Patents

Literature

67results about How to "Good production repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

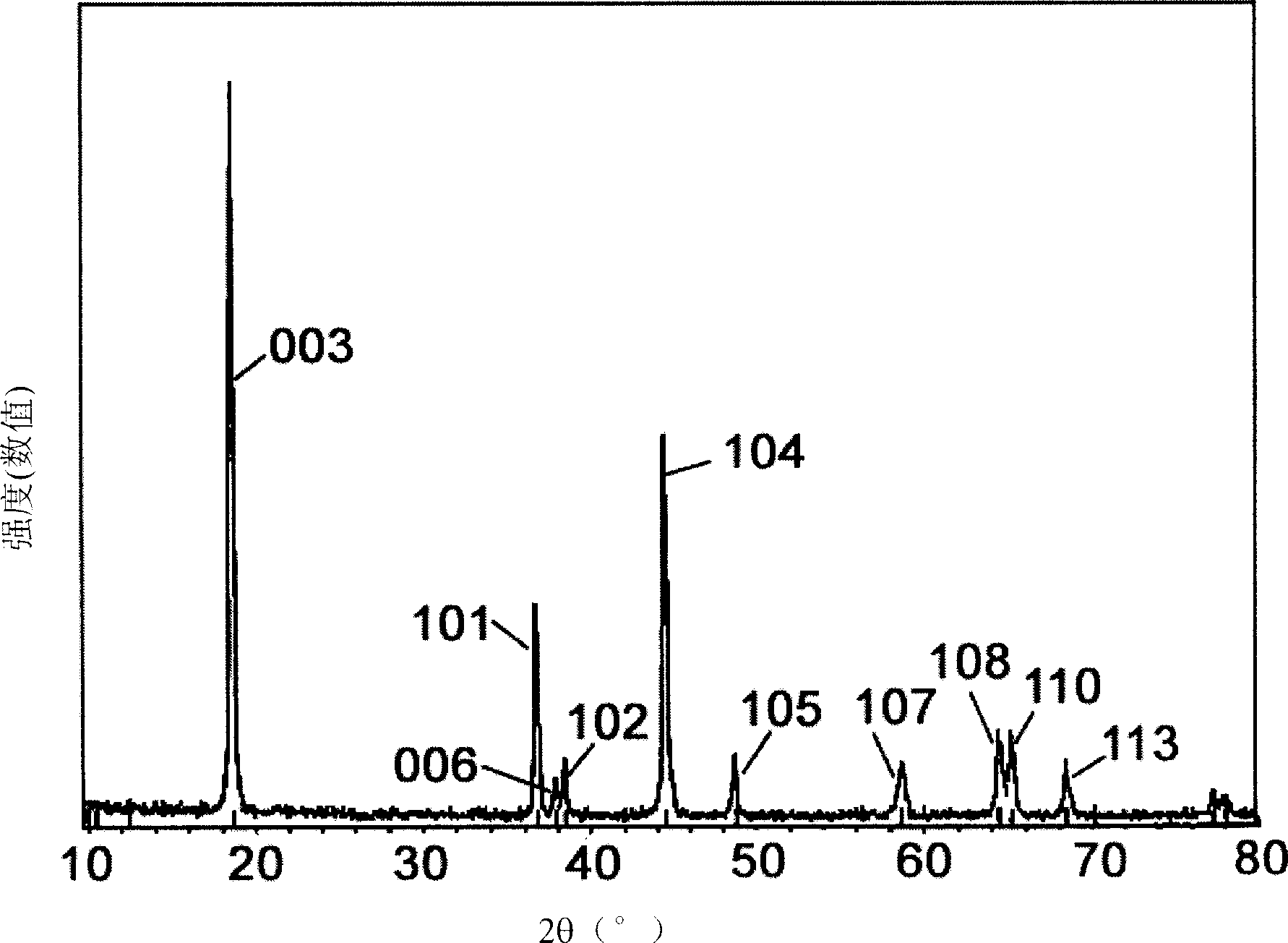

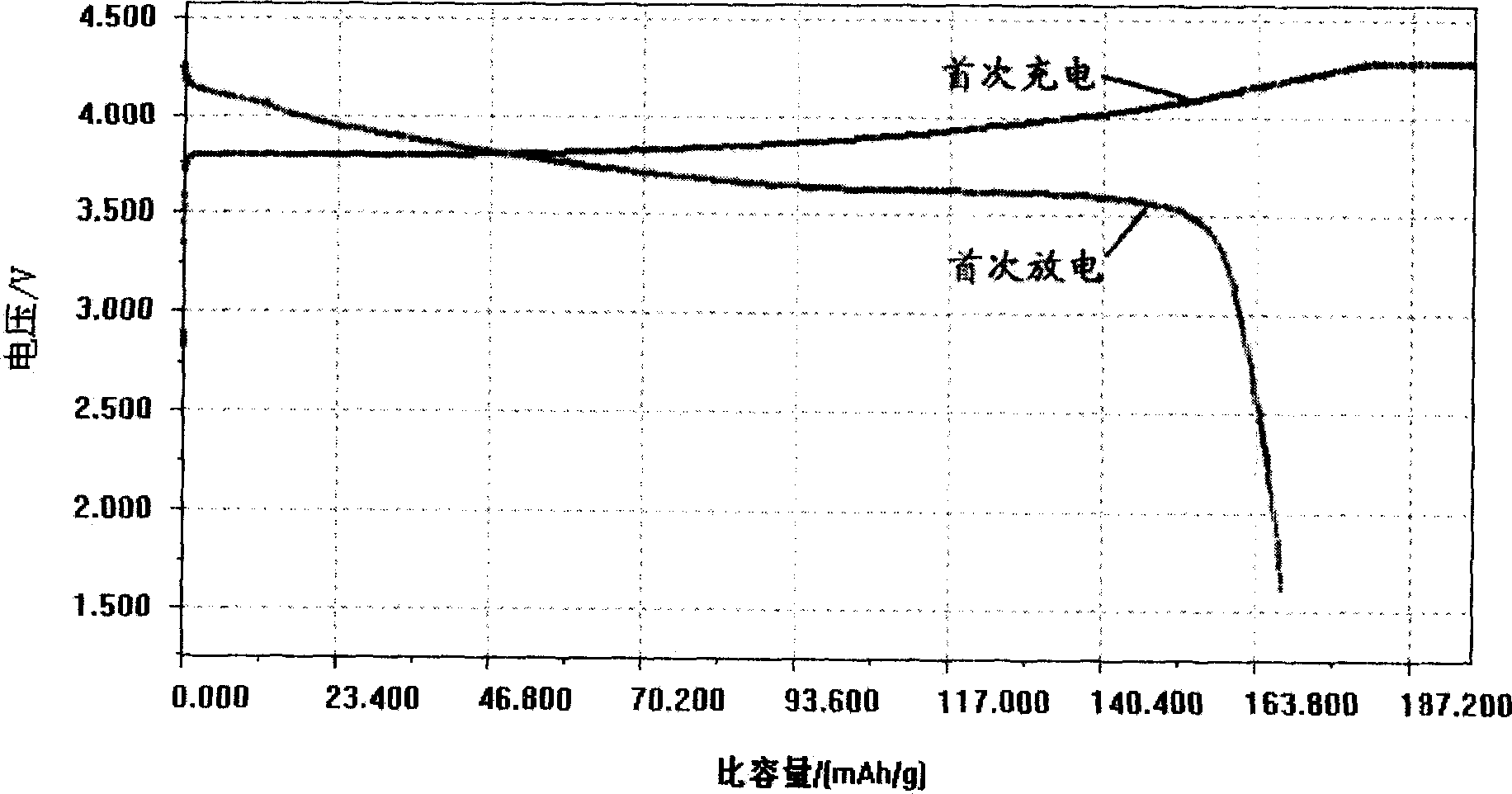

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

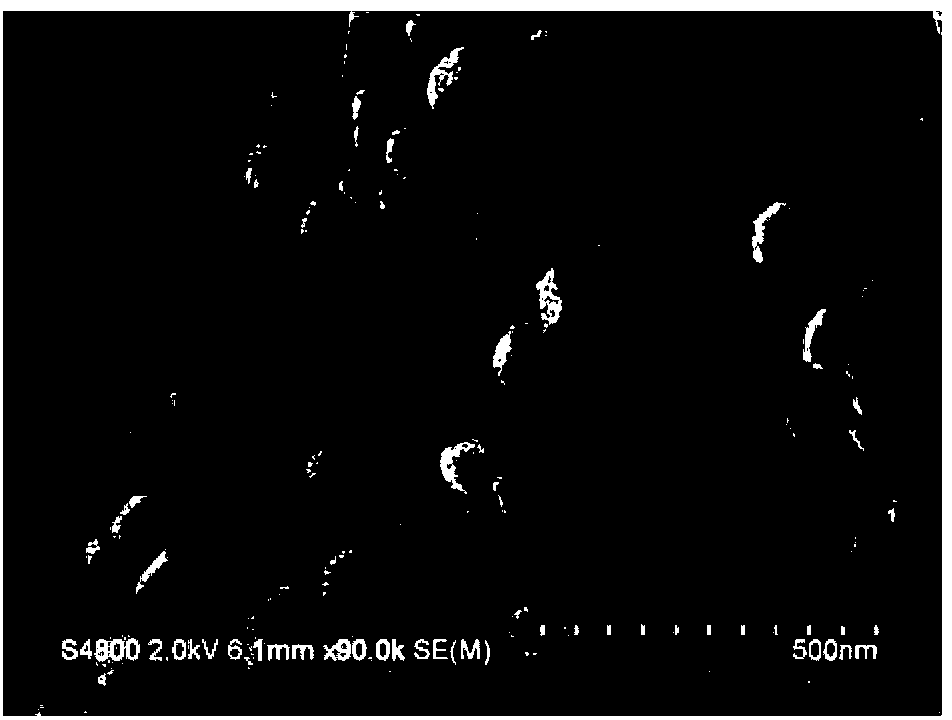

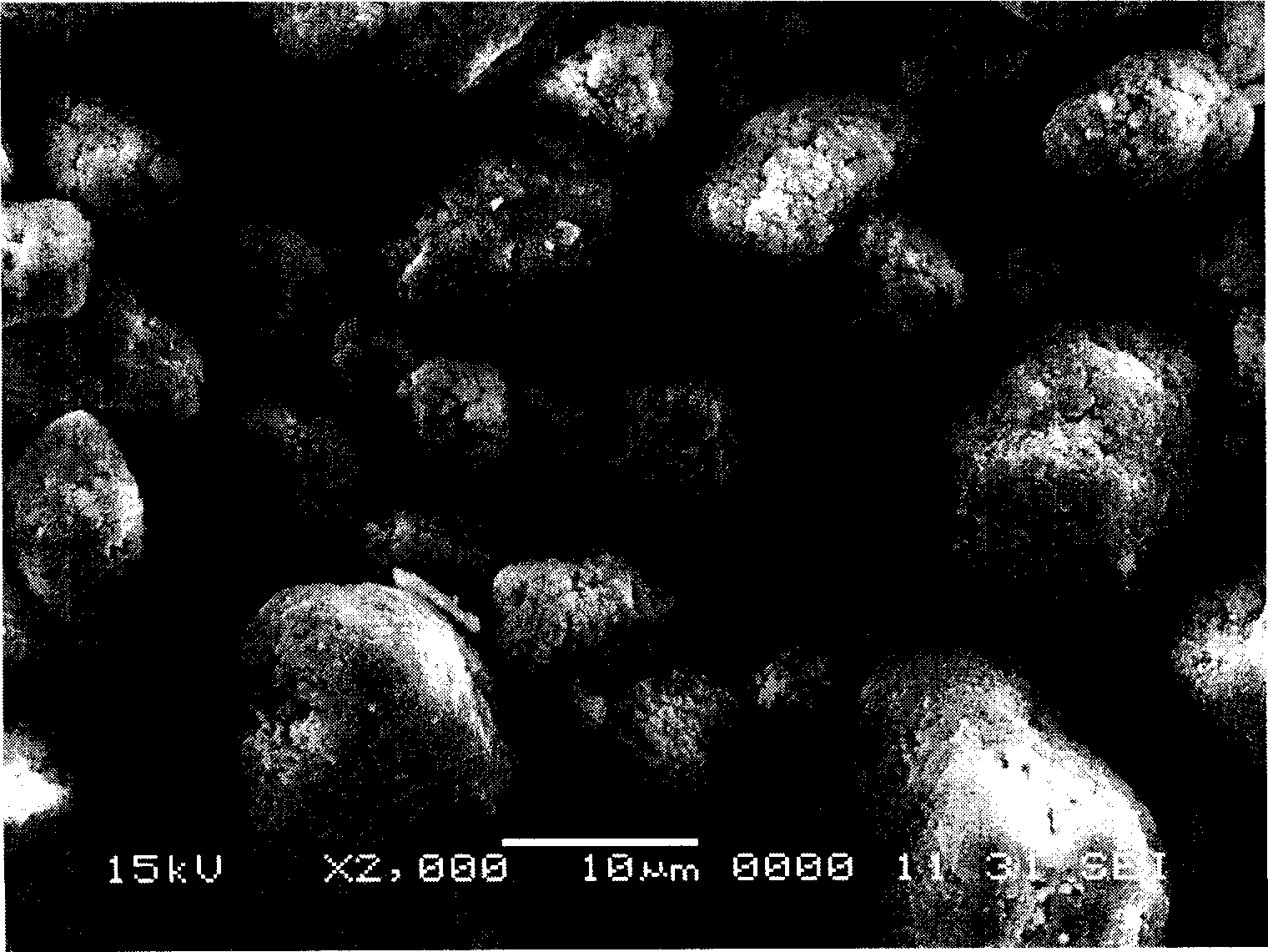

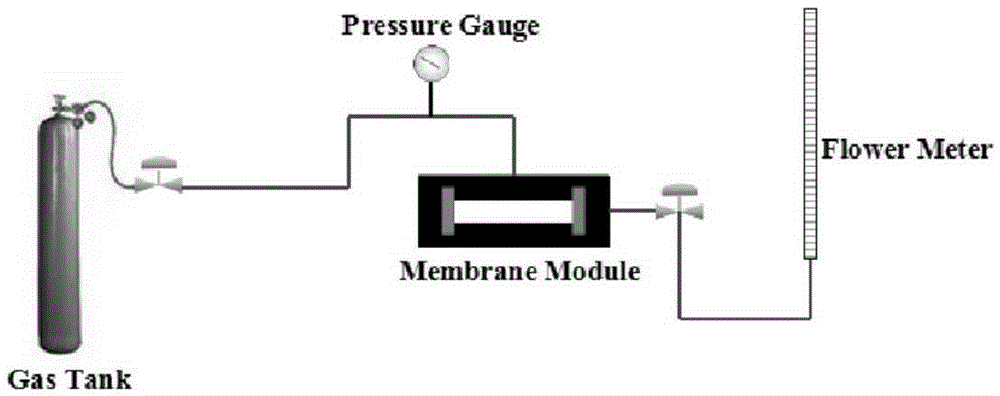

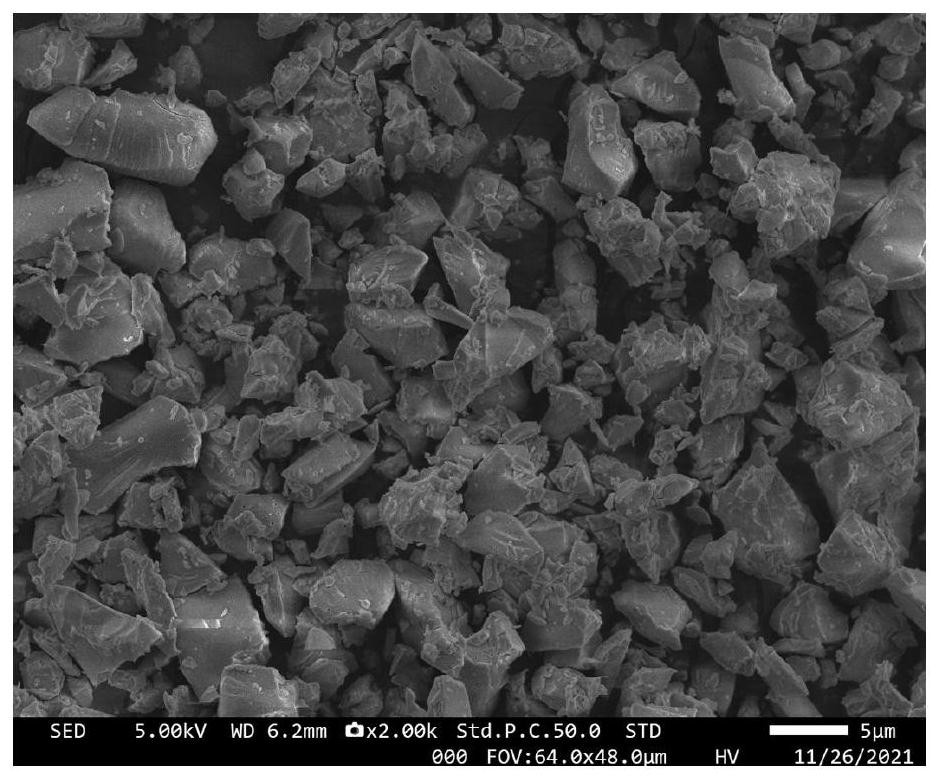

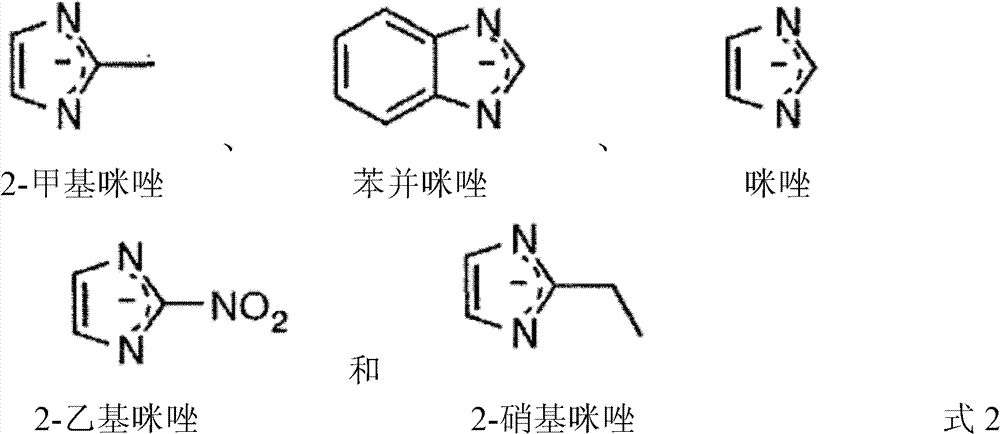

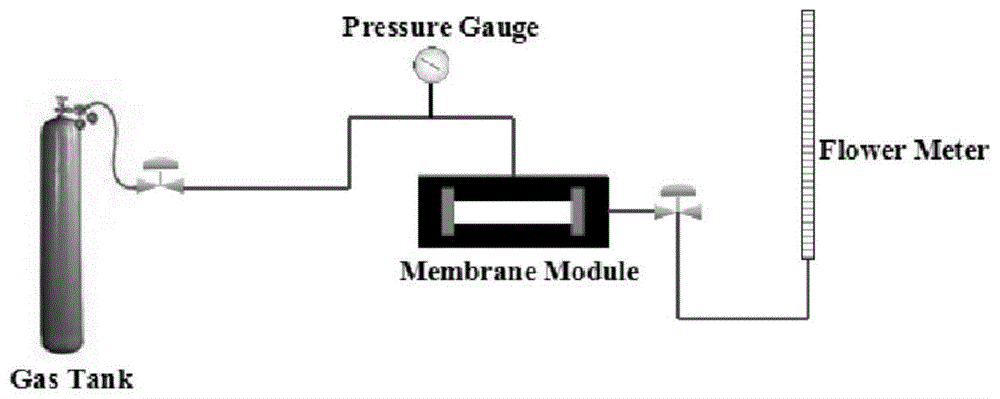

Method for preparing nano-zeolite metal-organic framework compounds by microreactor

InactiveCN102993221ALarge specific surface areaNarrow particle size distributionCopper organic compoundsZinc organic compoundsMicroreactorMetal-organic framework

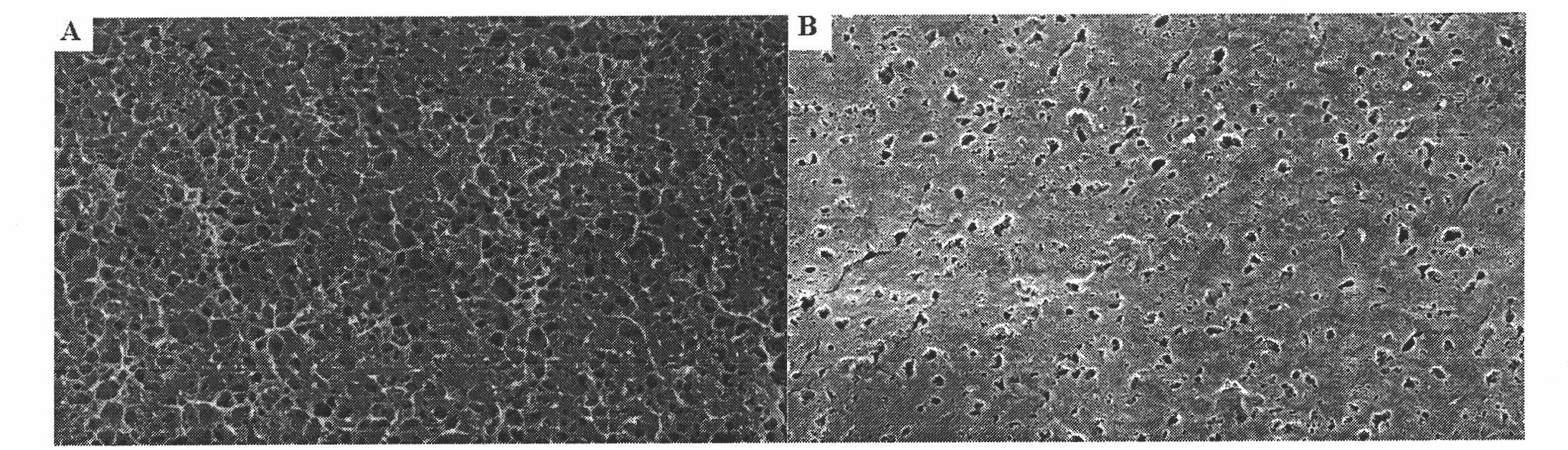

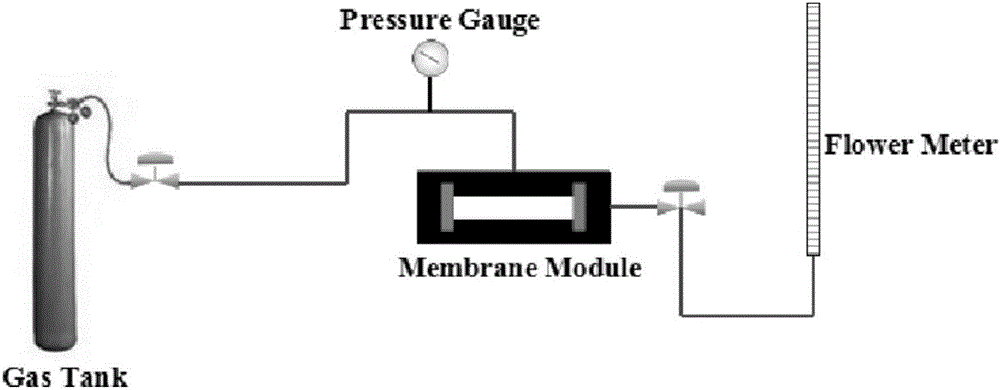

The invention relates to a method for preparing nano-zeolite metal-organic framework compounds by a microreactor, and belongs to the technical field of preparation of nano-particles, which is characterized by comprising the following steps of: constructing a microreactor by a porous film; respectively dissolving a metal precursor and an organic ligand in a solvent to prepare a metal precursor solution A and an organic ligand solution B; respectively arranging the metal precursor solution A and the organic ligand solution B at two sides of the film; by a pressure difference of the two sides of the film, uniformly pressing reactants at one side of the film into reactants at the other side of the film through the pores of the film, to generate nano-particles; and centrifuging, washing and drying to obtain the target product. The method for preparing the nano-zeolite metal-organic framework compounds by the microreactor is simple in operation, strong in controllability of particle structure, and is suitable for preparation and industrial production of various nano-zeolite metal-organic framework compounds.

