Visible light response type Zn2TiO4/g-C3N4 heterojunction material and application thereof

A g-c3n4, visible light technology, used in chemical/physical processes, ammonia preparation/separation, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, inability to get rid of organic scavengers or sacrificial agents, and high production costs , to achieve the effect of simple operation, good photocatalytic nitrogen fixation and ammonia production, and promotion of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

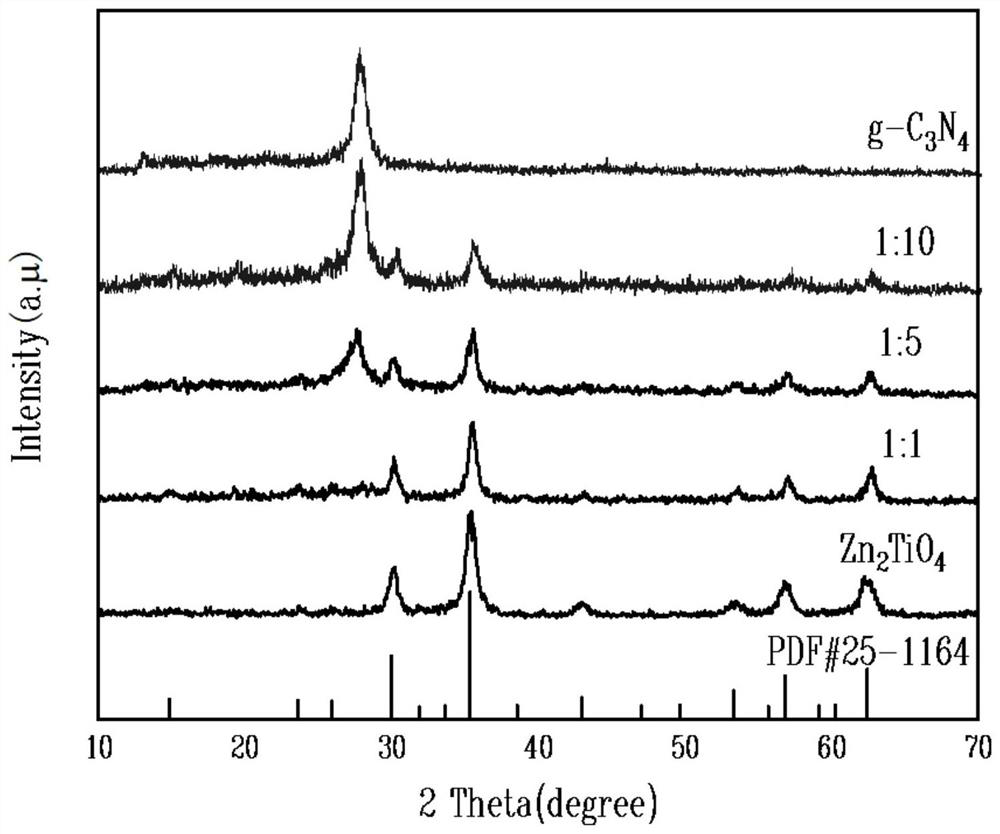

[0020] Example 1 Visible light responsive Zn 2 TiO 4 / g -C 3 N 4 The preparation method of heterojunction material (1) is as follows:

[0021] 1. Preparation of pure g-C 3 N 4

[0022] Spread 1 g of melamine in a covered quartz crucible, raise the temperature to 600 °C at a rate of 5 °C / min, heat for 2 h under nitrogen protection, then cool to room temperature, grind it into powder, and collect it for later use.

[0023] 2. Preparation of pure Zn 2 TiO 4

[0024] Dissolve 0.874g of zinc nitrate hexahydrate in 10ml of absolute ethanol, then add 2ml of glacial acetic acid, stir at room temperature for 30min, add 1ml of tetra-n-butyl titanate dropwise to the resulting mixed solution, continue stirring for 30min, and dissolve the resulting solution After aging for 24 hours, dry at 80°C overnight to obtain an intermediate product; the obtained intermediate product is placed in a muffle furnace, heated to 600°C at a heating rate of 5°C / min in an air environment, calcined at...

Embodiment 2

[0031] Example 2 Zn 2 TiO 4 / g -C 3 N 4 Application of heterojunction materials in catalytic nitrogen fixation under visible light irradiation (1) The method is as follows:

