No-coating weather-proof round steel production method

A production method and coating-free technology, which is applied in the production field of coating-free weather-resistant round steel, can solve problems such as the lack of high-strength coating-free bolt production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

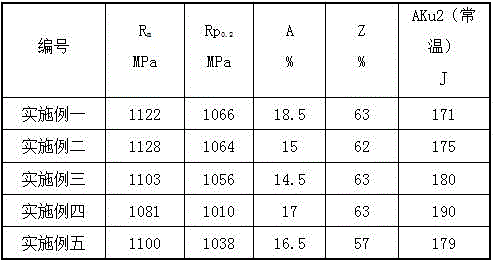

Examples

Embodiment Construction

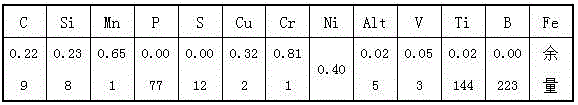

[0022] A method for producing coating-free weather-resistant round steel, the chemical composition of which is: C: 0.21-0.25%, Si: 0.13-0.28%, Mn: 0.60-0.75%, Cr: 0.70-0.90%, Ni: 0.38 ~0.45%, Cu: 0.30~0.40%, V: 0.04~0.07%, Al: 0.015~0.035%, Ti: 0.010~0.030%, B: 0.0010~0.0030%, H≤2ppm, the rest is Fe and unavoidable Impurity elements, P≤0.012%, S≤0.005%. Adding 0.30~0.40% Cu element can improve the atmospheric corrosion resistance of this round steel, and at the same time, it can also improve the strength and yield ratio of the steel when used in conjunction with P element.

[0023] The section size of the billet is 150*150mm2, which can ensure the uniform heat transfer of the billet during heating, and meet the requirements of low-temperature heating, and avoid copper embrittlement caused by high rolling temperature, which will affect the surface quality.

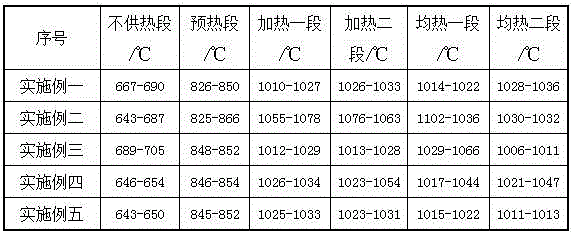

[0024] Heating process: heat storage furnace is used for heating, including non-heating section, preheating section, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com