Preparing method of chlorine-resistance aromatic polyamide composite nanofiltration membrane

An aromatic polyamide and composite nanofiltration membrane technology, applied in the field of membrane separation, can solve problems such as membrane separation performance deterioration, and achieve the effects of improving anti-pollution performance, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

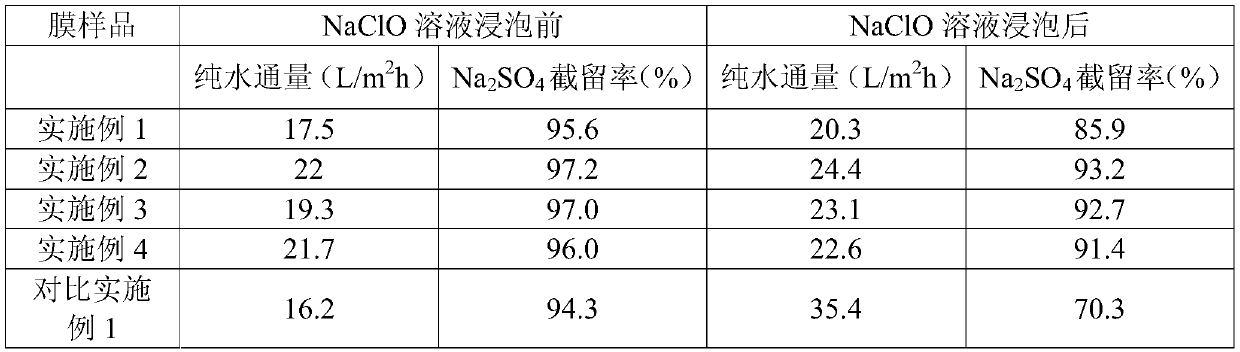

Examples

Embodiment 1

[0025] (1) Monomer solution configuration: m-phenylenediamine was dissolved in water to prepare an aqueous phase solution with a mass concentration of 1%, and trimesoyl chloride was dissolved in n-hexane to prepare an organic phase solution with a mass concentration of 0.01%;

[0026] (2) Interface polymerization: soak the polyvinylidene fluoride ultrafiltration bottom membrane in the aqueous phase solution for 30 minutes, take it out and remove the excess aqueous phase solution on the surface of the membrane with an air knife, and then immerse it in the organic phase solution for 30 seconds to carry out interfacial polymerization After reaction, the membrane was taken out and drained, heat-treated in an oven at 70°C for 5 minutes, then soaked in deionized water for 24 hours to remove unreacted monomers to obtain an aromatic polyamide composite nanofiltration membrane;

[0027] (3) Membrane surface activation: configure the activation solution of 1-(3-dimethylaminopropyl)-3-eth...

Embodiment 2

[0032] (1) Monomer solution configuration: o-phenylenediamine was dissolved in water to prepare an aqueous phase solution with a mass concentration of 15%, and biphenyltetrayl chloride was dissolved in n-hexane to prepare an organic phase solution with a mass concentration of 2%;

[0033] (2) Interface polymerization: soak the polysulfone ultrafiltration bottom membrane in the aqueous phase solution for 30 minutes, take it out and use an air knife to remove excess aqueous phase solution on the membrane surface, then immerse it in the organic phase solution for 30 seconds to carry out interfacial polymerization reaction, Then the membrane was taken out and drained, heat-treated in an oven at 100°C for 3 minutes, then soaked in deionized water for 24 hours to remove unreacted monomers to obtain an aromatic polyamide composite nanofiltration membrane;

[0034] (3) Membrane surface activation: configure the activation solution of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydroc...

Embodiment 3

[0038] (1) Monomer solution configuration: Dissolving syrylenetriamine in water to prepare an aqueous phase solution with a mass concentration of 0.1%, dissolving terephthaloyl chloride in n-hexane to prepare an organic phase solution with a mass concentration of 1%;

[0039](2) Interface polymerization: soak the polyacrylonitrile ultrafiltration bottom membrane in the aqueous phase solution for 30 minutes, take it out and remove the excess aqueous phase solution on the surface of the membrane with an air knife, and then immerse it in the organic phase solution for 30 seconds to carry out interfacial polymerization reaction , and then the membrane was taken out and drained, heat-treated in an oven at 50°C for 7 minutes, then soaked in deionized water for 24 hours to remove unreacted monomers to obtain an aromatic polyamide composite nanofiltration membrane;

[0040] (3) Membrane surface activation: configure the activation solution of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com