Patents

Literature

66results about How to "High cutting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

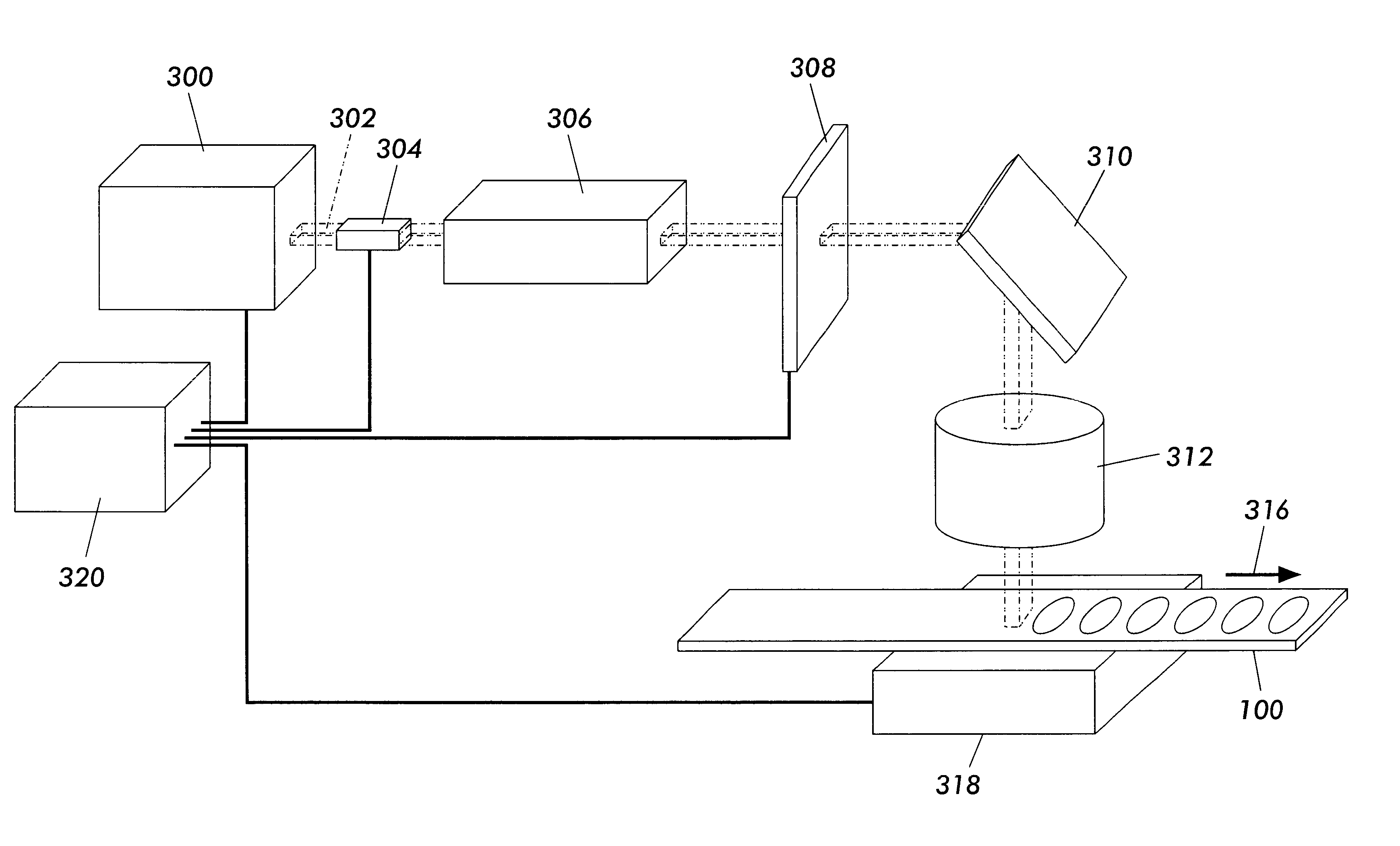

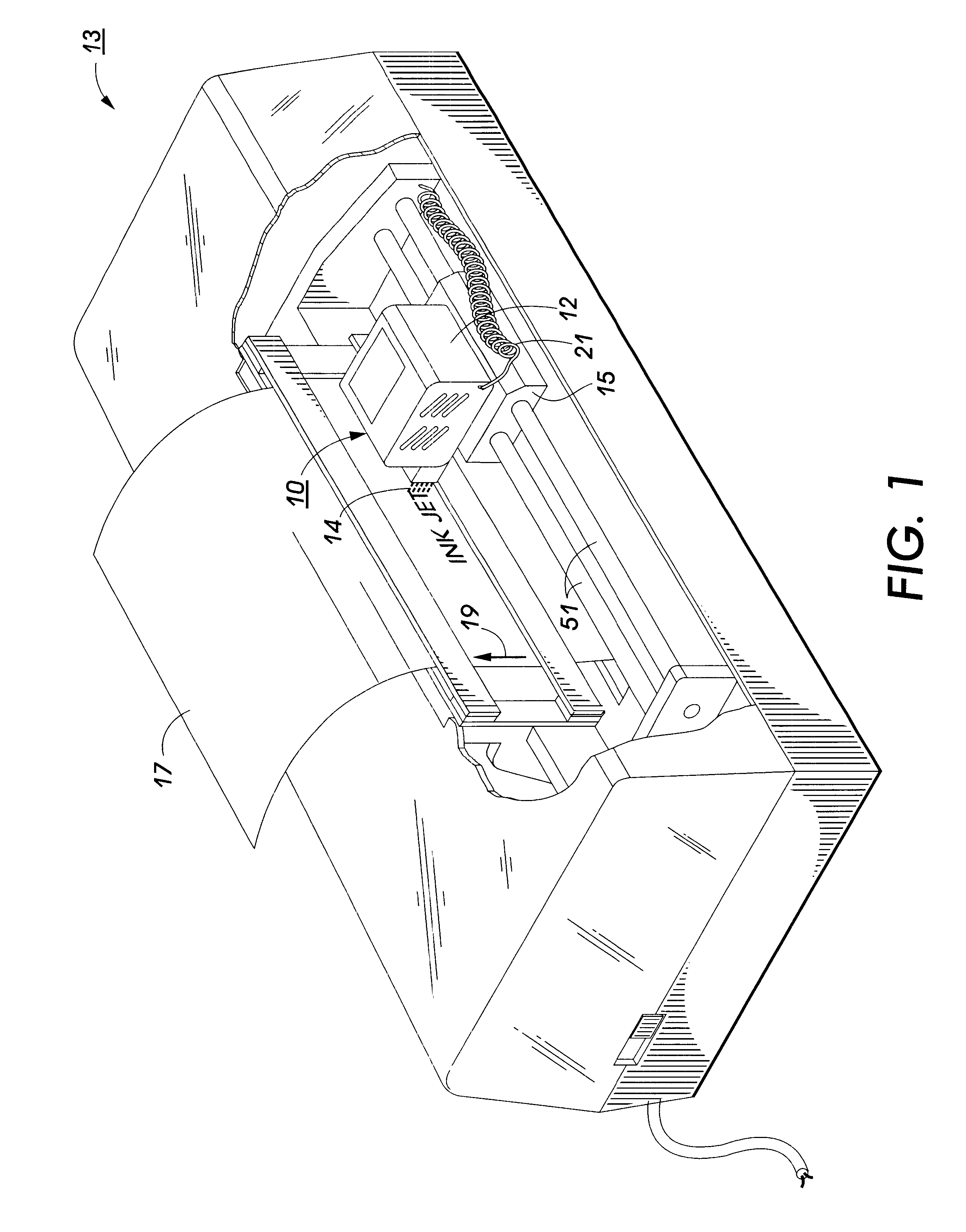

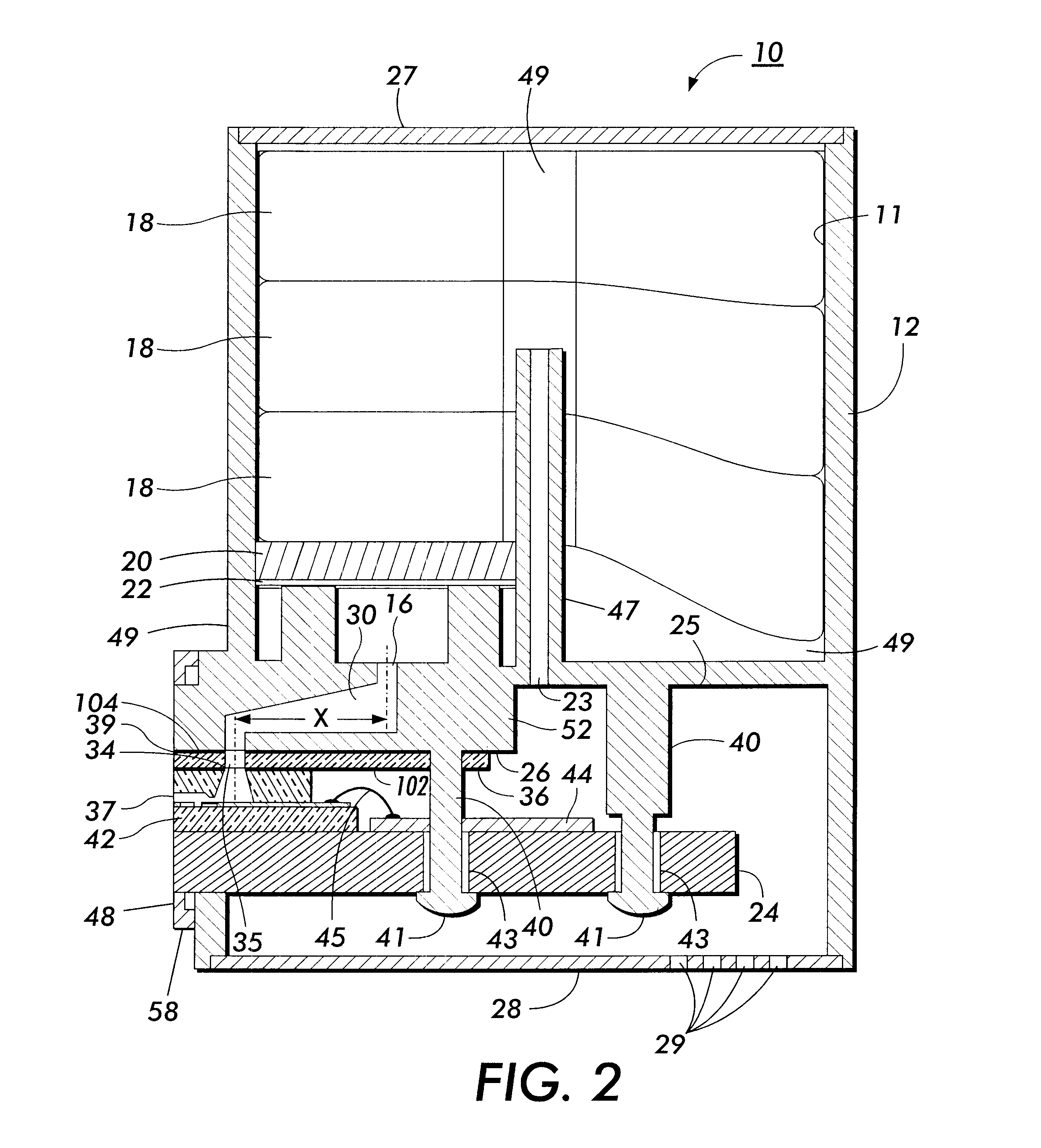

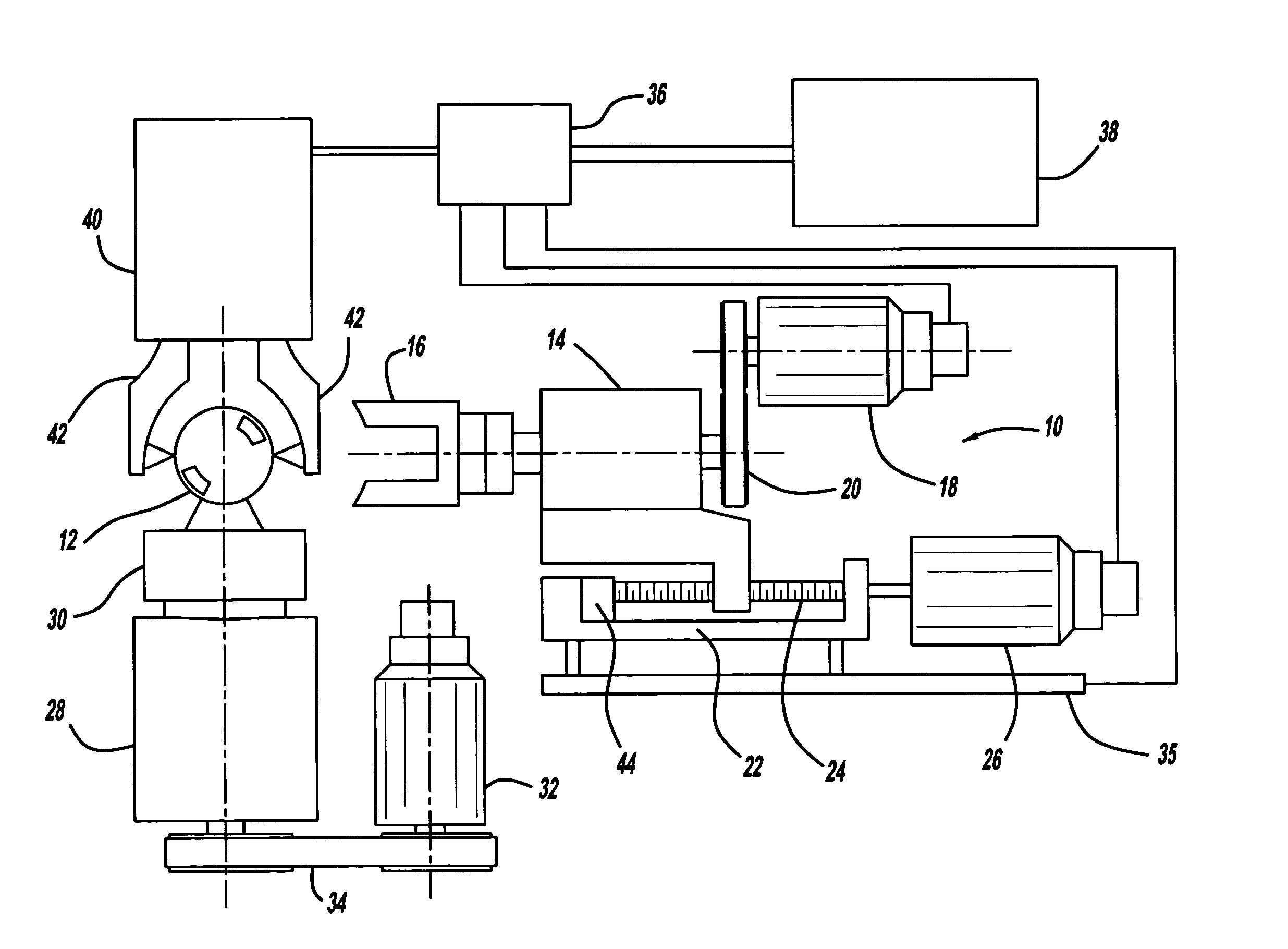

Systems and methods for controlling depths of a laser cut

InactiveUS6388231B1High cutting rateQuick Cut ProcessingWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser

A process for precision patterning or cutting of a sheet stock, such as an adhesive tape, includes the step of irradiating a surface of a sheet stock with an irradiation source to pattern or cut a part in the sheet stock and adjusting at least one of a beam width and the power of the irradiation source to form a cut in the sheet stock to a controlled depth. The method is particularly useful for precision cutting adhesive members, such as adhesive fluid seals, for an inkjet print cartridge.

