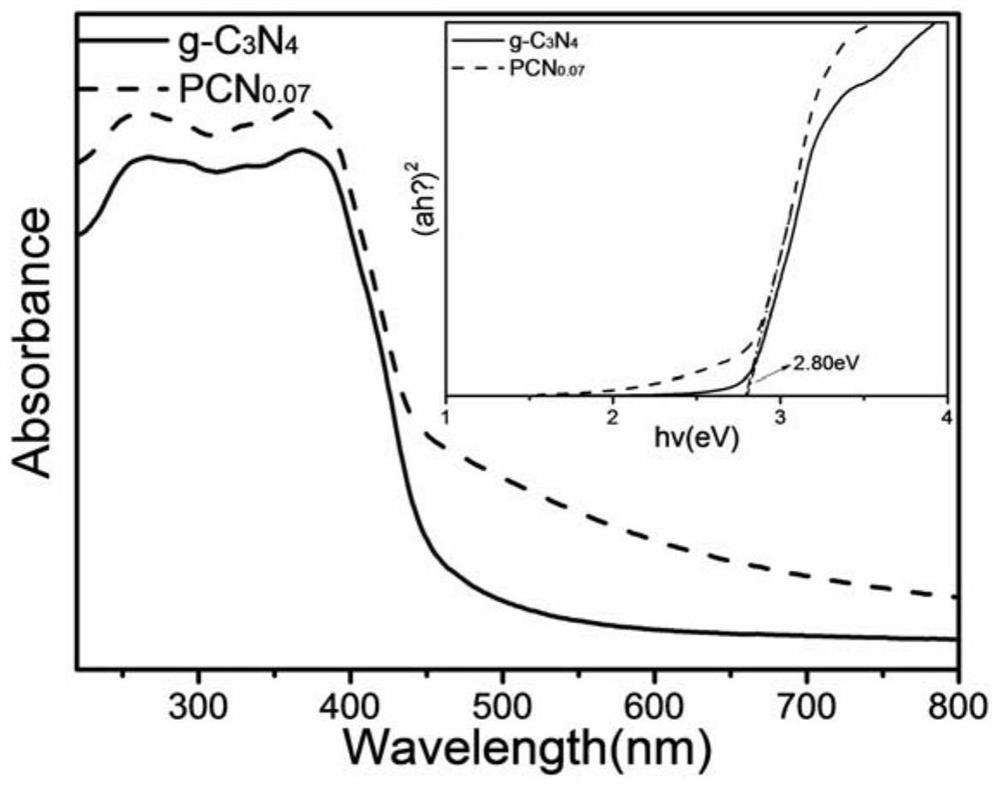

[0034] Disperse 3.0g of dicyandiamide and 0.01g of 4-phenoxyphenol in 20mL of absolute ethanol respectively, after mixing, stir magnetically at room temperature for 60min, ultrasonically for 30min, then heat and evaporate to dryness under magnetic stirring at 60-80°C , the obtained solid was calcined in a muffle furnace at 540-550°C for 4h, the heating rate was 5°C / min, and the 4-phenoxyphenol-doped carbon nitride photocatalyst PCN was obtained 0.01 .

Embodiment 2

[0036] A kind of preparation of 4-phenoxyphenol doped carbon nitride photocatalyst comprises the following specific steps:

[0037] Disperse 3.0g of dicyandiamide and 0.03g of 4-phenoxyphenol in 20mL of absolute ethanol respectively, after mixing, stir magnetically at room temperature for 60min, ultrasonically for 30min, then heat and evaporate to dryness under magnetic stirring at 60-80°C , the obtained solid was calcined in a muffle furnace at 540-550°C for 4h, the heating rate was 5°C / min, and the 4-phenoxyphenol-doped carbon nitride photocatalyst PCN was obtained 0.03 .

Embodiment 3

[0039] A kind of preparation of 4-phenoxyphenol doped carbon nitride photocatalyst comprises the following specific steps:

[0040]Separately disperse 3.0g of dicyandiamide and 0.05g of 4-phenoxyphenol in 20mL of absolute ethanol. After mixing, stir magnetically at room temperature for 60min, ultrasonicate for 30min, then heat and evaporate to dryness under magnetic stirring at 60-80°C , the obtained solid was calcined in a muffle furnace at 540-550°C for 4h, the heating rate was 5°C / min, and the 4-phenoxyphenol-doped carbon nitride photocatalyst PCN was obtained 0.05 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com