Owner:JIANGNAN UNIV

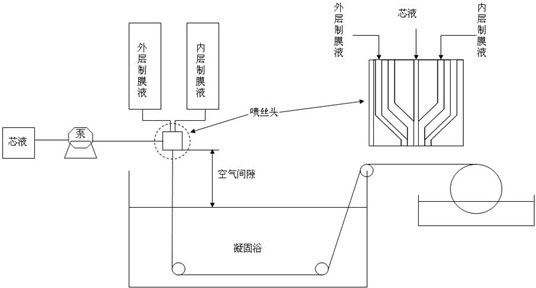

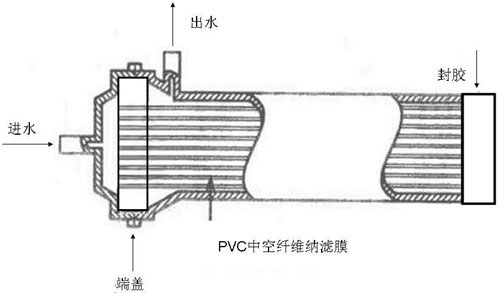

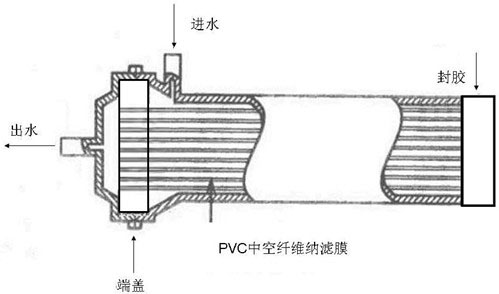

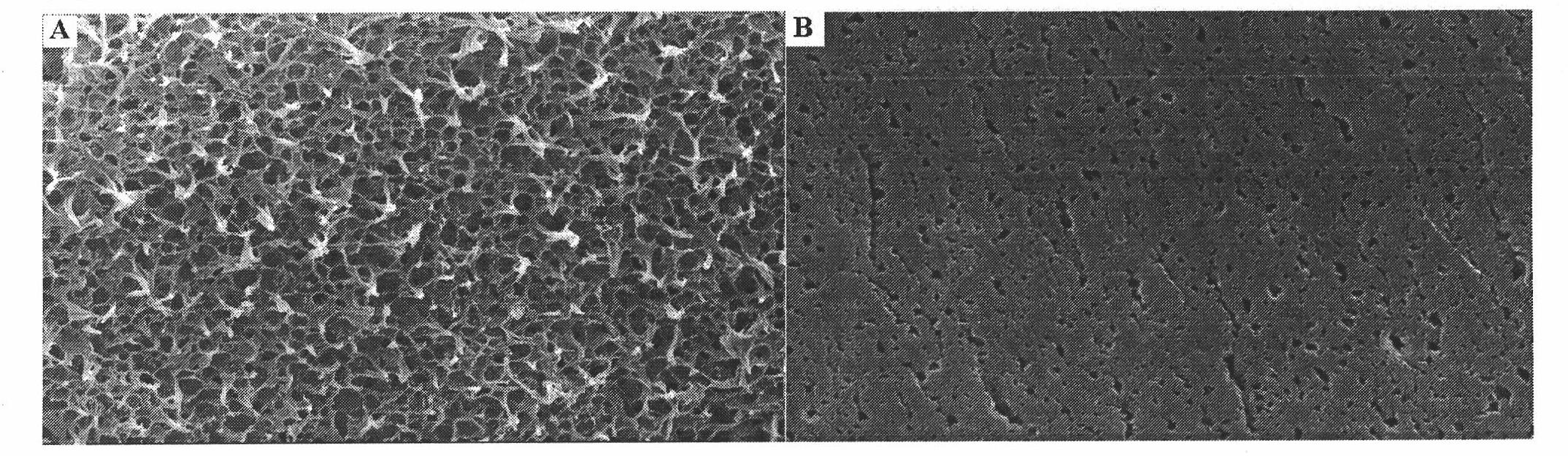

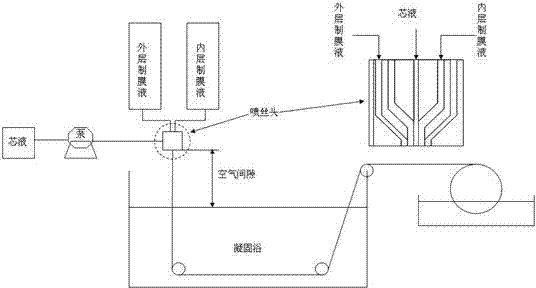

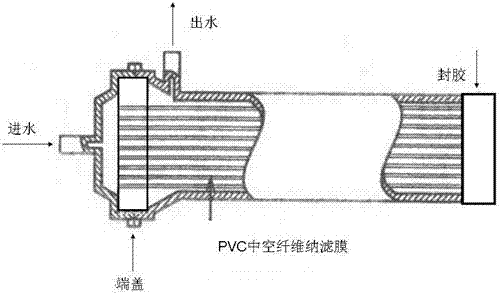

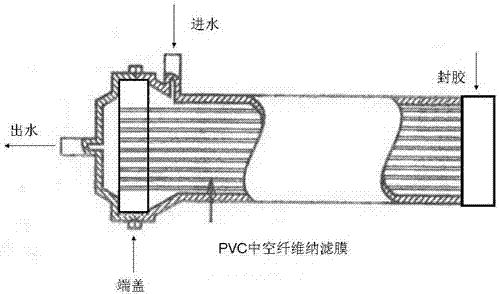

Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

ActiveCN102210979ABacteria resistantWith acid and alkali resistanceSemi-permeable membranesFiberPolyvinyl chloride

The invention discloses a method for preparing a positively charged polyvinyl chloride (PVC) hollow fiber nanofiltration membrane. The positively charged PVC hollow fiber nanofiltration membrane has a two-layer structure consisting of a positively charged compact skin layer and an electrically neutral porous support layer; the pore diameter of micropores of the compact skin layer is 1-5nm, and the pore diameter of micropores of the porous support layer is 10-100nm; and the outer diameter of the membrane is 1.5-3.0mm, and the inner diameter of the membrane is 0.5-2mm, wherein the positively charged compact skin layer comprises main components of polyvinyl chloride and cationic copolymer; and the electrically neutral porous support layer comprises main components of polyvinyl chloride and an inorganic filler. The method for preparing the positively charged PVC hollow fiber nanofiltration membrane comprises the following steps of: co-extruding positively charged compact skin layer membrane preparing liquid and electrically neutral porous support layer membrane preparing liquid in a two-layer ring shape; and curing and forming hollow fibers by using a dry-wet spinning process. The prepared hollow fiber nanofiltration membrane has the advantages of easily controlled interception property, high strength, simple preparation process and the like, and is a high-performance, low-cost and long-life nanofiltration membrane material for water treatment.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Polyester flat microporous membrane and preparation method thereof

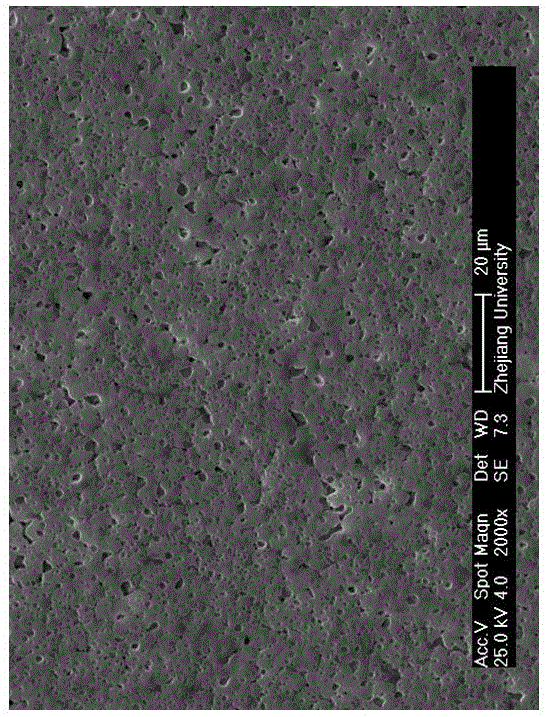

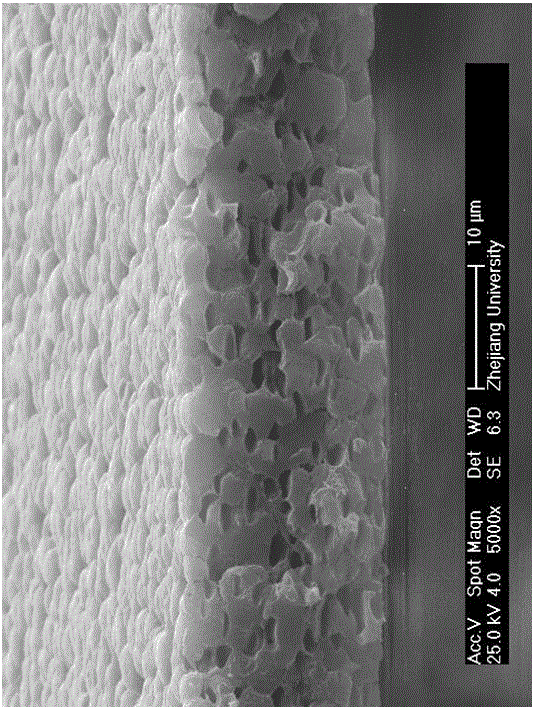

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

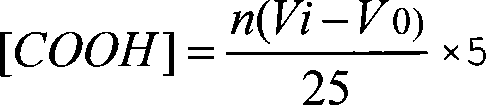

Surface fixed taurine ligand porous membrane material, preparation method and its application in blood fat adsorption separating

InactiveCN101058058AAchieve adsorptionAchieve separationSemi-permeable membranesOther chemical processesLipid compositionBlood plasma

It is aimed to provide a porous carrier surface fixed with taurine absorbed sulfo group. Its average hole radius is made by 0. 05-100mum medical polymer nonwoven cloth modified by 60Cogammacoradiated the polyacrylic acid surface together with porous film, with the help of one aminopropancdiol, 3 EDC activated carboxy group coupling with biologically compatible taurine absorbed sulfo group with the surface fixed with porous film carrier material reinforcing selective absorption and separation effect. It is simple, safe and effective. The material is compatible with blood, with excellent use in plasma absorption separation, clinical blood dynamic purification and waste plasma regeneration and utilization.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

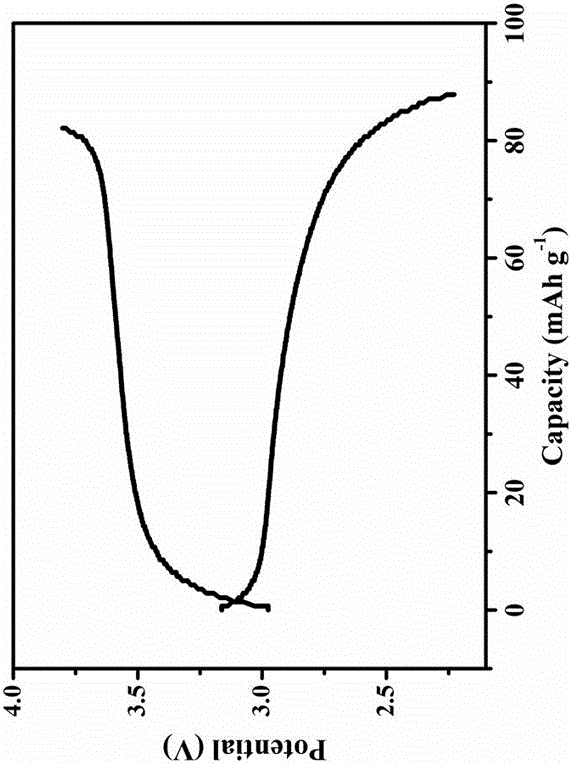

Diene/ether copolymer-based lithium ion gel electrolyte membrane and preparation method thereof

InactiveCN102074735AEffective mass transfer quantityImprove performanceSecondary cellsCross-linkPolyethylene oxide

The invention discloses a diene / ether copolymer-based lithium ion gel electrolyte membrane and a preparation method thereof. The lithium ion electrolyte membrane provided by the invention consists of cross-linked diene / ether copolymer, lithium salt and plasticizing agent, and the preparation method of the lithium ion electrolyte membrane comprises the following steps of: firstly, adopting a blocktype diene / polyether copolymer containing a poly-butadiene or polyprene chain segment and a polyethylene oxide or polypropylene oxide chain segment to form a membrane with the assistance of a solvent; secondly, performing crosslinking to form a gel membrane under the action of ultraviolet, heating or an initiating agent; and finally, swelling and activating the gel membrane by using a plasticizing agent and lithium salt solution to obtain the lithium ion gel electrolyte membrane. The prepared lithium ion gel electrolyte membrane has a two-phase micro-phase separation structure of polyolefin and polyether, wherein a diene polymer chain segment forms a cross-linked structure to improve the strength of the membrane, and a polyether phase absorbed plasticizing agent and the lithium salt provide a lithium ion transmission channel. The electrolyte membrane provided by the invention has the characteristic of high electrical conductivity and can be strengthened by using a non-woven cloth and the like, so the electrolyte membrane is suitable to be used as an electrolyte membrane material of power lithium ion batteries.

