Patents

Literature

86 results about "Copper sulphate pentahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphene/copper composite material

InactiveCN103736993AGood dispersionThe reaction conditions are mild and safeLiquid/solution decomposition chemical coatingWater bathsFiltration

The invention discloses a preparation method of a graphene / copper composite material. The preparation method includes the following steps: step 1, weighing copper sulfate pentahydrate, nickel sulfate, citric acid and boric acid so as to prepare a mixed solution A, and stirring the mixed solution A; step 2, placing the mixed solution A in a magnetic stirring water bath kettle for heating the mixed solution A, then adding graphene oxide solution into the mixed solution A, stirring, and preparing a mixed solution B; step 3, adding sodium hypophosphite solution into the mixed solution B, stirring, and performing an accelerated reaction and ultrasound dispersion treatment so as to obtain a solution of the graphene / copper composite material which is evenly dispersed; step 4, performing repeated suction filtration on the solution by using a microfiltration membrane, repeatedly washing filter residues until PH (potential of hydrogen) value of the filter residues is neutral, performing vacuum drying, and performing reduction so as to obtain the composite graphene / copper composite material. The preparation method of the graphene / copper composite material is simple, convenient to operate, and low in cost, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

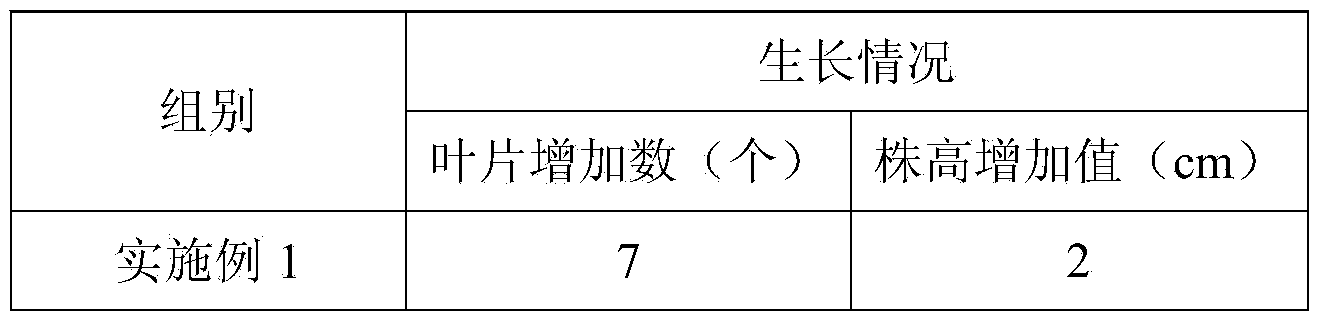

Special-purpose tuanke foliage fertilizer for flue-cured tobacco

InactiveCN101104569AIncrease productionHigh outputFertilisers by pryogenic processesAmmonium salt fertilisersPhosphateMonopotassium phosphate

The present invention is spherical plant foliar fertilizer especially used for flue-cured tobacco, which is basically composed of the following substances: fulvic acid, zinc sulfate, copper sulfate, ferrous sulfate, boric acid, potassium dihydrogen phosphate, potassium nitrate, rooting powder, ammonium molybdate and acetic acid. Wherein, the ferrous sulfate refers to the ferrous sulfate heptahydrate; the copper sulfate refers to the copper sulphate pentahydrate; the zinc sulfate refers to the zinc sulfate heptahydrate; the acetic acid refers to the acetic acid glacial; the ammonium molybdate and the boric acid are without crystal water. The production method of the foliar fertilizer is as follows: first, a certain amount of 36% acetic acid is added to the mixture of the 25 g / L fulvic acid, followed by zinc sulfate, copper sulfate, ferrous sulfate, boric acid, potassium dihydrogen phosphate and potassium nitrate in sequence, and then 0.1% alcohol containing 5g / L rooting powder is also added to the 25 g / L fulvic acid; then, upon ongoing stirring, 145g / L ammonium molybdate is slowly added to the mixture of the 25 g / L fulvic acid; the mixture is then shaken up and filled into a glass or plastic bottle(do not use metal containers), and then the bottle is sealed, and the spherical plant foliar fertilizer is thus obtained. Compared with the similar foliar fertilizer, the foliar fertilizer provided by the invention can significantly promote the growth and development in tobacco plant resettling period and budding period, markedly increase the yield and value of flue-cured tobacco, significantly increase potassium content of flue-cured tobacco and reduce chlorine content to enable more moderate nicotine content and coordinated chemical composition of tobacco leaves. Therefore, the invention has significant economic and social benefits.