Owner:XEROX CORP

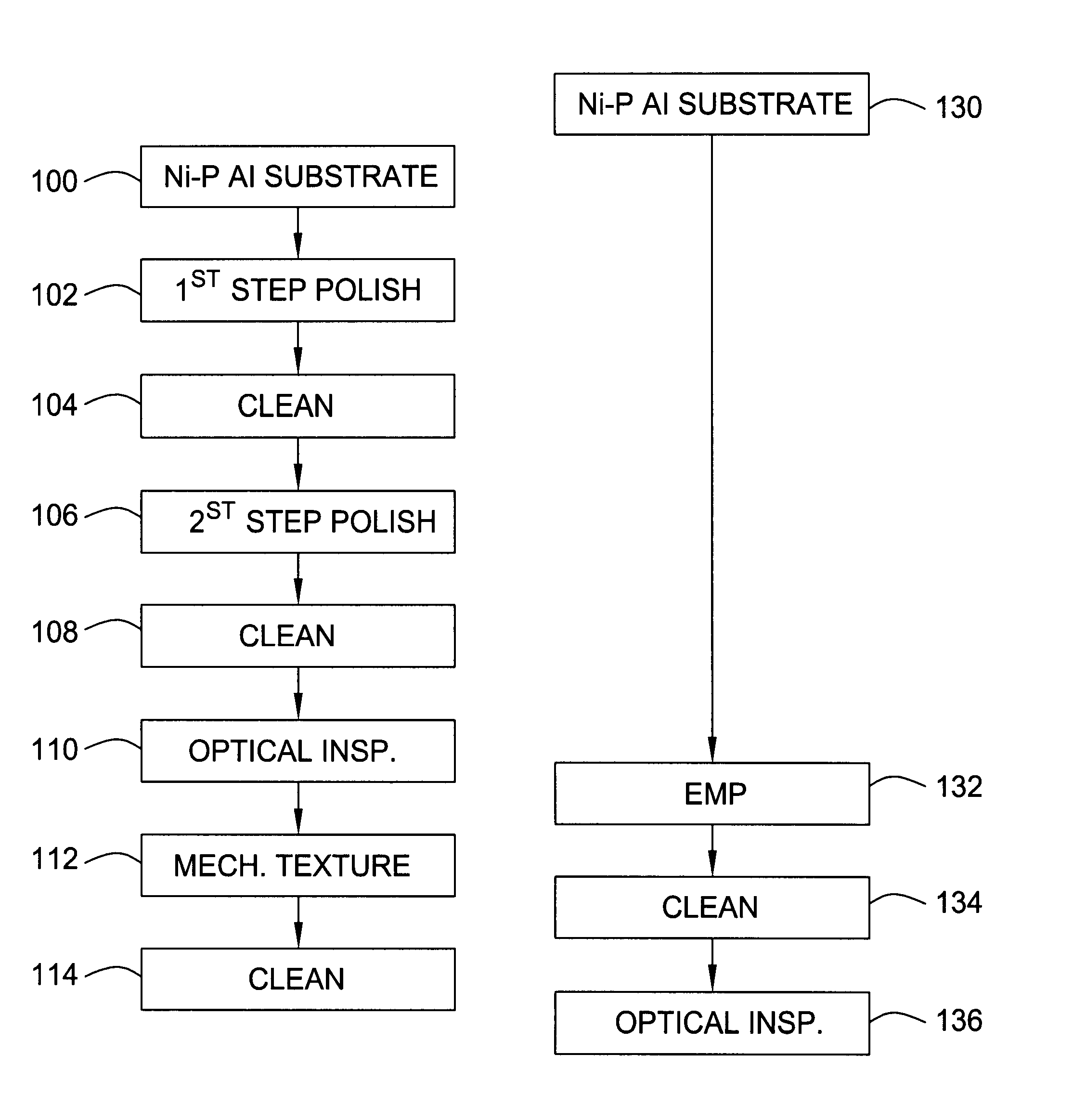

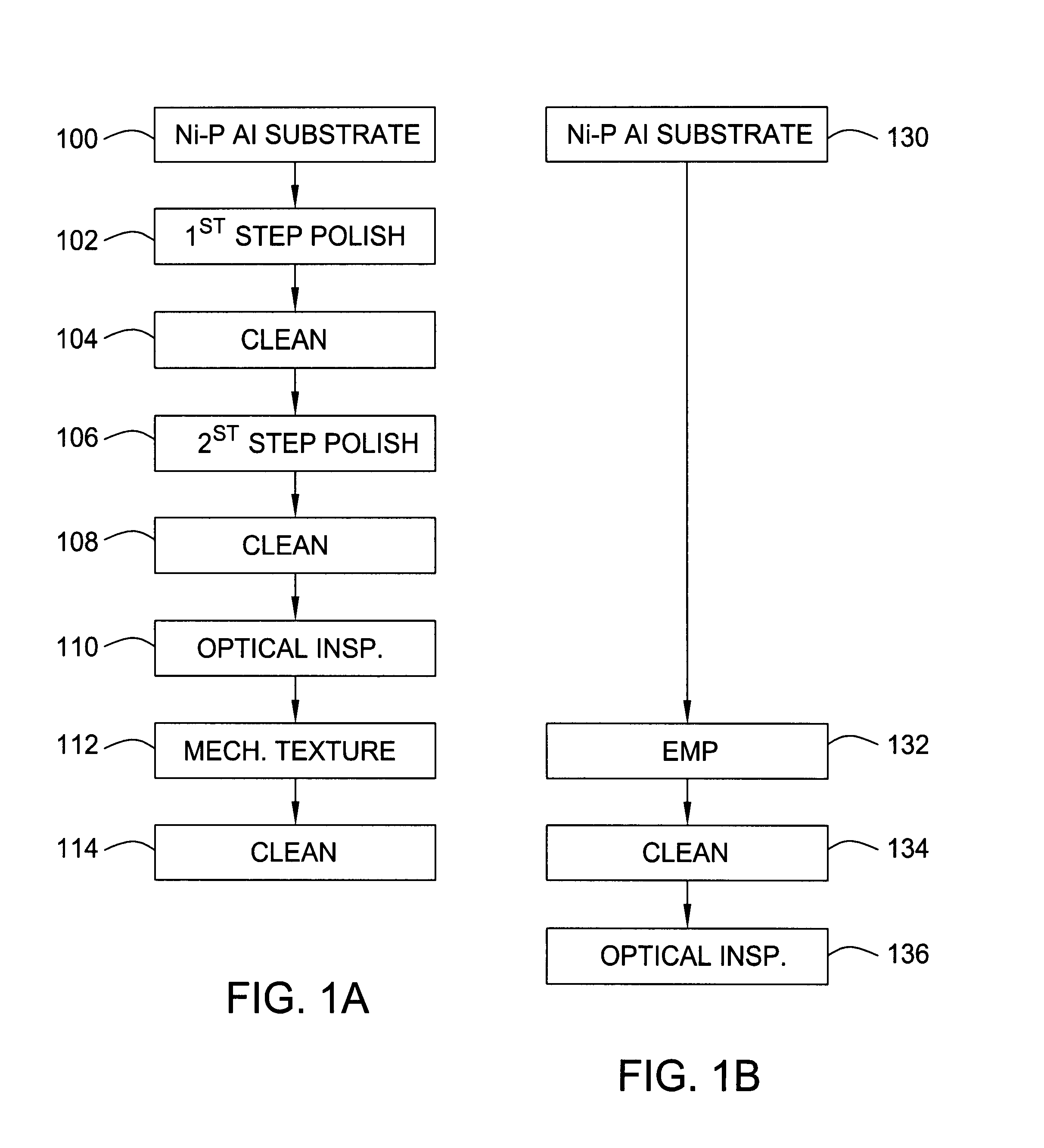

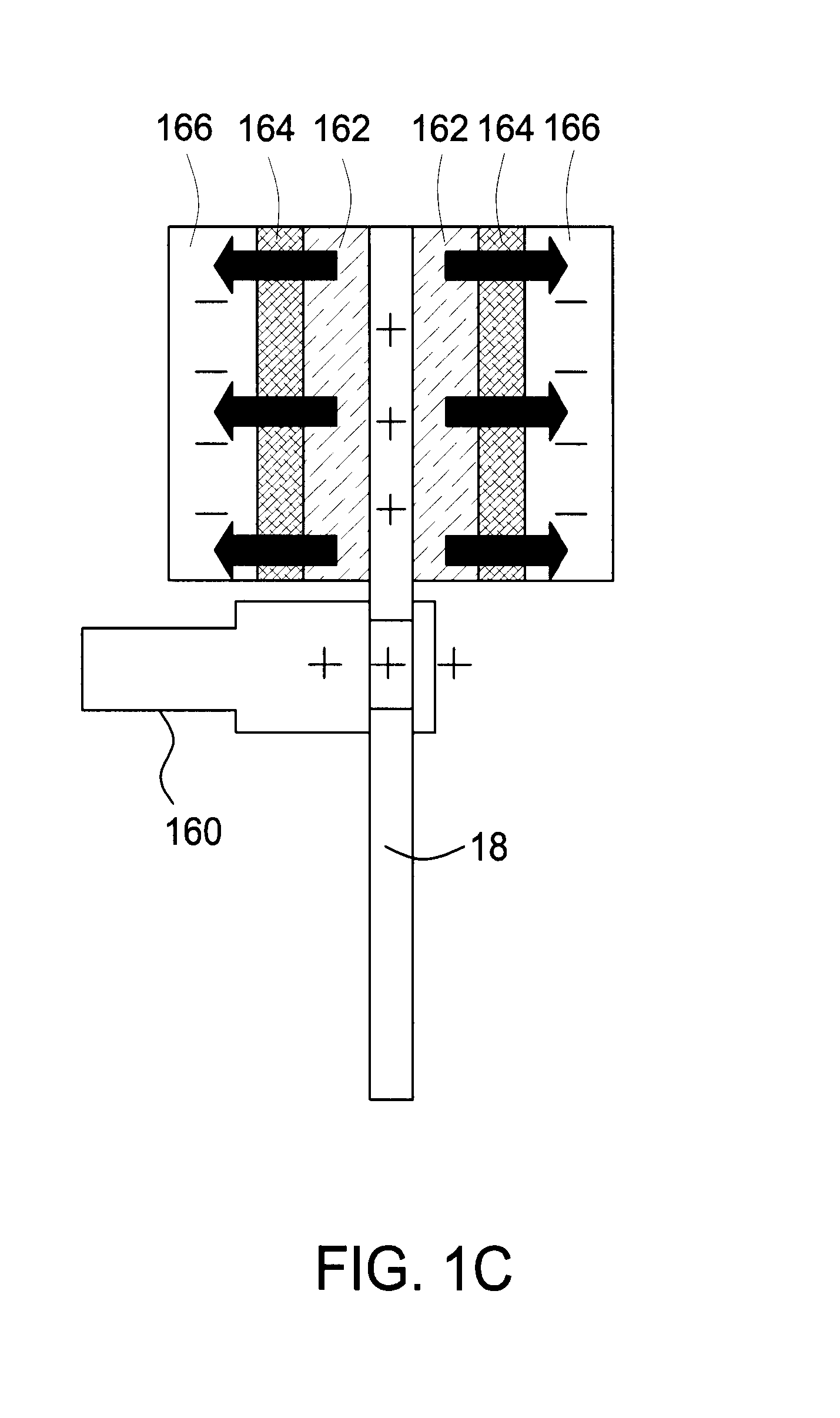

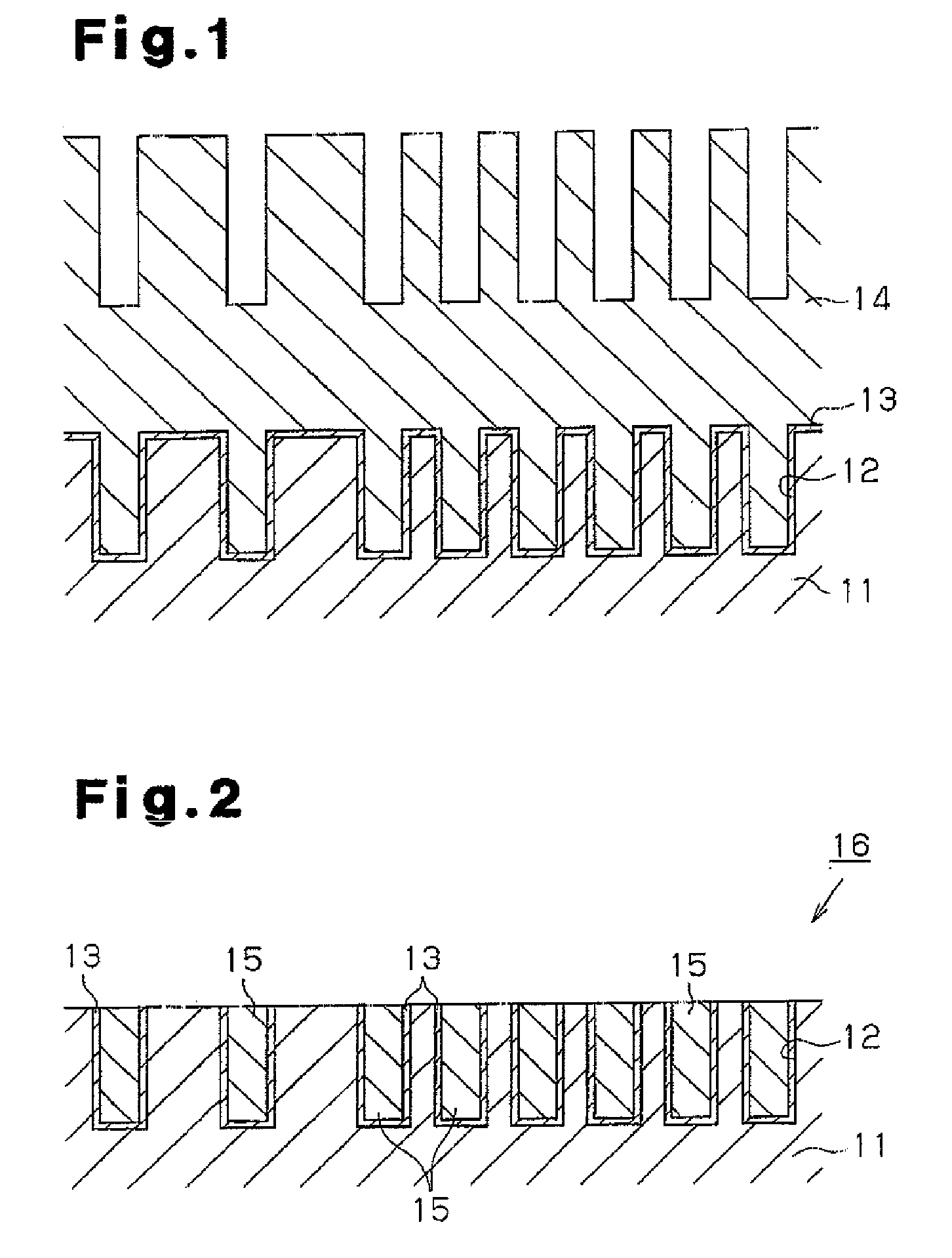

Single-step electromechanical mechanical polishing on Ni-P plated discs

InactiveUS6957511B1Reduce in quantityReduce processing timeBelt grinding machinesLapping machinesElectrical conductorSlurry

Beginning with a smooth ground aluminum blank with a relatively thin layer of leveled Ni—P, circumferential electropolishing / texturing is carried out to achieve a smooth oriented surface. A conductive slurry is provided between the disc and a porous texturing tape which is in contact with a conducting plate or equivalent conductor. The disc serves as the anode, and the conducting plate as the cathode, while the slurry, being conductive, functions as an electrolyte. In the presence of current, a reverse electroplating occurs so that the Ni—P dissolves to form Ni2+, or nickel ions which are carried away by the conductive slurry. The conductive slurry further supports or carries therein abrasive material so that by moving the porous texturing tape past the disc surface, the texturing tape picks up the abrasive material in the slurry and simultaneously with the reverse electroplating, provides the desired mechanical abrasion to achieve texturing of the disc surface. The abrasive material comprises diamond particles. The circumferential electropolishing / texturing polish is achieved by spinning the disc while applying the mechanical-chemical action through the slurry system to the disc surface with electric current passing through the electrically conducting interface during processing.

Owner:SEAGATE TECH LLC

Polishing composition and method for producing a memory hard disk

InactiveUS6280490B1High cutting rateSmall surface roughnessPigmenting treatmentOther chemical processesIron sulfateEthylenediamine

A polishing composition for a memory hard disk, which comprises the following components (a) to (d):(a) from 0.1 to 50 wt %, based on the total amount of the polishing composition, of at least one abrasive selected from the group consisting of silicon dioxide, aluminum oxide, cerium oxide, zirconium oxide, titanium oxide, silicon nitride and manganese dioxide,(b) from 0.001 to 10 wt %, based on the total amount of the polishing composition, of at least one iron salt selected from the group consisting of iron nitrate, iron sulfate, ammonium iron sulfate, iron perchlorate, iron chloride, iron citrate, ammonium iron titrate, iron oxalate, ammonium iron oxalate and an iron chelate complex salt of ethylenediaminetetraacetic acid,(c) from 0.01 to 30 wt %, based on the total amount of the polishing composition, of at least one peroxydisulfate salt selected from the group consisting of ammonium peroxydisulfate, potassium peroxydisulfate and sodium peroxydisulfate, and(d) water.

Owner:FUJIMI INCORPORATED

Polishing composition and polishing method

InactiveUS20050191823A1High cutting rateOther chemical processesDwelling equipmentColloidal silicaTitanium

A polishing composition includes more than 0.1% by mass of colloidal silica, and water, and has a pH of 6 or less. The polishing composition has the ability to polish a titanium material at a high stock removal rate. Thus, the polishing composition is suitable for use in applications for polishing a titanium-containing object.