Owner:ZHEJIANG UNIV

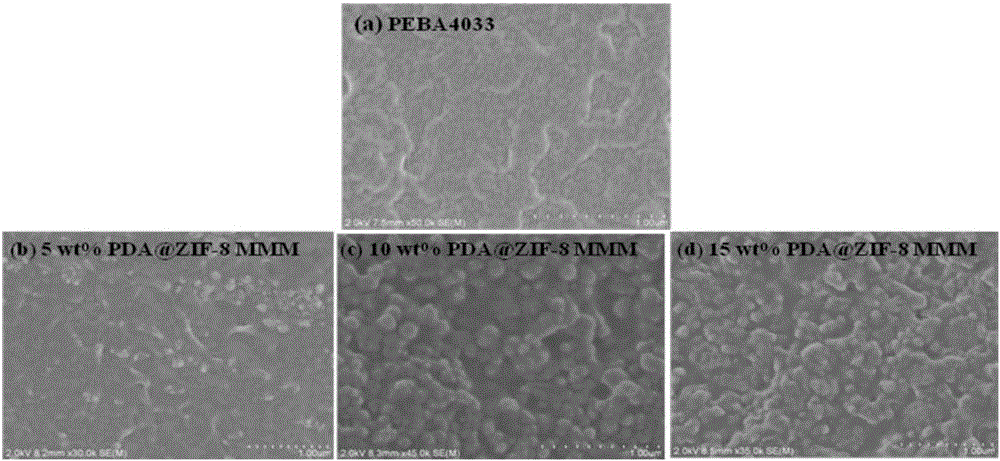

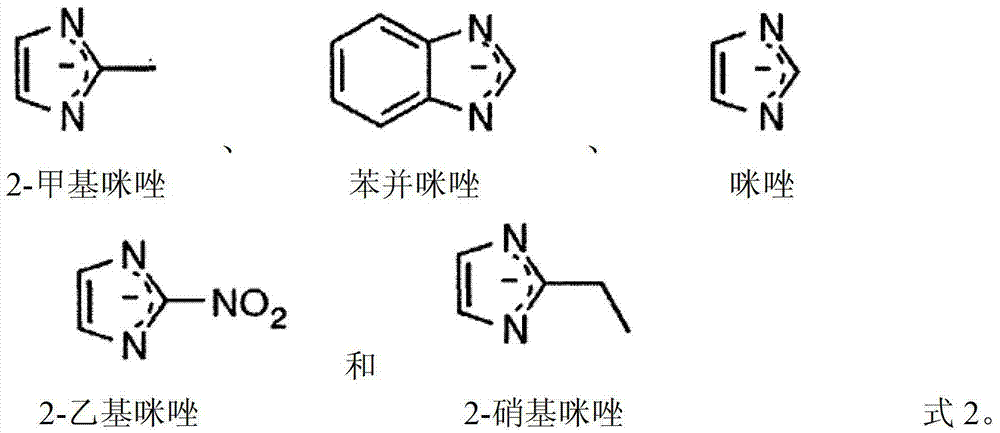

Dopamine-modified metal organic compound/polyether co-polyamide mixed substrate membrane and preparation and application thereof

InactiveCN106310984AImprove controllabilityGood production repeatabilitySemi-permeable membranesProductsPolyamideChemical compound

Owner:JIANGNAN UNIV

Nonionic surfactant gel and gas separating membrane and preparation method thereof

ActiveCN102489182AImprove permeabilityHigh separation selectivitySemi-permeable membranesDispersed particle separationSolventUltimate tensile strength

The invention relates to a nonionic surfactant gel and gas separating membrane and a preparation method thereof; the preparation method comprises the following technique steps, wherein the proportions of the ingredients are counted in parts by weight: (1) preparing suspension: stirring and blending 10-20 parts of polymer, 10-20 parts of nonionic surfactant and 60-80 parts of solvent for 3-6 h at a temperature of 20-60 DEG C and a stirring speed of 50-300 rpm to obtain uniform and transparent suspension; (2) scrapping the suspension on a glass plate through a stainless steel scrapping knife ata temperature of 20-50 DEG C to obtain liquid membrane with a thickness of 200-500 mum, and drying the liquid membrane in the air for 24-48 h to obtain the nonionic surfactant gel and gas separating membrane. The nonionic surfactant gel and gas separating membrane of the invention is formed with a gel-shaped structure by the polymer and the nonionic surfactant to obtain high gas permeability and separation selectivity and to obtain a good mechanical strength, so that the nonionic surfactant gel and gas separating membrane has an extensive industrial application prospect.

Owner:WUXI UNMIXED CLEANSE EQUIP

Multicomponent oxide containing cobalt nickel and preparation and application thereof

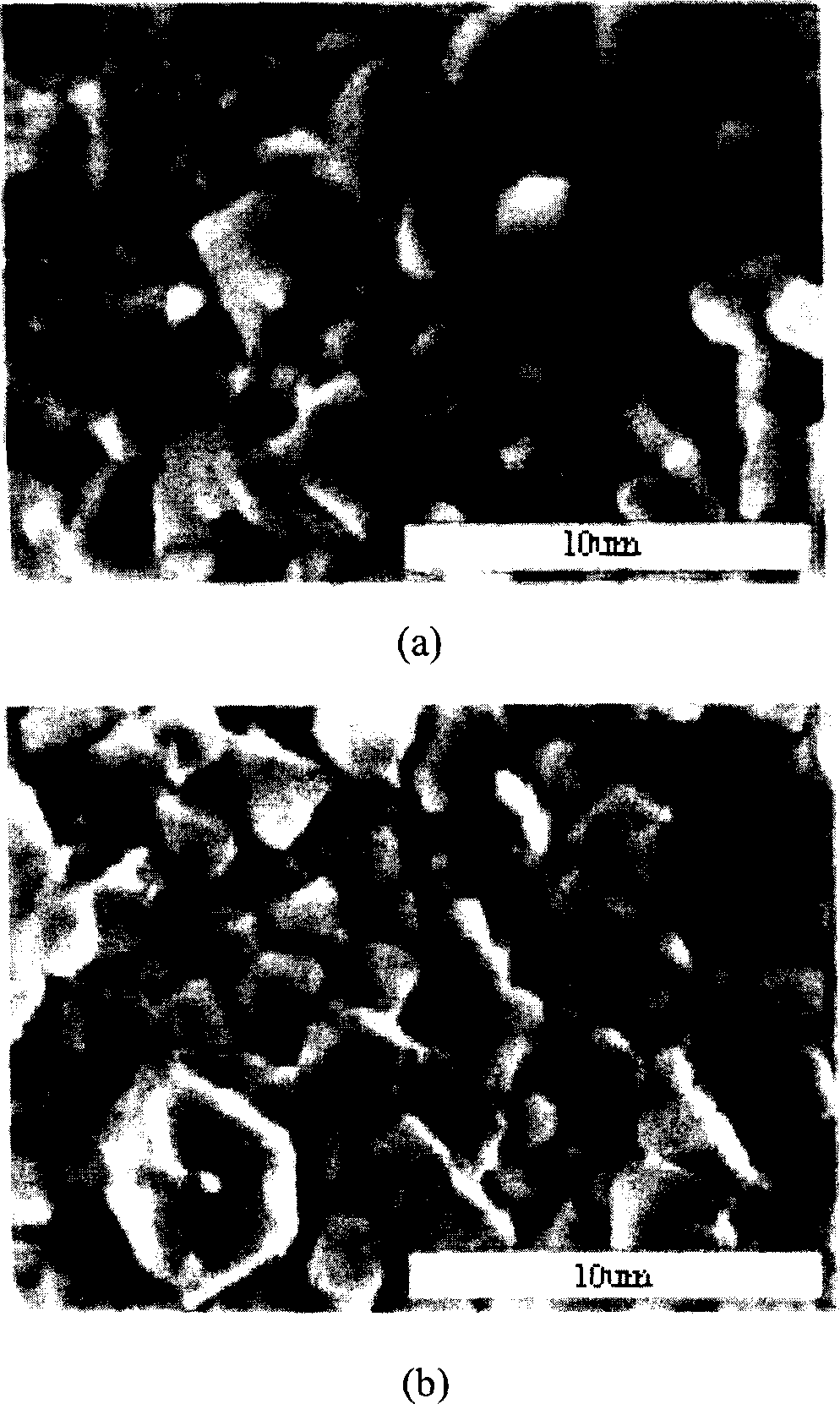

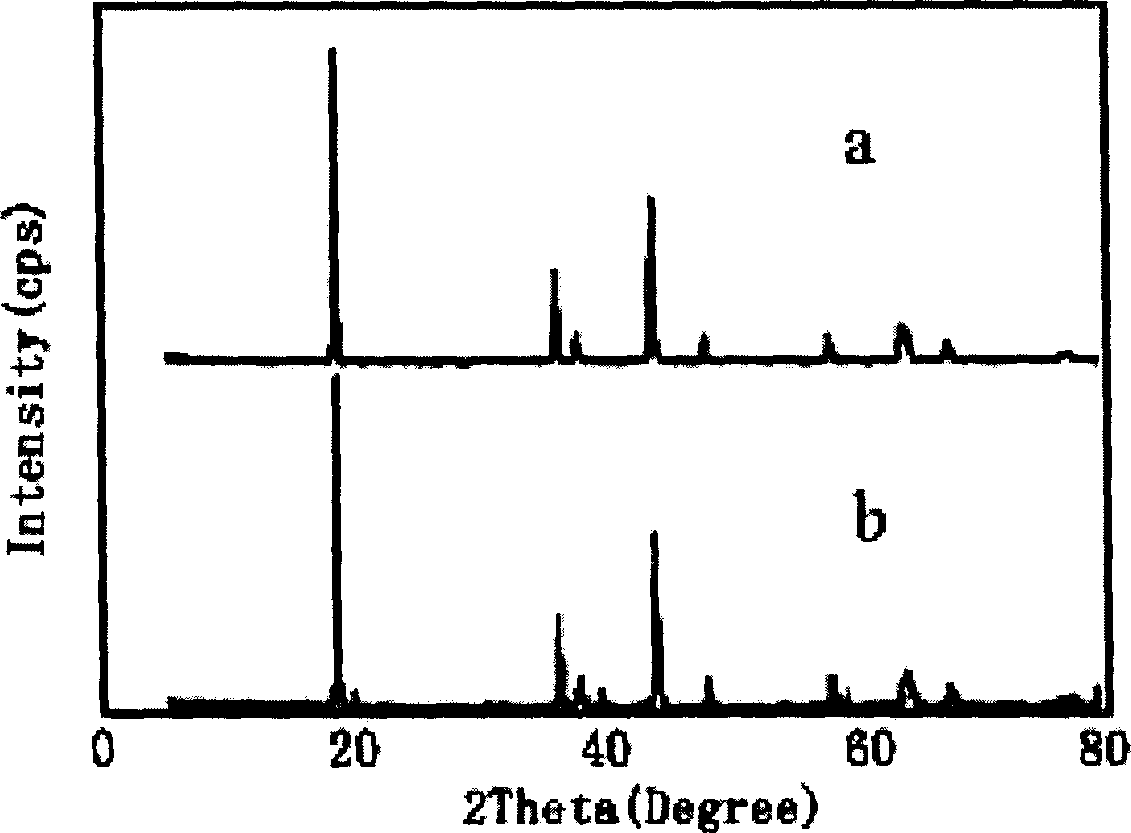

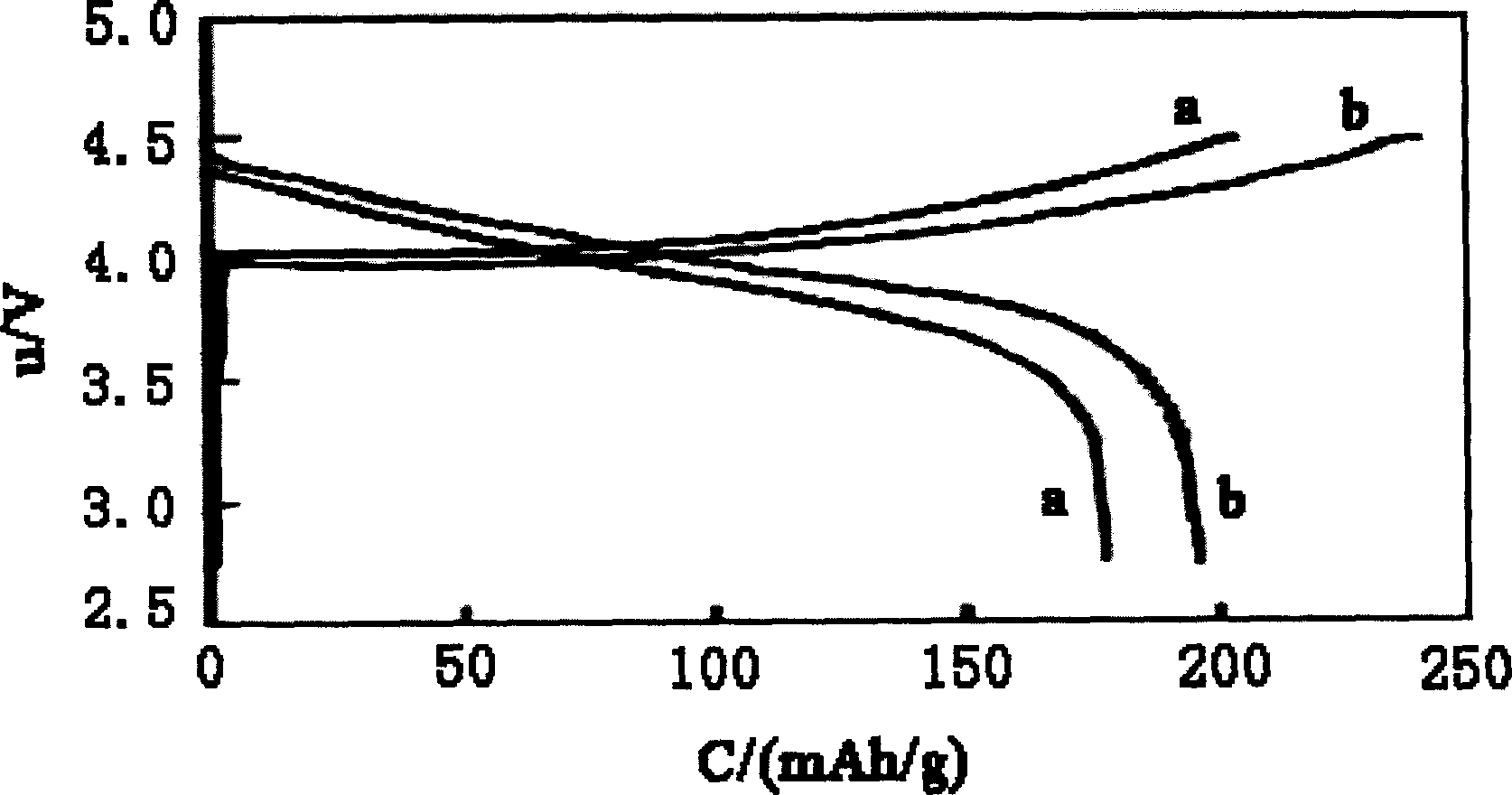

InactiveCN1870330AWell developed crystal formImprove cycle performanceElectrode manufacturing processesLithium compoundsLithium hydroxideManganese

A method for preparing multicomponent oxide containing Ni and Co includes preparing mixed ammonia complex solution by materials of Ni and Co as well as the other metal M in buffer solution; adding prepared ammonia complex solution and aqueous alkali slowly into reactor simultaneously to generate Ni-Co-M composite hydroxide by coprecipitation then obtaining forerunner after aging, separating, washing and drying; mix-grinding forerunner and lithium hydroxide to obtain final product of Lia(NibCoc) M1-b-cO2 after heat treatment.