Owner:介晓磊 +2

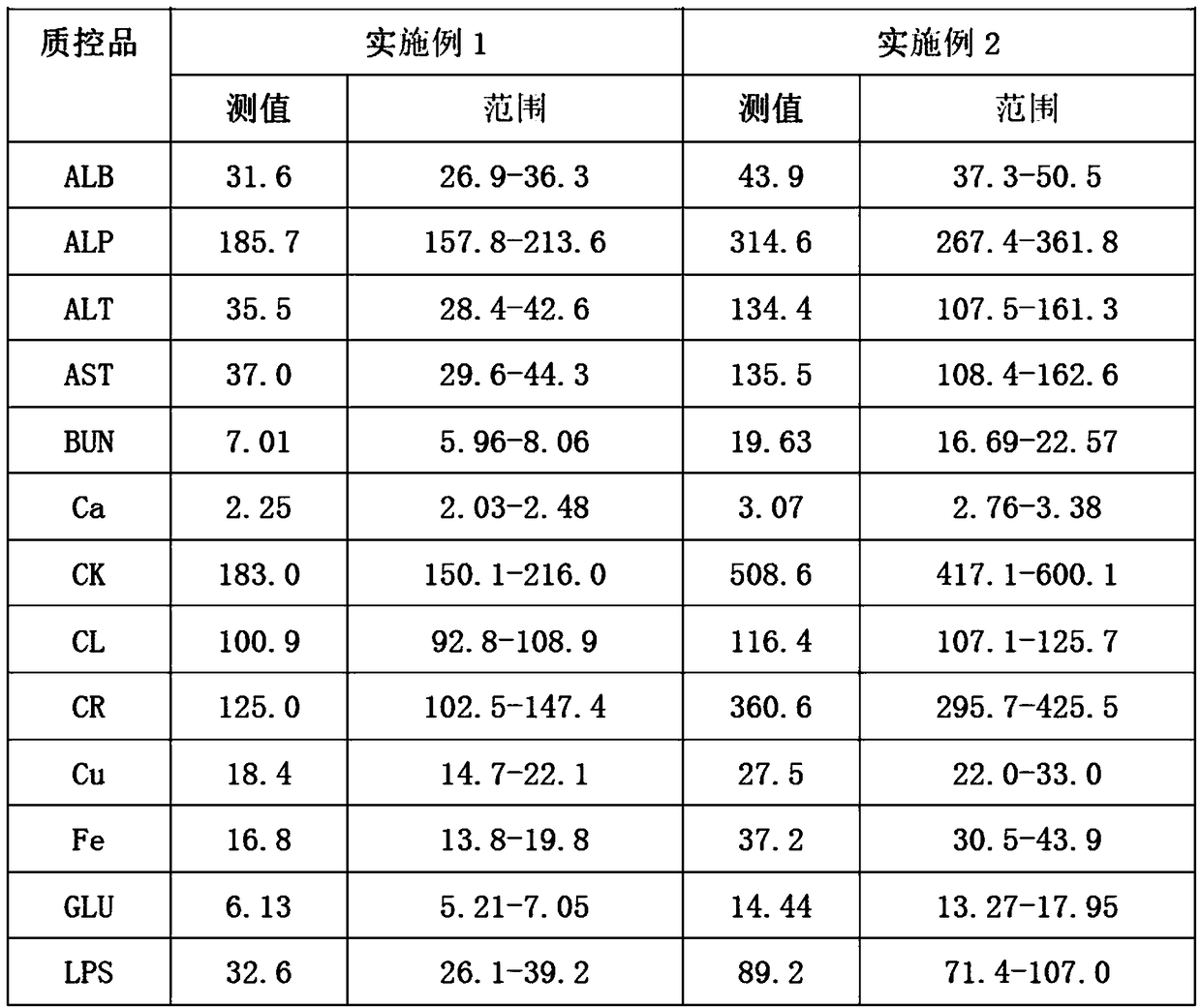

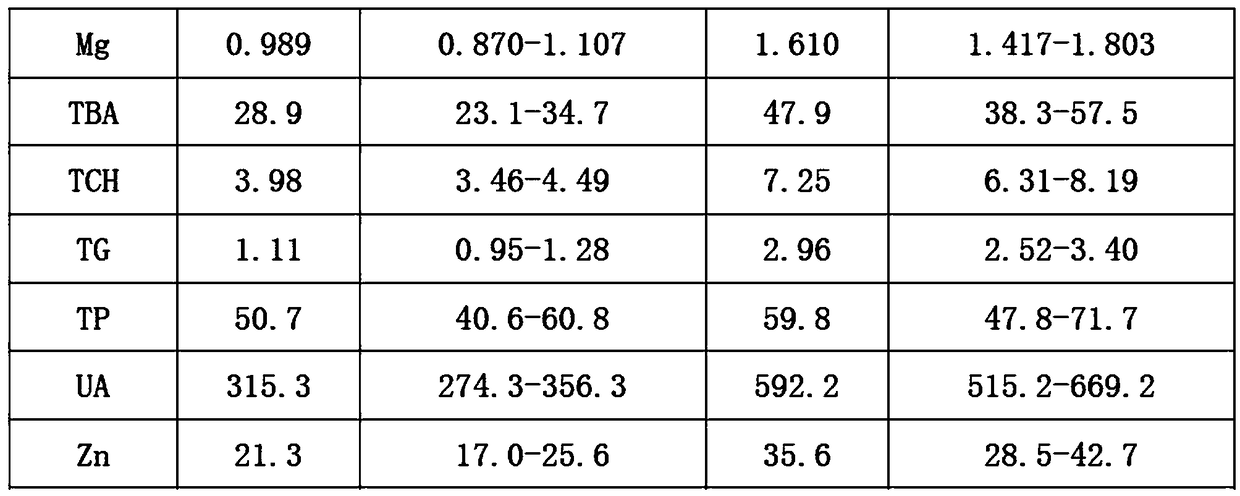

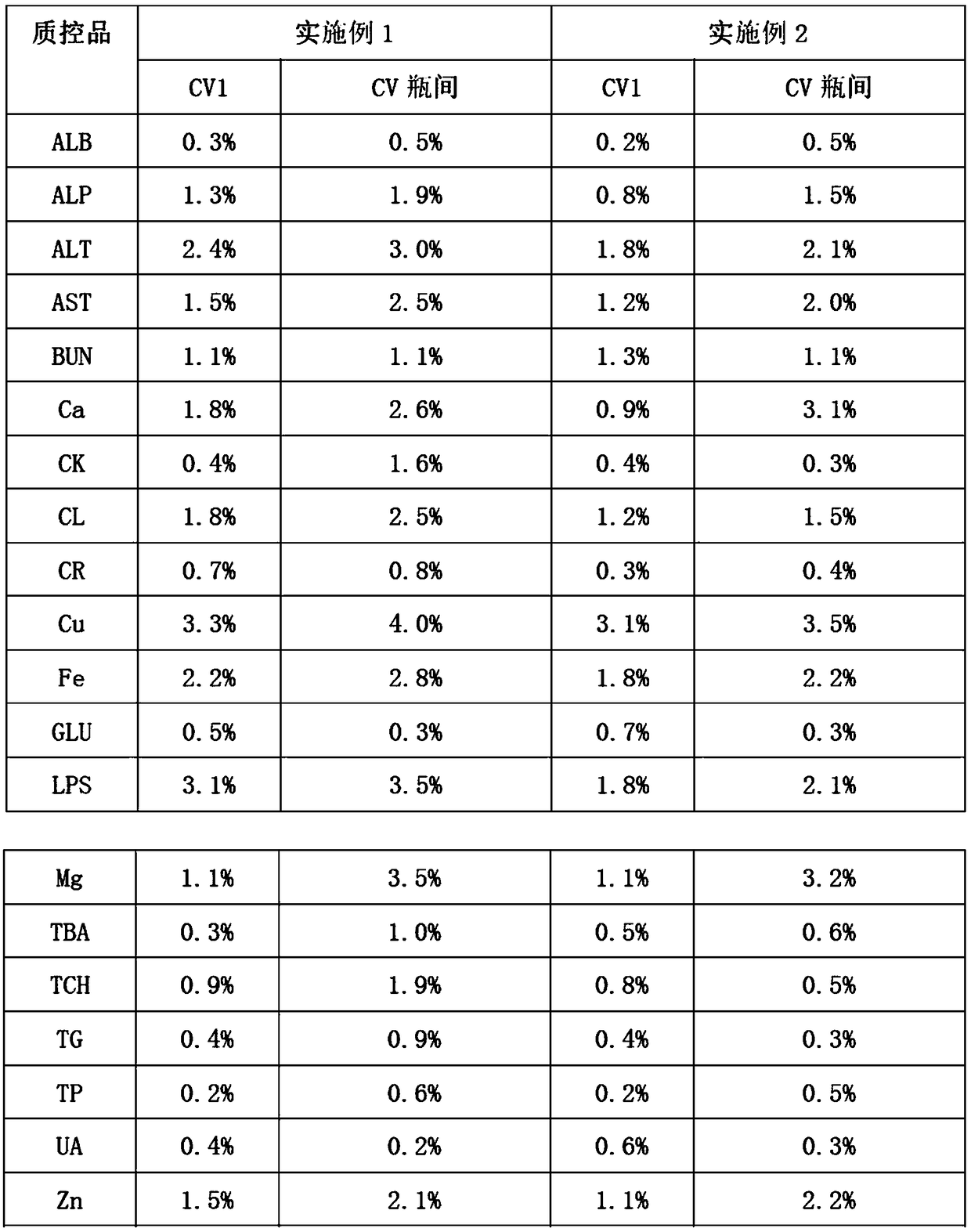

Preparation method of quality control serum for quality control of centrifugal microfluidic chips

ActiveCN108152519ASufficient sourceEasy to getBiological testingFreeze-dryingMonopotassium phosphate

The invention discloses a preparation method of quality control serum for quality control of centrifugal microfluidic chips. The method comprises the following steps: adding 0.6 to 1.0 percent of cholesteryl sodium sulfate into bovine plasma, and adding 0.02 to 0.06 percent of monopotassium phosphate; sequentially adding 0.04 to 0. 08 percent of ammonium ferric sulfate dodecahydrate, 0.5 to 0.9 percent of calcium chloride, 0.2 to 0.6 percent of bitter salt, 0.6 to 1 percent of urea, 9 to 13 percent of sodium chloride, 0.01 to 0.03 percent of zinc vitriol, 0.01 to 0.03 percent of chalcanthite,0.06 to 0.2 percent of glycocholic acid, 2 to 4 percent of glucose, 0.03 to 0.06 percent of creatinine, 0.08 to 0.2 percent of uric acid, and 0.07 to 0.11 percent of triolein into water; uniformly mixing obtained solution; adding glycol, saccharose and triton X-100, and uniformly mixing; sequentially adding albumin bovine serum, sodium azide, alanine aminotransferase, aspartic transaminase, alkaline phosphatase, lipase and creatine kinase, uniformly mixing, and performing freeze drying. The method has the advantages that the source of the raw materials is sufficient, the raw materials are easyto get, possible matrix effect is furthest avoided, and precipitation of the raw materials is prevented.

