Preparation method for carbon wave-absorbing material

A technology of absorbing material and carbon, applied in textiles, papermaking, fiber processing, etc., can solve the problems of narrow absorbing frequency and deviation of absorbing performance, and achieve good wavelength absorption performance, improve efficiency, and improve wavelength absorption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

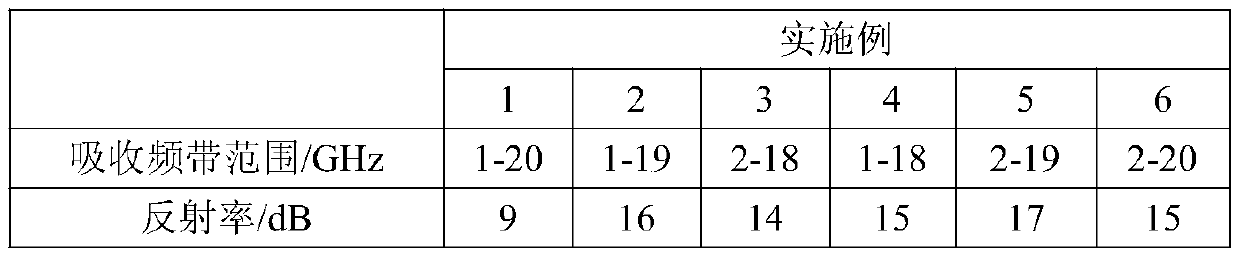

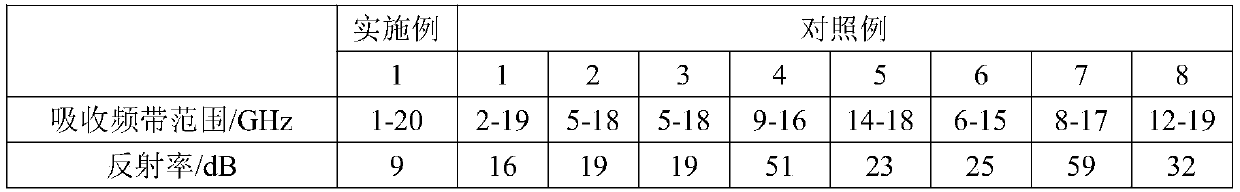

Examples

Embodiment 1

[0020] A preparation method of carbon absorbing material, comprising the following steps:

[0021] (1), Weigh 13.5 parts of acrylic acid, 5.2 parts of methoxypolyethylene glycol 550 monomethacrylate and 0.04 parts of 819 photoinitiator and add them to the reactor, the stirring speed is 60r / min, and the reaction temperature of the system is maintained at Stir at 40°C for 25 minutes, the product is irradiated by a 400W high-pressure mercury lamp for 2 seconds, the product is washed and dried, and the product, 18 parts of iron oxalate, 6.5 parts of cobalt oxalate and 4.5 parts of nickel oxalate are added to the reaction kettle, and the stirring speed is 50r / min, the reaction temperature was 115°C and 0.09MPa for 1.5h, the product was centrifuged and filtered, and the supernatant was heat-treated at 100°C for 0.5h, 200°C for 0.5h, 300°C for 1h, 400°C for 2h, 500 ℃ heat treatment for 2 hours, 600 ℃ heat treatment for 2 hours, 700 ℃ heat treatment for 2 hours, 800 ℃ heat treatment ...

Embodiment 2

[0026] A preparation method of carbon absorbing material, comprising the following steps:

[0027] (1), Weigh 10 parts of acrylic acid, 3 parts of methoxypolyethylene glycol 550 monomethacrylate and 0.01 part of 819 photoinitiator and add them to the reaction kettle, the stirring speed is 60r / min, and the reaction temperature of the system is maintained at Stir at 40°C for 25 minutes, the product is irradiated by a 100W high-pressure mercury lamp for 6 seconds, the product is washed and dried, and the product, 18 parts of iron oxalate, 6 parts of cobalt oxalate and 2 parts of nickel oxalate are added to the reaction kettle, and the stirring speed is 50r / min, the reaction temperature is 90°C and 0.2MPa for 1h, the product is centrifuged and filtered, the supernatant is heat-treated at 100°C for 0.5h, at 200°C for 0.5h, at 300°C for 1h, at 400°C for 2h, at 500°C Heat treatment for 2 hours, heat treatment at 600°C for 2 hours, heat treatment at 700°C for 2 hours, heat treatment ...

Embodiment 3

[0032] A preparation method of carbon absorbing material, comprising the following steps:

[0033] (1), Weigh 17 parts of acrylic acid, 8 parts of methoxypolyethylene glycol 550 monomethacrylate and 0.2 part of 819 photoinitiator and join in the reaction kettle, the stirring speed is 60r / min, and the reaction temperature of the system is maintained at Stir at 40°C for 25 minutes, the product is irradiated by a 3000W high-pressure mercury lamp for 1 second, after the product is washed and dried, the product, 18 parts of iron oxalate, 9 parts of cobalt oxalate and 5 parts of nickel oxalate are added to the reaction kettle, and the stirring speed is 50r / min, the reaction temperature is 125°C and 0.05MPa for 3h, the product is centrifuged and filtered, the supernatant is heat-treated at 100°C for 0.5h, at 200°C for 0.5h, at 300°C for 1h, at 400°C for 2h, at 500°C Heat treatment for 2 hours, heat treatment at 600°C for 2 hours, heat treatment at 700°C for 2 hours, heat treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com