Owner:FUJIMI INCORPORATED

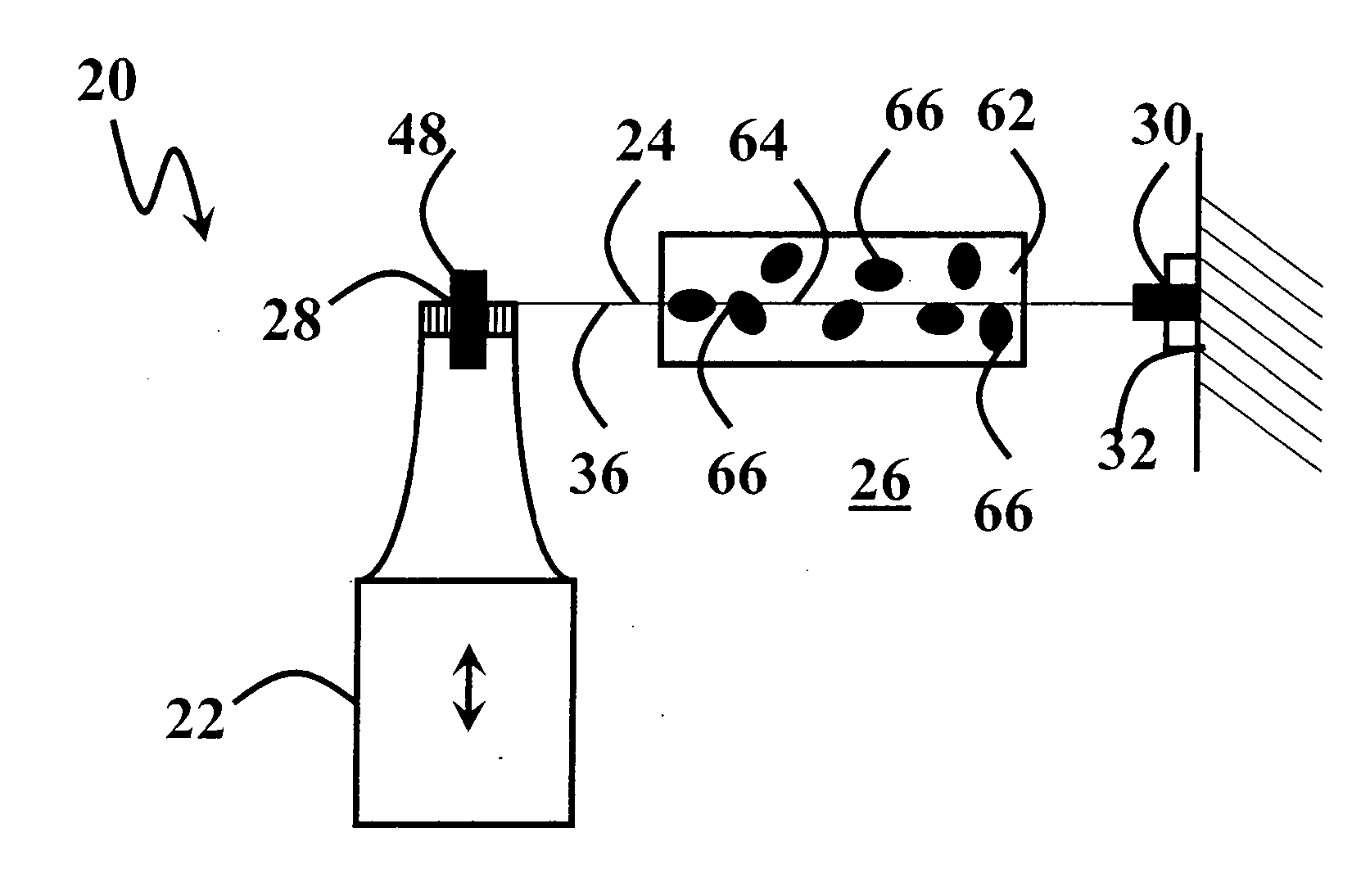

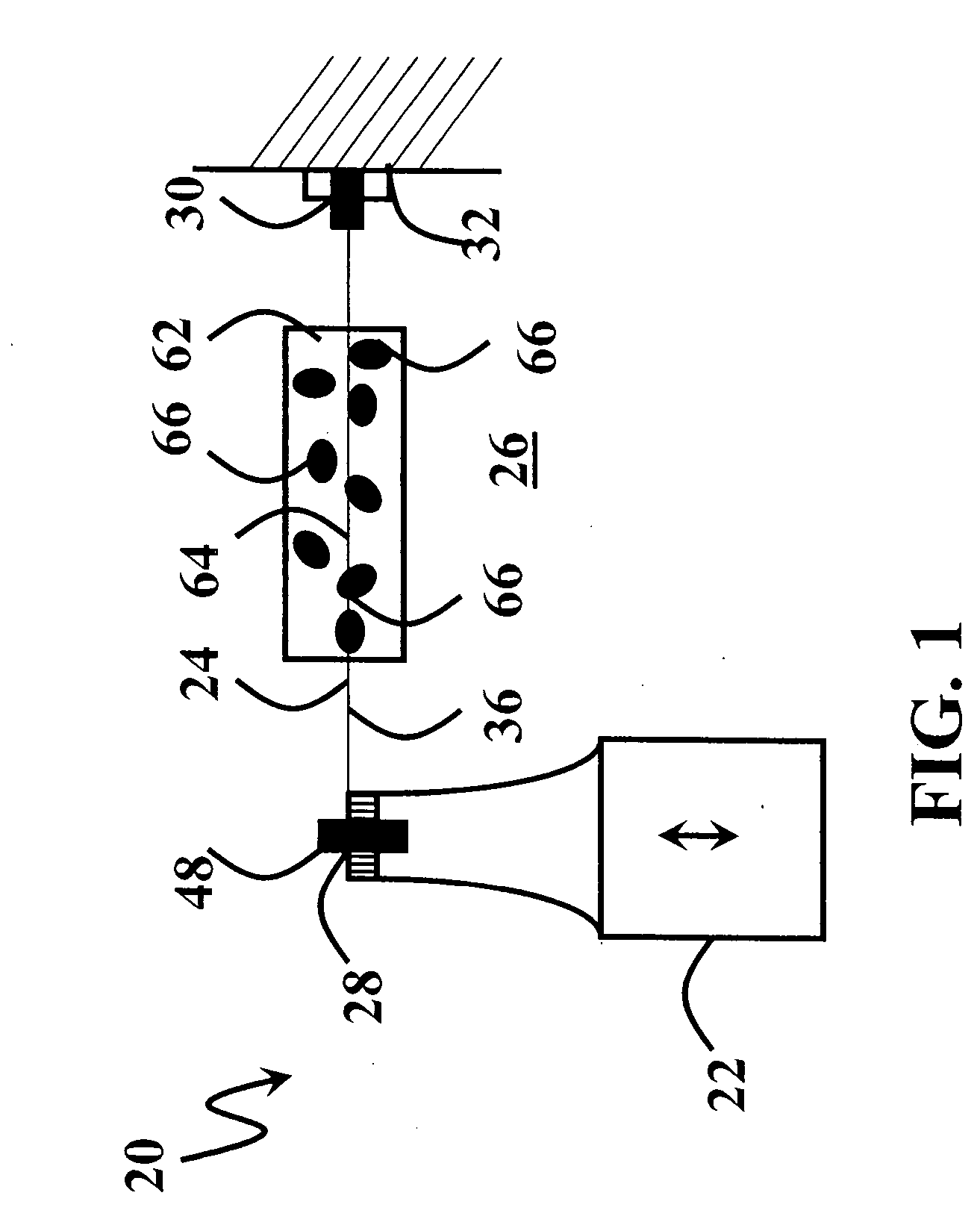

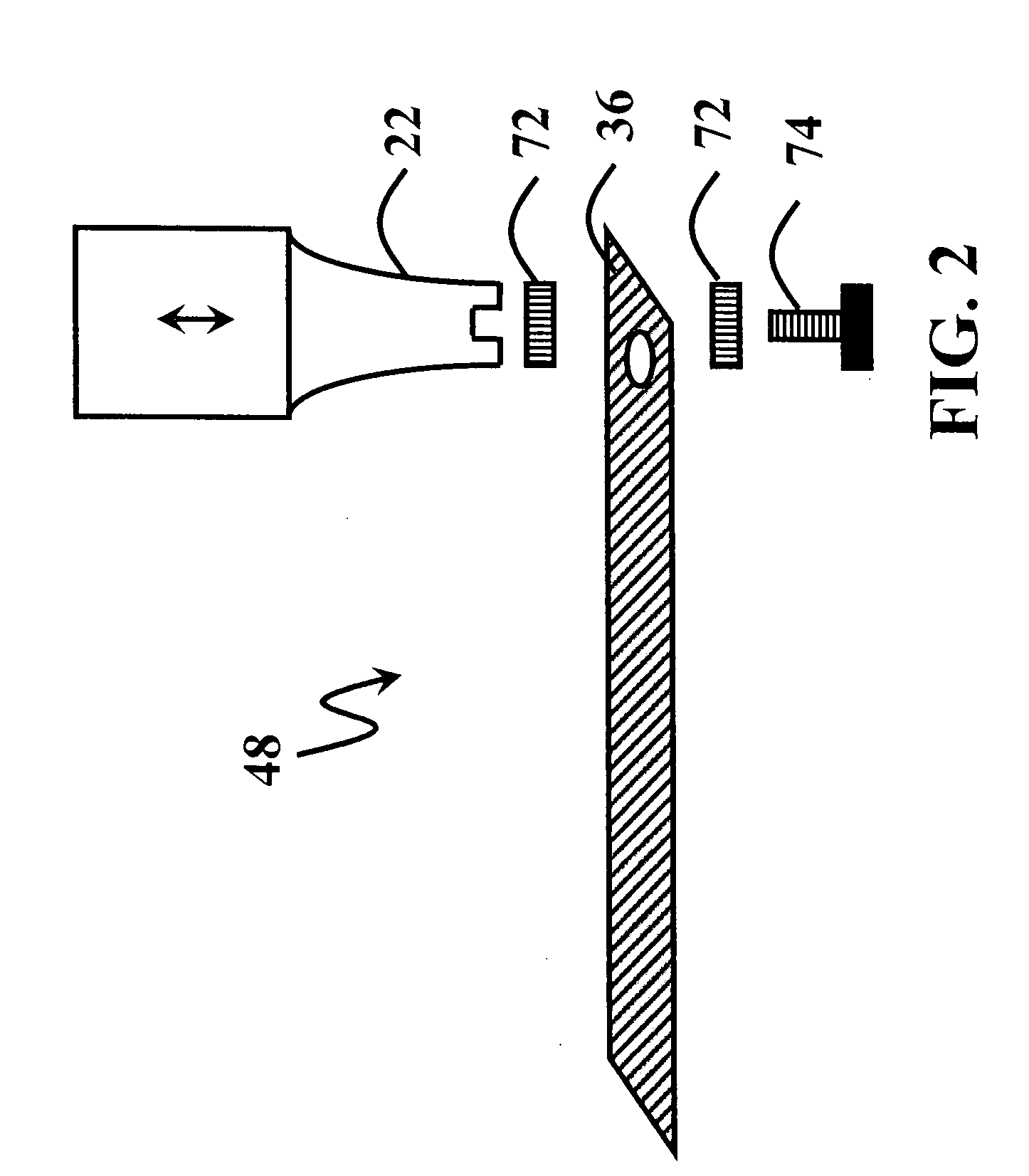

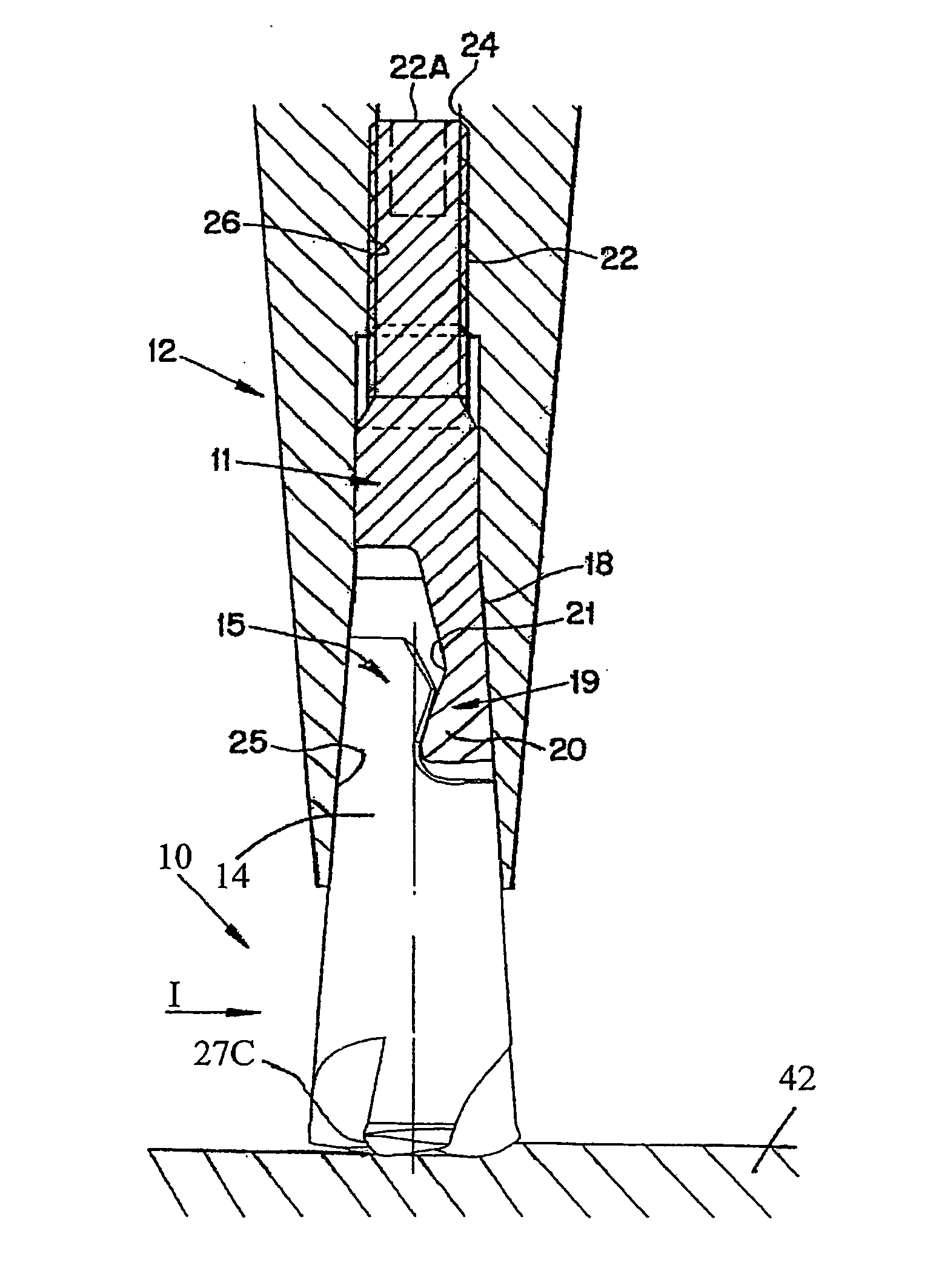

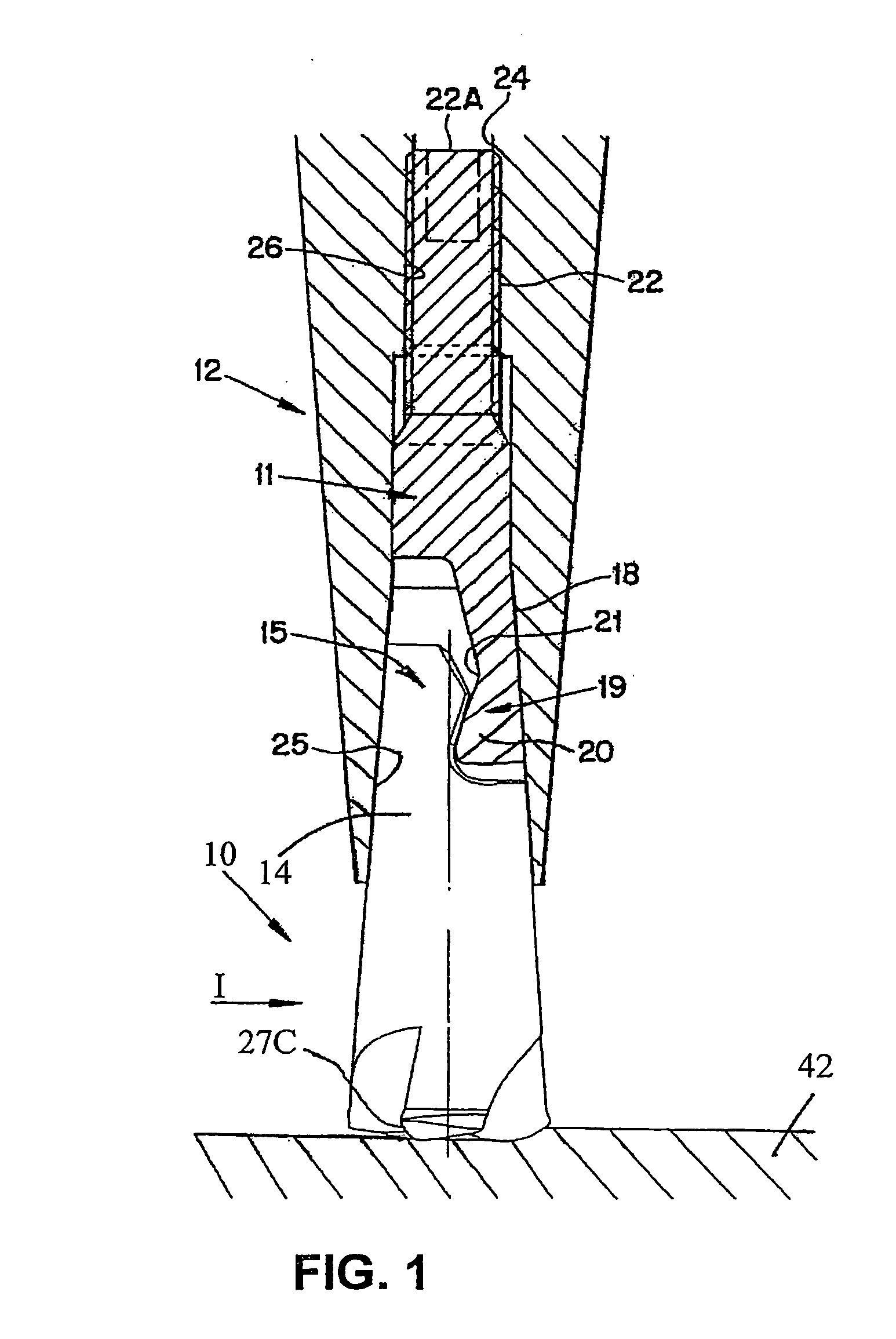

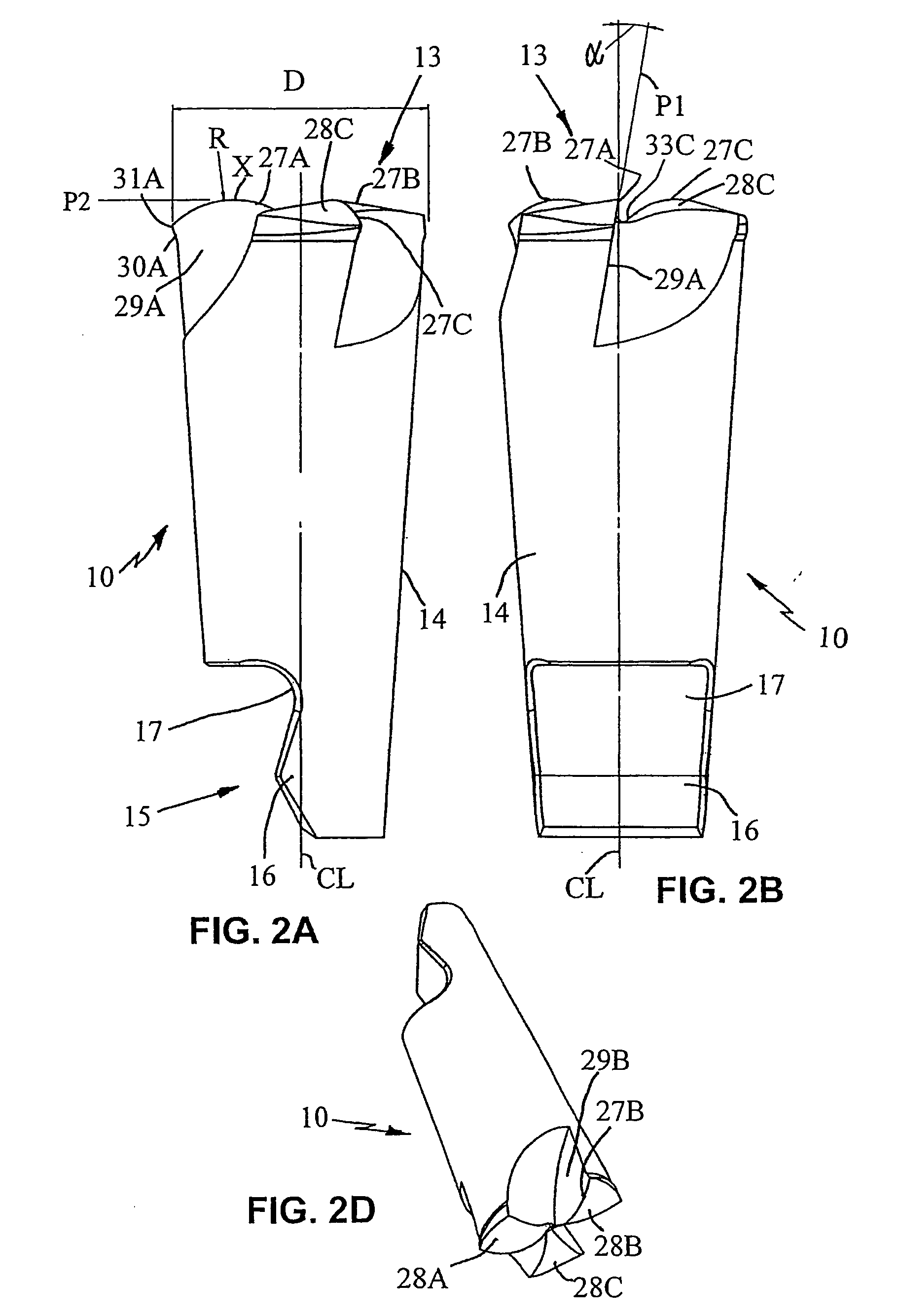

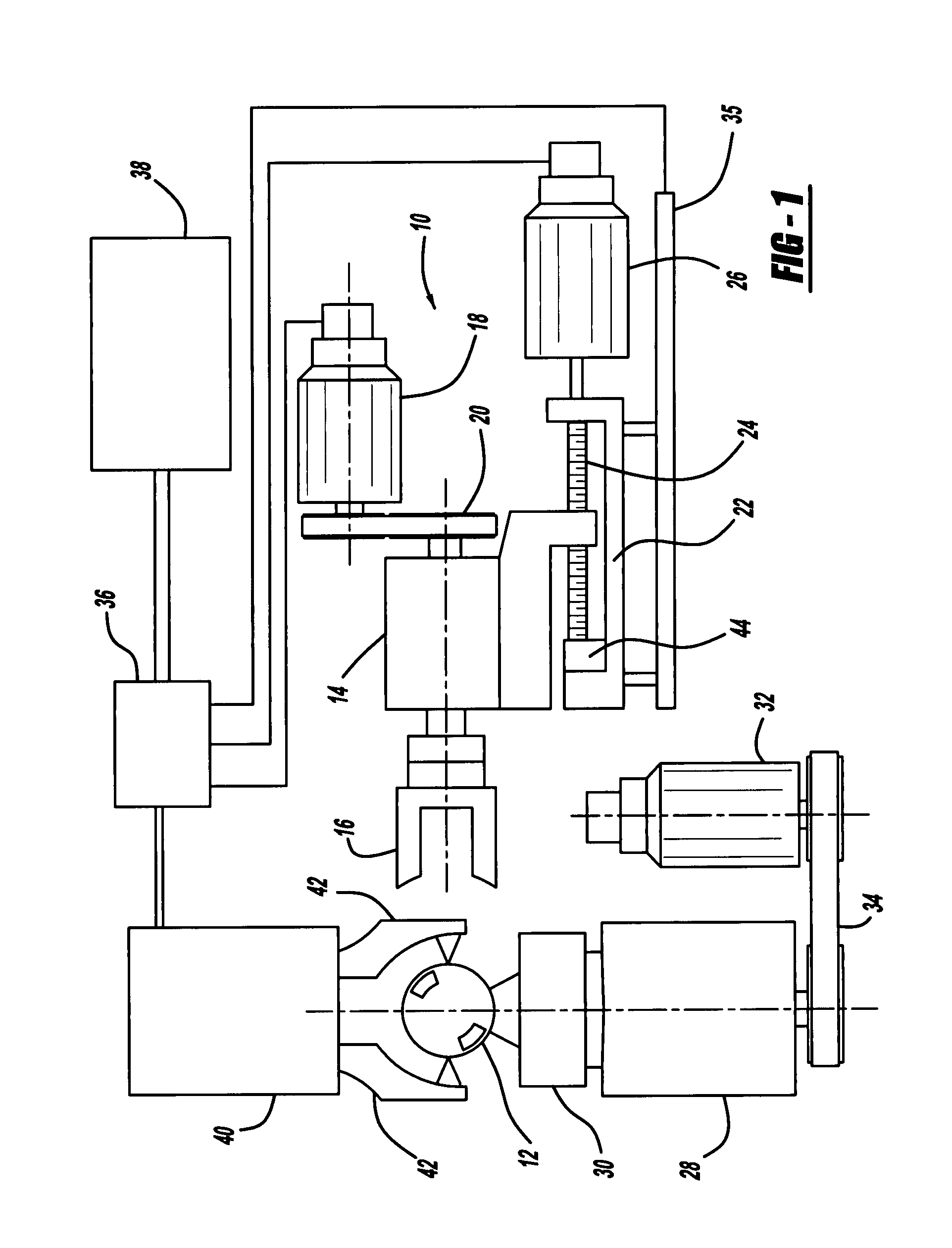

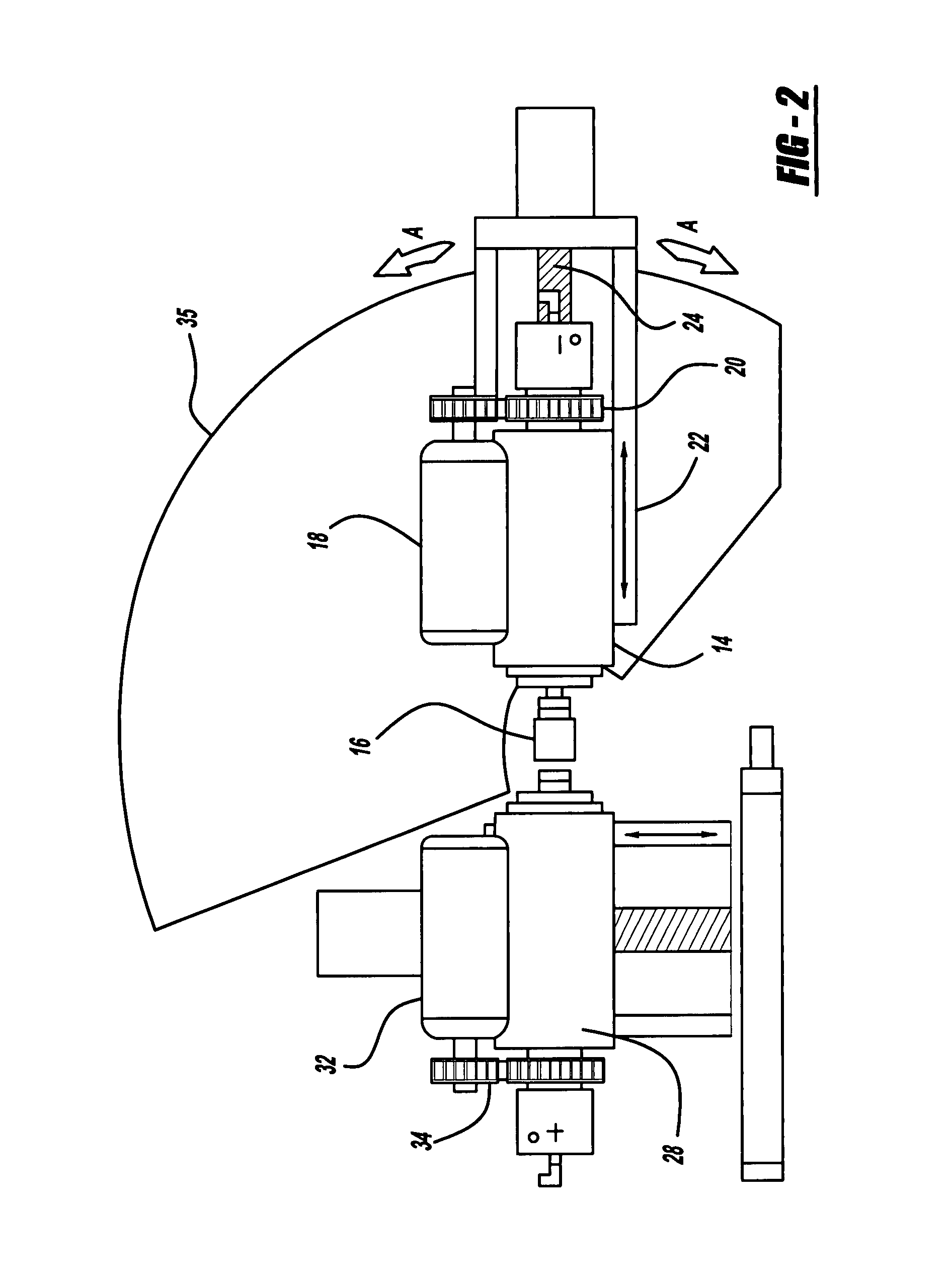

Apparatus and method for ultrasonic cutting

InactiveUS20070199423A1Minimal intrusionSimplify cutting operationMetal working apparatusEngineeringUltrasound

This invention relates generally to cutting product by ultrasonic tools and methods. Specifically, the invention relates to an elongated cutting element removably coupled to an ultrasonic resonant horn to form a cutting zone and a method of use. The elongated cutting element can include simple, less costly, easily replaceable elements that resonate at ultrasonic frequencies but don't follow complex and restrictive acoustic rules.

Owner:CREATIVE RESONANCE

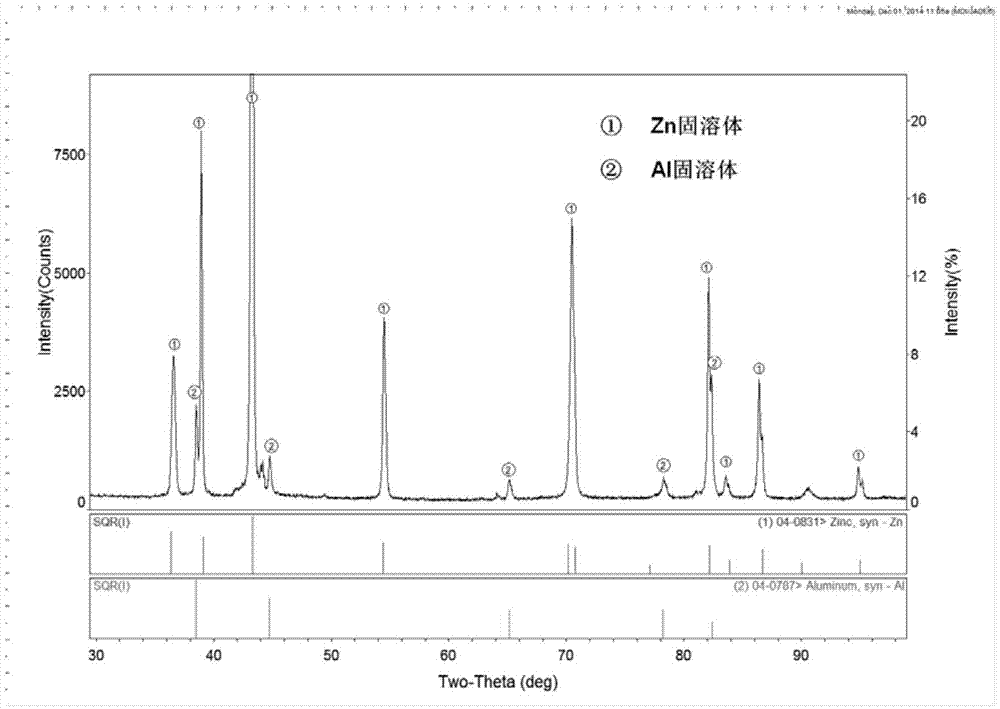

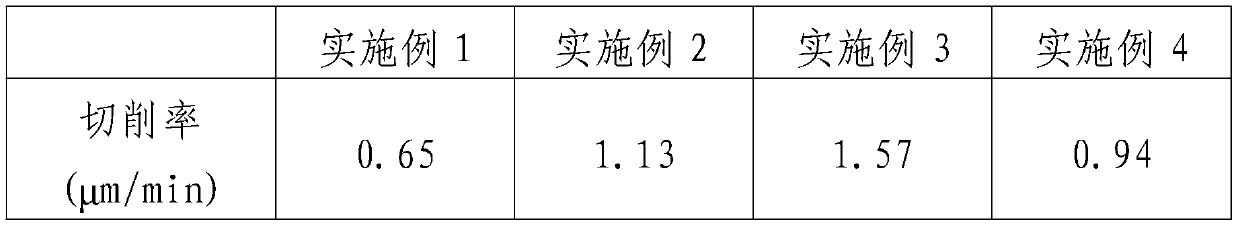

Deformed zinc-based alloy material as well as preparation method and application thereof

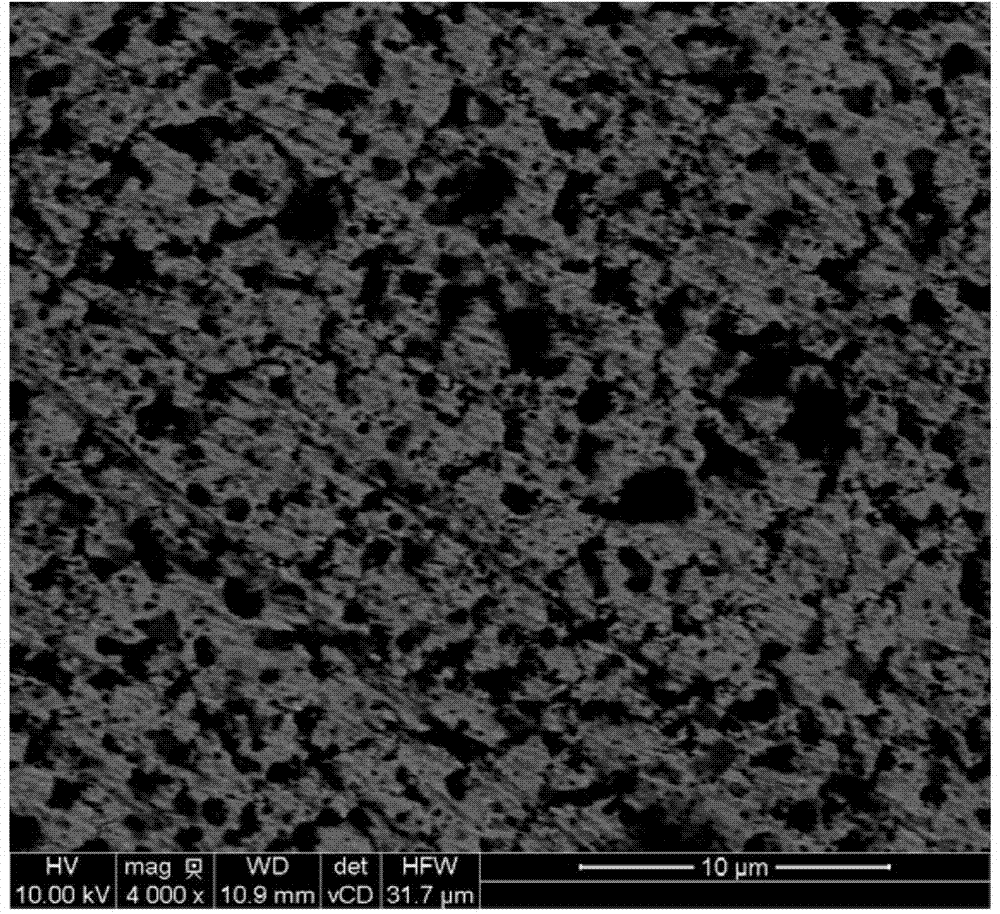

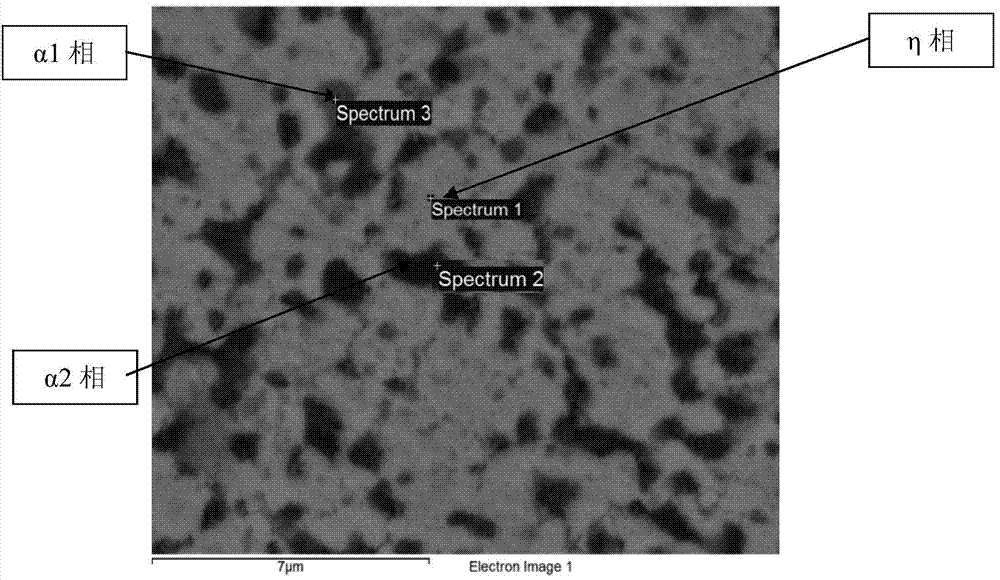

ActiveCN104498773AImprove machinabilityHigh cutting rateCoupling contact membersMetal/alloy conductorsSolid solutionUltimate tensile strength

The invention discloses a deformed zinc-based alloy material. The deformed zinc-based alloy material comprises the following components in percentage by weight: greater than or equal to 3% and less than or equal to 15% of Al, greater than or equal to 0.1% and less than or equal to 4.8% of Cu and the balance of Zn and unavoidable impurities. The microstructures of the zinc-based alloy material comprise an alpha phase and an eta phase, wherein the alpha phase is an Al-substituted-by-Zn solid solution using Al as a matrix and the eta phase is a Zn-substituted-by-Cu and Al solid solution using Zn as a matrix; and the optimal solute content of solid solutions can be obtained by virtue of the preparation method disclosed by the invention. By the synergy of the alpha phase and the eta phase, the comprehensive performance of the alloy is promoted and improved, the alloy has moderate strength, the tensile strength can reach 350MPa or more, the elongation can reach above 10%, the electrical conductivity can reach above 25% IACS, the cutting rate can reach 50-85% of that of C3604 lead brass, the alloy can completely meet the requirement on the performances of AC / DC power plug, FC communication connectors and the like and can be used as an alternative material of the traditional brass alloy.