Owner:NINGBO MEIKANG BAOSHENG BIOMEDICAL ENG

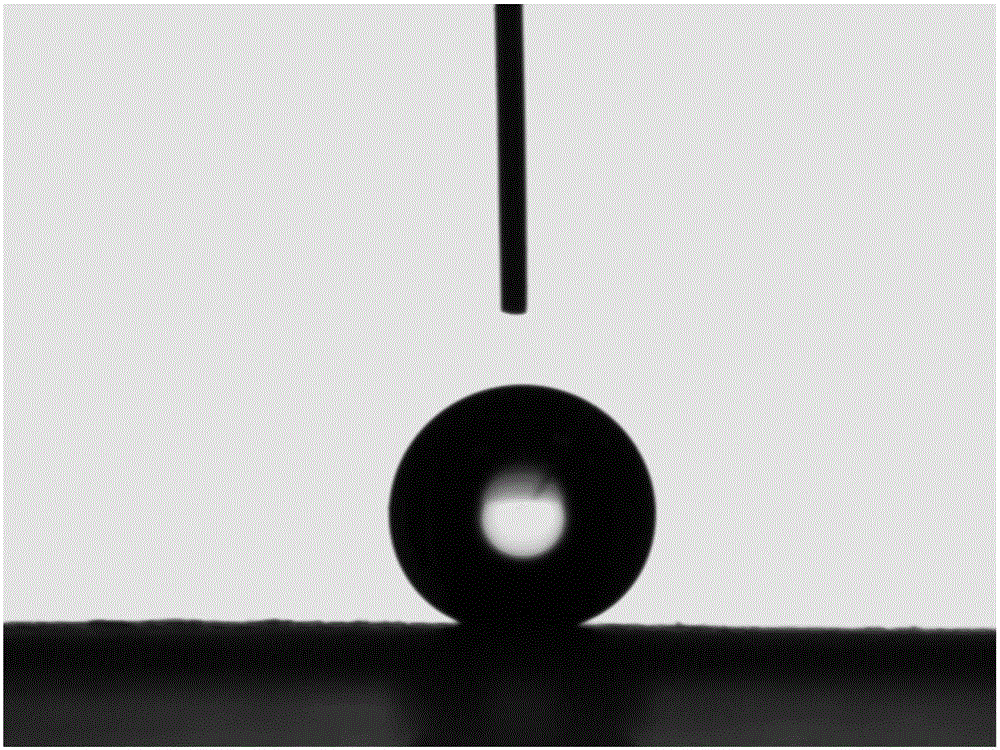

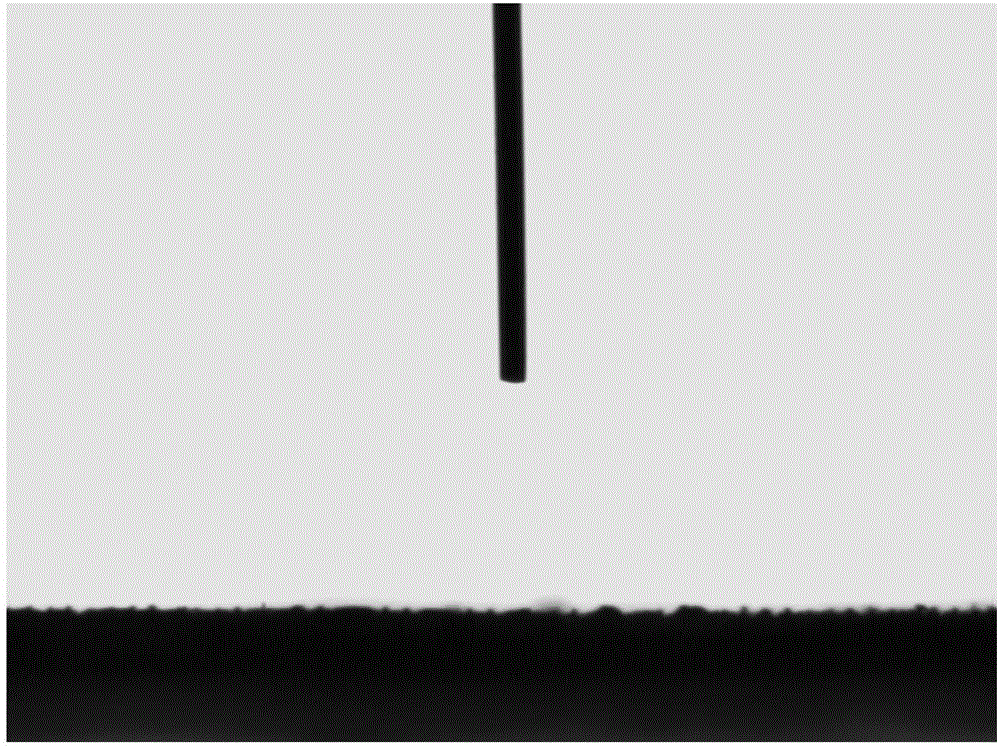

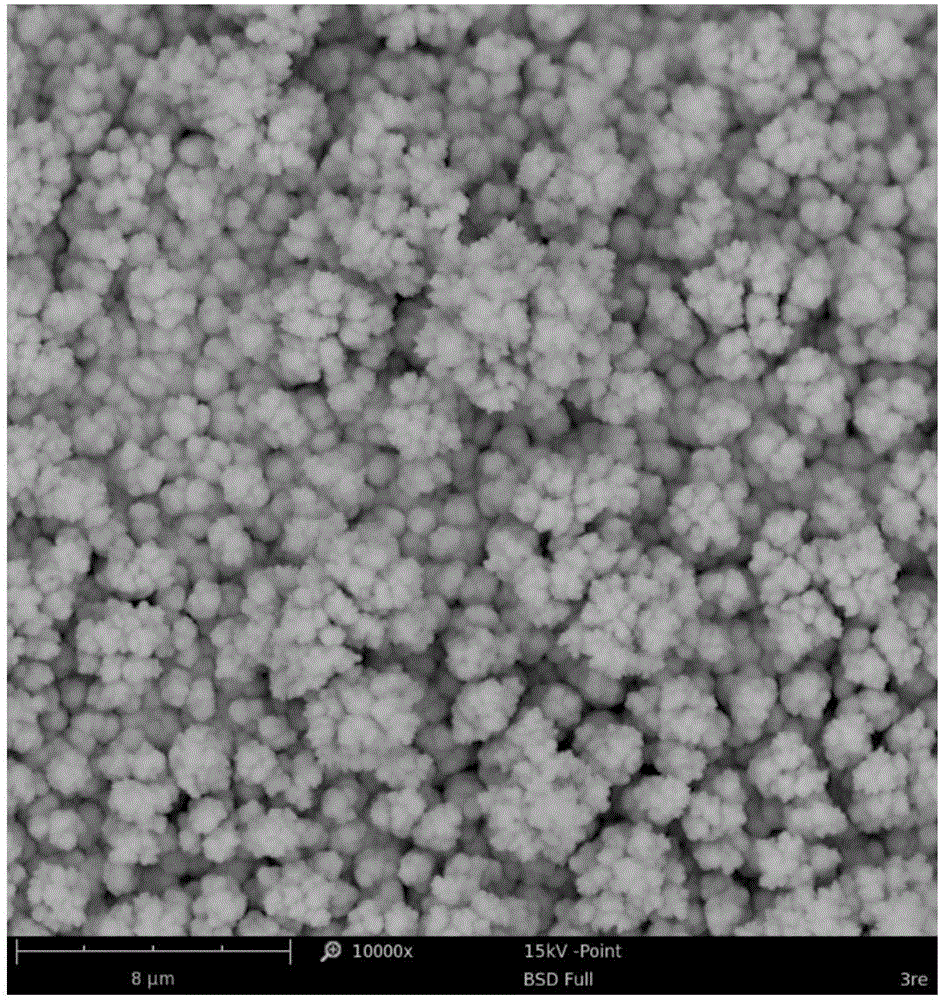

Super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and preparation method thereof