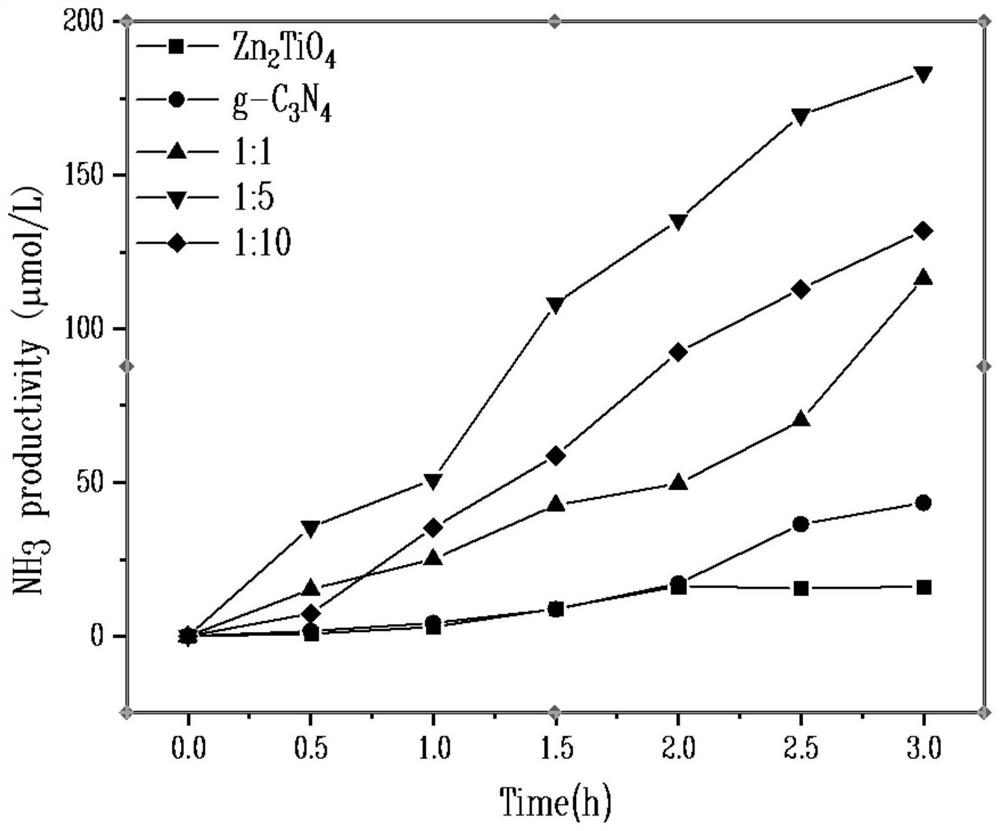

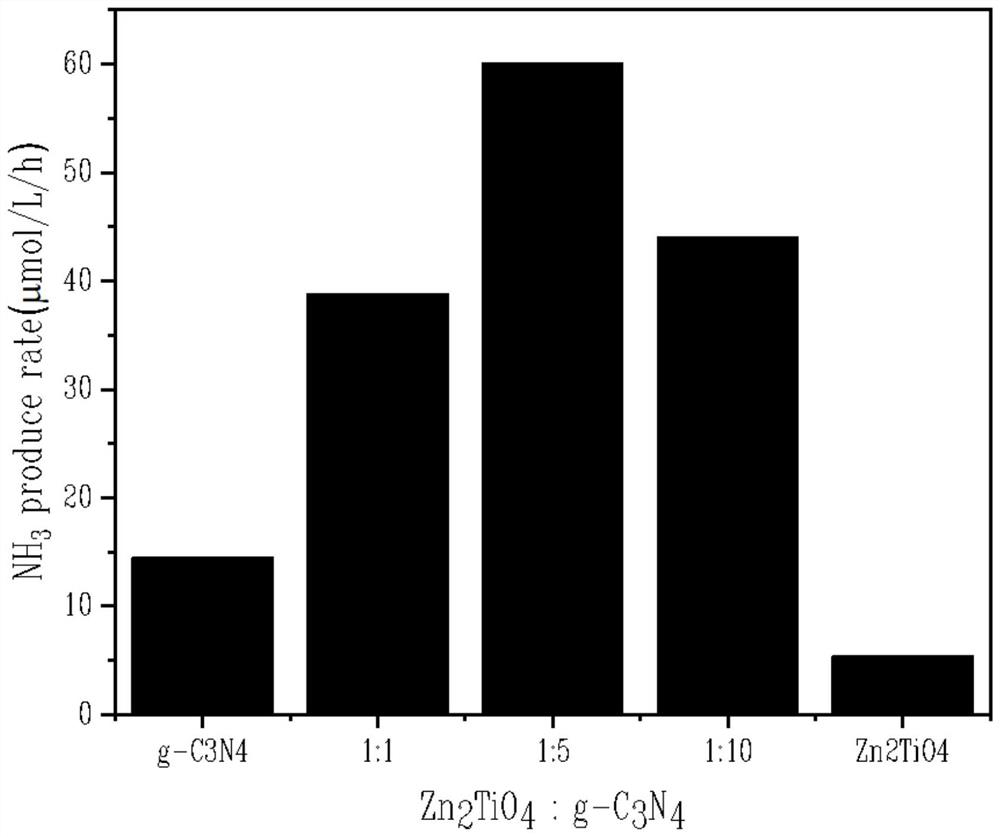

[0032] Under normal temperature and pressure conditions, add 50mL methanol aqueous solution (0.001mol / L) in the container, then add the pure sample g-C prepared by 50mg embodiment 1 respectively 3 N 4 , pure Zn 2 TiO 4 Zn prepared with different mass ratios 2 TiO 4 / g -C 3 N 4 Heterojunction materials were subjected to ultrasound for 10 minutes to obtain a dispersion. Under the condition of visible light irradiation, nitrogen gas N was passed into the container at a rate of 10 mL / min. 2 After reacting for 180min, the supernatant was taken, and the ammonia production efficiency was determined by Nessler's reagent spectrophotometry. The result is as figure 2 and image 3 .

[0033] Depend on figure 2 Visible, Zn 2 TiO 4 / g -C 3 N 4 The ammonia yield of heterojunction materials is signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com