Owner:SHENZHEN BAK BATTERY CO LTD

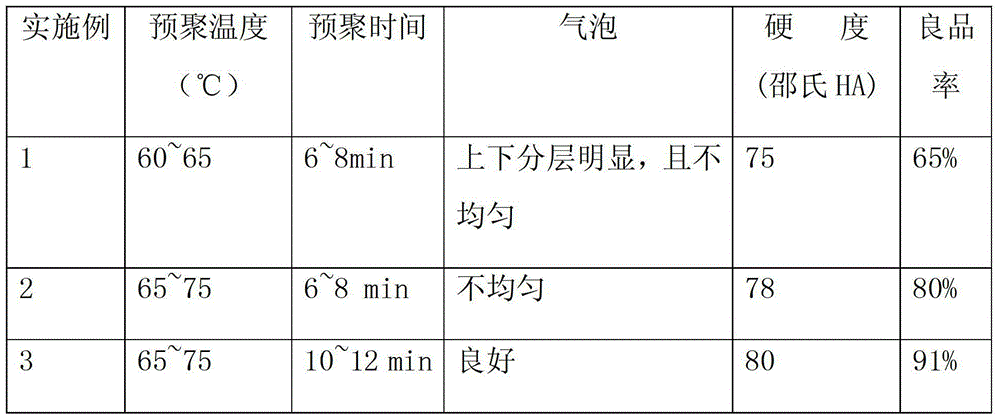

Preparation method of polyurethane polishing material

The invention discloses a preparation method of polyurethane polishing material; the polyurethane polishing material is prepared by a 'rapid three-step method' technology, so that the viscosity and the reaction head of all reaction stages can be better controlled, the demands that the material has a certain aperture ratio and solid filler is rapidly and evenly mixed can be met, and the effects of stable operation and good production repeatability can be achieved; and a prepared polyurethane polished section is even in foams, the service life and the cutting rate are greatly improved, and the highest yield reaches up to more than 95%.

Owner:HEFEI HONGGUANG ABRASIVE SCI & TECH

Green preparation method of silicon rubber/silicon dioxide pervaporation membrane based on emulsion film forming

The invention relates to a green preparation method of a silicon rubber / silicon dioxide pervaporation membrane based on emulsion film forming and belongs to the technical field of membrane separation. The green preparation method has main characteristics that (1) mixing and emulsifying water-soluble sol, a surfactant and polysiloxane to prepare water-in-oil polysiloxane emulsion, wherein the diameter of water-phase liquid drops is 1-45 microns; and (2) adding a catalyst and a cross-linking agent and mixing to obtain an emulsion type membrane casting solution, coating the emulsion type membrane casting solution on a polyvinylidene fluoride ultrafiltration membrane, and carrying out drying and cross-linking to prepare the silicon rubber / silicon dioxide pervaporation membrane. Based on an emulsion film forming technology, any organic solvent is not added in a membrane preparation process, so that volatile organic steam is not generated and a green and environment-friendly membrane preparation concept is met. The prepared hybridized silicon rubber pervaporation membrane has the characteristics of large permeation flux, good separation effect, stable structure and the like, is suitable for removing low-concentration organic matters in water and is particularly suitable for separating low-molecular-weight alcohols in a fermentation solution.

Owner:JIANGNAN UNIV

Method for preparing hot reversible gel gas separation membrane

InactiveCN102512975AEasy to makeImprove permeabilitySemi-permeable membranesDispersed particle separationWater bathsProduct gas

The invention relates to a method for preparing a hot reversible gel gas separation membrane, which is characterized by comprising the following processing steps of (1), preparing membrane preparation materials: mixing 15 to 60 parts by weight of polymer and 40-85 parts by weight of ionic liquid, fusing and blending the materials at 130 to 180 DEG C to obtain an uniform membrane preparation material; and (2), forming a gel gas separation membrane: pressing the membrane preparation material into a flat liquid membrane with a thickness of 150 to 450 microns by a flat vulcanizing machine, and solidifying the flat liquid membrane for 1 to 3 hours in a water bath at 20 to 70 DEG C to obtain the hot reversible gel gas separation membrane, wherein the temperature for pressing is 140 to 190 DEG C. A thermally induced phase separation method is adopted to prepare the hot reversible gel gas separation membrane; the preparation process is simple; the disclosed compound gel gas separation membrane has high gas permeability and separation selectivity, meanwhile the membrane also has high mechanical intensity and broad industrial application prospect.

Owner:JIANGNAN UNIV

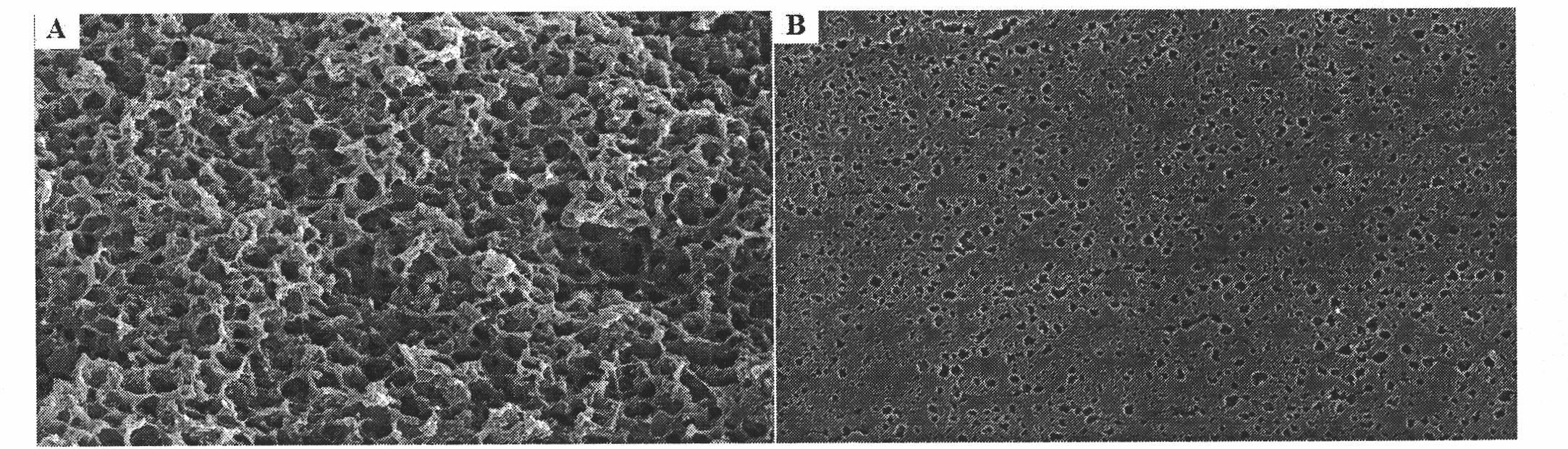

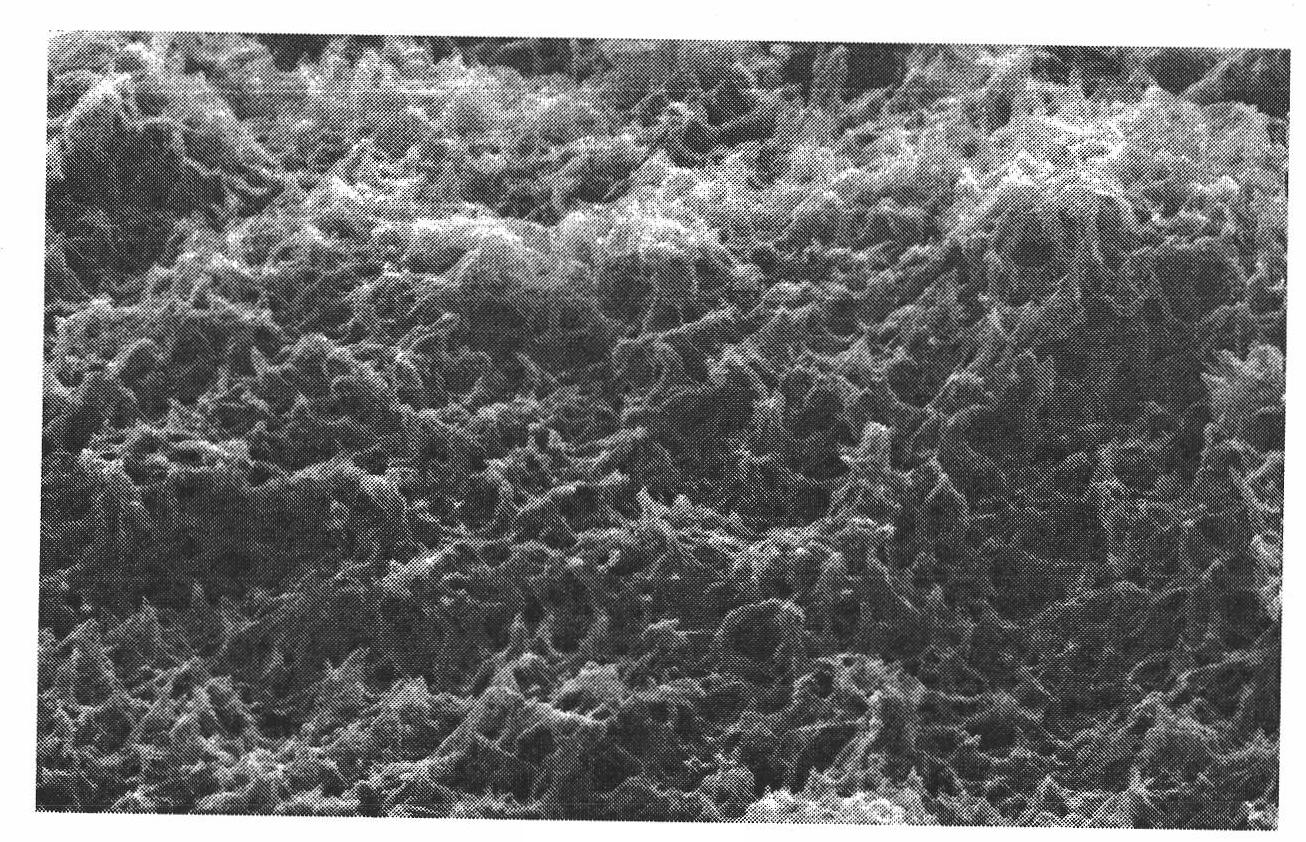

Modified halloysite nanotube/polyether copolyamide mixed matrix membrane and preparation method thereof

The invention discloses a modified halloysite nanotube / polyether copolyamide mixed matrix membrane and a preparation method thereof, which belong to the technical field of membrane separation. The method is characterized in that polyether copolyamide is used as a polymer substrate, and halloysite nanotubes are used as an inorganic filler. The method comprises the following steps of firstly, carrying out surface etching on the halloysite nanotube, and then carrying out surface coating modification on the etched halloysite nanotube, and blending the modified halloysite nanotube with polyether copolyamide to prepare the mixed matrix membrane. The preparation process is simple and easy to operate, and the prepared mixed matrix membrane is applied to CO2 / N2 gas separation and has good separation performance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