ActiveCN106823469AFast etchThe process is easy to implementNon-miscible liquid separationCopper wireMetallic materials

The invention belongs to the technical field of metal material surface treatment and discloses a super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and a preparation method thereof. The preparation method comprises the steps of cleaning and drying the copper wire meshes, and taking two pieces of copper wire meshes as two electrodes of AC separately; carrying out electrodeposition in a deionized water electroplate liquid containing thioacetamide, ethylenediamine tetraacetic acid disodium and copper sulfate pentahydrate; and cleaning the copper meshes subjected to electrodeposition and then carrying out high-temperature drying at 80-200 DEG C to obtain the super-hydrophobic and super-oleophilic copper wire mesh. The two electrodes of the AC can be quickly etched at the same time, and the super-hydrophobic and super-oleophilic copper wire mesh is suitable for large-area production, special equipment does not need to be used, and the treatment process is easy to implement; and the related solution formula does not contain a toxic fluorine-containing or carbon-containing low surface energy material, is free of harm to the environment and a human body, and has good economical and environmental benefits.

Owner:SOUTH CHINA UNIV OF TECH

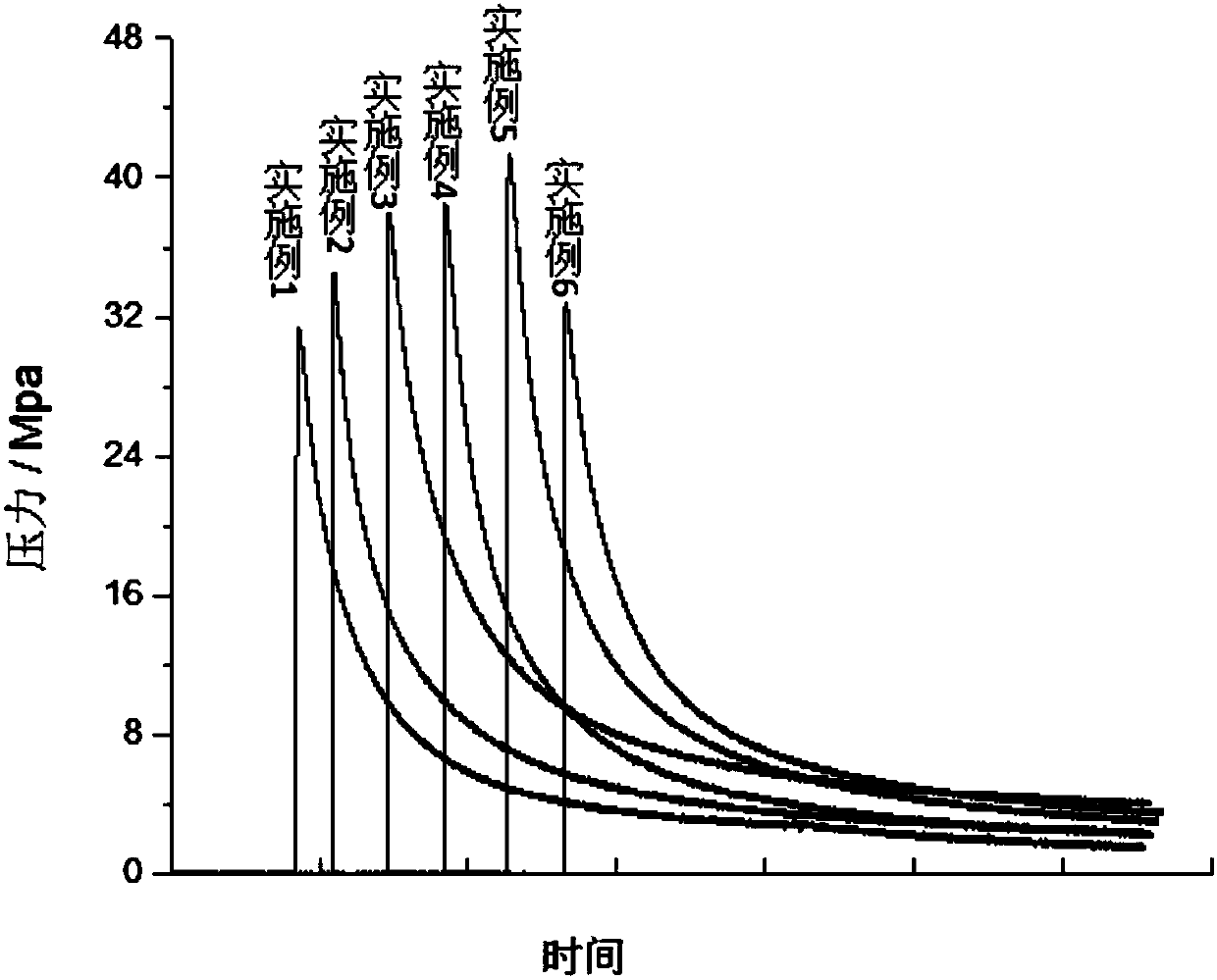

Insensitive primary explosive prepared by using electrostatic spraying process and preparation method thereof

InactiveCN107935799AReduce staticReduced friction sensitivityExplosive working-up apparatusDetonatorNitrocellulose

Owner:NANJING UNIV OF SCI & TECH

Preparation method for antioxidant copper nanopowder

ActiveCN105945302AExperiment operation is simpleLow costMaterial nanotechnologyTransportation and packagingDispersitySolvent

Owner:JINLING INST OF TECH

Fruit and vegetable nutrient solution

InactiveCN108033842AFull of nutritionPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserContinuous croppingPhosphate

The invention discloses a fruit and vegetable nutrient solution. The fruit and vegetable nutrient solution comprises a solution A and a solution B, wherein the solution A mainly consists of the following components: calcium nitrate, potassium nitrate, ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex (EDDHA-Fe), ethylene diamine tetraacetic acid disodium ferric salt (EDTA-Fe); and the solution B mainly consists of the following components: magnesium sulfate heptahydrate, potassium sulfate, potassium dihydrogen phosphate, manganese sulfate tetrahydrate, boric acid, zincsulfate heptahydrate, copper sulphate pentahydrate, and ammonium molybdate. The fruit and vegetable nutrient solution is rich in nutrients, does not contain harmful substances, promotes crop growth,is suitable for hydroponic and substrate culture, and is suitable for large-scale popularization; and the culture solution and matrix of the nutrient solution are easy to renew, and pathogenic bacteria are also easy to remove, so that disease and pest control and soil disinfection are almost not needed, and continuous cropping obstacle can be avoided.