Owner:NINGBO POWERWAY ALLOY MATERIAL

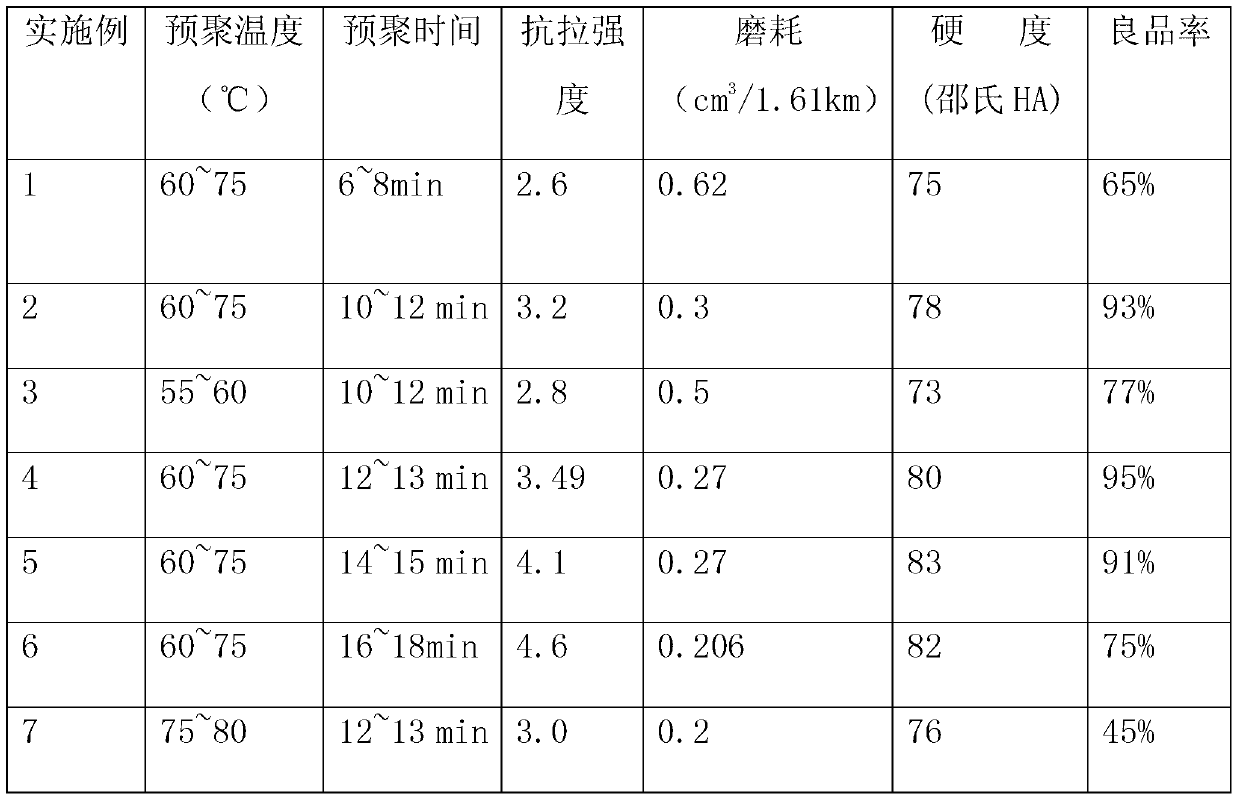

Method for preparing polyurethane polishing disc

The invention relates to a method for preparing a polyurethane polishing disc, in particular to a proportioning and a preparing process of the polyurethane polishing disc. The method comprises the following steps: taking toluene diisocynate, polyether polyol, a chain extender, a cross-linking agent, a copolymer of polysiloxane and polyalkoxy-ether and cerium oxide as raw materials based on the weight ratio of 100:200-240:45-60:16-25:1.5-2.5:90-110; and pre-polymerizing the toluene diisocynate and the polyether polyol to form component A, mixing the chain extender, the cross-linking agent, the copolymer of polysiloxane and polyalkoxy-ether and the cerium oxide to form component B, adding the component A and the component B to a vacuum closed mixing vessel to mix quickly for 5-15 seconds, infusing the components into a die, cooling and curing into polyurethane blank, and then cutting the blank into slices to finally obtain the polyurethane polishing disc. The polyurethane polishing disc obtained by the method of the invention has good elasticity and good microcellular structure and can be used in high-precision grinding and polishing process of various lenses, glasses, prisms, mirror surfaces, optical parts and other glass products. The method of the invention has the advantages of good wear resistance, high polishing efficiency, high polishing precision, high cutting rate, no passivation, simple and convenient operation, low cost and the like.

Owner:张海龙

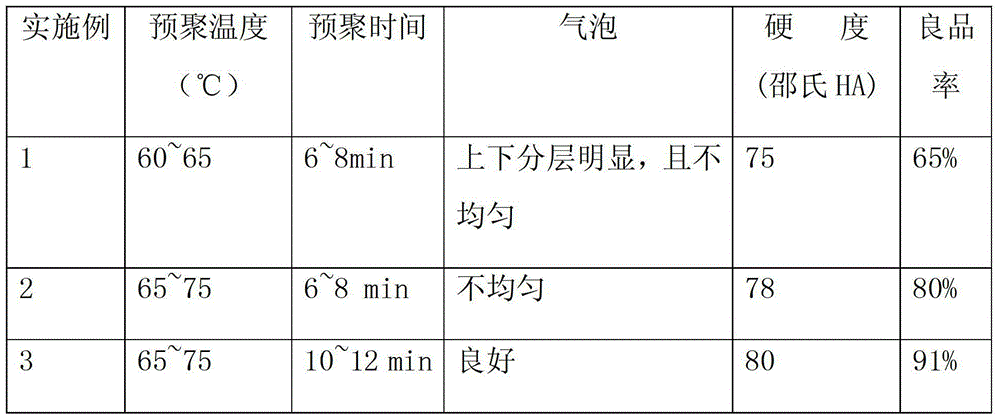

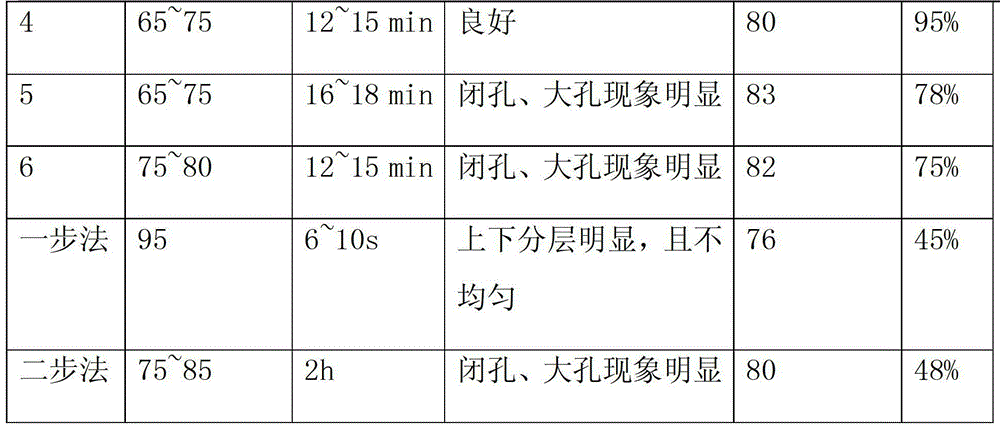

Preparation method of polyurethane polishing material

The invention discloses a preparation method of polyurethane polishing material; the polyurethane polishing material is prepared by a 'rapid three-step method' technology, so that the viscosity and the reaction head of all reaction stages can be better controlled, the demands that the material has a certain aperture ratio and solid filler is rapidly and evenly mixed can be met, and the effects of stable operation and good production repeatability can be achieved; and a prepared polyurethane polished section is even in foams, the service life and the cutting rate are greatly improved, and the highest yield reaches up to more than 95%.

Owner:HEFEI HONGGUANG ABRASIVE SCI & TECH

Milling cutter having three continuously curved cutting edges

ActiveUS20040223817A1High strengthHigh cutting rateTransportation and packagingMilling cuttersRotational axisEngineering

Owner:SECO TOOLS AB

Silicon-cerium polishing liquid and preparation method thereof

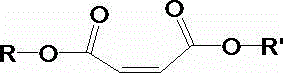

ActiveCN104312441AImprove polishing efficiencyHigh polishing precisionPolishing compositions with abrasivesCeriumPhysical chemistry

The invention relates to a silicon-cerium polishing liquid which comprises micron order cerium dioxide powder, nanoscale cerium dioxide powder, colloidal silicon dioxide, succinic acid ester or succinate, a negative ion dispersant and the balance of water, wherein the grain size of the micron order cerium dioxide powder is 0.5-2.0 microns, the micron order cerium dioxide powder with the gain size of less than 1.5 microns accounts for over 60% and the micron order cerium dioxide powder with the grain size of less than 1.8 microns accounts for below 5%; the grain size of the nanoscale cerium dioxide powder is 20-100nm, the nanoscale cerium dioxide powder with the gain size of less than 50nm accounts for 30-35% and the nanoscale cerium dioxide powder with the gain size of greater than 80nm accounts for 10-15%. The silicon-cerium polishing liquid provided by the invention can be used for a high-precision grinding and polishing process of glass, sapphires, resin lenses and semiconductor substrates and has the advantages of being high in polishing efficiency, high in polishing precision and high in cutting rate.

Owner:包头中科雨航抛光材料有限公司

Method for recycling waste rare earth polishing powder and rare earth polishing liquid

ActiveCN104371555AImprove leaching rateImprove qualityPolishing compositions with abrasivesRare-earth elementPhysical chemistry

The invention relates to a method for recycling waste rare earth polishing powder. The method comprises the following steps: mixing waste rare earth polishing powder with nitric acid, and adding hydrogen peroxide to the bottom of a liquid; heating to dissolve the waste rare earth polishing powder, so as to obtain a liquid containing a rare-earth element; adding ammonium hydroxide to the obtained liquid containing the rare-earth element and adjusting the pH value to be 5.0-6.0; adding hydrogen peroxide under a heating condition, and then adding a little of suspension liquid of Ce(OH)4; stirring and standing to obtain a rare earth hydroxide sediment; and roasting to obtain a rare earth oxide, and then grinding the rare earth oxide until the particle size is smaller than 2 microns. The rare-earth polishing liquid prepared from the rare earth oxide recycled by the method can be applied to high-precision grinding and polishing processes of glass, sapphire, resin lenses and semiconductor substrates, and has the advantages of high polishing efficiency, high polishing accuracy and high cutting rate.

Owner:包头中科雨航抛光材料有限公司

Silicon carbide polishing solution and application thereof

ActiveCN111518478AImprove polishing efficiencyNo volatility issuesPolishing compositions with abrasivesCarbide siliconWafer fabrication

The invention provides a silicon carbide polishing solution and application thereof, belonging to the field of silicon carbide polishing solutions. The silicon carbide polishing solution in the invention uses a non-aqueous solvent for replacing water, so the problem that the characteristics of reaction activation energy, coordination performance, oxidation-reduction potential and the like of eachcomponent in the polishing solution are limited by an aqueous solution is avoided; the silicon carbide polishing solution provided by the invention has good diamond suspension property, can improve polishing efficiency, has no volatility problem, is easy to store for a long time, and is an ideal polishing solution with sub-nanoscale finish degree for manufacturing of semiconductor compound wafers.

Owner:宁波日晟新材料有限公司

Roasting process of lanthanum-cerium oxide rear-earth polishing powder

InactiveCN103253694AFine granularityGood shape structureRare earth metal compoundsRoom temperatureLanthanum

The invention discloses a roasting process of lanthanum-cerium oxide rear-earth polishing powder, which belongs to the chemical field. The roasting process comprises the following temperature courses in sequence: (a), a first heat-up stage, wherein the temperature is increased to 970 DEG C from the room temperature within 180 minutes-210 minutes; (b), a first constant-temperature stage, wherein the temperature is kept within 970 DEG C+ / - 5 DEG C for 150 minutes-180 minutes; (c), a second heat-up stage, wherein the temperature is increased to 1090 DEG C from 970 DEG C within 30 minutes-60 minutes; (d), a second constant-temperature stage, wherein the temperature is kept within 1090 DEG C+ / -5 DEG C for 180 minutes-240 minutes; and (e), a cool-down stage, wherein the temperature is reduced to 60 DEG C-100 DEG C from 1090 DEG C within 20 minutes-40 minutes. The polishing powder manufactured by the roasting process is high in cutting rate, small in scratching depth to a ground object and low in proportion.

Owner:郭尧

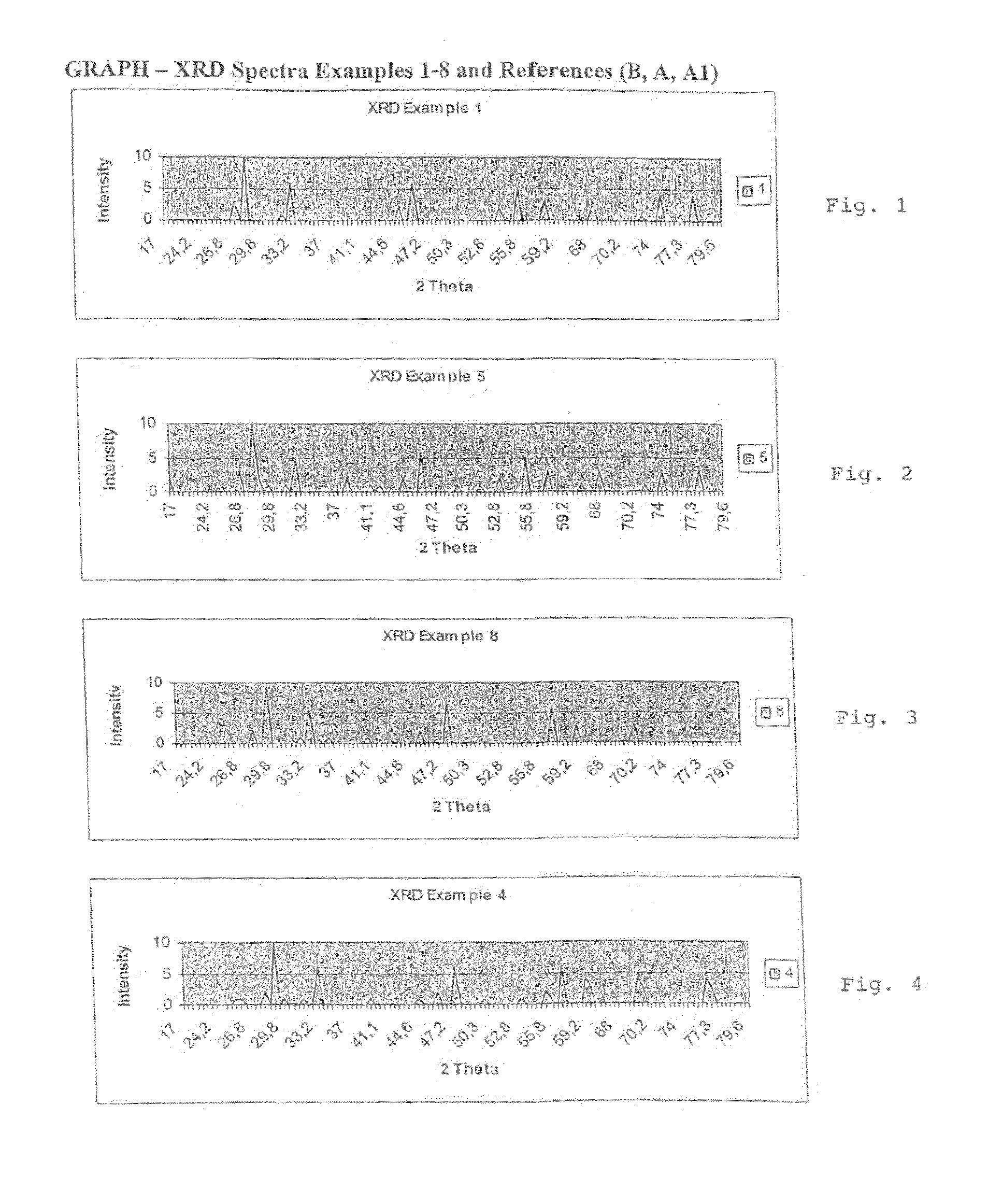

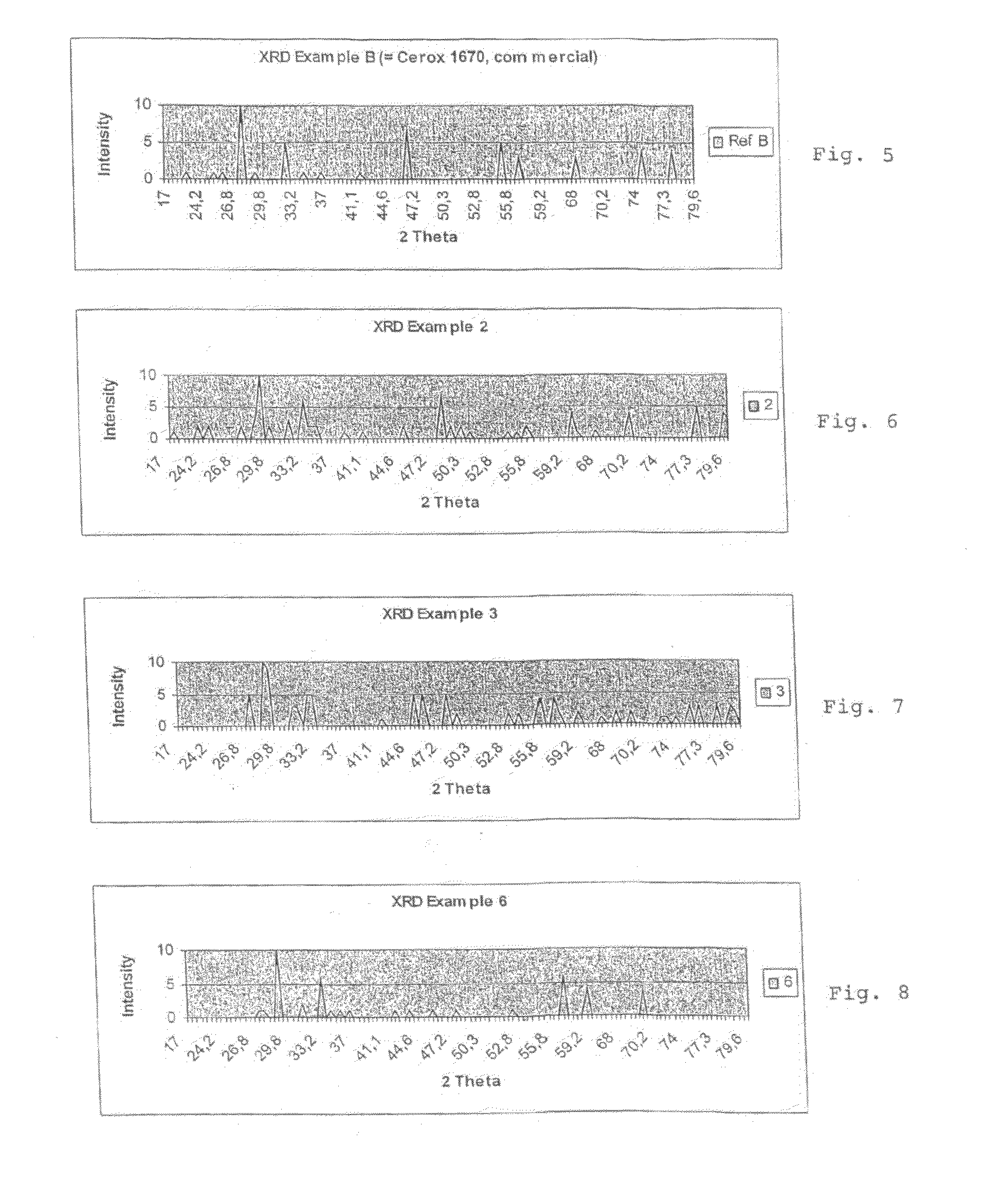

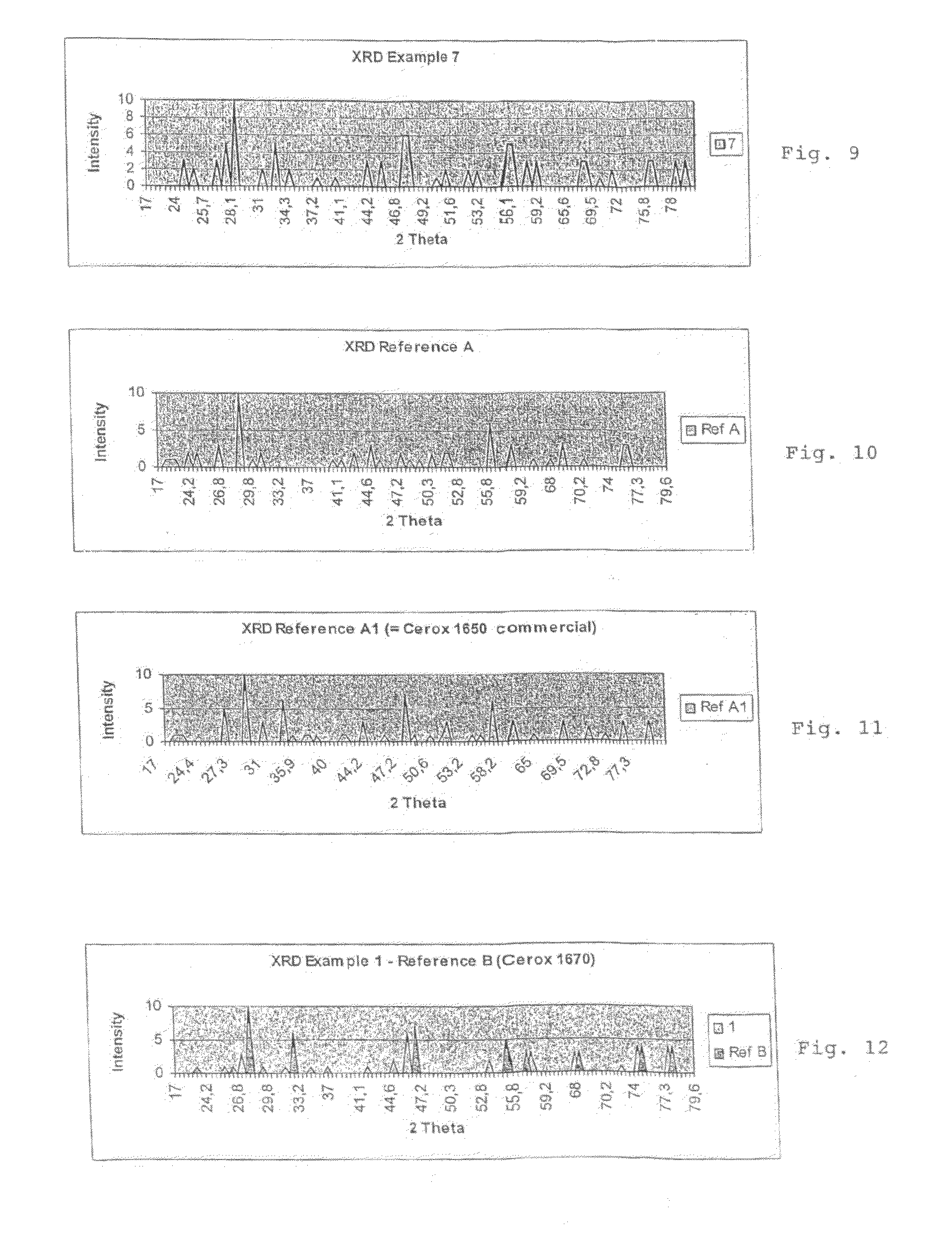

Ceria Based Glass Polishing Composition and a Process For the Manufacture Thereof

ActiveUS20080307712A1Improved stock removal rateAdditional stepPhosphorus oxidesPigmenting treatmentCerium oxideAqueous suspension

The invention is directed to a process for the manufacture of a ceria based polishing composition, comprising (a) suspending an inorganic cerium salt or cerium hydroxide with a cerium content calculated as cerium oxide in the range of 50%-100% based on Total rare earth oxide (TREO) in an aqueous medium thereby obtaining an aqueous suspension, (b) treating said aqueous suspension with an acid or a salt of an acid selected from the group of HF, H3PO4 and H2SO4, thereby obtaining a solid suspended in said aqueous medium, (c) separating said solid from said aqueous medium, and (d) calcining the separated solid at a temperature between 750° C. and 1,200° C. and grinding the calcined solid to grain sizes in the range of 0.5 μm to 5.0 μm.