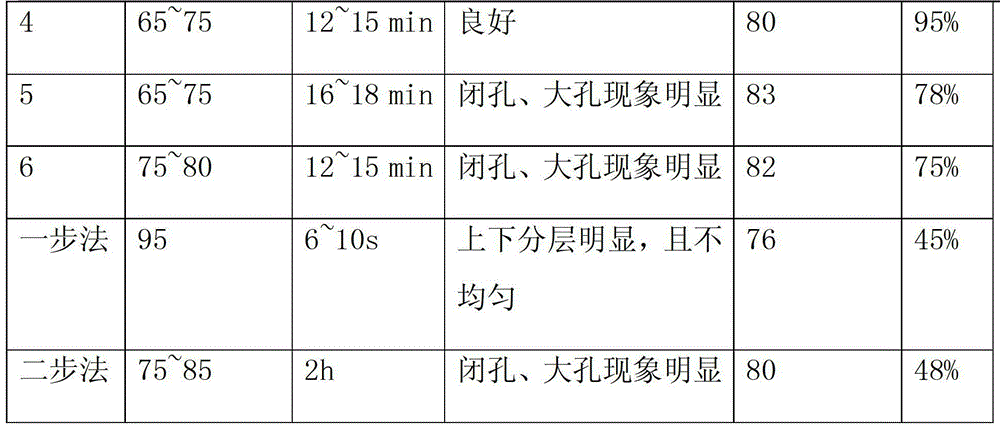

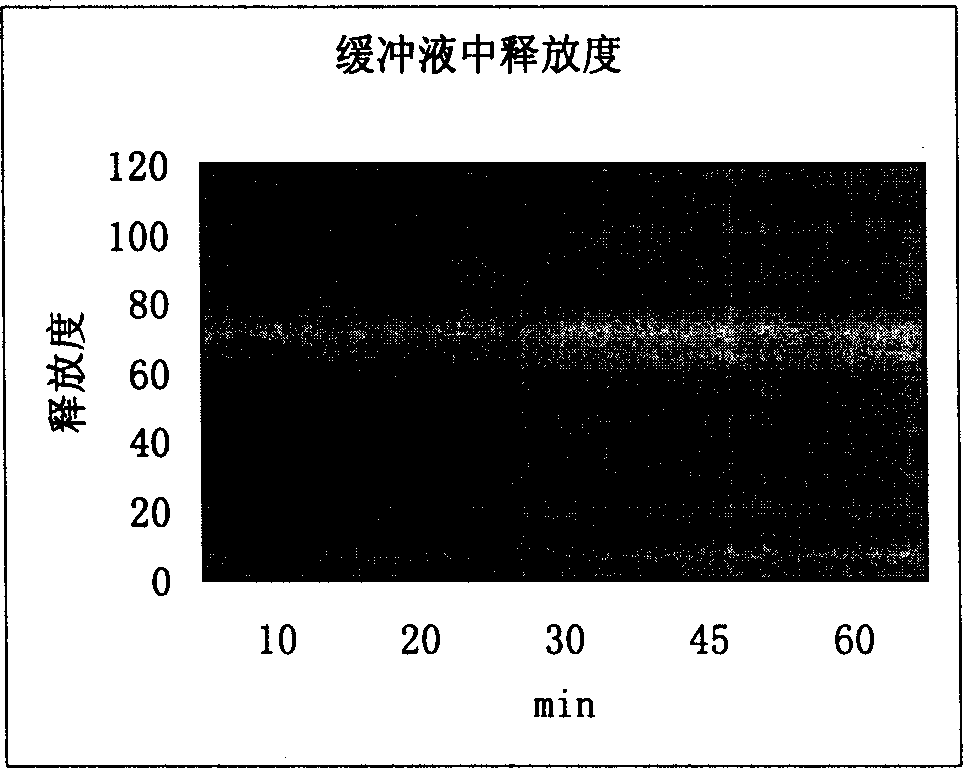

Method for preparing slow release micro pill of aspirin

InactiveCN1554348ASolve processing problemsReduce manufacturing costOrganic active ingredientsAntipyreticAspirinAcrylic resin

The slow releasing micro pill of aspirin has the recipe comprising aspirin, cane sugar or lactose, starch, dextrin or avicel, povidone or hydroxypropyl methyl cellulose, ethanol, Tween-80, acrylic resin and talcum powder. The preparation process includes processing the main material and supplementary material, mixing in certain proportion, pelletizing to form medicine containing micro pill and coating. The present invention has low production cost.

Owner:TIANJIN PACIFIC PHARMA

Hollow polyester fiber microporous membrane and preparation method thereof

The invention relates to a preparation method of a hollow polyester fiber microporous membrane, which belongs to the technical field of membrane separation. The preparation method comprises the following steps of: mixing a polyester and a diluent to form mixed liquid; performing melt blending, standing and degassing to obtain a membrane-making liquid melt; extruding the diluent serving as core liquid and the membrane-making liquid melt by using a spinning jet to prepare a hollow fiber liquid membrane; after the liquid membrane passes through an air gap, solidifying the liquid membrane in a cold bath, and performing hollow molding to prepare a hollow fiber membrane precursor; soaking the hollow fiber membrane precursor into an extractant and drying to prepare the hollow polyester fiber microporous membrane. In the hollow polyester fiber microporous membrane, the porosity is 45 to 80 percent and the average aperture is 0.05 to 5.0 mu m. The hollow polyester fiber microporous membrane has the characteristics of simple preparation process, easily-controlled membrane structure, high flux and porosity, high mechanical strength and the like, and is a high-performance and low-cost filtering membrane material for water treatment.

Owner:JIANGNAN UNIV

Preparing method of chlorine-resistance aromatic polyamide composite nanofiltration membrane

ActiveCN109821427AGood water permeabilityImprove pollutionReverse osmosisPolyamideBiological activation

The invention relates to a preparing method of a chlorine-resistance aromatic polyamide composite nanofiltration membrane, and belongs to the technical field of membrane separation. According to the preparing method, through interficial polymerization between polyamine and aromatic acyl chloride, a polyamide layer is generated; a membrane is immersed in an activation solution, the unreacted acyl chloride in polyamide is hydrolyzed to carboxyl, and then the carboxyl is activated to active ester; the polyamine serves as a connecting unit of the active ester and oxidized graphene quantum dots, the oxidized graphene quantum dots are grafted on the surface of a polyamide membrane, and preparation of the chlorine-resistance aromatic polyamide composite nanofiltration membrane is achieved. According to the preparing method, the chlorine-resistance aromatic polyamide composite nanofiltration membrane is prepared by adopting interficial polymerization first, and then conducting quantum dot modification afterwards; the preparing technology is simple, the operation is convenient, and the production repeatability is high.

Owner:JIANGNAN UNIV

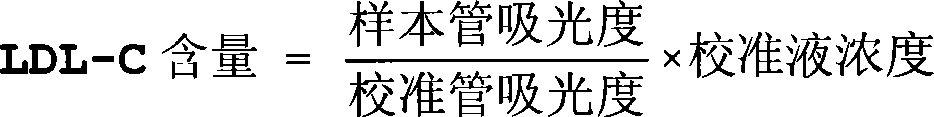

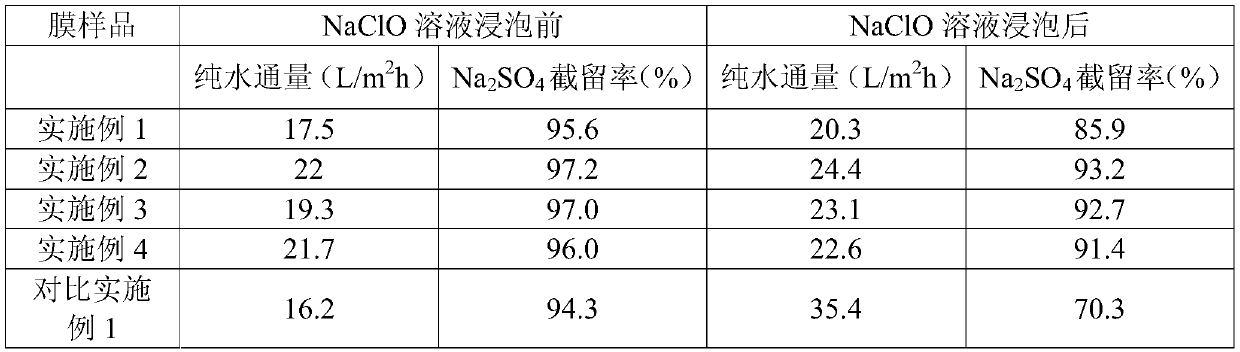

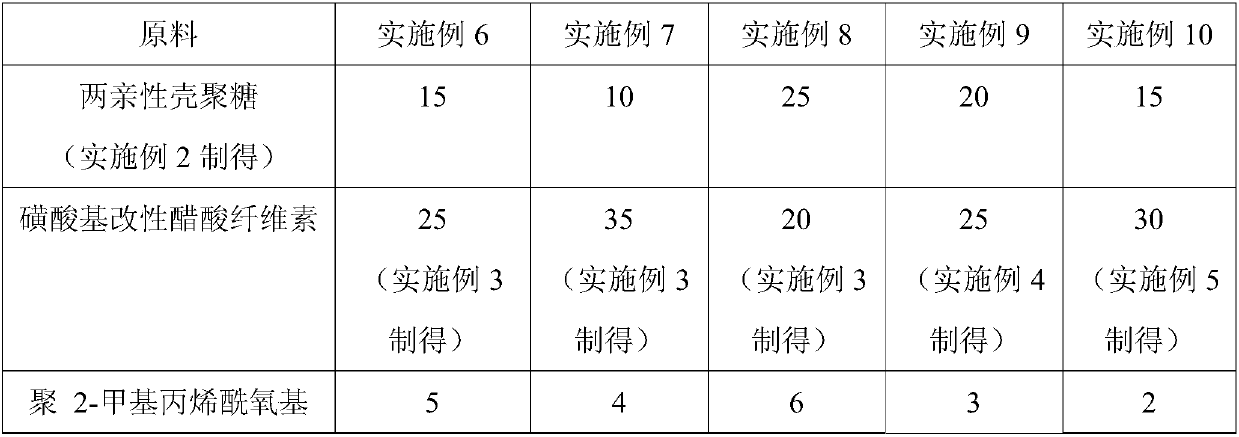

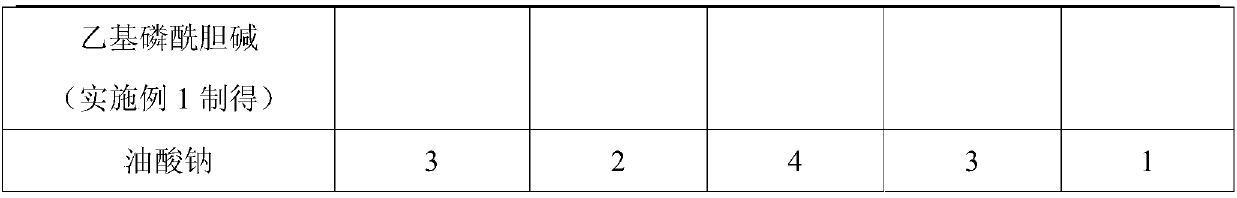

Filter membrane for removing low density lipoproteins, and preparation method thereof

InactiveCN109647227AGood biocompatibilityImprove stabilitySemi-permeable membranes2-methacryloyloxyethyl phosphorylcholineVery low-density lipoprotein

The invention discloses a filter membrane for removing low density lipoproteins, and a preparation method thereof. The filter membrane comprises, by weight, 10-25 parts of amphiphilic chitosan, 20-35parts of sulfonic group-modified cellulose acetate, 2-6 parts of poly(2-methacryloyloxyethyl phosphorylcholine) and 1-4 parts of sodium oleate. The filter membrane can effectively reduce the LDL level in the blood, has a good filtering effect on VLDL, TC and TG, has few influences on the level of beneficial proteins in the blood, such as high density lipoproteins, albumins and immunoglobulin IgG,is suitable for purifying the blood of clinical hyperlipidemia patients, can also be applied to the finishing industry of blood products, and can be combined with relevant separation auxiliary devices to recover useful plasma from the waste human plasma that does not meet the blood transfusion standards and produce blood products with high added values.

Owner:广州达济医学科技有限公司

Water-soluble metallic organic molecular cage-based polydimethylsiloxane composite membrane and preparation method thereof

InactiveCN106390769AEvenly distributedSimple processMembranesSemi-permeable membranesCross-linkSeparation factor

The invention relates to a water-soluble metallic organic molecular cage-based polydimethylsiloxane composite membrane and a preparation method thereof, and belongs to the field of membrane separation techniques and high and new techniques. The preparation method of the membrane comprises the following technological steps: (1), the preparation of a membrane-making pre-emulsion: uniformly mixing polydimethylsiloxane, metallic organic molecular cages, a surfactant and water at 25 DEG C, so as to subsequently form the membrane-making pre-emulsion; (2), the formation of filled polymer composite membrane in a thermal cross-linking manner: adding a cross-linking agent and a catalyst into membrane-making material liquid, agitating an obtained mixture at 25 DEG C, defoaming the agitated membrane-making material liquid in a vacuum manner, then coating a polyvinylidene fluoride ultrafiltration membrane with the defoamed membrane-making material liquid, putting the polyvinylidene fluoride ultrafiltration membrane in a baking oven to cure the defoamed membrane-making material liquid until the cross linking is complete. As the water-soluble metallic organic molecular cages are uniformly distributed in the membrane, the composite membrane prepared by adopting the method provided by the invention is good in penetrating quality to organic vapor, and is high in the separation factor to organic vapor / nitrogen by hydrophobic inner cavities and the regulation and the control on spaces among chains of the membrane of the water-soluble metallic organic molecular cages.