Owner:贵州华以农业科技有限公司

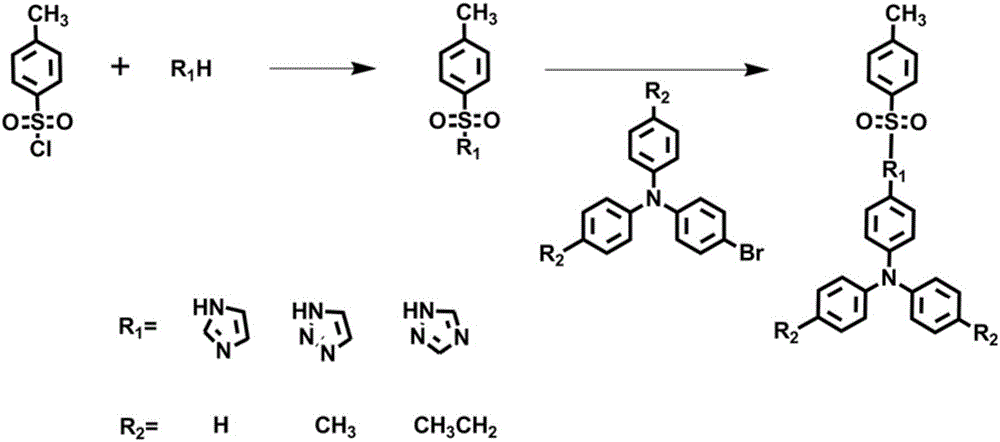

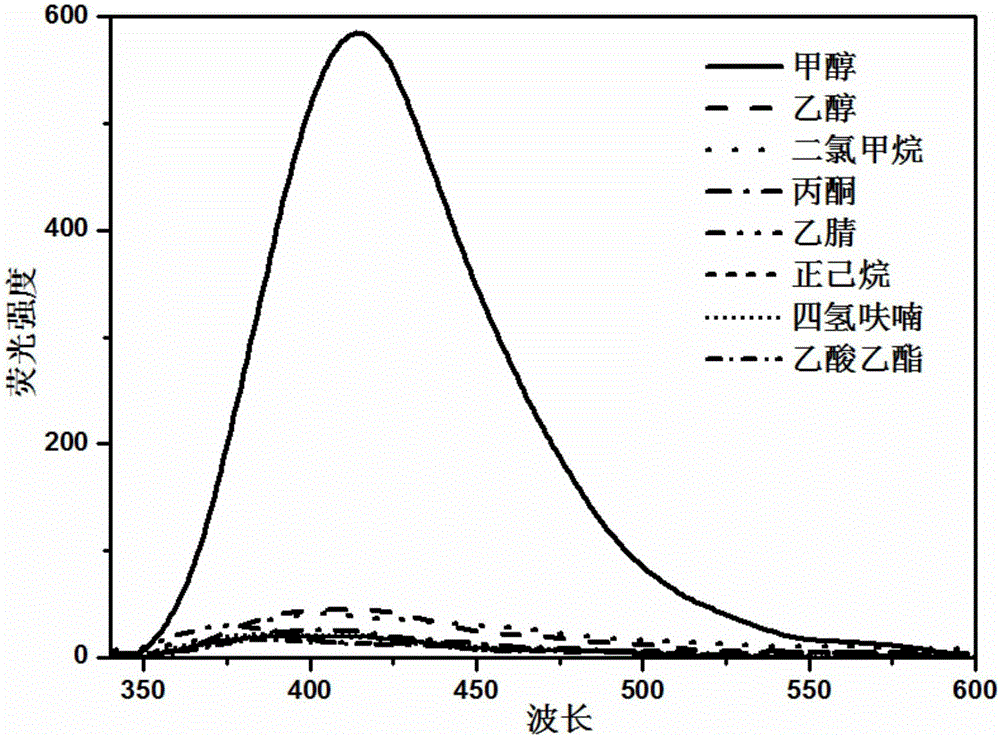

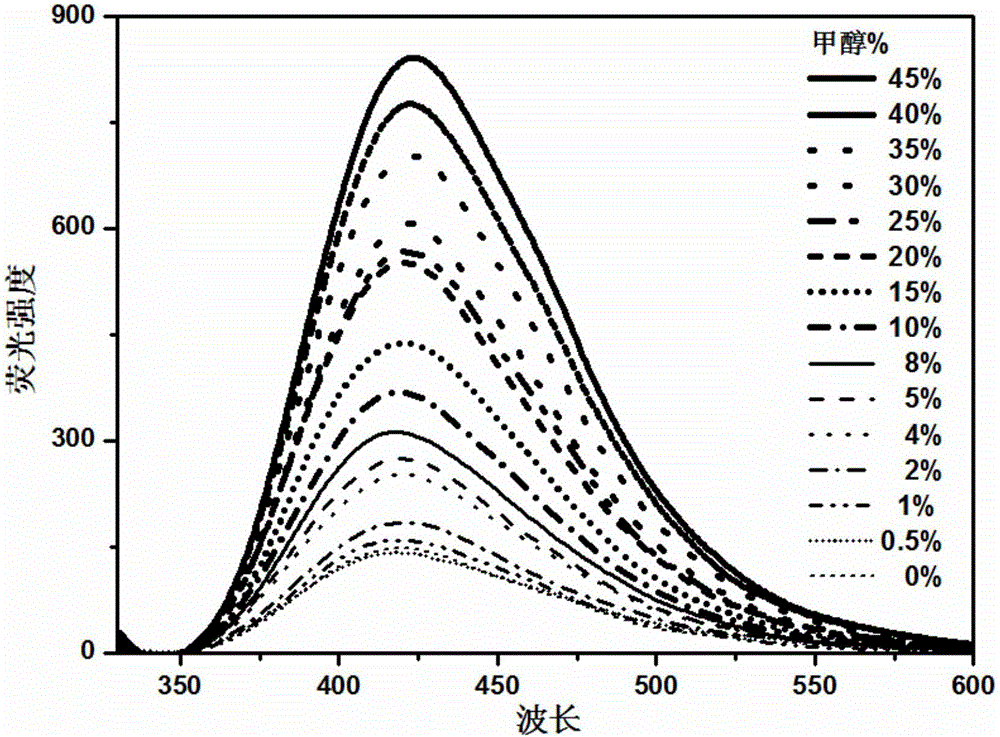

Organic small molecular fluorescent probe for detecting methanol and preparation method of organic small molecular fluorescent probe

InactiveCN105968051AMild conditionsEasy to makeOrganic chemistryFluorescence/phosphorescenceChromatographic separationSodium ascorbate

The invention discloses a preparation method of an organic small molecular fluorescent probe for detecting methanol. The preparation method comprises the following steps: firstly, preparing 1-(p-toluenesulfonyl) imidazole; secondly, preparing the organic small molecular fluorescent probe: adding a proper amount of 4-bromotriphenylamine and the 1-(p-toluenesulfonyl) imidazole into a tetrahydrofuran solution, and then adding a catalyst consisting of copper sulfate pentahydrate and sodium ascorbate into the solution; protecting by nitrogen and stirring for 12 hours, extracting with dichloromethane, drying by using anhydrous magnesium sulfate, and performing rotary evaporation to obtain a crude product; performing column chromatographic separation on the crude product by using ethyl acetate and petroleum ether, wherein the volume ratio of the ethyl acetate to the petroleum ether is 1 to (10 to 20), and separating to obtain a solid, namely the organic small molecular fluorescent probe for detecting the methanol. The fluorescent probe disclosed by the invention has a high fluorescent selective response to the methanol; the fluorescence intensity is remarkably enhanced along with the prolonging of time; the organic small molecular fluorescent probe has the advantages of easiness in preparation, good chemical stability, high sensitivity and the like.

Owner:北京珐默兹医药科技有限公司

Novel metal cooling liquid

InactiveCN104087398AImprove cooling effectFast coolingLubricant compositionO-Phosphoric AcidPolyvinyl alcohol

The invention discloses a novel metal cooling liquid which is prepared from the following raw materials in parts by weight: 13-15 parts of glycerol, 12-14 parts of silicone oil, 8-10 parts of 1, 2-propylene glycol, 12-15 parts of tall oil fatty acid, 5-6 parts of castor oil butyl ester, 6-8 parts of calcium nitrate, 5-6 parts of ammonium sulfate, 7-8 parts of ammonium chloride, 6-10 parts of sodium sulfite, 6-8 parts of potassium sorbate, 3-5 parts of sodium hydrogen carbonate, 4-6 parts of sodium carbonate, 5-8 parts of polyvinyl alcohol resin, 7-9 parts of sodium polyacrylate, 3-5 parts of hydroxyethyl cellulose, 5-8 parts of glycerinum, 3-5 parts of copper sulfate pentahydrate, 3-6 parts of hydrogen peroxide, 8-10 parts of phosphoric acid and 60-80 parts of purified water. The novel metal cooling liquid is high in cooling capacity at different temperatures such as low temperature, medium temperature and high temperature, high in cooling speed and good in compatibility, so that the quality stability of a workpiece is guaranteed.