Owner:TREIBACHER IND AG

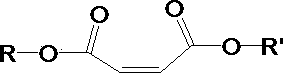

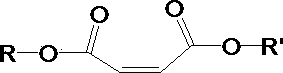

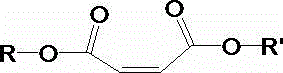

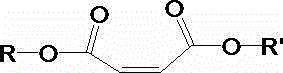

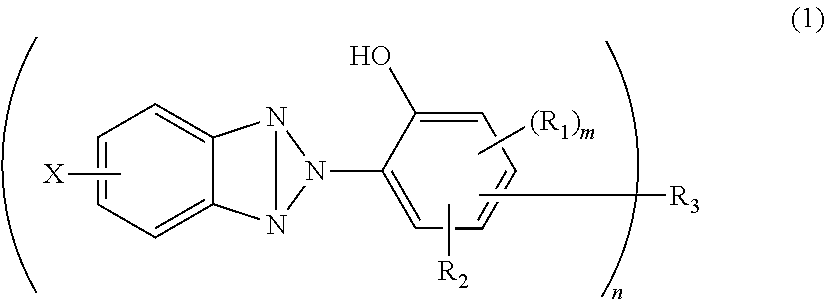

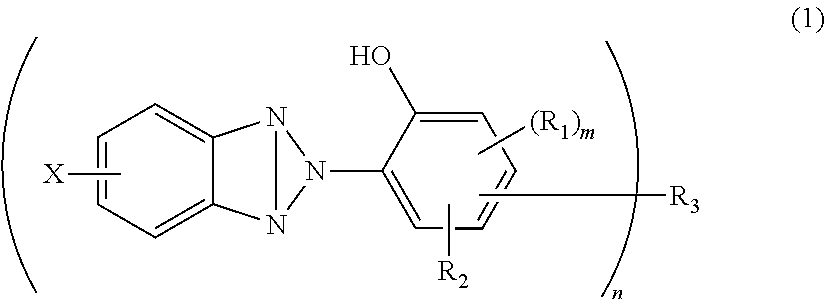

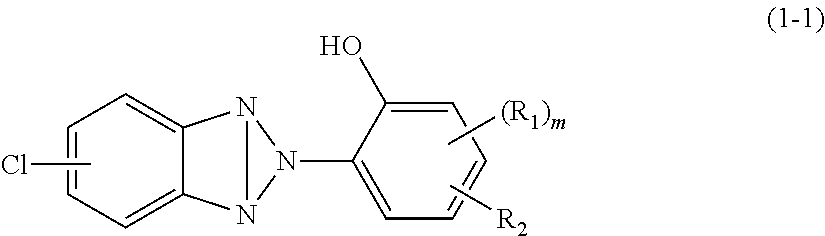

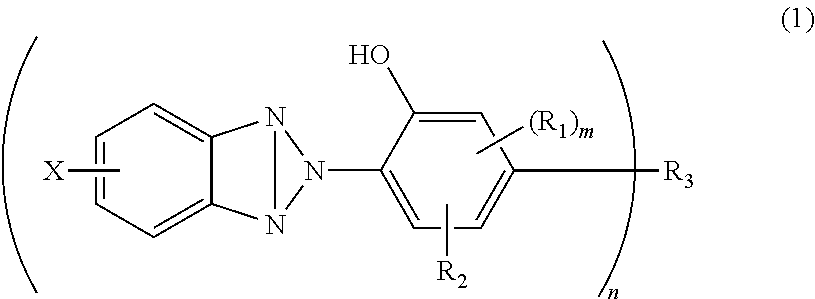

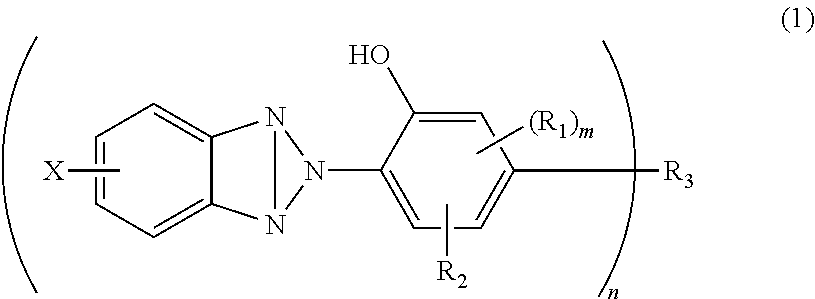

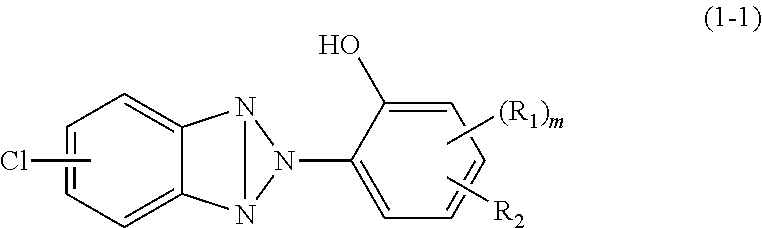

Transparent plastic substrate and plastic lens

To provide a transparent plastic substrate having a high cut rate of blue light, a plastic lens and a transparent plastic member. A transparent plastic substrate containing a benzotriazole compound represented by the formula (1), a plastic lens containing the transparent plastic substrate, and a transparent plastic member containing a benzotriazole compound represented by the formula (1).

Owner:HOYA LENS THAILAND LTD

Transparent plastic substrate and plastic lens

Owner:HOYA LENS THAILAND LTD

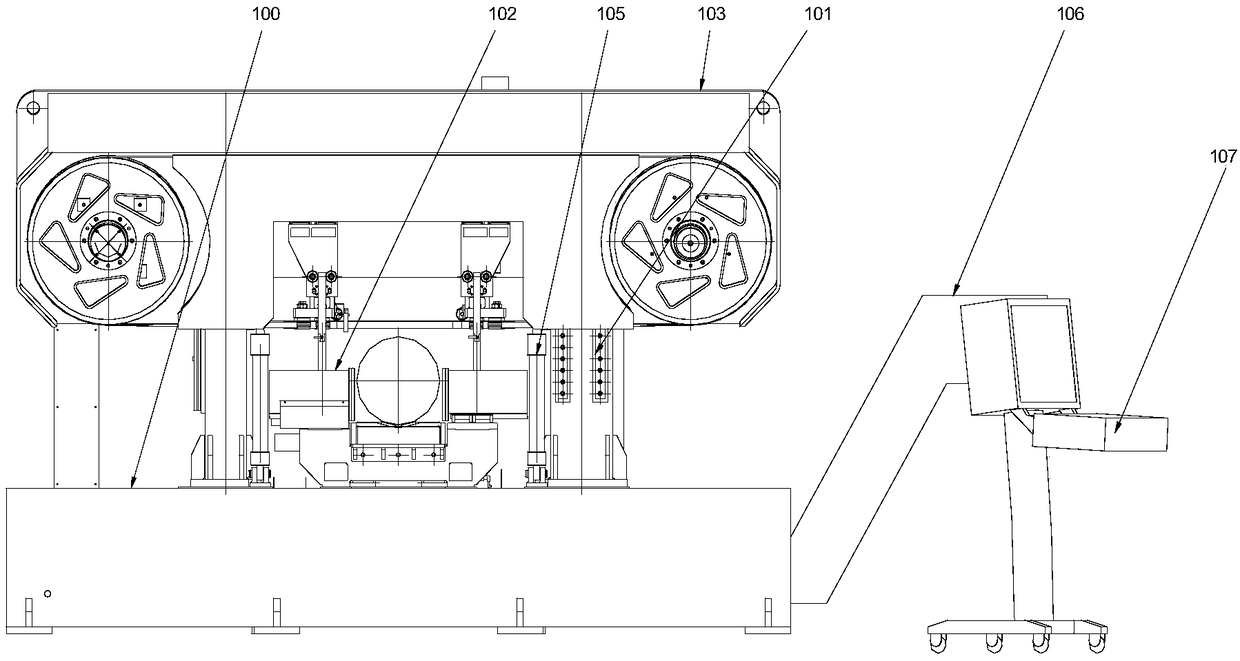

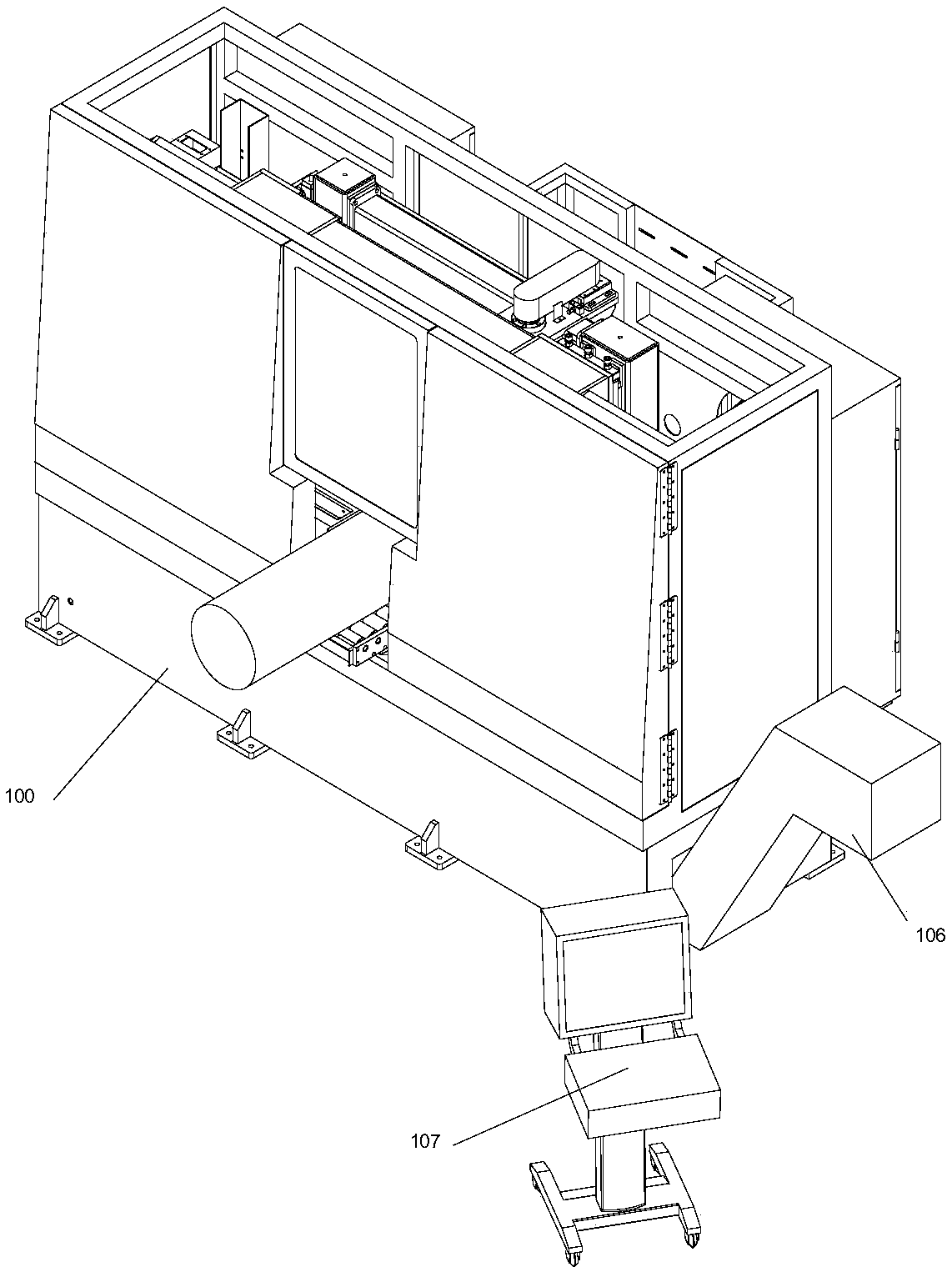

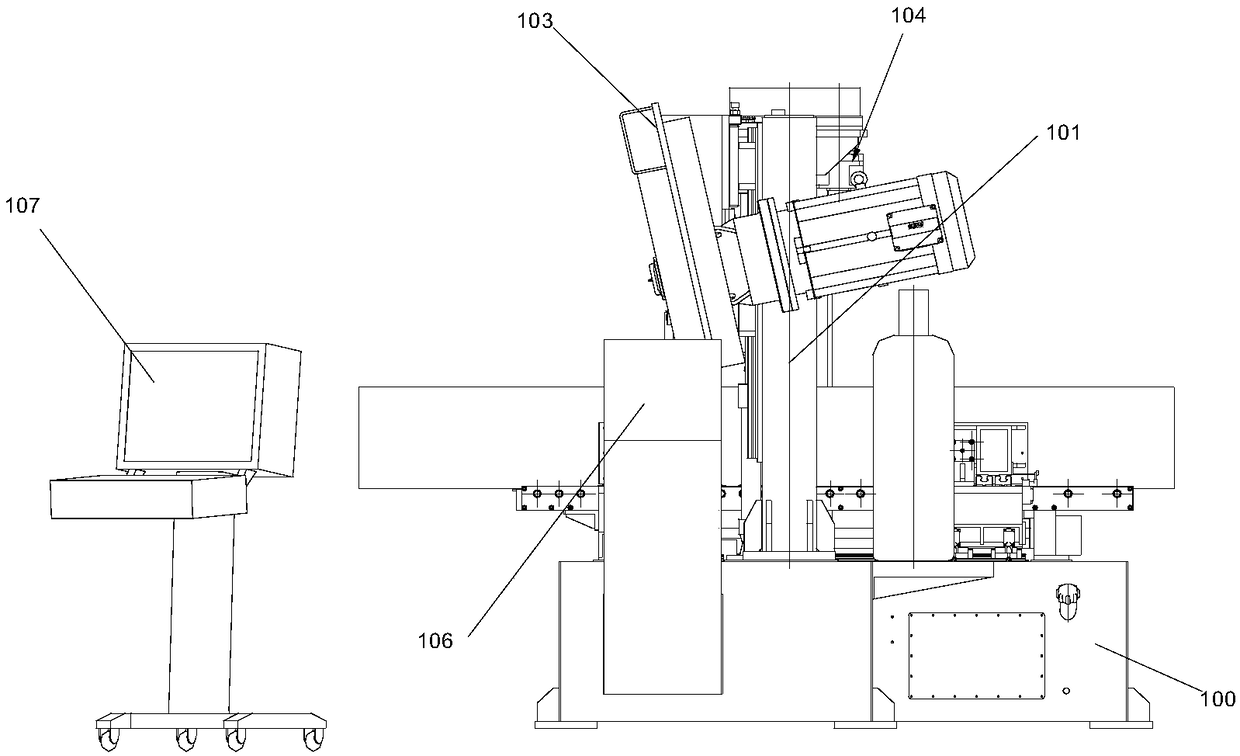

Ultrahigh-speed horizontal band sawing machine

PendingCN108526593AChange mechanical stateEliminate Directional Rotational MomentMetal sawing devicesUltra high speedMotor drive

The invention discloses an ultrahigh-speed horizontal band sawing machine. The ultrahigh-speed horizontal band sawing machine comprises a base, a vertical column, a machine table and a sawing frame and further comprises a servo driving system and a sawing frame lifting balance system. The servo driving system comprises a servo motor, a decelerator and a ball lead screw. The decelerator is mountedon the vertical column, the ball lead screw is connected with the sawing frame, and the servo motor drives the sawing frame to rise and fall by driving the ball lead screw to rotate. The sawing framelifting balance system is used for reducing the axial linear load of the servo motor and provided with symmetrically arranged oil cylinders, a hose and an energy storage device. The lower ends of theoil cylinders are fixed to the base, the upper ends of the oil cylinders are connected with the sawing frame, and the energy storage device is connected with the two oil cylinders through the hose. The sawing frame is inclined forwards relative to the vertical column to be arranged. According to the ultrahigh-speed horizontal band sawing machine, the design that the rear inclination angle of a traditional sawing frame is 35 degrees is changed, the design that the front inclination angle is 12 degrees is adopted, thus the overall gravity center of the sawing frame and the motion axis are basically overlapped, the mechanical state of lifting motion of the sawing frame in the sawing process is changed, moment of rotation in the Y-axis direction of the sawing frame is eliminated, friction resistance between a sliding sleeve and the vertical column during lifting motion of the sawing frame is reduced, and the service life of the machine is prolonged.

Owner:昆山汉田机械工业有限公司

Preparation method for polyurethane polishing material by using network interpenetration

InactiveCN103342795AStable material systemLong storage time at room temperaturePolishing compositions with abrasivesEpoxyPolyol

The invention discloses a preparation method for a polyurethane polishing material by using network interpenetration. A secondary hydroxyl group and an epoxy group in polymer polyol and an epoxy resin are allowed to react with isocyanate by using an interpenetrating polymer network (IPN) method, then polishing powder is interpenetrated and filled into a polyurethane network, so pressure resistance, heat resistance and hydrolytic stability of the polyurethane polishing material can be improved, and wear resistance of a substrate material is appropriately reduced at the same time; meanwhile, since a part of organic dispersions are filled in the structure of the material, wear resistance of a polyurethane foam substrate is reduced, which enables the substrate and a polishing powder filling material to fall off synchronously, so the problems of great possibility of passivation and reduction of a stock removal rate of a polishing gasket with high wear resistance are solved.

Owner:HEFEI HONGGUANG ABRASIVE SCI & TECH

Polishing composition and polishing method

ActiveUS20080233836A1High cutting rateOther chemical processesDwelling equipmentColloidal silicaColloid

A polishing composition includes more than 0.1% by mass of colloidal silica, and water, and has a pH of 6 or less. The polishing composition has the ability to polish a titanium material at a high stock removal rate. Thus, the polishing composition is suitable for use in applications for polishing a titanium-containing object.

