Preparation method of AgBr/Ag2CrO4 n-n hetero-junction composite photocatalyst

A heterojunction, silver chromate technology, applied in the field of photocatalytic materials, can solve the problems of easy recombination of electrons and holes, reduced photocatalytic effect, narrow band gap, etc. Catalytic effect, good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

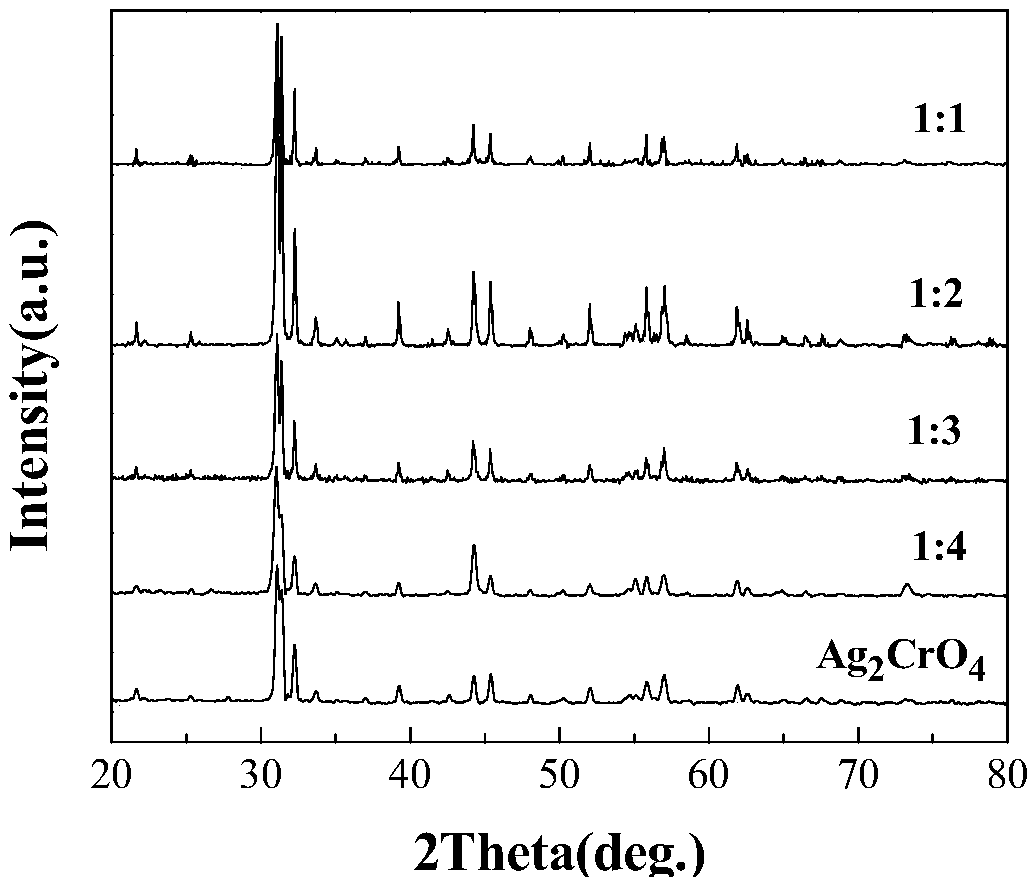

[0032] 1) In the dark condition, 0.006moLAgNO 3 Disperse in 25mL deionized water and stir to form mixed solution A; 0.003molNa 2 CrO 4 4H 2 O was dispersed in 25 mL of deionized water to form solution B, and then solution B was added dropwise to solution A and stirred for 1 h, then allowed to stand for 4 h, the product was washed several times with deionized water and absolute ethanol, and dried at 60 °C for 10 h.

[0033] 2) Add 0.003moL of the above-prepared Ag 2 CrO 4 Disperse in 25mL of deionized water; then add 20mL of 0.1mol / L KBr solution dropwise, stir for 4h and then let it stand, the product was washed several times with deionized water and absolute ethanol, and dried at 60°C for 10h. Obtain AgBr / Ag with a molar ratio of 1:1 2 CrO 4 .

Embodiment 2

[0035] 1) In the dark condition, 0.006moLAgNO 3 Disperse in 25mL deionized water and stir to form mixed solution A; 0.003molNa 2 CrO 4 4H 2 O was dispersed in 25 mL of deionized water to form solution B, and then solution B was added dropwise to solution A and stirred for 1 h, then allowed to stand for 4 h, the product was washed several times with deionized water and absolute ethanol, and dried at 60 °C for 10 h.

[0036] 2) Add 0.003moL of the above-prepared Ag 2 CrO 4 Disperse in 25mL of deionized water; then add 12mL of 0.1mol / L KBr solution dropwise, stir for 4h and then let stand, the product was washed several times with deionized water and absolute ethanol, and dried at 60°C for 10h. Obtain AgBr / Ag with a molar ratio of 1:2 2 CrO 4 .

Embodiment 3

[0038] 1) In the dark condition, 0.006moLAgNO 3 Disperse in 25mL deionized water and stir to form mixed solution A; 0.003molNa 2 CrO 4 4H 2 O was dispersed in 25 mL of deionized water to form solution B, and then solution B was added dropwise to solution A and stirred for 1 h, then allowed to stand for 4 h, the product was washed several times with deionized water and absolute ethanol, and dried at 60 °C for 10 h.

[0039] 2) Add 0.003moL of the above-prepared Ag 2 CrO 4 Disperse in 25mL of deionized water; then add 8.5mL of 0.1mol / L KBr solution dropwise, stir for 4h and then let stand, the product was washed several times with deionized water and absolute ethanol, and dried at 60°C for 10h. Obtain AgBr / Ag with a molar ratio of 1:3 2 CrO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com