Owner:梁胜光

A regeneration and recovery method of an electrochemical acidic etching solution used for printed circuit boards

InactiveCN106167915ALow costReduce pollutionPhotography auxillary processesElectrolysis componentsRecovery methodElectrochemistry

The invention discloses a regeneration and recovery method of an electrochemical acidic etching solution used for printed circuit boards, and belongs to the field of electrochemical metal copper recovery. The acidic etching solution is added into an electrolytic tank. The electrolytic tank is divided into a cathode chamber and an anode chamber through an ion separating membrane. A metal copper plate is adopted as a cathode in the cathode chamber. A substrate to be etched is adopted as an anode in the anode chamber. Electrochemical treatment is performed according to following parameters, wherein the etching solution adopted comprises 50-70 g / L of copper (II) sulfate pentahydrate and sulfuric acid having a concentration of 10-11%, the etching reacting temperature is 25-35 DEG C, and an adopted etching current density is 3-10 A / dm<2>. The method can regenerate and recover the acidic etching solution, cam recover the metal copper synchronously, greatly reduces the agent cost of a PCB etching process, effectively shortens a recovery period and increases the production efficiency.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD

Preparation method for electronic grade high-purity copper sulfate pentahydrate

InactiveCN103058258AEfficient removalIncrease concentrationCopper sulfatesHigh concentrationCu2 ions

The invention provides a method for preparing electronic grade high-purity copper sulfate pentahydrate through purifying with industrial grade copper sulfate pentahydrate as a raw material. According to the method, after the industrial grade copper sulfate pentahydrate is prepared to the solution with a certain concentration and a certain pH value, the copper extraction is implemented for the solution by adopting extractant M5640; then back extraction is executed by adopting back extractant at a higher temperature; and the direct cooling crystallization, the centrifugation and the drying are implemented to obtain the product. The preparation method adopts the extractant M5640 to extract the copper, so that impurities, such as iron, nickel, lead, zinc and the like in industrial copper sulfate raw materials can be removed more efficiently, and the back extraction temperature is heated up; copper ions in the obtained copper sulfate solution have high concentration; the direct cooling crystallization can be implemented after the oil removing purification, so that the concentration crystallization technique in the conventional extraction method can be avoided; compared with the traditional technique for removing impurities and purifying copper sulfate through hydrolytic precipitation method and the conventional extraction method, the preparation method has the characteristics of simple technique, high product purity, low energy consumption and low production cost; and the prepared copper sulfate pentahydrate is suitable for IC (Integrated Circuit) products.

Owner:GUANGDONG GUANGHUA SCI TECH

Nutrient solution in soilless culture of camellia and preparation method therefor

The present invention discloses a nutrient solution in soilless culture of camellias and a preparation method therefor. The nutrient solution comprises the following components by concentrations: 3500 mg / l of potassium dihydrogen phosphate, 2500 mg / l of potassium nitrate, 300 mg / l of magnesium sulfate heptahydrate, 200 mg / l of calcium chloride dihydrate, 150 mg / l of ammonium sulfate, 4 mg / l of a boric acid, 12 mg / l of manganese sulfate tetrahydrate, 3 mg / l of zinc sulfate heptahydrate, 0.03 mg / l of copper sulphate pentahydrate, 30 mg / l of ferrous sulfate heptahydrate, 120 mg / l of inositol, 12 mg / l of vitamin B1, 3 mg / l of glycine and 60 g / l of sucrose. During the preparation of the nutrient solution, a solution is prepared by dissolving calcium chloride dihydrate in a small amount of water, a mixed solution is prepared by dissolving other components in another small amount of water, then the two solutions are mixed together, and the pH value of the prepared nutrient solution is adjusted to 5.5 by a dilute hydrochloric acid.