Owner:FUJIMI INCORPORATED

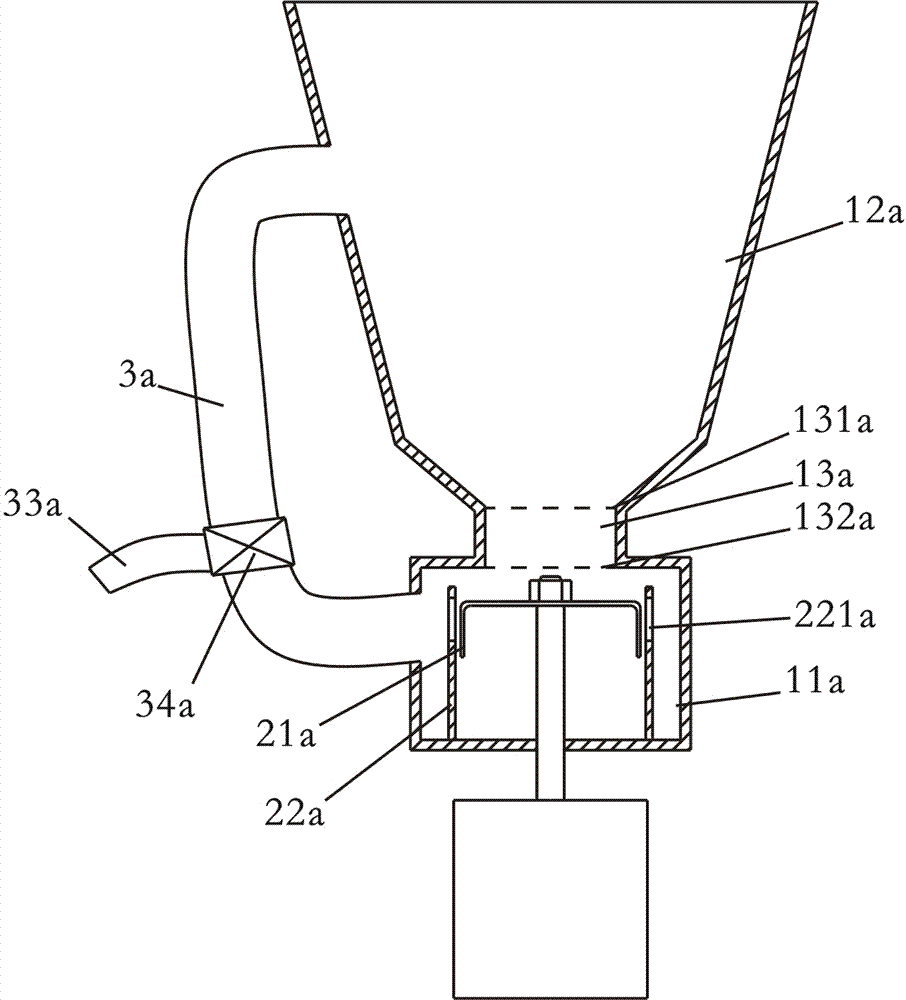

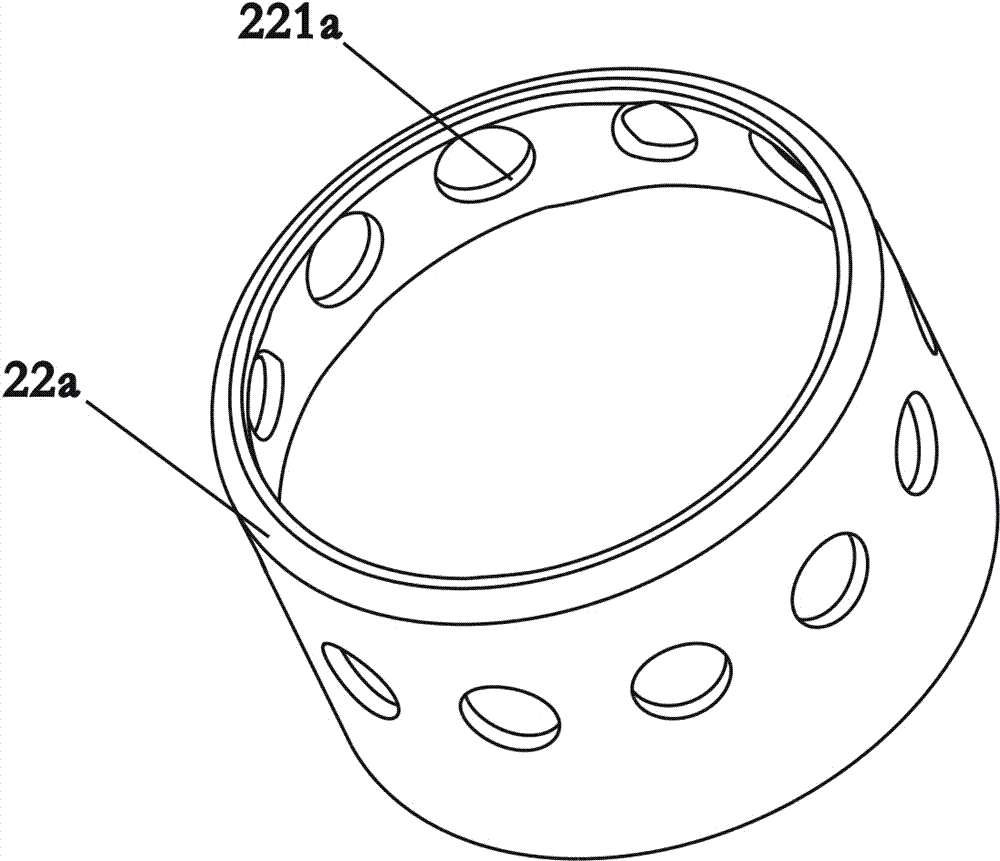

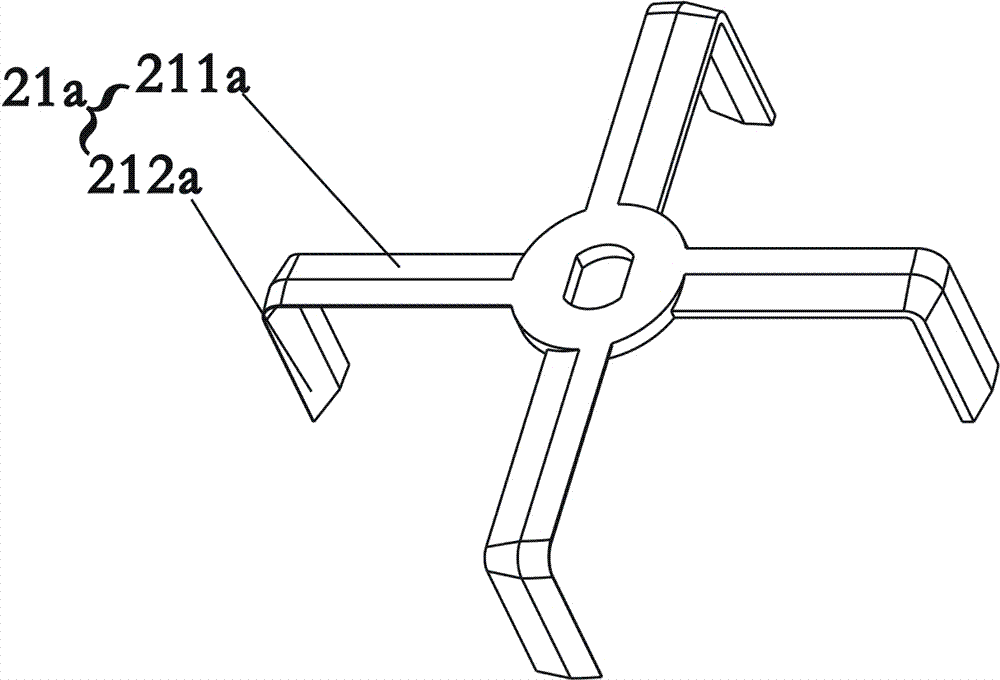

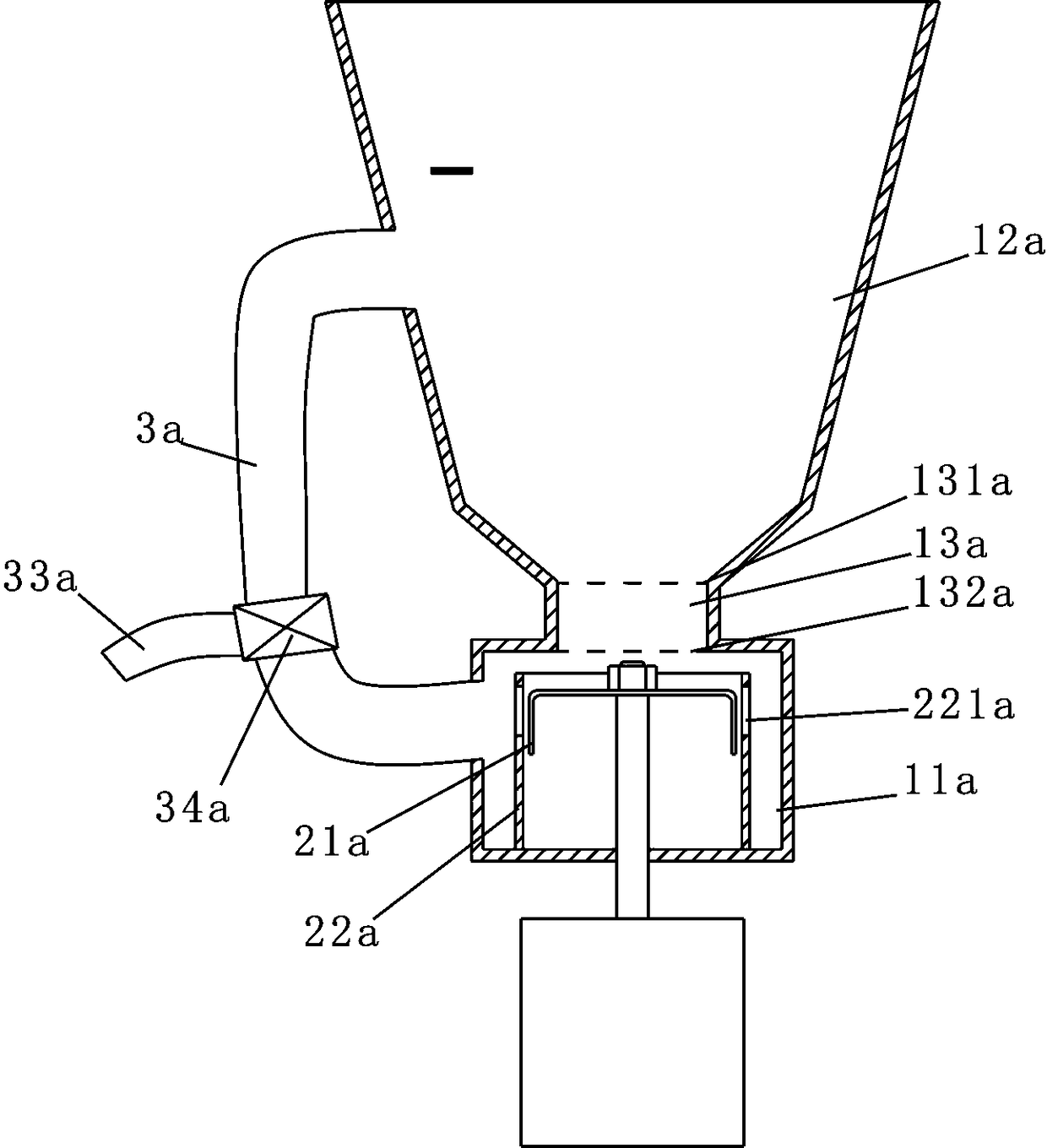

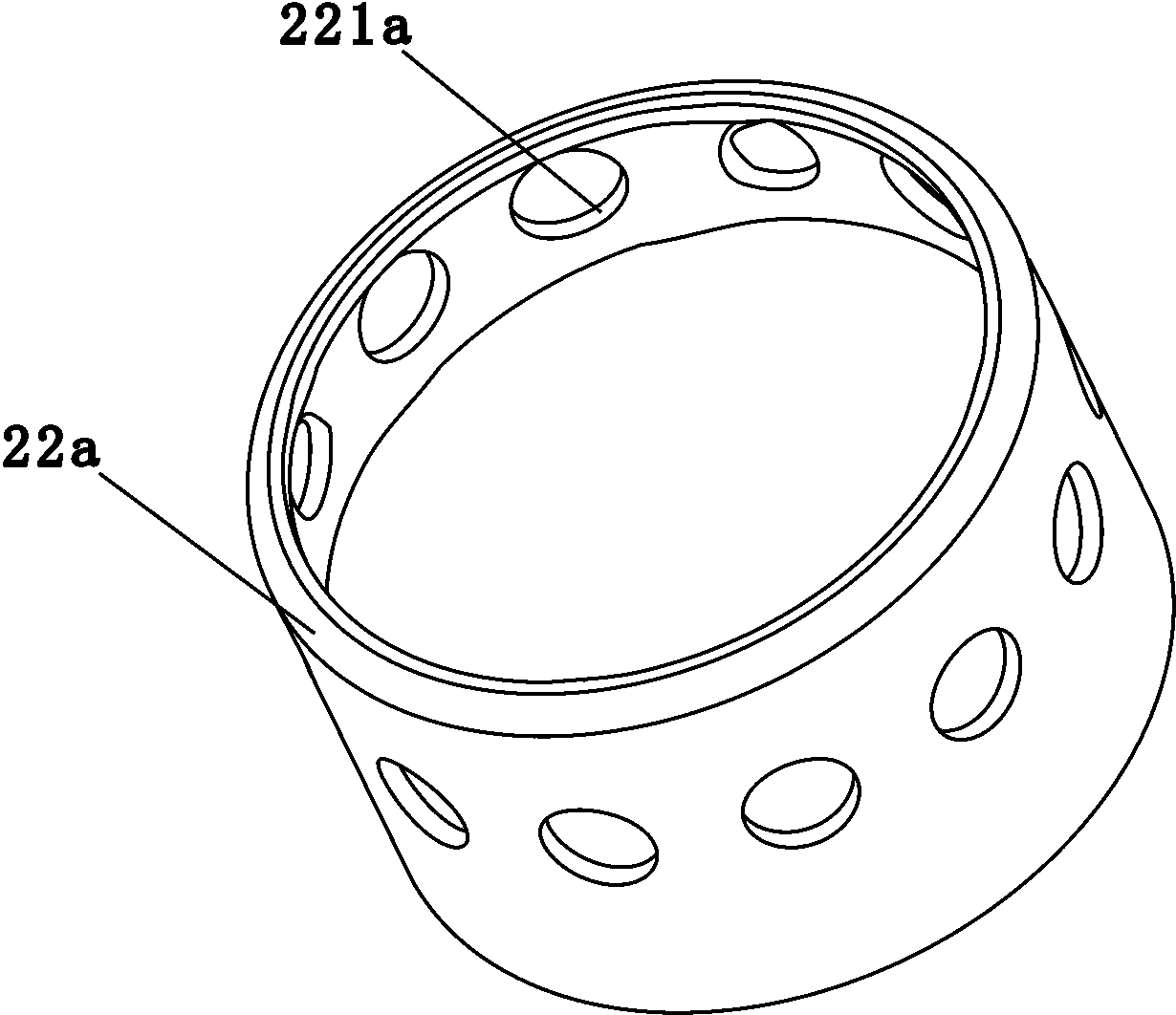

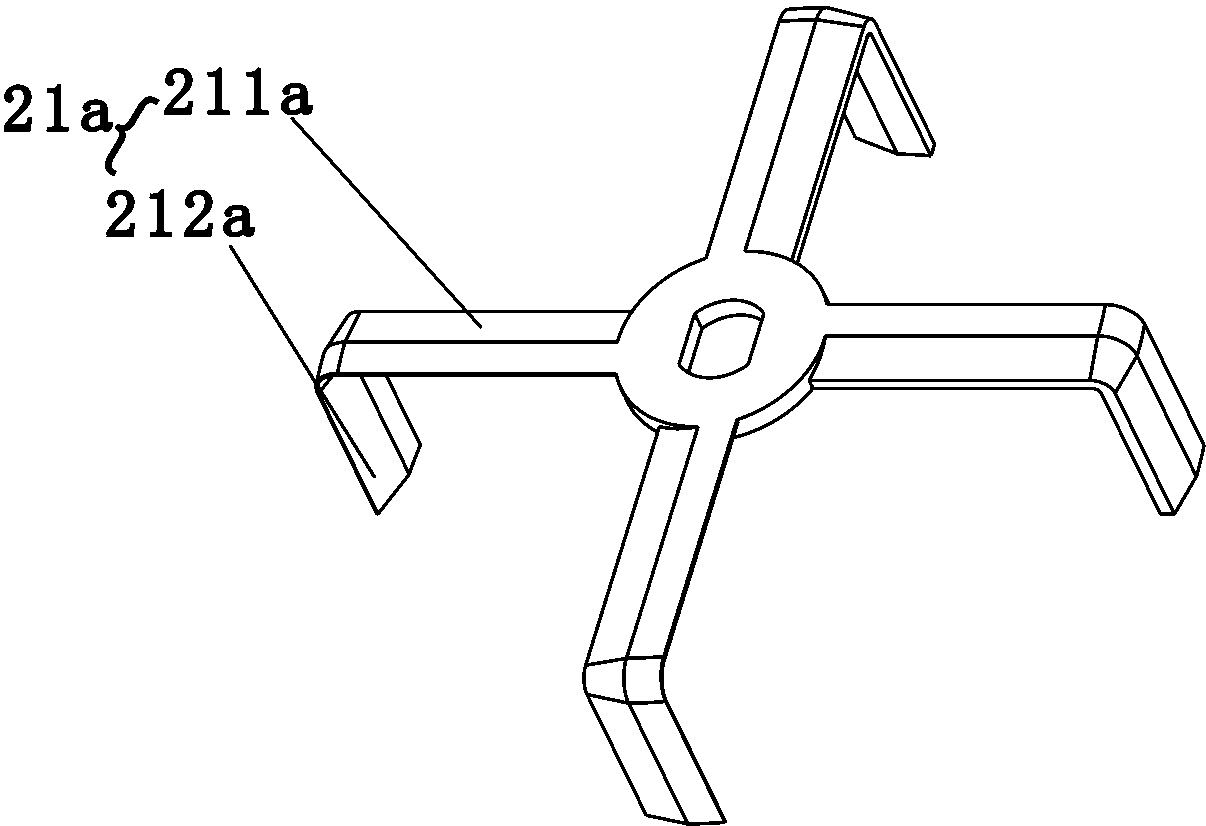

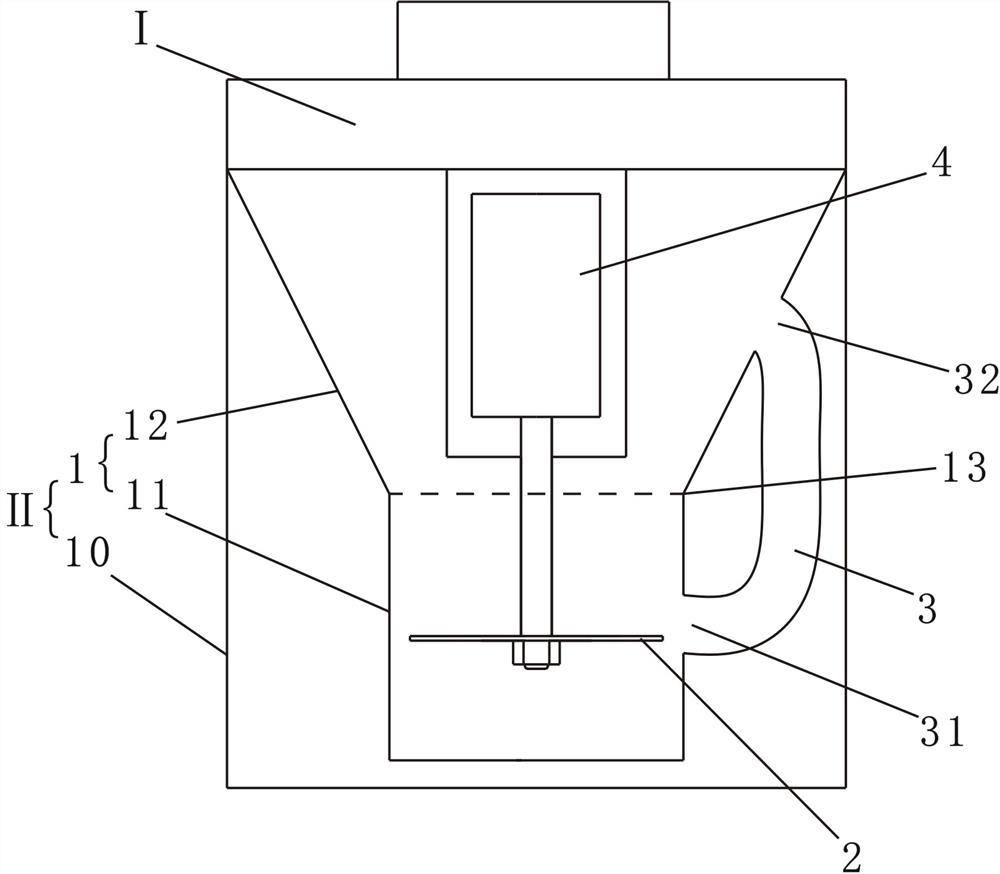

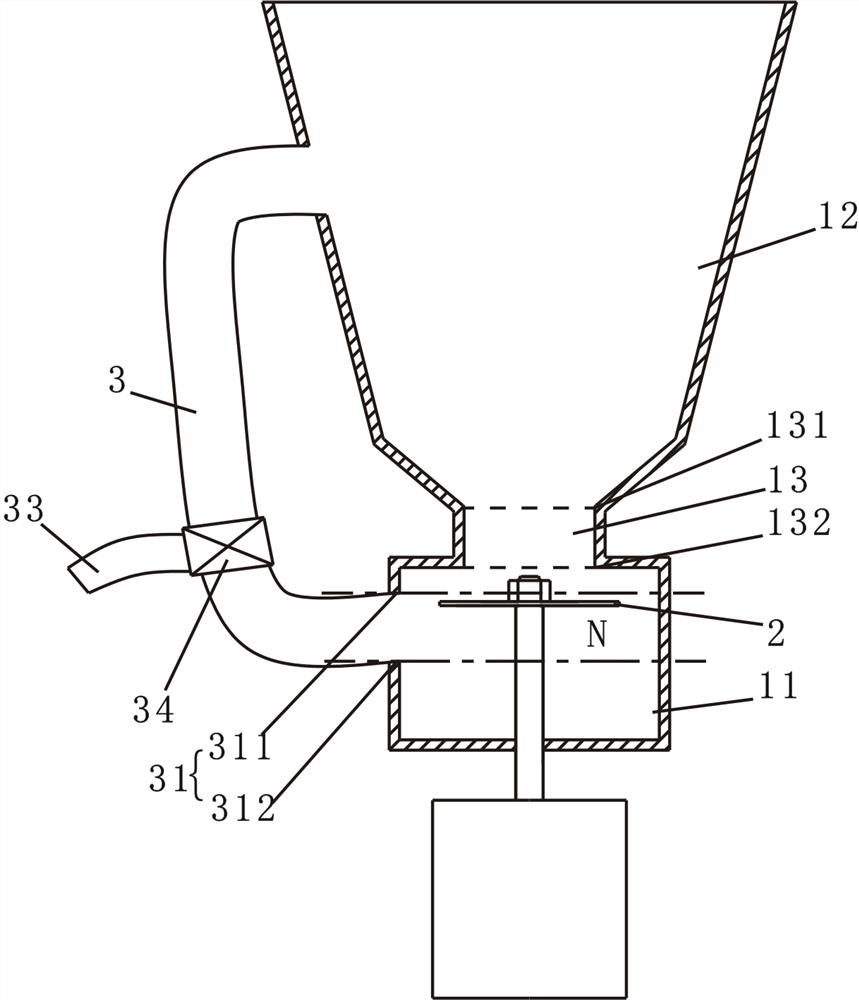

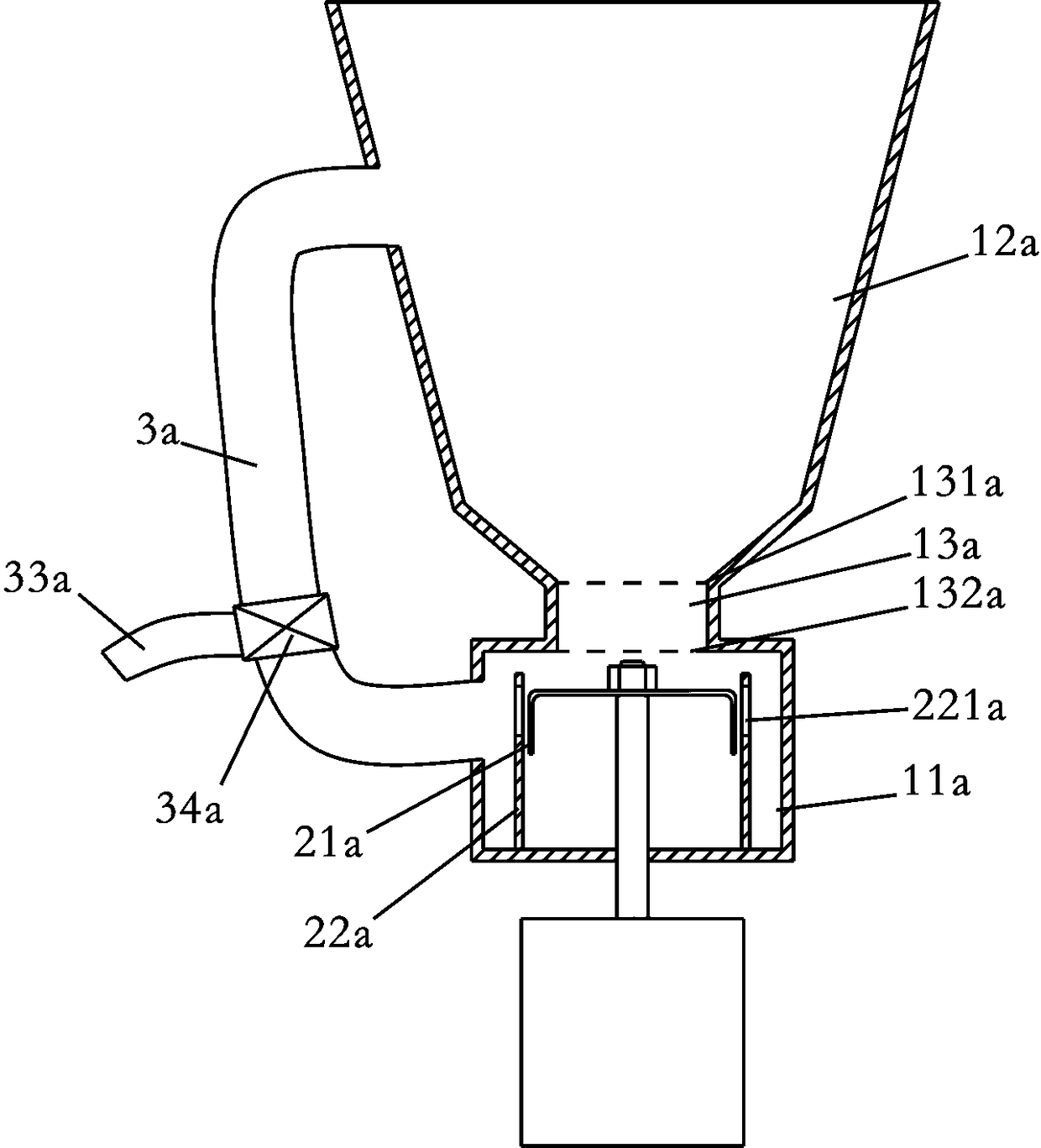

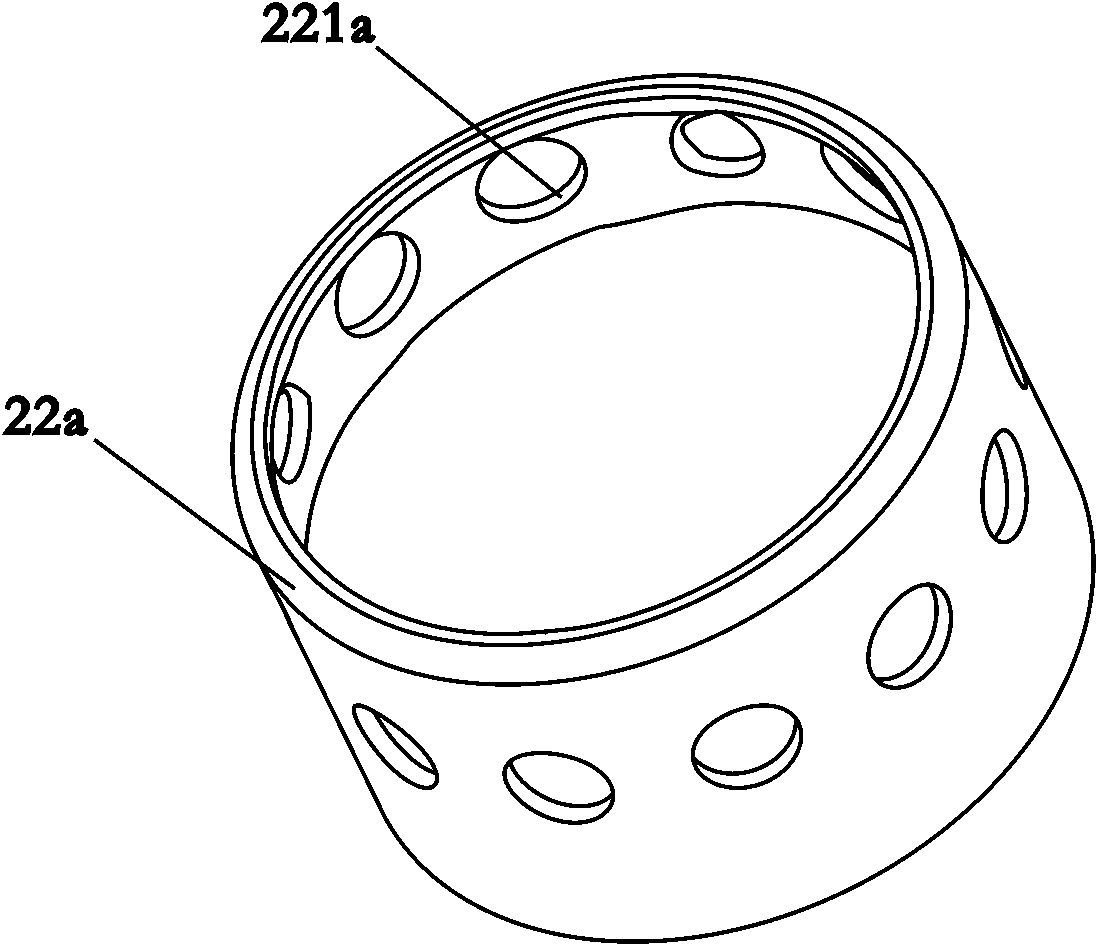

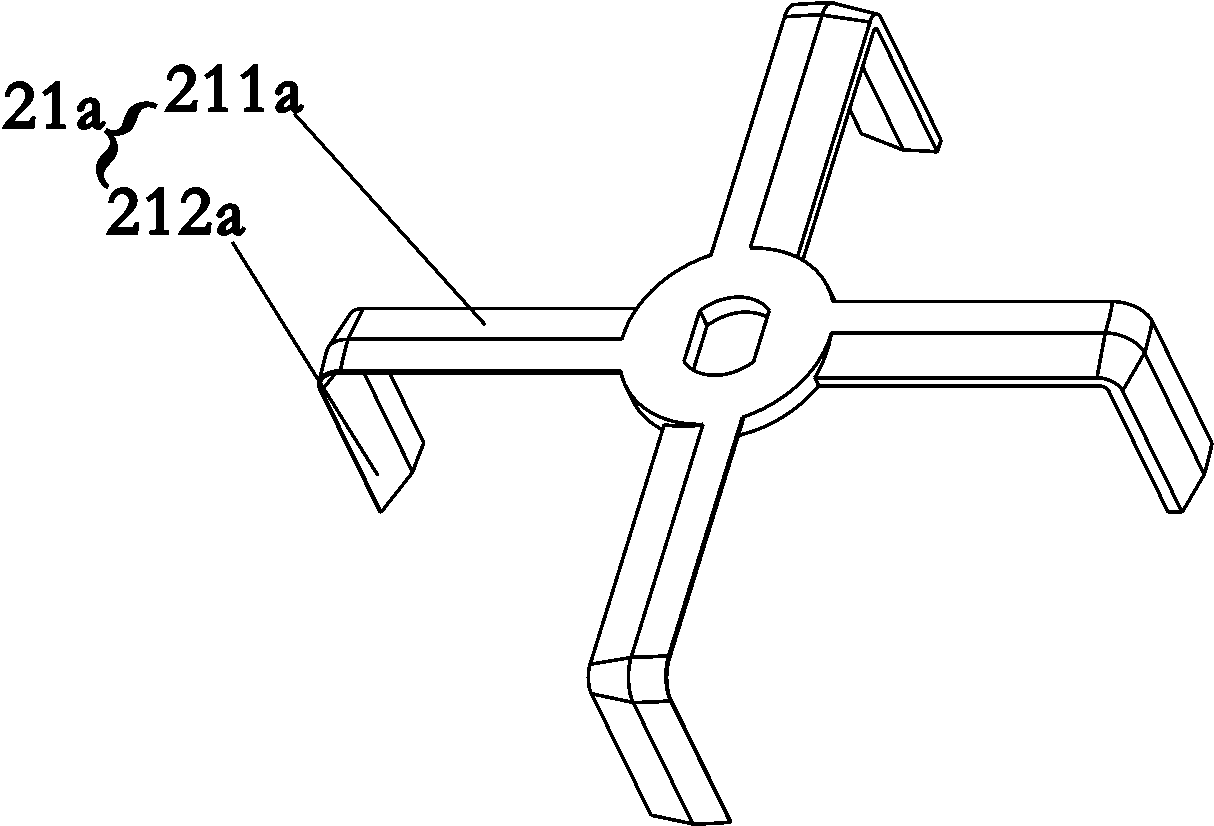

Crushing device for foodstuff processing machine and foodstuff processing machine

ActiveCN107319964ANot easy to escapeHigh efficiency of centralized crushingKitchen equipmentEngineeringHome appliance

The invention relates to home appliances for kitchens and especially relates to a foodstuff processing machine. The crushing device for a foodstuff processing machine comprises a container, crushing blades installed inside the container and a circulation pipeline which vertically runs through the container; the crushing blades are driven by a motor; the circulation pipeline is installed outside the container; the container comprises a crushing chamber which is installed at a bottom of the container, a backflow chamber which is positioned above the crushing chamber and a flow collecting port for communicating the crushing chamber and the backflow chamber; the capacity of the crushing chamber is 20mL to 400mL; the crushing blades are installed inside the crushing chamber; the flow collecting port is installed above the crushing blades; an inlet of the circulation pipeline is positioned inside the crushing chamber; an outlet of the circulation pipeline is positioned inside the backflow chamber; the area of the opening of the flow collecting port is smaller than the area of the opening of any horizontal cross section of the backflow chamber under the circulation pipeline outlet. Compared with the prior art, the invention has the advantages of simple structure, low cost, centralized crushing of material by the crushing device, high crushing efficiency, no bean block phenomenon and convenient cleaning.

