Skeleton and gel matrix-integrated active membrane of lithium-ion battery and preparation method of skeleton and gel matrix-integrated active membrane

A lithium-ion battery, gel matrix technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as battery safety hazards, improve temperature resistance, enhance protection Liquid performance, increase the effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing an active diaphragm for a lithium-ion battery integrating a skeleton and a gel matrix, comprising the steps of:

[0033] 1) The linear polymer PVDF or PVDF-HFP with a mass percentage of 8-25%, the amphiphilic polymer with a hydrophilic chain end of vinyl group at the end of a hydrophilic chain with a mass percentage of 5-15%, and the mass percentage Mix 0.1-10% additives and 60-85% solvent at 45-60°C to make a casting solution; scrape the film-making solution on a stainless steel carrier or a glass carrier to a thickness of 80-200 microns liquid film, and immerse in a coagulation bath at 0-60°C to solidify into a precursor skeleton;

[0034] 2) A monomer or oligomer containing 1-20% by mass of unsaturated double bonds, a thermal initiator with a mass percentage of 0.01-3% and a thermal initiator with a mass percentage of 75-90% The solvent is prepared into a solution; soak the skeleton prepared in step 1) in the solution for 0.5-2 hours, take it ...

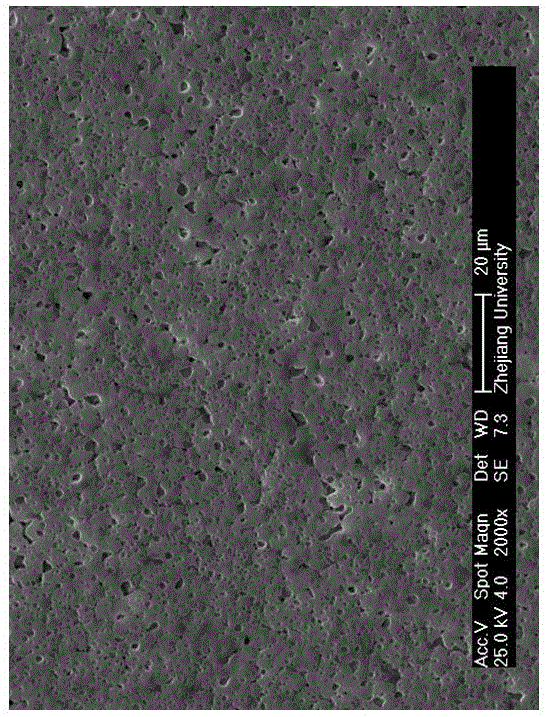

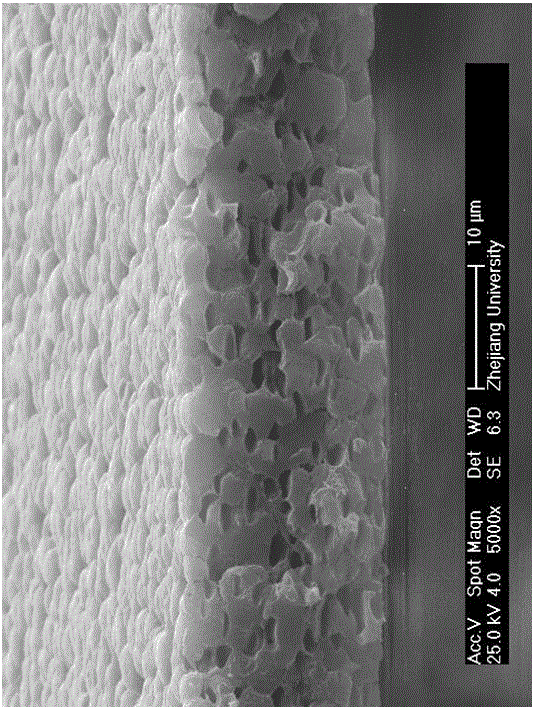

Embodiment 1

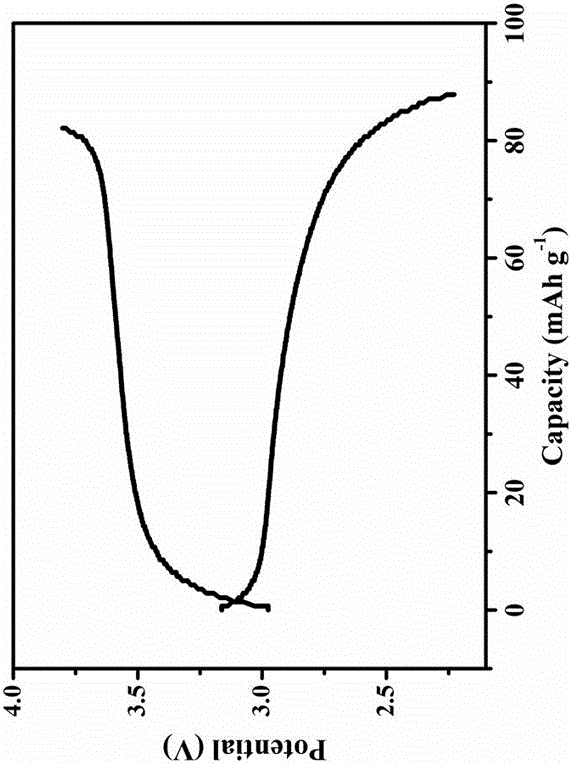

[0046] 1) The polymer PVDF with a mass percentage of 20%, the amphiphilic polymer with a vinyl end at the end of a hydrophilic chain with a mass percentage of 5%, the additive PEG2000 with a mass percentage of 2%, and the mass percentage The solvent N, N-dimethylacetamide with a content of 73% is mixed at 60°C to make a casting solution; the film-making solution is scraped into a liquid film with a thickness of 30 microns on a stainless steel carrier or a glass carrier, and immersed in 40°C solidified into a precursor skeleton in a coagulation bath;

[0047] 2) The monomer divinyl-1,4-butanediol ether (mass percentage is 10%), thermal initiator azobisisobutyronitrile (mass percentage is 0.02%) and solvent acetone (mass percentage The percentage content is 90%) to prepare a solution; soak the skeleton prepared in step (1) in the solution for 1 h, take it out, put it into a sealable glass mold, thermally polymerize at 65°C for 5 h, wash and dry After that, the lithium ion batte...

Embodiment 2

[0049] 1) The polymer PVDF-HFP with a mass percentage of 20%, the amphiphilic polymer with a vinyl end at the end of a hydrophilic chain with a mass percentage of 8%, and the additive polyethylene with a mass percentage of 2% Pyrrolidone and 70% by mass solvent N, N-dimethylformamide are mixed at 70°C to make a casting solution; the film-making solution is scraped on a stainless steel carrier or a glass carrier to form a liquid film with a thickness of 40 microns , and immersed in a coagulation bath at 30°C to solidify into a precursor skeleton;

[0050] 2) The monomer methyl methacrylate (8% by mass), the thermal initiator azobisisobutyronitrile (0.02% by mass) and the solvent acetone (92% by mass) Prepare a solution; soak the skeleton prepared in step (1) in the solution for 1 h, take it out, put it into a sealable glass mold, thermally polymerize at 65°C for 4 h, wash and dry to get the skeleton and gel Gel-matrix-integrated active separators for lithium-ion batteries, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com