Owner:SHENZHEN WENKE GARDENING IND

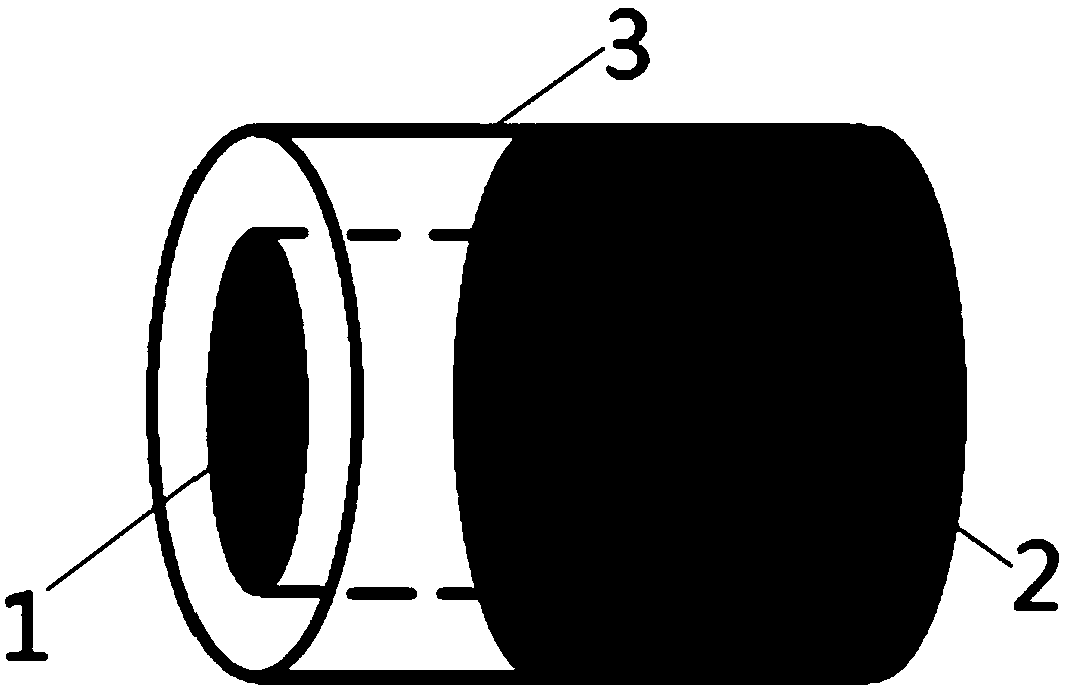

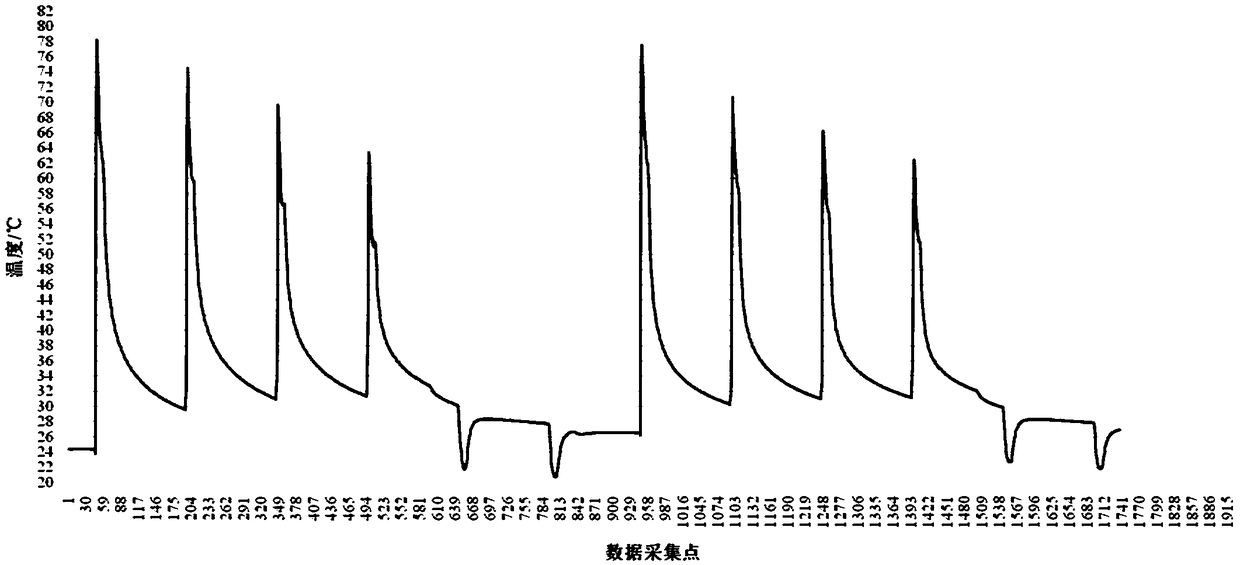

Cooling mouth stick, heat-not-burn cigarette and application of cooling mouth stick and heat-not-burn cigarette

InactiveCN109463799AEasy phase changeGood effectTobacco smoke filtersTobacco devicesSodium phosphatesEngineering

The invention relates to a cooling mouth stick, a heat-not-burn cigarette and application of the cooling mouth stick and heat-not-burn cigarette. The cooling mouth stick comprises a cooling section, wherein the cooling section comprises carriers of which the surfaces are provided with a cooling material, and the carriers are distributed in the cooling section to form multiple channels penetratingthrough the cooling section; the cooling material is a crystallization water compound, and the crystallization water compound is at least one of ferrous sulfate, aluminum potassium sulfate dodecahydrate, sodium phosphate dibasic dodecahydrate, magnesium sulfate heptahydrate, copper sulfate pentahydrate and sodium sulfate decahydrate; preferably, the carriers are paper. The cooling mouth stick, theheat-not-burn cigarette and the application of the cooling mouth stick and heat-not-burn cigarette have the advantages that the temperature of a smoke inlet is effectively reduced, and the reductionrange can reach above 10 DEG C; the characteristic of crystalline hydrate absorbing heat to release crystallization water is utilized to effectively reduce the smoke temperature of first three mouthsof the heat-not-burn cigarette.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Nutrient solution capable of improving low-temperature resistance of tomatoes as well as preparation method and application thereof

ActiveCN109678603AImprove low temperature resistanceIncrease productionMagnesium fertilisersAlkali orthophosphate fertiliserManganeseMonopotassium phosphate

The invention belongs to the technical field of plant nutrient liquid and particularly discloses nutrient solution capable of improving low-temperature resistance of tomatoes as well as a preparationmethod and application thereof. The nutrient liquid comprises urea, potassium nitrate, nitric acid tetrahydrate, monopotassium phosphate, magnesium sulfate heptahydrate, ammonium molybdate tetrahydrate, chelated iron, boric acid, manganese sulfate monohydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, 5-aminolevulinic acid and the like. The nutrient liquid is applied to blooming andfruiting periods of the tomatoes and can completely meet the nutrients needed in the growing process of the tomatoes; and the formula and the use amount of the nutrient liquid are adjusted according to different nutrient demanded quantity and demanded varieties in different growing periods of the tomatoes, so that the low-temperature resistance of the tomatoes can be improved significantly, the content of effective nutritional substances of the tomatoes is increased and the quality of the tomatoes is improved.

Owner:NORTHWEST A & F UNIV

Toothpaste for helping digestion and promoting appetite and preparation method thereof

InactiveCN104958208ARelieves symptoms of indigestionIncrease appetiteCosmetic preparationsToilet preparationsBiotechnologySODIUM METAPHOSPHATE

The invention relates to toothpaste for helping digestion and promoting appetite and a preparation method thereof. The toothpaste comprises, by mass, 3-9 parts of chalk, 1-5 parts of xanthan gum, 0.7-3 parts of silica aerogel, 0.8-3.5 parts of sodium metaphosphate, 0.15-0.45 part of sodium monofluorophosphate, 0.1-0.6 part of alkyldimethyl benzylammonium chloride, 0.05-0.25 part of sodium chloride, 0.03-0.08 part of stannous pyrophosphate, 0.002-0.006 part of copper sulfate pentahydrate, 0.1-0.3 part of titanium dioxide, 0.02-0.06 part of sodium dihydrogen phosphate, 0.2-0.7 part of vitamin C, 0.08-0.15 part of essence, 3.2-8.5 parts of water, 1-5 parts of malt, 1-5 parts of radish seeds and 1-5 parts of green tangerine peel. The toothpaste has the functions of helping digestion and promoting appetite.

Owner:JIANGSU QILIKANG SKIN PHARMA

Biological soil restoration fertilizer

InactiveCN105367325AImprove biological activityGood water permeabilityWaste based fuelFertilizer mixturesEcological environmentSlag

The invention discloses a biological soil restoration fertilizer. The fertilizer is prepared from, by weight, 32-36 parts of biogas slurry, 4-5 parts of saccharomyces cerevisiae, 6-9 parts o brown sugar, 3-4 parts of calcium powder, 1-2 parts of copper sulphate pentahydrate, 26-30 parts of flax fiber bundles, 15-17 parts of siderite slag, 15-17 parts of limonite slag, 68-70 parts of orange peels, 3-6 parts of an EM compound microbial agent and a defined amount of water. By means of the biological soil restoration fertilizer, biological activity of soil can be effectively improved, growth and expanding of plant roots are facilitated, water permeability and air permeability of the soil are improved, the soil is prevented from being eroded by bacteria and pests, healthy growth of plants is promoted, meanwhile, heavy metal can be subjected to a precipitation reaction, a chelation reaction and other reactions in the soil, bio-availability of the heavy metal is lowered, the absorbing capacity of the crops for the heavy metal is reduced, quality of agricultural products is improved, and the ecological environment of the soil is restored.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

Colloidal granular fertilizer and preparation method thereof

InactiveCN102850123ADifficult to breedReduce consumptionFertiliser formsFertilizer mixturesShellacLiquid content

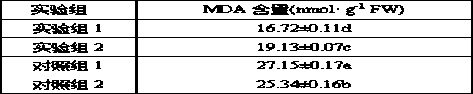

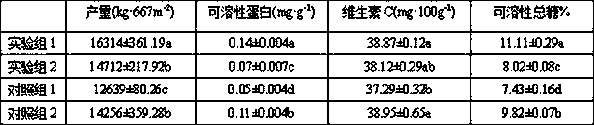

The invention discloses a colloidal granular fertilizer and a preparation method thereof. The preparation method comprises the following steps: mixing a water soluble fertilizer and a colloidal liquid to form a fertilizer aqueous solution, wherein the water soluble fertilizer comprises at least one selected from a group comprising KH2PO4, MgSO4.7H2O, MnSO4.4H2O, H3BO3, Na2B4O7.10H2O, CuSO4.5HO2, ZnSO4.7H2O, (NH4)6Mo7O24.4H2O, CO(NH2)2, Fe-EDTA and KNO3, the colloidal liquid comprises at least one selected from a group comprising agar, a xanthan gum, shellac, a cyanopsis tetrag onoloba gum, a natto gum, a pectin, a synthetic aqueous glue and poly (lactic-co-glycolic acid), and the colloidal liquid content in the fertilizer aqueous solution is 1.5-15 wt%; and adding the fertilizer aqueous solution to water with a temperature of 0-4 DEG C, such that the fertilizer aqueous solution is subjected to solidification molding.