Owner:JOYOUNG CO LTD

Food processing machine

ActiveCN108309086AImprove efficiencyThe surface of the slurry is smoothKitchen equipmentEngineeringMechanical engineering

The invention relates to a small household electrical appliance in a kitchen, especially a food processing machine. The food processing machine comprises a container and is characterized in that the container comprises a crushing chamber located at the bottom of the container, a backflow chamber arranged on the crushing chamber and a flow gathering opening used for communicating the crushing chamber with the backflow chamber; a crushing blade is arranged in the crushing chamber; the capacity of the crushing chamber ranges from 22 mL to 380 mL; the side wall of the backflow chamber is equippedwith a water level marking line; the outside located outside the container is equipped with a circulating pipeline connecting the crushing chamber with the backflow chamber; an inlet of the circulating pipeline is located in the crushing chamber; an outlet of the circulating pipeline is located in the backflow chamber and the outlet of the circulating pipeline is no higher than the water level marking line. Compared with the prior art, the food processing machine is simple in structure and relatively low in cost and capable of effectively reducing bubbles. Additionally, the machine can crush material in a concentrated manner at great crushing efficiency. No bulky material appears. Additionally, the machine is convenient to clean.

Owner:JOYOUNG CO LTD

Method for finishing a workpiece

InactiveUS7645180B2Reduce potential loss of processing tool efficiencyHigh cutting rateGrinding feed controlAutomatic grinding controlContact pressureMaterial removal

A method for abrasive material removal that includes the steps of establishing an optimum force profile relating to the force or contact pressure applied by a processing tool on a workpiece. The actual force generated during the metal removal operation is monitored and compared to the optimum force profile. Based on the comparison of the actual force with the optimum force profile machine parameters are adjusted such that the actual force generated follows the established optimum force profile.

Owner:THIELENHAUS MICROFINISH

Method for recycling waste rare earth polishing powder and rare earth polishing liquid

ActiveCN104371555BImprove leaching rateImprove qualityPolishing compositions with abrasivesRare-earth elementAmmonium hydroxide

The invention relates to a method for recycling waste rare earth polishing powder. The method comprises the following steps: mixing waste rare earth polishing powder with nitric acid, and adding hydrogen peroxide to the bottom of a liquid; heating to dissolve the waste rare earth polishing powder, so as to obtain a liquid containing a rare-earth element; adding ammonium hydroxide to the obtained liquid containing the rare-earth element and adjusting the pH value to be 5.0-6.0; adding hydrogen peroxide under a heating condition, and then adding a little of suspension liquid of Ce(OH)4; stirring and standing to obtain a rare earth hydroxide sediment; and roasting to obtain a rare earth oxide, and then grinding the rare earth oxide until the particle size is smaller than 2 microns. The rare-earth polishing liquid prepared from the rare earth oxide recycled by the method can be applied to high-precision grinding and polishing processes of glass, sapphire, resin lenses and semiconductor substrates, and has the advantages of high polishing efficiency, high polishing accuracy and high cutting rate.

Owner:包头中科雨航抛光材料有限公司

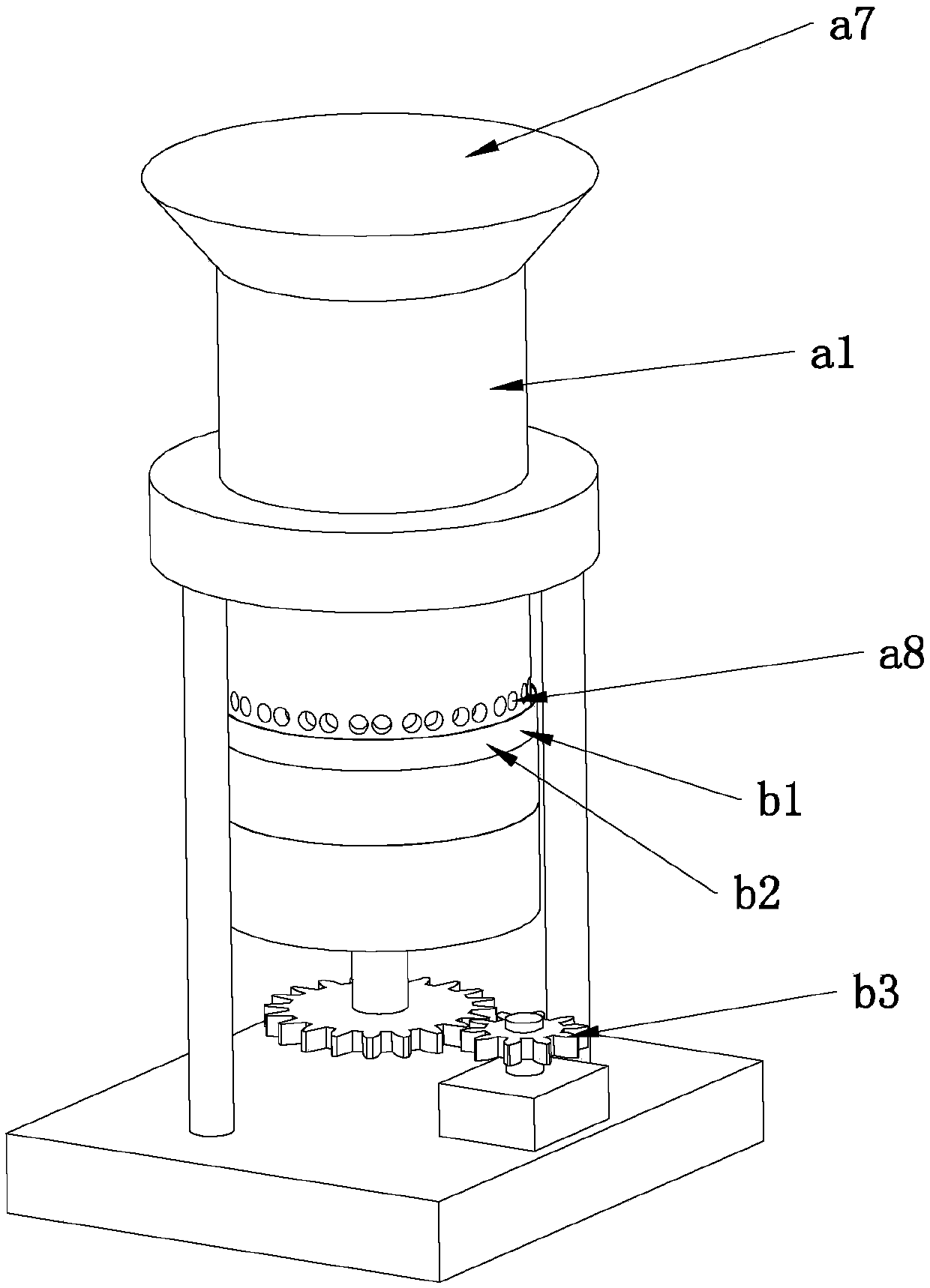

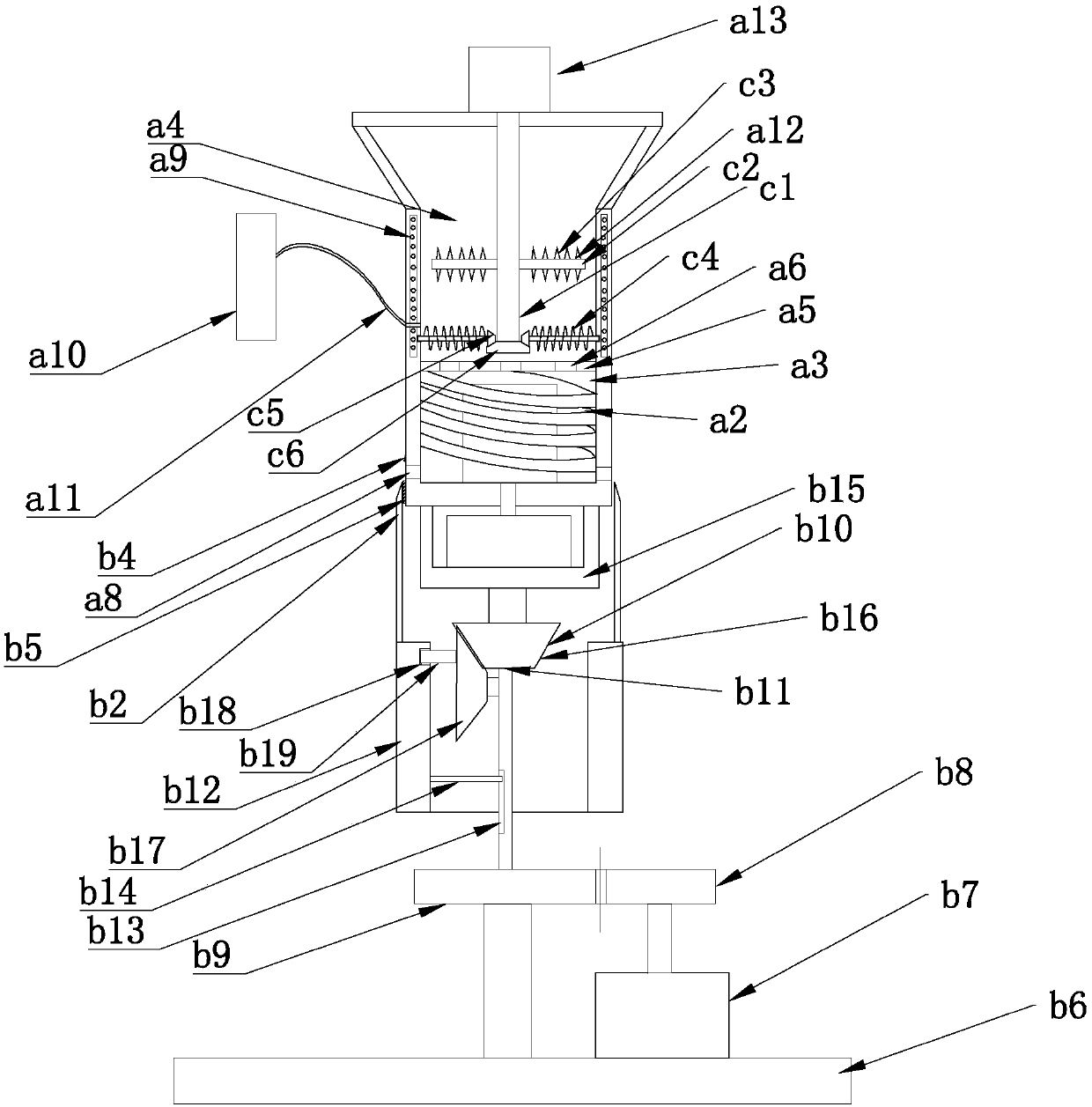

Corn straw briquetting device for evenly cutting materials

InactiveCN109624379ANeat and firm cutHigh cutting rateCuttersCleaning using toolsEngineeringBriquette

The invention discloses a corn straw briquetting device for evenly cutting materials. The corn straw briquetting device for evenly cutting the materials comprises a die compacting seat, a compressionblock and a heating device. The die compacting seat comprises a compression cavity and a softening heating cavity, wherein the softening heating cavity is formed in the upper end of the compression cavity, the softening heating cavity communicates with the compression cavity, the softening heating cavity is separated from the compression cavity through a partition plate, and the partition plate isprovided with a plurality of feeding openings. The compression assembly is arranged in the compression cavity, and the heating device is arranged in the softening heating cavity. Hole-shaped discharging openings are circumferentially formed in the positions, at the lower end of the compression cavity, of the die compacting seat. The compression assembly includes an extruding screw, and the extruding screw can extrude and press straw powder into strips through the discharging openings. A material cutting device is arranged at the lower end of the die compacting seat, the material cutting device comprises an annular blade and a driving assembly which drives the annular blade to move up and down at the discharging openings, wherein the annular blade sleeves the lower end of the die compacting seat, the annular blade is used for cutting a cylindrical straw briquette into sections to achieve the uniform size of finished products, and end parts are compact, and looseness is not prone to occurring.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Alumina polishing solution for copper polishing and preparation method thereof

ActiveCN110256968AReduce equipment damageReduce pollutionPolishing compositions with abrasivesIonCorrosion inhibitor

The invention discloses an alumina polishing solution for copper polishing and a preparation method thereof, belonging to the technical field of preparation of blue glass polishing materials. The alumina polishing solution comprises the following components by weight: 100-400 parts of alumina, 1-40 parts of a surfactant, 1-80 parts of a corrosion inhibitor, 1-100 parts of a pH adjuster, 1-40 parts of a dispersant, 1-40 parts of a suspending agent and 1000 parts of deionized water. The preparation method comprises the following steps: A, material preparation; B, initial mixing; C, re-mixing; and D, pH adjustment. The alumina polishing solution has the characteristics of high polishing efficiency, little environmental pollution, little corrosion to equipment, etc., and is applicable to high-precision polishing of copper surfaces.

Owner:HUNAN HAOZHI TECH

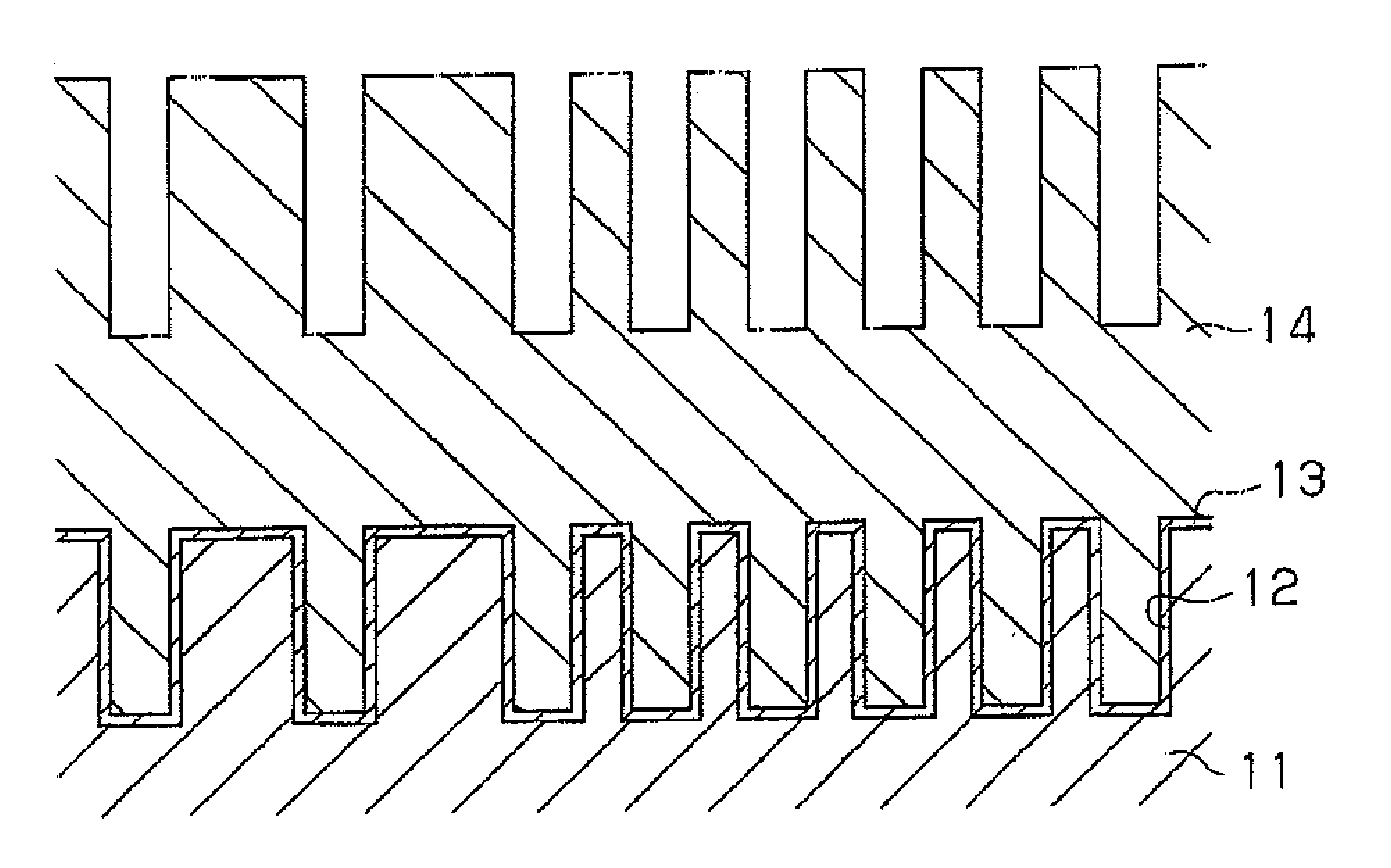

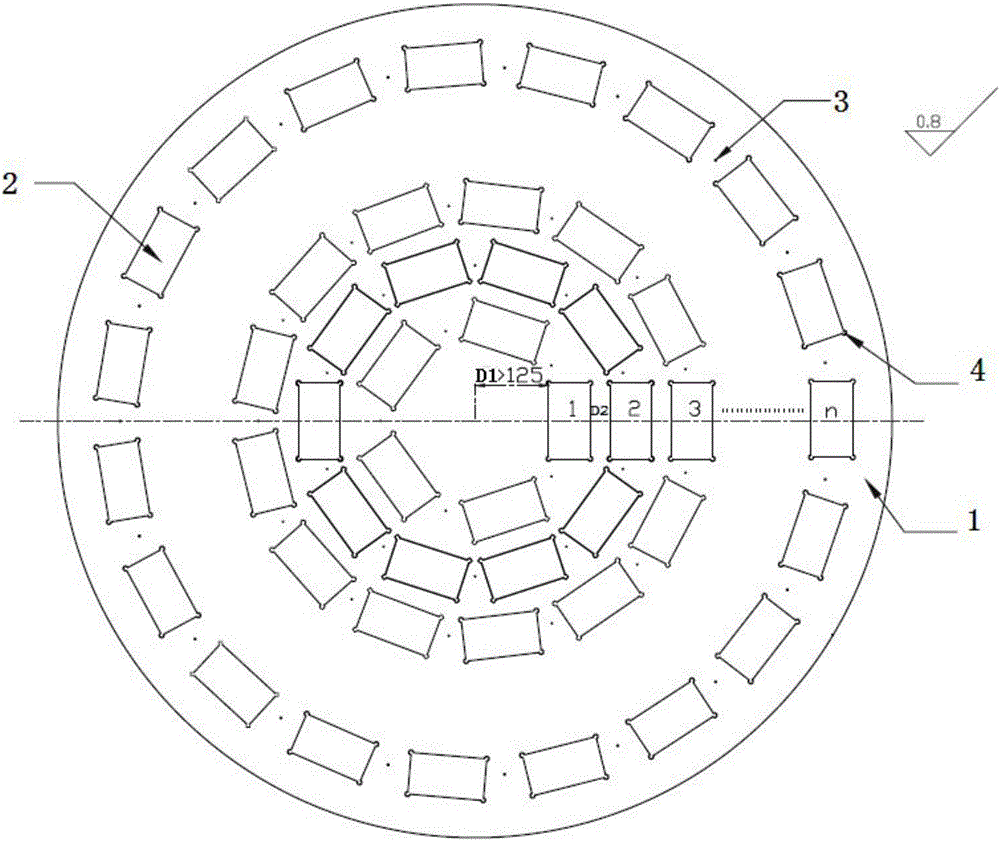

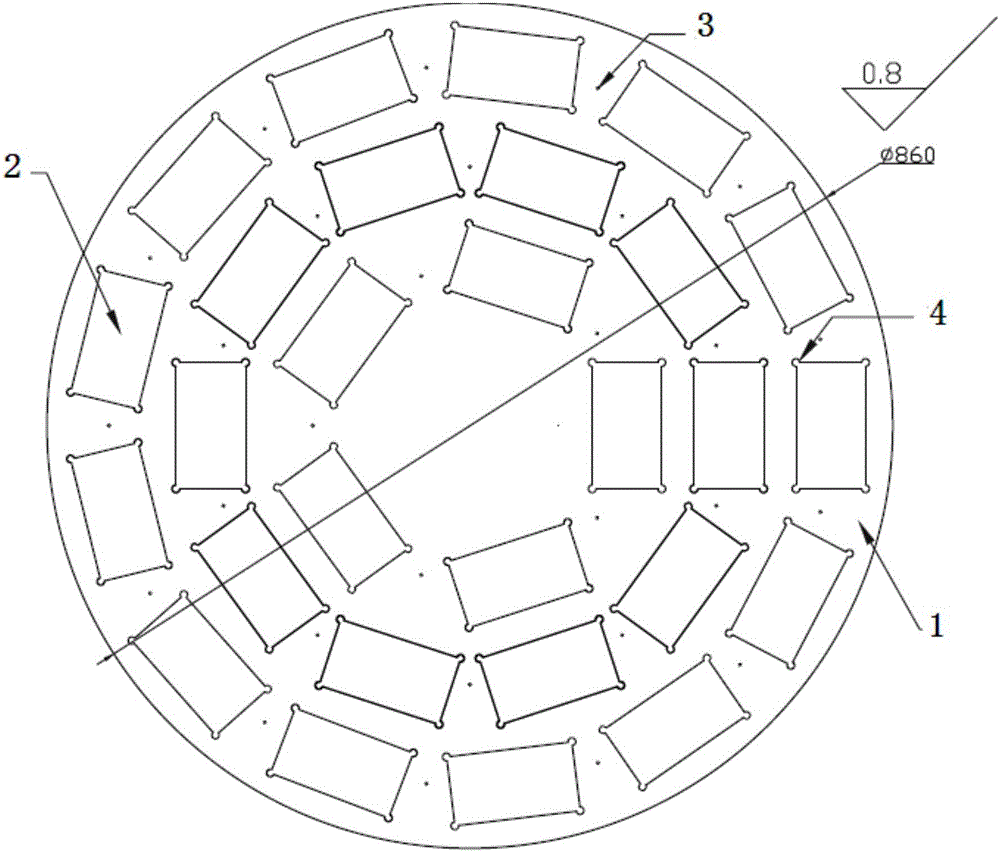

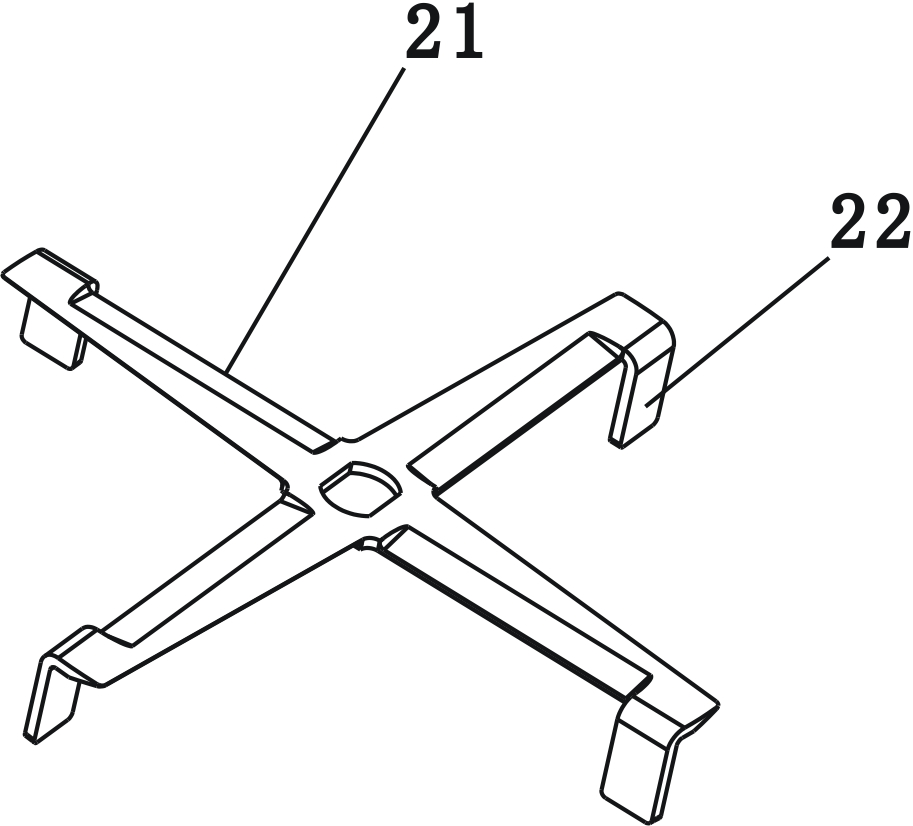

Novel polishing fixing jig for small and medium single liquid crystal display panels

InactiveCN106425857AAffect the polishing effectMaximize arrangementPolishing machinesGrinding work supportsLiquid-crystal displayEngineering

The invention discloses a novel polishing fixing jig for small and medium single liquid crystal display panels. The jig is characterized by comprising a plastic sheet, rectangular limiting grooves used for containing the liquid crystal display panels are formed in the plastic sheet and are arranged with the center of the plastic sheet as the circle center according to equally-divided annular matrixes, and a through exhaust hole is formed between every two adjacent groove positions in each annular matrix. According to the jig, the plastic sheet is combined with an adsorption pad in a vacuum adsorption mode. The optimum and the maximized panel arrangement mode is provided. The jig is suitable for common automatic Oscar polishing and transverse movement type automatic polishing in the industry, the grinding and cutting rate is high, the uniformity is good, the polishing efficiency is improved, and the fragment rate is lowered.