Owner:JIANGNAN UNIV

Skeleton and gel matrix-integrated active membrane of lithium-ion battery and preparation method of skeleton and gel matrix-integrated active membrane

ActiveCN107437600AImprove stabilityHigh porosityCell seperators/membranes/diaphragms/spacersAdditive ingredientDouble bond

The invention discloses a skeleton and gel matrix-integrated active membrane of a lithium-ion battery and a preparation method of the skeleton and gel matrix-integrated active membrane. A skeleton is a porous membrane prepared from a linear polymer PVDF or PVDF-HFP as a first ingredient and a linear, comb-like or hyperbranched amphiphilic polymer of vinyl at the end of a hydrophilic chain as a second ingredient; the aperture of the membrane is 0.05-1.0micron and the thickness of the membrane is 20-80 microns; and the formula composition of a gel matrix comprises a monomer or oligomer containing unsaturated double bonds, a thermal initiator and a solvent. By adopting a phase inversion method in the membrane preparation process, the obtained membrane is high in porosity, efficient and controllable within a relatively wide aperture range and narrow in aperture distribution, and the fluid retention property is relatively well strengthened. The controllability of the membrane structure is good and the production repeatability is good; the wettability of an electrolyte is improved, and an electrode and a membrane resistor in the battery are reduced; and the temperature tolerance of the battery is improved, the battery does not explode or combust at relatively high temperature, and the skeleton and gel matrix-integrated active membrane is especially suitable for a power lithium-ion battery.

Owner:XUCHANG UNIV

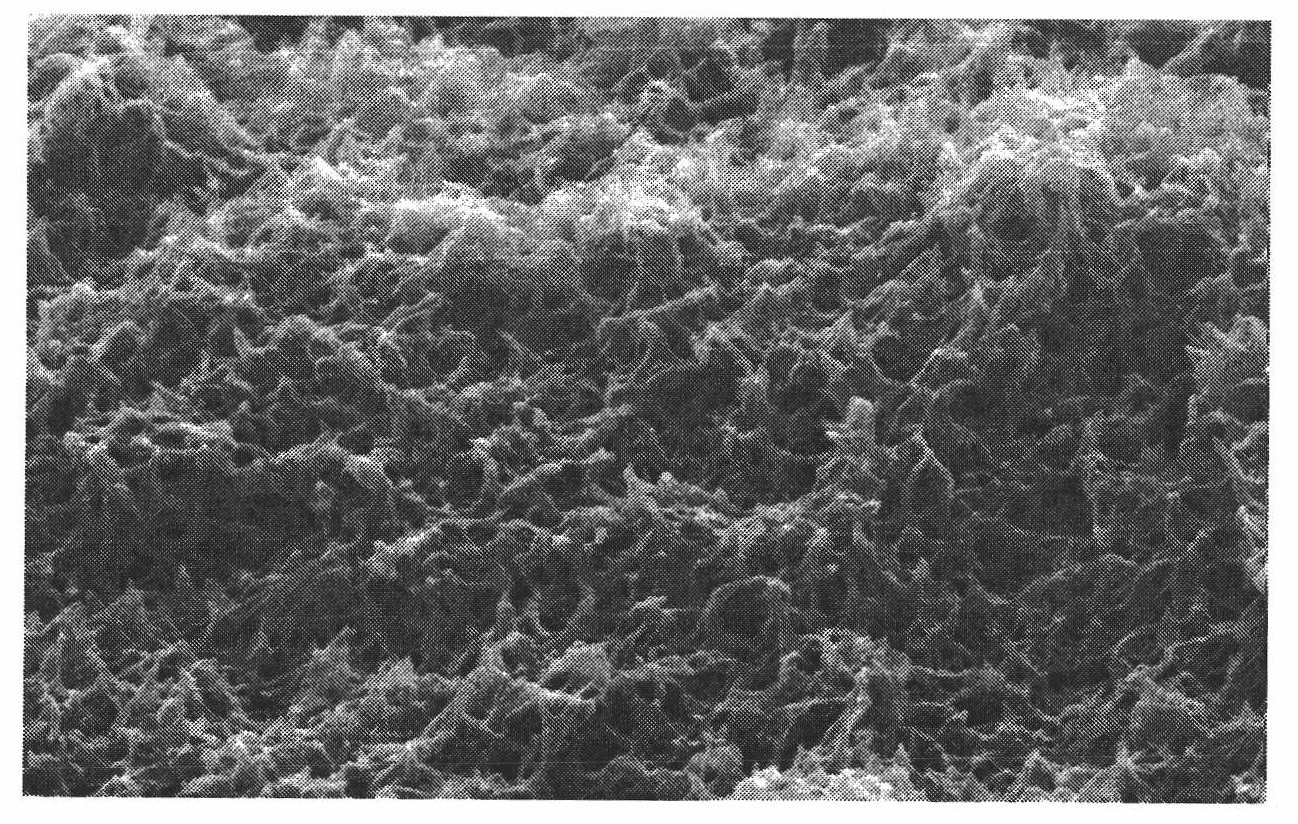

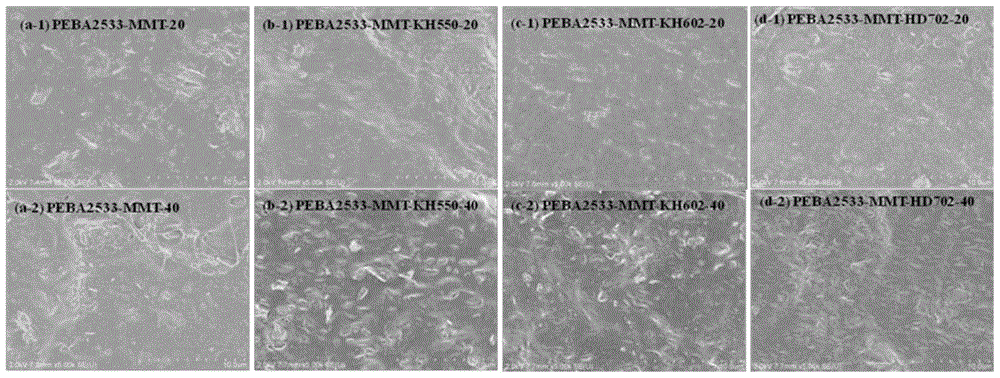

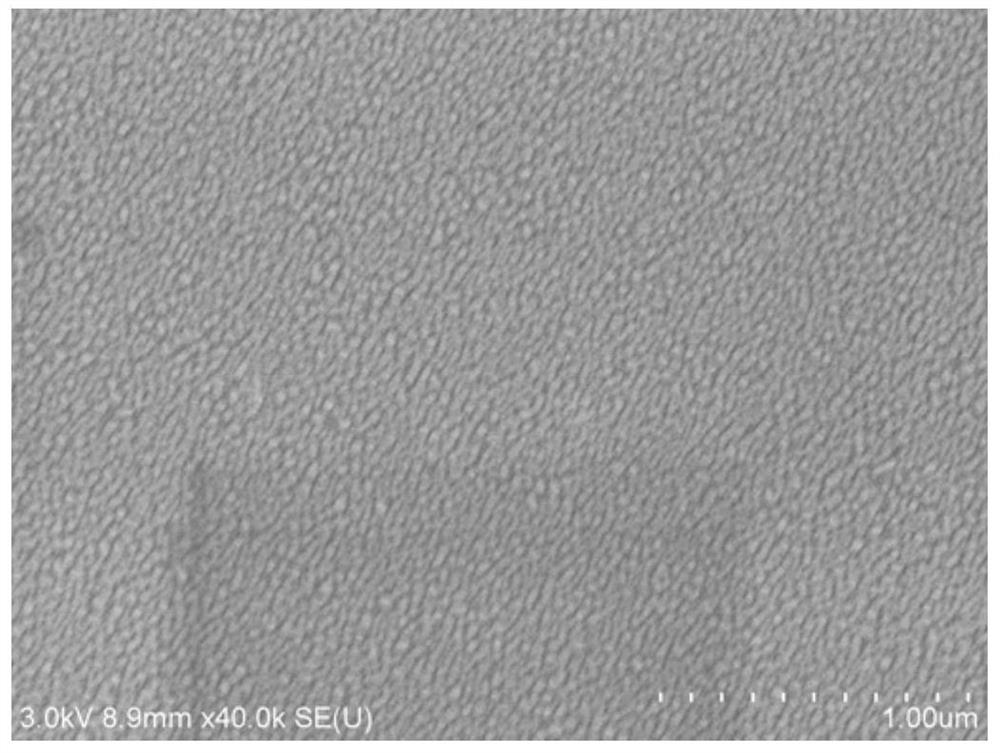

Polyethylene glycol functionalized montmorillonite/polyether copolyamide mixed matrix membrane used for gas separation

ActiveCN105381725AGood controllabilityGood production repeatabilitySemi-permeable membranesDispersed particle separationSilane couplingCarbon dioxide

The invention relates to a polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane used for gas separation, belonging to the technical field of membrane separation. The mixed matrix membrane is characterized in that montmorillonite, polyethylene glycol, a silane coupling agent and polyether copolyamide are used as main raw materials; the silane coupling agent is used for modifying montmorillonite at first; then modified polyethylene glycol is grafted onto the modified montmorillonite; the grafted modified montmorillonite is mixed with polyether copolyamide at a certain temperature under stirring; and knife coating is carried out so as to obtain the polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane with controllable thickness. The polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane prepared in the invention has excellent tensile strength and fracture elongation and high permeation flux and separation factors, and is especially applicable to separation of carbon dioxide in the air.

Owner:JIANGNAN UNIV

Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

ActiveCN102210979BBacteria resistantWith acid and alkali resistanceSemi-permeable membranesFiberPolyvinyl chloride

The invention discloses a method for preparing a positively charged polyvinyl chloride (PVC) hollow fiber nanofiltration membrane. The positively charged PVC hollow fiber nanofiltration membrane has a two-layer structure consisting of a positively charged compact skin layer and an electrically neutral porous support layer; the pore diameter of micropores of the compact skin layer is 1-5nm, and the pore diameter of micropores of the porous support layer is 10-100nm; and the outer diameter of the membrane is 1.5-3.0mm, and the inner diameter of the membrane is 0.5-2mm, wherein the positively charged compact skin layer comprises main components of polyvinyl chloride and cationic copolymer; and the electrically neutral porous support layer comprises main components of polyvinyl chloride and an inorganic filler. The method for preparing the positively charged PVC hollow fiber nanofiltration membrane comprises the following steps of: co-extruding positively charged compact skin layer membrane preparing liquid and electrically neutral porous support layer membrane preparing liquid in a two-layer ring shape; and curing and forming hollow fibers by using a dry-wet spinning process. The prepared hollow fiber nanofiltration membrane has the advantages of easily controlled interception property, high strength, simple preparation process and the like, and is a high-performance, low-cost and long-life nanofiltration membrane material for water treatment.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Polyvinyl acetate/polyion liquid semi-interpenetrating polymer network film and photocuring preparation method thereof

InactiveCN103657451AImprove stabilityHigh mechanical strengthSemi-permeable membranesPolymer scienceCarvacryl acetate

The invention belongs to the field of preparation of gas separation films, and particularly relates to a polyvinyl acetate / polyion liquid semi-interpenetrating polymer network film and a photocuring preparation method thereof. The preparation method comprises the following steps: 1) preparing a film preparation solution, namely uniformly mixing polyvinyl acetate, a solvent and an ionic liquid monomer at 50 DEG C to form the film preparation solution; 2) crosslinking to form an interpenetrating network polymer film: adding a crosslinking agent and a photoinitiator into the film preparation solution, carrying out ultrasonic treatment on the mixed film preparation solution, and curing in a photocuring machine until the film preparation solution is crosslinked into a film; and 3) after-treatment: drying the prepared film in air for 24 hours, transferring into a vacuum drying oven, and drying at 30 DEG C for 12 hours. The polymerizable ionic liquid monomer used as one component in the semi-interpenetrating polymer network film has the advantages of favorable compatibility with other components, high stability and low tendency to loss, and can ensure the physical structure and enduring and stable properties of the film.

