Surface grain corrosion method for IN718C nickel-based superalloy aviation bearing seat

A nickel-based superalloy, IN718C technology, applied in the field of surface grain corrosion of IN718C nickel-based superalloy aviation bearing seat, can solve the problems of difficult to control corrosion effect, reduce product qualification rate, unstable solution composition, etc., to achieve corrosion Controllable process parameters, improved qualification rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

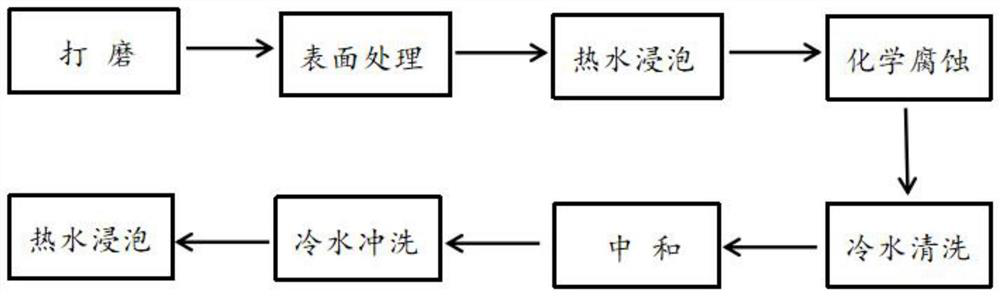

[0025] A method for surface grain corrosion of an IN718C nickel-based high-temperature alloy aviation bearing seat, comprising the steps of:

[0026] 1) Grinding: Grinding the surface of the casting to remove the corrosion-resistant layer of 0.3-0.5 mm, and completely remove the corrosion-resistant layer on the surface after heat treatment;

[0027] 2) Surface treatment: use sandblasting to remove surface pollutants, remove casting surface pollutants, ensure the surface finish of castings, and at the same time cause compressive stress on the surface of castings, and the surface is in an activated state; the specific operation method of sandblasting is: choose 10mm For the nozzle of the sandblasting machine, adjust the pressure to 0.4-0.6Mpa, select 80-120 mesh sand, and spray on the surface of the casting for 5-6 minutes.

[0028] 3) Hot water soaking: Soak the casting in clean hot water with a water temperature of 45-65°C for at least 15 minutes to prepare for enhancing the c...

Embodiment 2

[0036] A method for surface grain corrosion of an IN718C nickel-based high-temperature alloy aviation bearing seat, comprising the steps of:

[0037] 1) Grinding: Grinding the surface of the casting to remove the corrosion-resistant layer of 0.3-0.5 mm, and completely remove the corrosion-resistant layer on the surface after heat treatment;

[0038] 2) Surface treatment: use sandblasting to remove surface pollutants, remove casting surface pollutants, ensure the surface finish of castings, and at the same time cause compressive stress on the surface of castings, and the surface is in an activated state; the specific operation method of sandblasting is: choose 10mm For the nozzle of the sandblasting machine, adjust the pressure to 0.4-0.6Mpa, select 80-120 mesh sand, and spray on the surface of the casting for 5-6 minutes.

[0039] 3) Hot water soaking: Soak the casting in clean hot water with a water temperature of 45-65°C for at least 15 minutes to prepare for enhancing the c...

Embodiment 3

[0047] A method for surface grain corrosion of an IN718C nickel-based high-temperature alloy aviation bearing seat, comprising the steps of:

[0048] 1) Grinding: Grinding the surface of the casting to remove the corrosion-resistant layer of 0.3-0.5 mm, and completely remove the corrosion-resistant layer on the surface after heat treatment;

[0049] 2) Surface treatment: use sandblasting to remove surface pollutants, remove casting surface pollutants, ensure the surface finish of castings, and at the same time cause compressive stress on the surface of castings, and the surface is in an activated state; the specific operation method of sandblasting is: choose 10mm For the nozzle of the sandblasting machine, adjust the pressure to 0.4-0.6Mpa, select 80-120 mesh sand, and spray on the surface of the casting for 5-6 minutes.

[0050] 3) Hot water soaking: Soak the casting in clean hot water with a water temperature of 45-65°C for at least 15 minutes to prepare for enhancing the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com