Owner:NANJING HUADONG ELECTRONICS INFORMATION & TECH +1

Grinding device for food processing machine and food processing machine

ActiveCN107319964BNot easy to escapeHigh efficiency of centralized crushingKitchen equipmentElectric machineryEngineering

The invention relates to small kitchen appliances, in particular to a food processor. The crushing device for the food processor includes a container, a crushing blade arranged in the container, and a circulation pipeline connecting the container up and down. The crushing blade is driven by a motor. The circulation pipeline is arranged outside the container, and the container includes a crushing chamber located at the bottom of the container, a return chamber located above the crushing chamber, and a connecting The flow gathering port of the grinding chamber and the reflux chamber. The capacity of the grinding chamber is 20mL~400mL. The grinding blade is set in the grinding chamber. The flow gathering port is set above the grinding blade. The inlet of the circulation pipeline is located in the grinding chamber. The circulation pipeline The outlet is located in the reflux chamber, and the mouth area of the flow gathering port is smaller than the mouth area of any horizontal section of the reflux chamber below the outlet of the circulation pipeline. Compared with the existing technology, the present invention has a simple structure and lower cost, and the crushing device can crush materials in a centralized manner, with high crushing efficiency, no bean lumps, and easy cleaning.

Owner:JOYOUNG CO LTD

Preparation method of rare earth fluoride polishing powder and preparation method of rare earth fluoride polishing solution

ActiveCN110885637AGuaranteed decentralizationGuaranteed uniformityPolishing compositions with abrasivesPyrrolidinonesSlurry

The invention discloses a preparation method of rare earth fluoride polishing powder and a preparation method of a rare earth fluoride polishing solution. The preparation method of rare earth fluoridepolishing powder comprises the steps of: 1) respectively taking rare earth carbonate and rare earth fluoride as precursor raw materials, mixing the rare earth carbonate and the rare earth fluoride ina ball mill, performing ball-milling until slurry particles D50 are 2.0-2.5 [mu]m, wherein a high-energy ball mill is adopted as the ball mill, and the solid content of ball-milled slurry is controlled to be 40-50%; 2) adding polyvinylpyrrolidone into the slurry treated in the step 1), performing mixing, and performing spray drying to obtain powder; and 3) calcining, refining and grading the powder obtained in the step 2) to prepare rare earth fluoride polishing powder. The invention also discloses a preparation method of a polishing solution by mixing the polishing powder and water. After the polishing powder prepared by the invention is applied to surface treatment, the high cutting rate is achieved on the premise of ensuring no surface defects such as scratches on the surface of optical glass, the preparation method is simpler, lower in and shorter in production period, and a large wastewater treatment system does not need to be arranged for each manufacturer.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

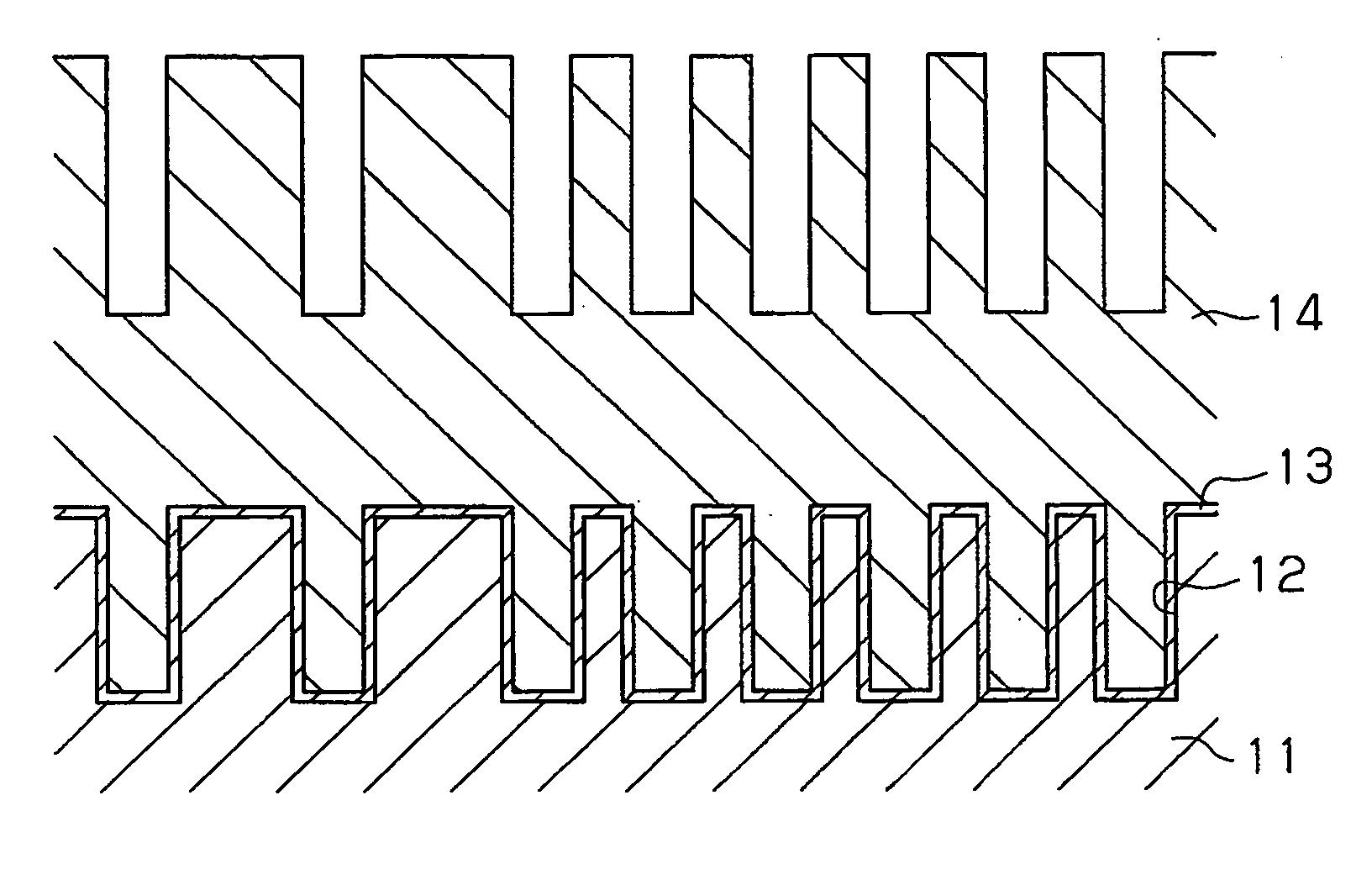

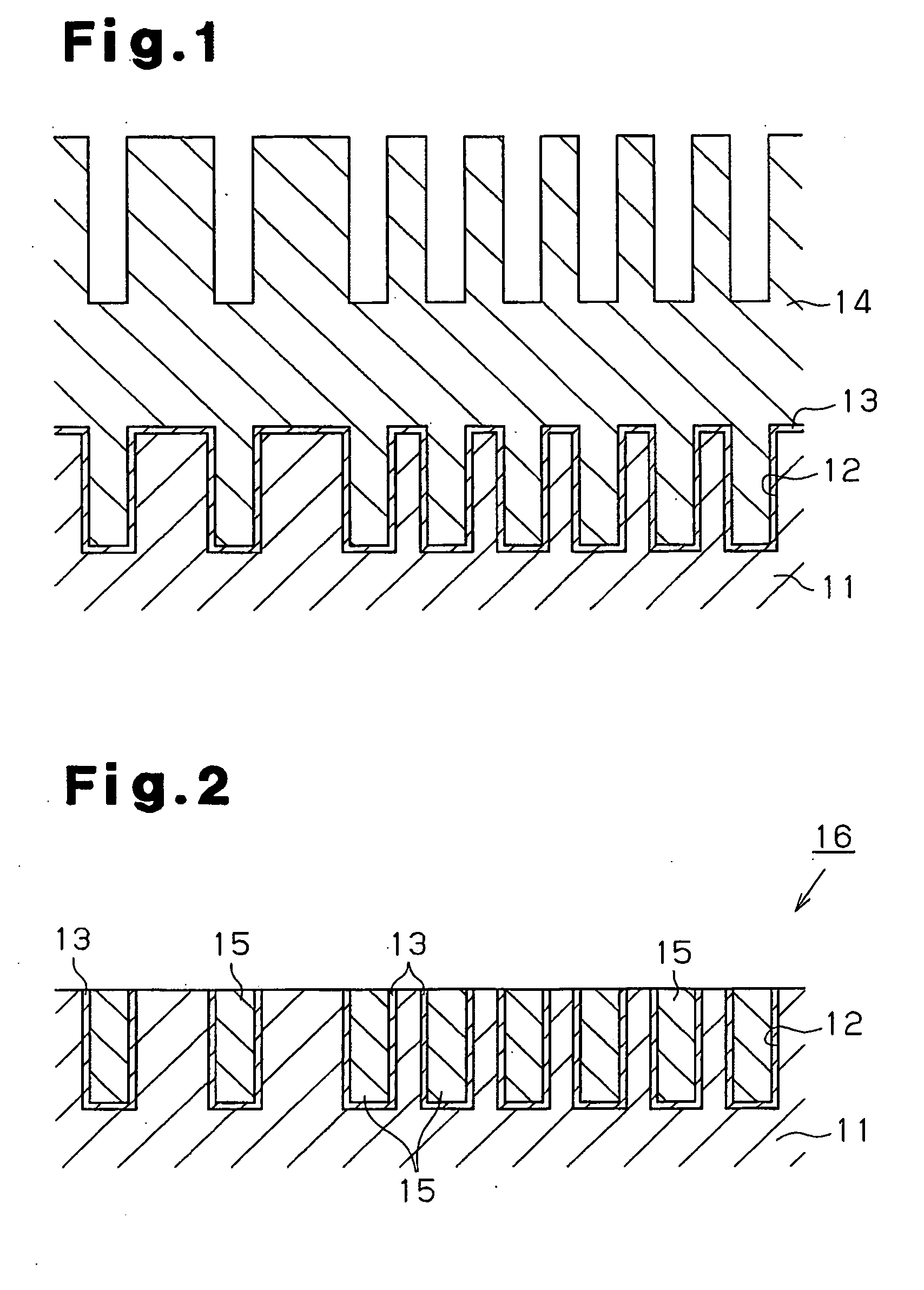

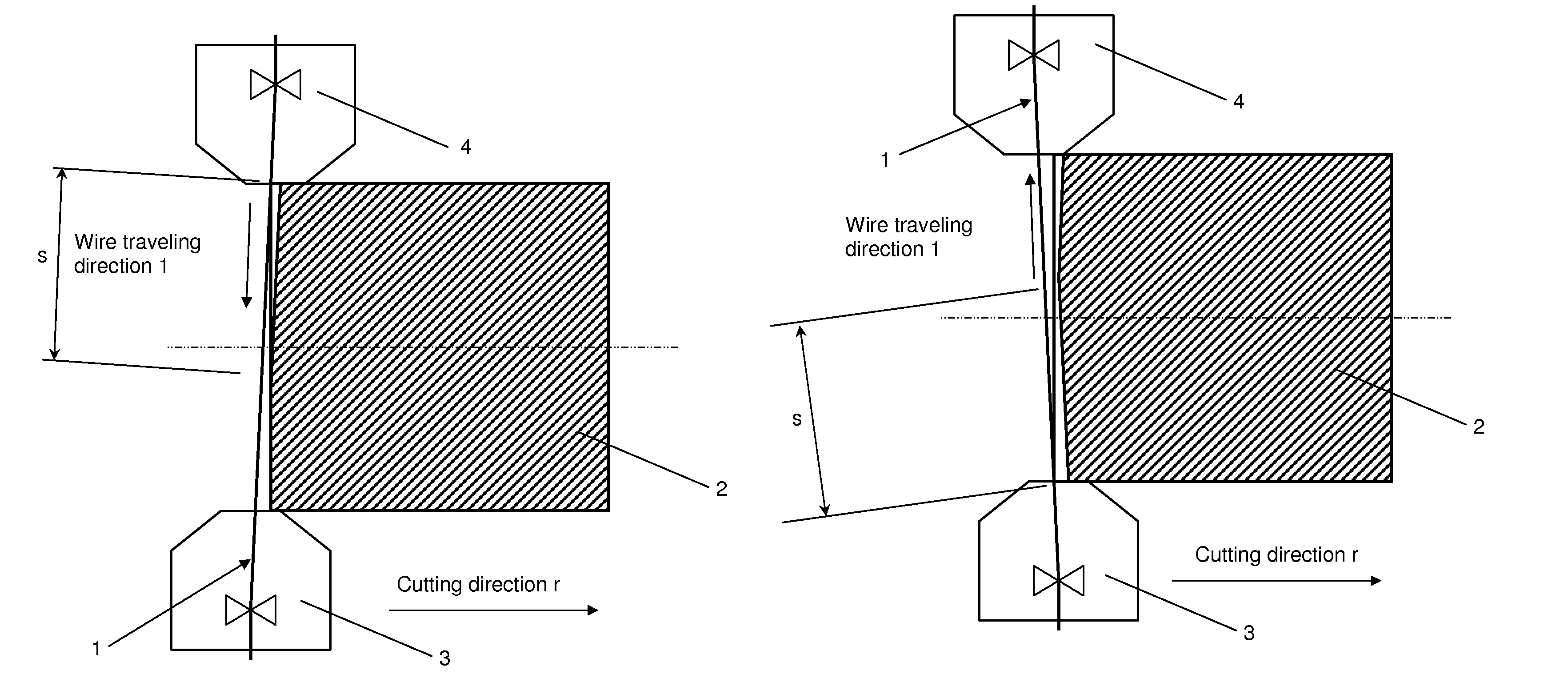

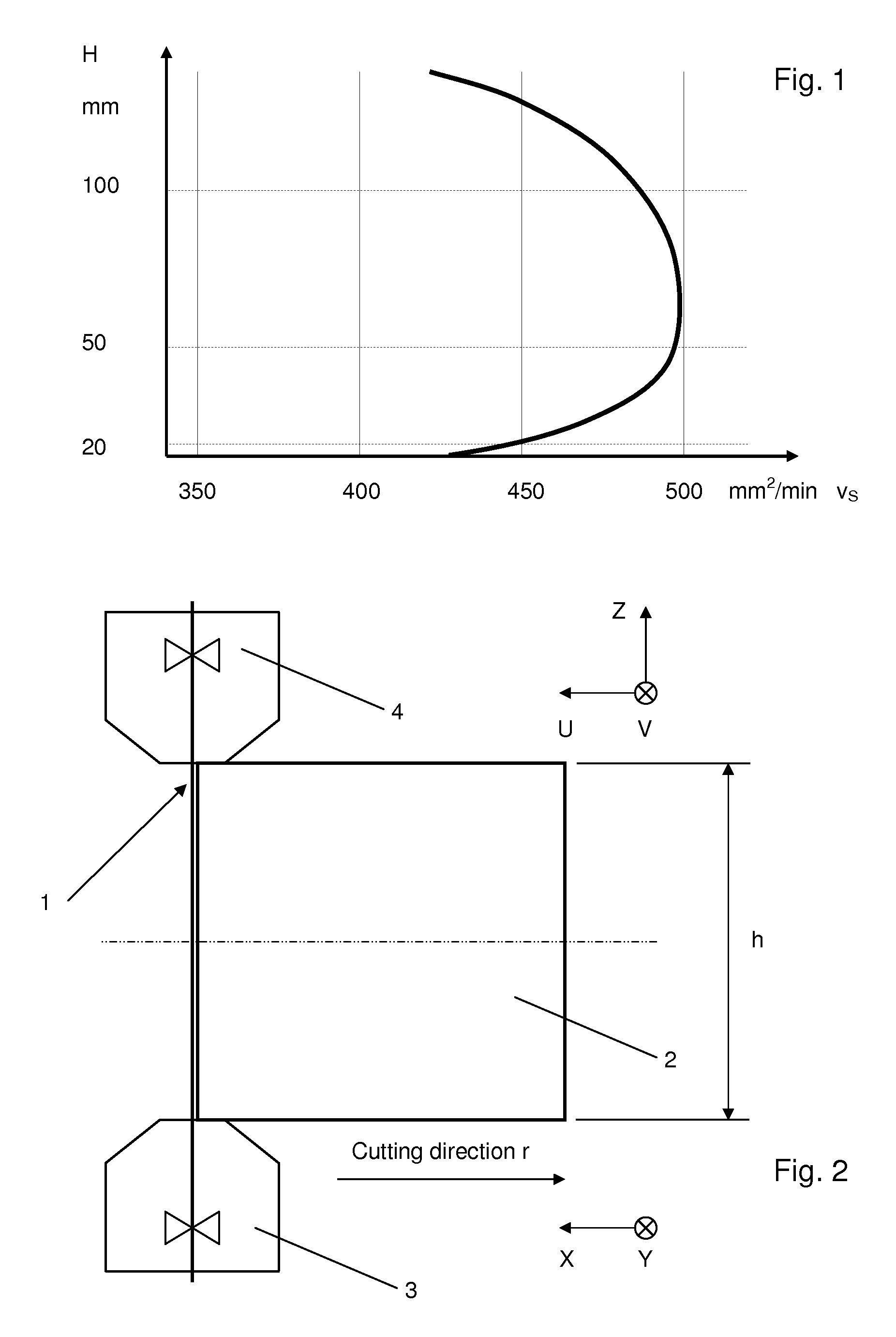

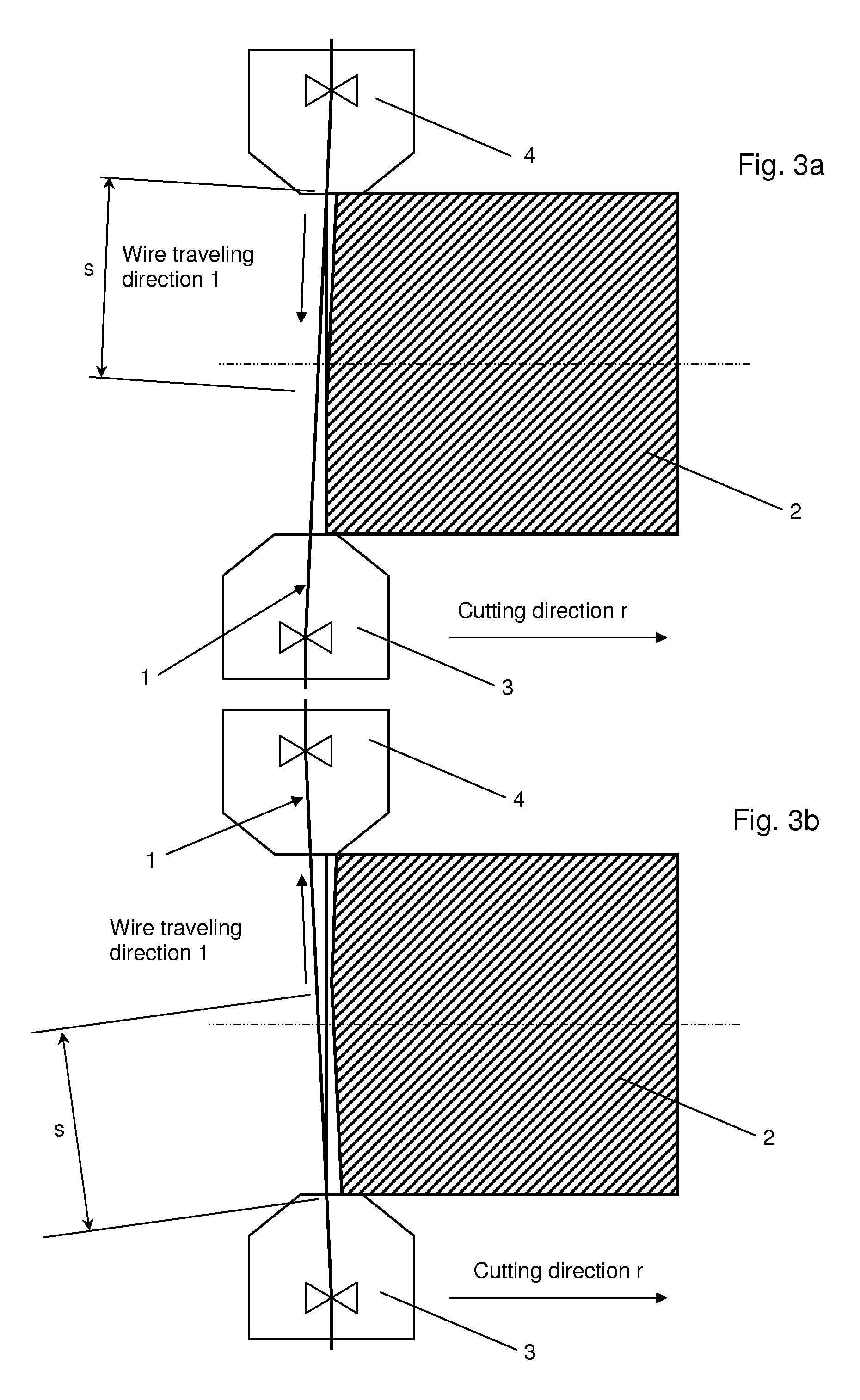

Wire cutting method

ActiveUS9193020B2Fine surfaceWork lessElectrolysis componentsFeeding apparatusWire cuttingEngineering

A method for cutting by a traveling wire, wherein the wire traveling direction of the wire and / or the workpiece are / is inclined alternately in relation to one another into at least two different specific angular positions in the cutting direction, with the result that the effective cutting height (s) on the workpiece (2) becomes smaller than the entire workpiece height.

Owner:AGIE CHARMILLES

Crushing device used for food processing machine and the food processing machine

ActiveCN108309087ANot easy to escapeHigh efficiency of centralized crushingKitchen equipmentDiameter ratioEngineering

The invention relates to a small household electrical appliance in a kitchen, especially a food processing machine. A crushing device used for the food processing machine comprises a container, a crushing blade arranged in the container and a circulation pipeline communicating the container up and down. The crushing blade is driven by a motor to drive. The circulation pipeline is arranged outsidethe container. The container comprises a crushing chamber located at the bottom of the container, a backflow chamber located on the crushing chamber and a flow gathering opening communicating the crushing chamber with the backflow chamber. The capacity of the crushing chamber ranges from 30 mL to 380 mL. A crushing blade is arranged in the crushing chamber. An inlet of the circulation pipeline islocated in the crushing chamber. An outlet of the circulation pipeline is located in the backflow chamber. The diameter ratio of the diameter of an equal-area circle of the flow gathering opening to the diameter of an equal-area circle of a horizontal cross-section of a plane container where the circulation pipeline is located ranges from 0.2 to 0.75. Compared with the prior art, the food processing machine is simple in structure and relatively low in cost and capable of collectively crushing material. The crushing efficiency is high. No bulky material appears. The food processing machine is convenient to clean.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com