Owner:JIANGNAN UNIV

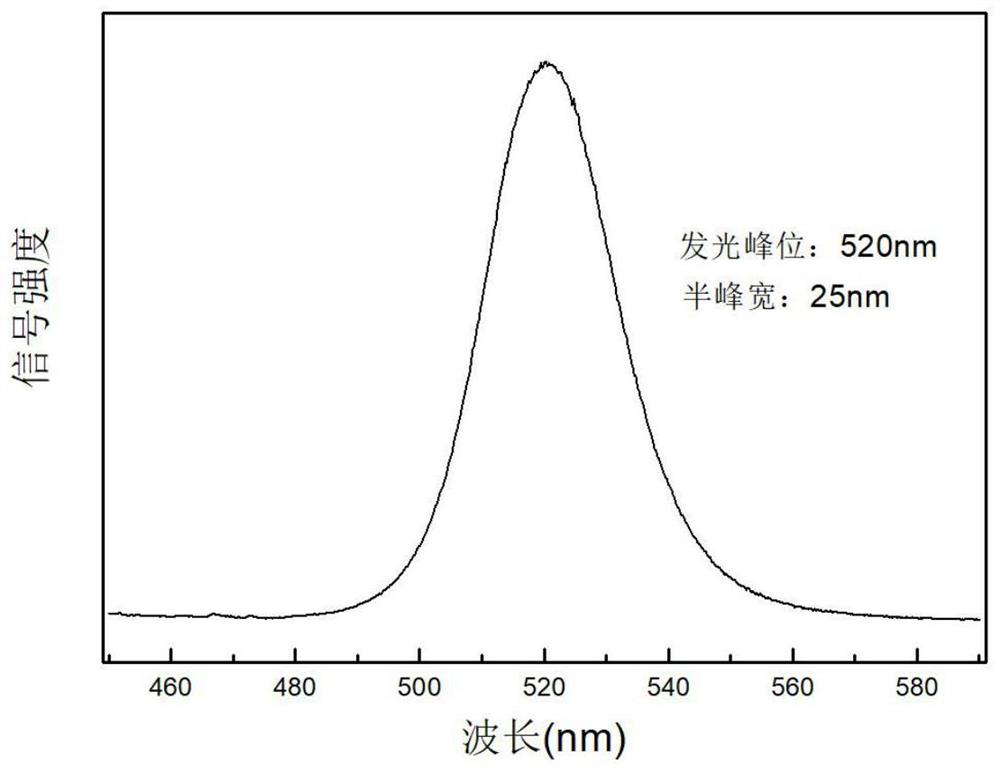

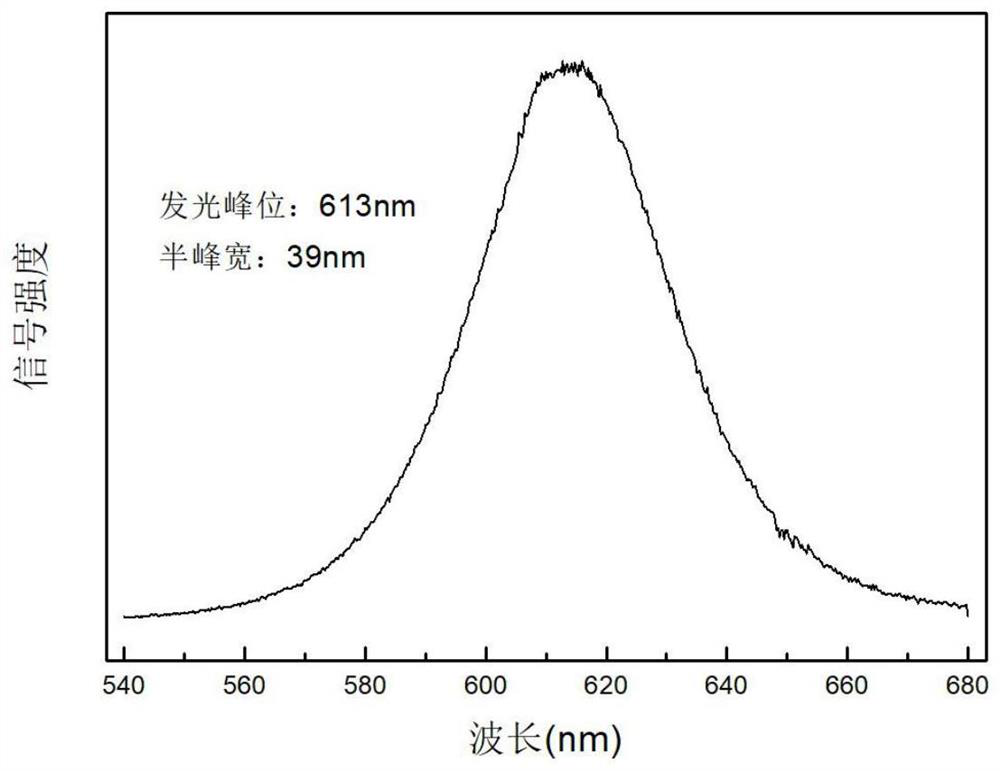

Perovskite quantum dot glass and preparation method and application thereof

PendingCN114455837AImprove quantum efficiencyHalf maximum widthGlass furnace apparatusPhysical chemistryPolluted environment

The invention belongs to the field of solid luminescent materials, and particularly relates to perovskite quantum dot glass and a preparation method and application thereof.The perovskite quantum dot glass is prepared through a pressure-adjustable high-temperature-resistant closed container, the boiling point of a quantum dot precursor can be increased through high pressure, volatilization of raw materials is reduced, and due to the closed environment, the performance of the perovskite quantum dot glass is improved. The volatilization of raw materials can be effectively controlled from the source, the size uniformity of the quantum dots in the glass is greatly improved, and the raw materials are not wasted and the environment is not polluted. Besides, the annealing step and the high-temperature melting step are carried out in the same closed container, so that the temperature and the shape of the glass melt can be prevented from being rapidly changed, the thermal stress of the glass is reduced, the product yield is improved, meanwhile, the process operation is simpler and more convenient, the production repeatability is better, the heat energy of the annealing step is saved, and the production cost is reduced. Therefore, the preparation method disclosed by the invention can be suitable for industrial large-scale production.

Owner:WUXI UTMOST LIGHT TECH CO LTD

Metal organic compound filled cross-linked polysiloxane pervaporation membrane and preparation method thereof

InactiveCN102489190BIncrease the degree of cross-linkingGood film formingSemi-permeable membranesCross-linkAlcohol

The invention relates to a metal organic compound filled cross-linked polysiloxane pervaporation membrane and a preparation method thereof, and belongs to the field of membrane separation. The method comprises the following steps of: mixing a cross-linking agent, a catalyst, linear polysiloxane and a solvent, reacting to generate prepolymer, adding a metal organic compound, and performing cross-linking reaction to obtain a membrane casting solution; and coating the membrane casting solution on a macromolecular porous bottom membrane, drying, and heating to obtain a product, namely the metal organic compound filled cross-linked polysiloxane pervaporation membrane. The metal organic compound filled cross-linked polysiloxane pervaporation membrane prepared by the method has the characteristics of high permeation flux, good separation effect, high strength, stable structure and the like, is suitable for removing low-concentration organic compounds from water, and is particularly suitable for separating low molecular alcohol from a fermentation solution.

Owner:JIANGNAN UNIV

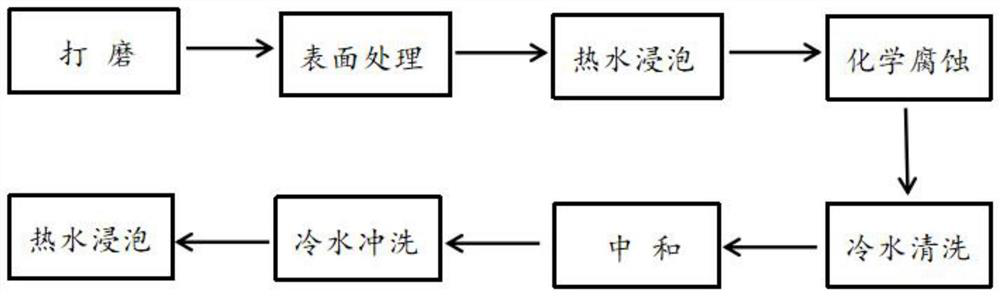

Corroding method of DD5 single-crystal high-temperature alloy turbine blade

ActiveCN107955949ACorrosion process parameters are controllableGood production repeatabilitySingle crystalSuperalloy

The invention discloses a corroding method of a DD5 single-crystal high-temperature alloy turbine blade. The method includes the following steps of firstly, sand blasting; secondly, primary chemical corroding, wherein a 40% ferric trichloride solution and a 37% hydrochloric acid solution are used for preparing a corroding solution, and chemical erosion is conducted on a cast in the first step for9 minutes; thirdly, primary washing, reactants adhering to the surface of the cast and generated during chemical erosion in the second step are washed away through an ultrasonic washing machine, the ultrasonic frequency is 20 KHz, the water temperature is 50 DEG C, and the washing time is 5 minutes; fourthly, secondary electrochemical corroding; fifthly, secondary washing; sixthly, tertiary electrochemical corroding; seventhly, neutralizing, wherein the cast in the six step is placed in a 5% NaHCO3 room-temperature solution to be soaked for 3 minutes, and acid liquid on the surface of the castis neutralized; eighthly, drying. The corrosion effect is clear, and it can be avoided that due to local excessive corrosion, surface structure and appearance size of the cast are not qualified.

Owner:ANHUI YINGLIU HANGYUAN POWER TECH CO LTD

Hyperbranched polysiloxane multilayer compound film and preparation method thereof

The invention relates to a hyperbranched polysiloxane multilayer film and a preparation method thereof. The following process steps are adopted: 1) After reacting hyperbranched polysiloxane, solvent, 107 glue and catalyst at 60-80°C for 12 hours, Form a casting film feed solution, and apply the gained casting film solution on the polyvinylidene fluoride porous base film to obtain a hyperbranched polysiloxane film; 2) vinyltriethoxysilane, solvent, 107 glue, and catalyst After reacting at 60-80° C. for 6 hours, a casting film material solution is formed, which is coated on the above-mentioned hyperbranched polysiloxane film to obtain a hyperbranched polysiloxane multilayer composite film. The hyperbranched polysiloxane multilayer composite membrane prepared by the present invention has a three-layer membrane structure, the bottom layer is a polyvinylidene fluoride ultrafiltration membrane supported by non-woven fabric, the middle layer is a hyperbranched polysiloxane membrane, and the top layer is separated The layer is an extremely thin polysiloxane film. The hyperbranched polysiloxane multilayer composite membrane prepared by the invention has a gradient distribution of porosity from top to bottom, which greatly improves the performance of pervaporation separation of butanol in water.

Owner:JIANGNAN UNIV

Modified magnesium oxide/polyether copolyamide nano composite membrane and preparation method thereof

InactiveCN112791605AImprove interface affinityImprove mechanical propertiesSemi-permeable membranesPolymer substratePolyamide

The invention belongs to the technical field of membrane preparation, and mainly relates to a modified magnesium oxide / polyether copolyamide nano composite membrane and a preparation method thereof. The method comprises the following steps of modifying magnesium oxide by using a titanate coupling agent as a modifier, dissolving the modified magnesium oxide and polyether copolyamide to prepare a membrane casting solution, and finally preparing the membrane casting solution into the membrane. The problems that magnesium oxide is poor in dispersity in a polymer substrate and poor in compatibility with polymers are solved, and the prepared modified magnesium oxide / polyether copolyamide nano composite membrane has high gas permeation flux and separation factors and is suitable for CO2 / N2 separation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A Polyethylene Glycol Functionalized Montmorillonite/Polyether Copolyamide Mixed Matrix Membrane for Gas Separation

ActiveCN105381725BImprove controllabilityGood production repeatabilitySemi-permeable membranesDispersed particle separationSeparation factorMontmorillonite

The invention relates to a polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane used for gas separation, belonging to the technical field of membrane separation. The mixed matrix membrane is characterized in that montmorillonite, polyethylene glycol, a silane coupling agent and polyether copolyamide are used as main raw materials; the silane coupling agent is used for modifying montmorillonite at first; then modified polyethylene glycol is grafted onto the modified montmorillonite; the grafted modified montmorillonite is mixed with polyether copolyamide at a certain temperature under stirring; and knife coating is carried out so as to obtain the polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane with controllable thickness. The polyethylene glycol functionalized montmorillonite / polyether copolyamide mixed matrix membrane prepared in the invention has excellent tensile strength and fracture elongation and high permeation flux and separation factors, and is especially applicable to separation of carbon dioxide in the air.

Owner:JIANGNAN UNIV

A preparation method of chlorine-resistant aromatic polyamide composite nanofiltration membrane

The invention relates to a preparation method of a chlorine-resistant aromatic polyamide composite nanofiltration membrane, belonging to the technical field of membrane separation. It generates a polyamide layer through interfacial polymerization between polyamines and aromatic acid chlorides; the membrane is immersed in an activation solution, and the unreacted acid chlorides in the polyamide are hydrolyzed into carboxyl groups and then activated into active esters; the polyamines are then used as active esters and oxidized The connecting unit of graphene quantum dots grafts graphene oxide quantum dots onto the surface of polyamide membranes to realize the preparation of chlorine-resistant aromatic polyamide composite nanofiltration membranes. The invention adopts the method of interfacial polymerization first and then quantum dot modification to prepare the chlorine-resistant polyamide composite nanofiltration membrane, the preparation process is simple, the operation is convenient, and the production repeatability is good.

Owner:JIANGNAN UNIV

Surface grain corrosion method for IN718C nickel-based superalloy aviation bearing seat

PendingCN112981406AImprove pass rateSimplified and safe operation stepsPreparing sample for investigationAviationHigh pressure water

The invention discloses a surface grain corrosion method of an IN718C nickel-based superalloy aviation bearing seat. The surface grain corrosion method comprises the following steps: polishing the surface of a casting to remove a corrosion layer; removing casting surface pollutants through sand blasting, so that the casting surface is in an activated state; chemically etching the casting soaked in the hot water in a corrosive liquid prepared from copper sulfate pentahydrate, a hydrochloric acid solution and water; swinging and cleaning with cold water until no corrosive liquid is left on the surface; washing with a high-pressure water gun after neutralizing the casting; and performing surface detection after hot water soaking and drying. Compared with an existing hydrochloric acid and ferric trichloride proportional corrosion and hydrofluoric acid and nitric acid bleaching method, the corrosion method using the proportion of copper sulfate, hydrochloric acid and water has the advantages that the operation steps are simplified and safe, the corrosion process parameters are more controllable, the process is stable, surface crystal grains are clearly and uniformly displayed, the production repeatability is good, the cost is low, and the qualified rate of corrosion production is improved.

Owner:ANHUI YINGLIU HANGYUAN POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com