Preparation method of polyurethane polishing material

A polishing material and a manufacturing method technology, applied in the manufacturing field of polyurethane polishing materials, can solve the problems of high storage condition requirements, large viscosity change, uneven pore size, etc., and achieve good production repeatability, improved yield and improved cutting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

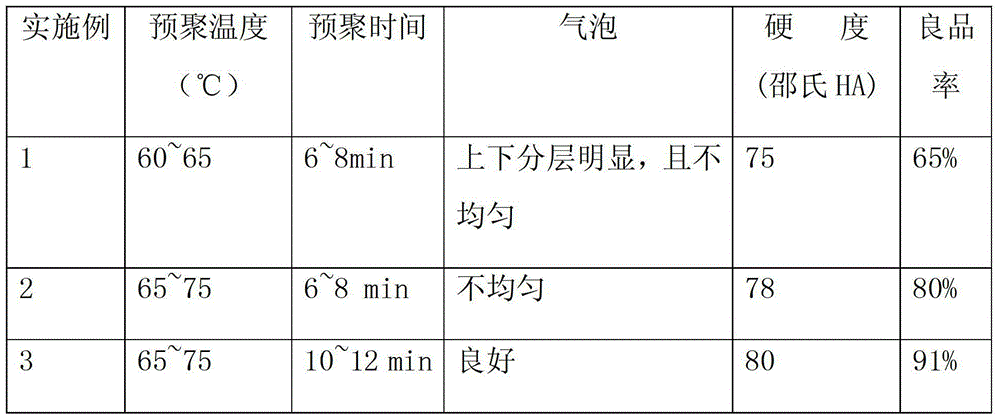

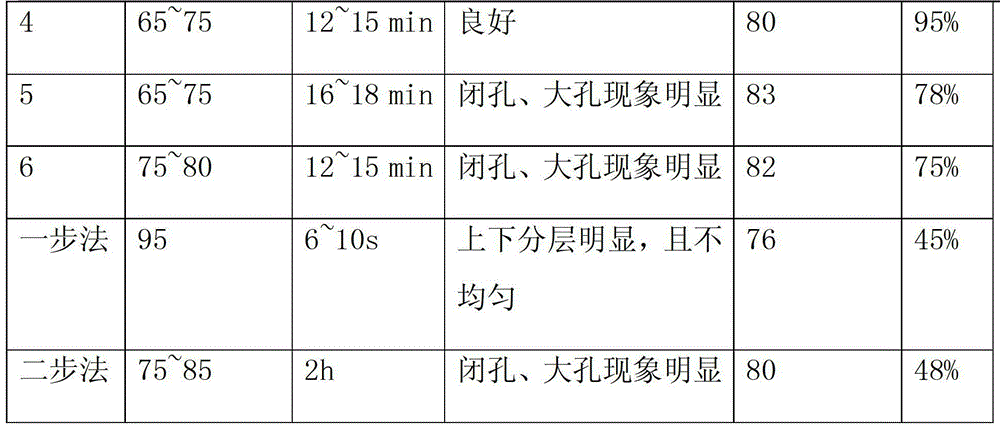

Embodiment 1

[0020] The present embodiment provides a kind of manufacture method of polyurethane polishing material, comprises the following steps:

[0021] a. Rapid prepolymerization: heat diisocyanate and polyether polyol in a reaction kettle and stir to make it react rapidly for 6-8 minutes at a temperature of 60-65°C to make a viscosity of 1600-1800cp.s / 25°C Prepolymers containing terminal isocyanate groups;

[0022] b. Rapid chain extension: add chain extender to the above prepolymer and mix at high speed, and stir for 2-3 minutes at a temperature of 85-90°C to make a carbamate with a viscosity of 2600-3000cp.s / 25°C liquid;

[0023] c. Rapid foaming: Add filler, water and additives to the above liquid, keep the temperature at 110-115°C, then stir at high speed for 10-25 seconds, then quickly pour the material into the foaming mold, and put it in an oven at 115-120°C heating for more than 16 hours,

[0024] Wherein the total amount of the diisocyanate is 24kg, including toluene diis...

Embodiment 2

[0026] The present embodiment provides a kind of manufacture method of polyurethane polishing material, comprises the following steps:

[0027] a. Rapid prepolymerization: heat diisocyanate and polyether polyol in a reaction kettle, and stir to make it react rapidly for 6-8 minutes, the temperature is 65-75°C, and the viscosity is 1600-1800cp.s / 25°C Prepolymers containing terminal isocyanate groups;

[0028] b. Rapid chain extension: add chain extender to the above prepolymer and mix at high speed, and stir for 2-3 minutes at a temperature of 85-90°C to make a carbamate with a viscosity of 2600-3000cp.s / 25°C liquid;

[0029] c. Rapid foaming: Add filler, water and additives to the above liquid, keep the temperature at 110-115°C, then stir at high speed for 10-25 seconds, then quickly pour the material into the foaming mold, and put it in an oven at 115-120°C heating for more than 16 hours,

[0030] Other various parameters, raw material composition are identical with embodi...

Embodiment 3

[0032] The present embodiment provides a kind of manufacture method of polyurethane polishing material, comprises the following steps:

[0033] a. Rapid prepolymerization: heat diisocyanate and polyether polyol in a reaction kettle and stir to make it react rapidly for 10-12 minutes at a temperature of 65-75°C to make a viscosity of 1600-1800cp.s / 25°C Prepolymers containing terminal isocyanate groups;

[0034] b. Rapid chain extension: add a chain extender to the above prepolymer and mix at high speed, and stir for 2 to 3 minutes at a temperature of 87 to 90°C to make a carbamate with a viscosity of 2600 to 3000cp.s / 25°C liquid;

[0035] c. Rapid foaming: Add filler, water and additives to the above liquid, keep the temperature at 110-115°C, then stir at high speed for 10-25 seconds, then quickly pour the material into the foaming mold, and put it in an oven at 115-120°C heating for more than 16 hours,

[0036] Wherein the total amount of the diisocyanate is 26kg, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com