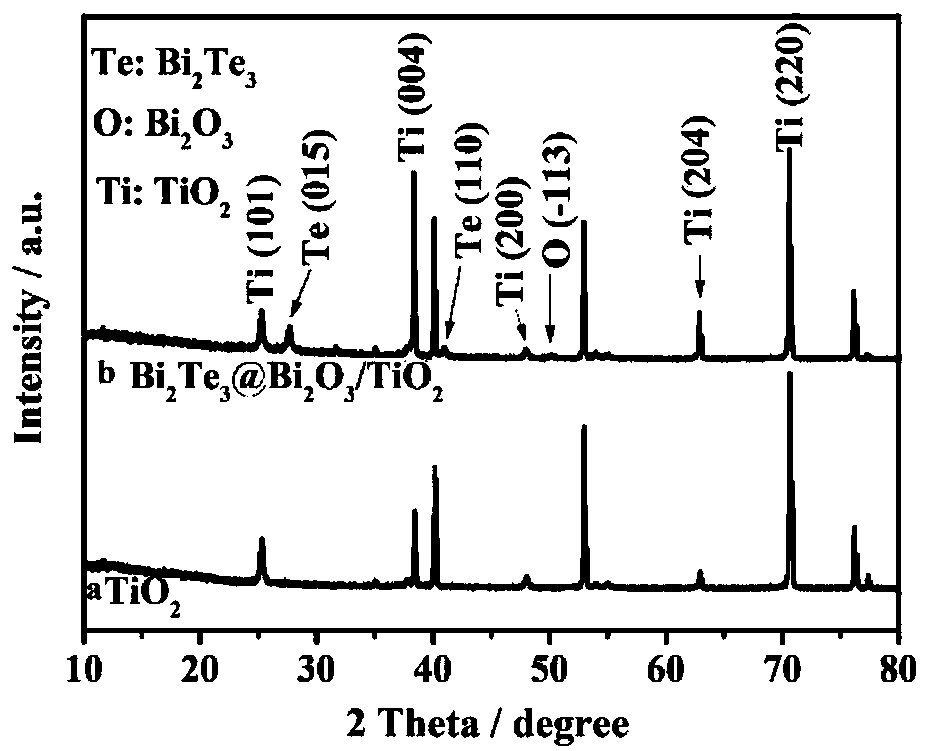

Preparation method of Bi2Te3/Bi2O3/TiO2 ternary heterojunction film

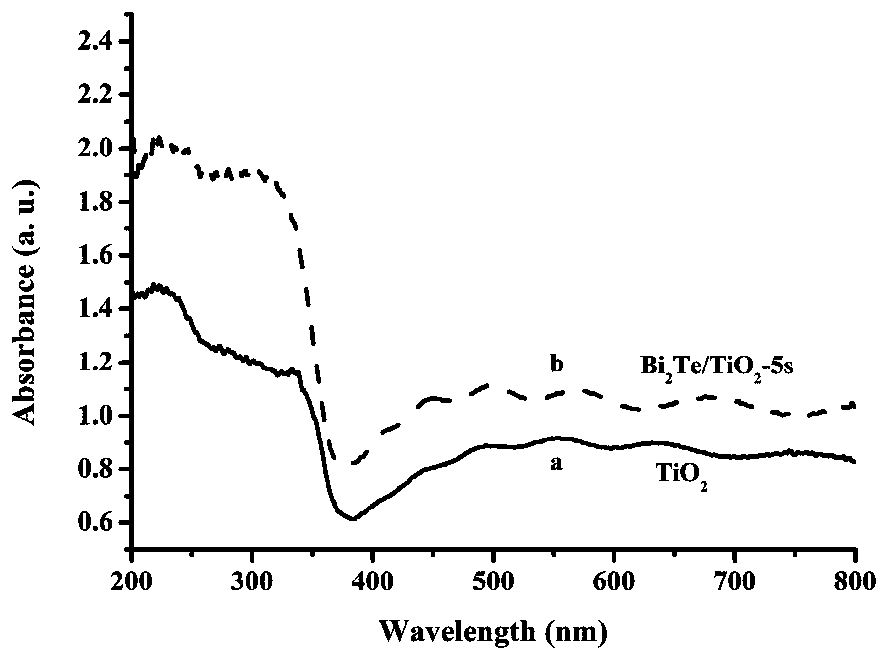

A heterojunction and thin-film technology, applied in the field of nanomaterials, can solve the problems of low utilization rate of sunlight and achieve the effects of simple preparation process, regular shape and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Cut a commercially available titanium plate (purity greater than 99.5%) into a sample of 0.3mm×10mm×20mm, and use pure water and acetone to repeatedly ultrasonically clean it several times, each time for 20 minutes, to remove inorganic or organic particles on the surface of the sample. Impurities, dry at room temperature for later use.

[0042] First, 0.9g ammonium fluoride (NH 4 F) Dissolve in 5mL pure water, then add 12mL hydrogen peroxide (H 2 o 2 ) and 12mL nitric acid (concentration of 65% HNO 3 ) and stir it evenly with a magnetic stirrer to obtain a polishing solution. Immerse the titanium plate sample in the polishing solution, and chemically polish until the surface of the sample is uniform, smooth and free of impurities. After taking it out, alternately ultrasonically clean it twice with pure water and absolute ethanol, each time for 10 minutes, to obtain a clean titanium plate sample.

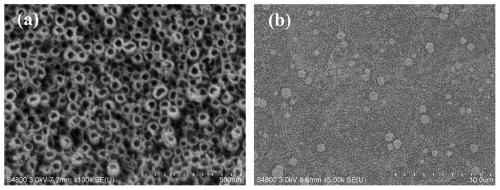

[0043] Preparation of TiO on the surface of titanium plate sample 2...

Embodiment 2

[0054] Cut a commercially available titanium plate (purity greater than 99.5%) into a sample of 0.3mm×10mm×20mm, and use pure water and acetone to repeatedly ultrasonically clean it several times, each time for 20 minutes, to remove inorganic or organic particles on the surface of the sample. Impurities, dry at room temperature for later use.

[0055] First, 0.9g ammonium fluoride (NH 4 F) Dissolve in 5mL pure water, then add 12mL hydrogen peroxide (H 2 o 2 ) and 12mL nitric acid (concentration of 65% HNO 3 ) and stir it evenly with a magnetic stirrer to obtain a polishing solution. Immerse the titanium plate sample in the polishing solution, and chemically polish until the surface of the sample is uniform, smooth and free of impurities. After taking it out, alternately ultrasonically clean it twice with pure water and absolute ethanol, each time for 10 minutes, to obtain a clean titanium plate sample.

[0056] Preparation of TiO on the surface of titanium plate sample 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com