Comprehensive utilization method for high-iron high-calcium high-silicon waste magnesite and boron mud

A magnesite and high-calcium technology, which is applied in chemical instruments and methods, preparation of organic compounds, carboxylate preparation, etc., can solve the problem of limiting the reuse of waste magnesite resources, and achieve low harmful impurities and simple process , the effect of small lattice size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

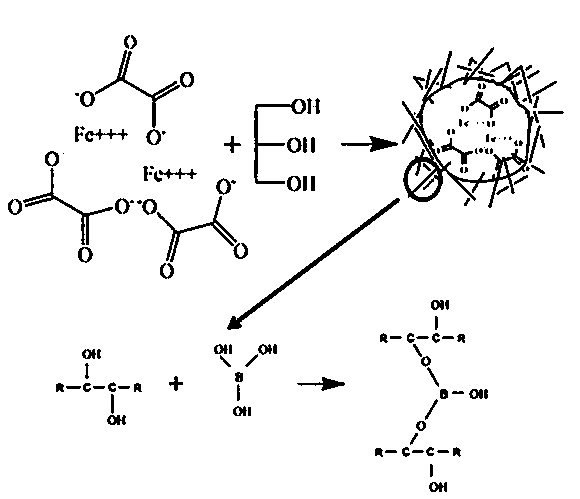

Method used

Image

Examples

Embodiment 1

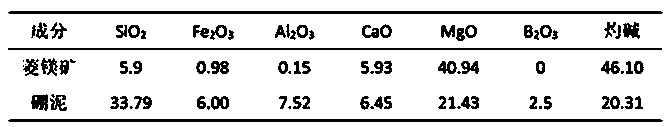

[0035] The implementation steps of the present invention are as follows:

[0036] (1) Calcining high-iron, high-calcium and high-silicon waste magnesite in a rotary kiln, the calcination temperature is 1200°C, and the calcination time is 1.5h to obtain light-calcined magnesia, which is ground after cooling, with a fineness of 325 mesh and a passing rate of 95 %, the hydration activity of the prepared light-burned magnesium oxide powder is 71.1%;

[0037] (2) Weigh 1 part of oxalic acid, 1 part of glycerol, 2 parts of fly ash, 27 parts of lightly burned magnesium oxide powder, 13.7 parts of magnesium sulfate heptahydrate, 0.3 parts of citric acid, 25 parts of water, 1 part of Glass fiber silk, 25 parts of boron mud, 1 part of dolomite, 2 parts of sawdust, 1 part of perlite. Mix oxalic acid and glycerol in water to obtain a mixed solution, and dry mix fly ash, magnesium sulfate heptahydrate, citric acid, glass fiber, dolomite, sawdust and perlite;

[0038] (3) Pour lightly bur...

Embodiment 2

[0045] The implementation steps of the present invention are as follows:

[0046] (1) Same as embodiment 1;

[0047](2) Weigh 0.1 parts of oxalic acid, 0.1 parts of glycerol, 2 parts of fly ash, 40 parts of light-burned magnesium oxide powder, 25 parts of magnesium sulfate heptahydrate, 0.3 parts of citric acid, 25 parts of water, 2.1 parts by weight Glass fiber, 1 part of dolomite, 2 parts of sawdust, 1 part of perlite. Mix oxalic acid and glycerol in water to obtain a mixed solution, and dry mix fly ash, magnesium sulfate heptahydrate, citric acid, glass fiber, dolomite, sawdust and perlite;

[0048] (3)-(5) are the same as embodiment 1.

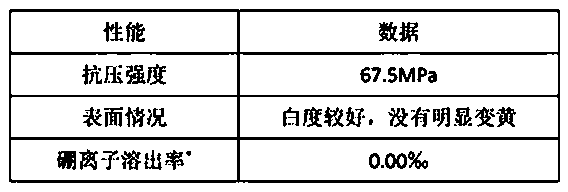

[0049] The cured samples were tested, and the performance data are as follows:

[0050]

Embodiment 3

[0052] The implementation steps of the present invention are as follows:

[0053] (1) Same as embodiment 1;

[0054] (2) Weigh 0.1 part of oxalic acid, 0.1 part of glycerol, 0.5 part of fly ash, 40 parts of lightly burned magnesium oxide powder, 21 parts of magnesium sulfate heptahydrate, 0.3 part of citric acid, 22 parts of water, 1 part of Glass fiber filaments, 5 parts of dolomite, 5 parts of sawdust, 5 parts of perlite. Mix oxalic acid and glycerol in water to obtain a mixed solution, and dry mix fly ash, magnesium sulfate heptahydrate, citric acid, glass fiber, dolomite, sawdust and perlite;

[0055] (3)-(5) are the same as embodiment 1.

[0056] The cured samples were tested, and the performance data are as follows:

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com