Owner:CPT TECH GRP +1

Preparation method for self-repairing lubricating grease by recovering nano copper powder from waste circuit boards

InactiveCN110029009AGood dispersionExperiment operation is simpleProcess efficiency improvementLubricant compositionDispersityDensity difference

The invention relates to a preparation method for self-repairing lubricating grease by recovering nano copper powder from waste circuit boards. The method comprises the following steps: crushing wastecircuit boards containing copper, and sorting the crushed raw material by using a hydraulic shaking table; separating metal-enriched powder through density difference; then ionizing metal by using aleaching agent, extracting copper sulfate pentahydrate by using extraction and back extraction, further extracting and separating the nano-metal copper powder by using a liquid phase reduction method,and then conducting saponification reaction to prepare the lubricating grease. The additional value of the recovered copper powder is improved by applying the nano-copper powder to the lubricating grease to realize a self-repairing function. The nano-copper powder prepared by the method is good in dispersity, can be used in lubricating grease, operation is simple and the cost is low.

Owner:JINLING INST OF TECH

Soilless culture composite fertilizer for potted rosa chinensis minima

InactiveCN103319230AEasy to viewReduced incidence of powdery mildewFertilizer mixturesEthylenediamineCalcium nitrate tetrahydrate

The invention discloses a soilless culture composite fertilizer for potted rosa chinensis minima. The soilless culture composite fertilizer comprises the following four components: (1) component A which comprises three compounds, i.e., calcium nitrate terahydrate, ammonium nitrate and disodium iron ethylenediaminetetraacetate; (2) component B which comprises three compounds, i.e., potassium nitrate, potassium dihydrogen phosphate and magnesium sulfate heptahydrate; (3) component C which comprises one compound, i.e., potassium metasilicate; and (4) component D which comprises five compounds, i.e., manganese sulfate terahydrate, zinc sulphate heptahydrate, boric acid, copper sulphate pentahydrate and sodium molybdate dihydrate. When the soilless culture composite fertilizer provided by the invention is used for soilless culture of potted rosa chinensis minima, growth and development of rosa chinensis minima are normal, the symptom of nutritional deficiency or poisoning of nutrient elements does not occur, the potted rosa chinensis minima is plump and balanced and has a high ornamental value, the incidence rate of powdery mildew of the potted rosa chinensis minima is decreased by 22 to 37% compared with that of potted rosa chinensis minima cultivated with soil, and the potted rosa chinensis minima is clean and sanitary and is suitable for being enjoyed in a house. The composite fertilizer is easy to absorb and use, can mitigate the harm of powdery mildew, substantially meets demands of growth and development of rosa chinensis minima and has a practical application value in production practice of soilless culture of the potted rosa chinensis minima.

Owner:JIANGSU ACAD OF FORESTRY

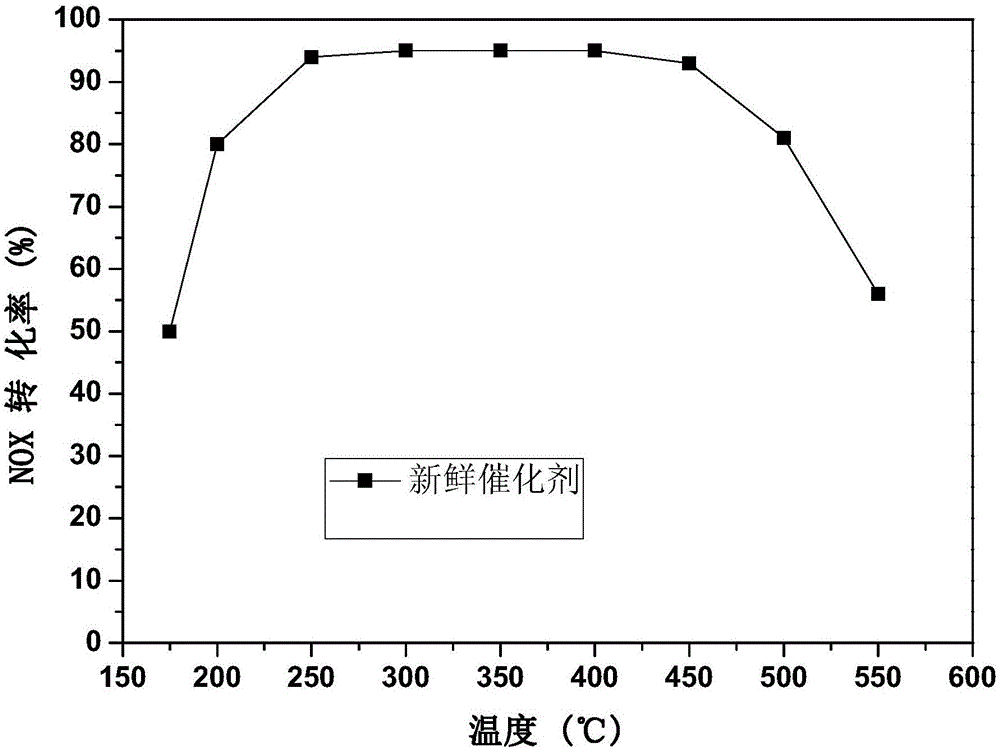

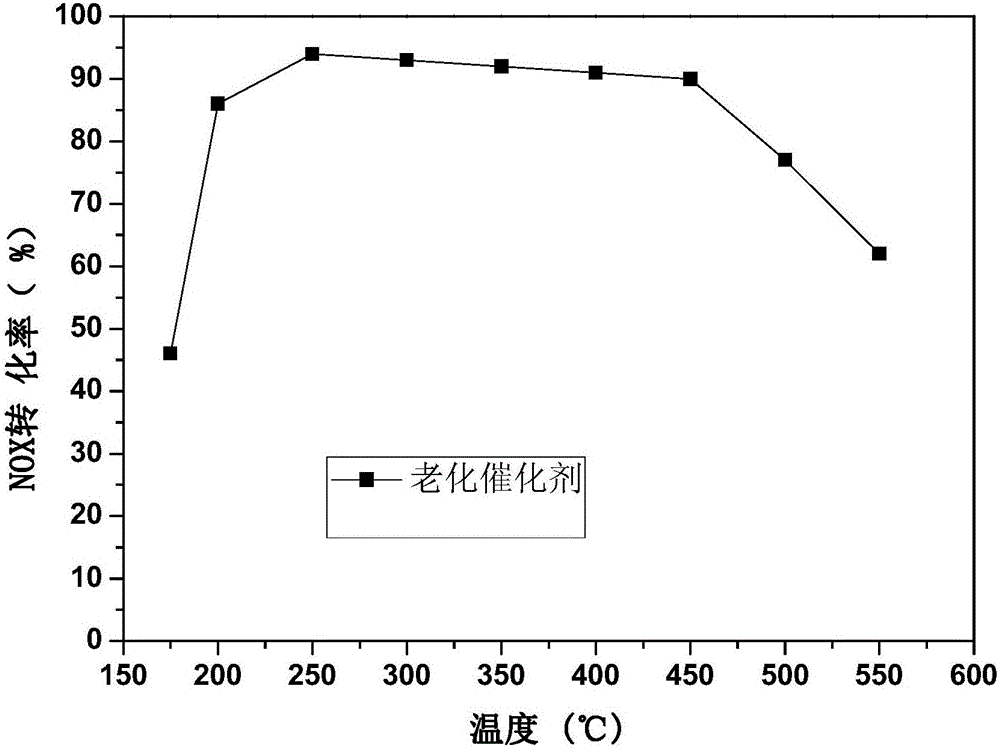

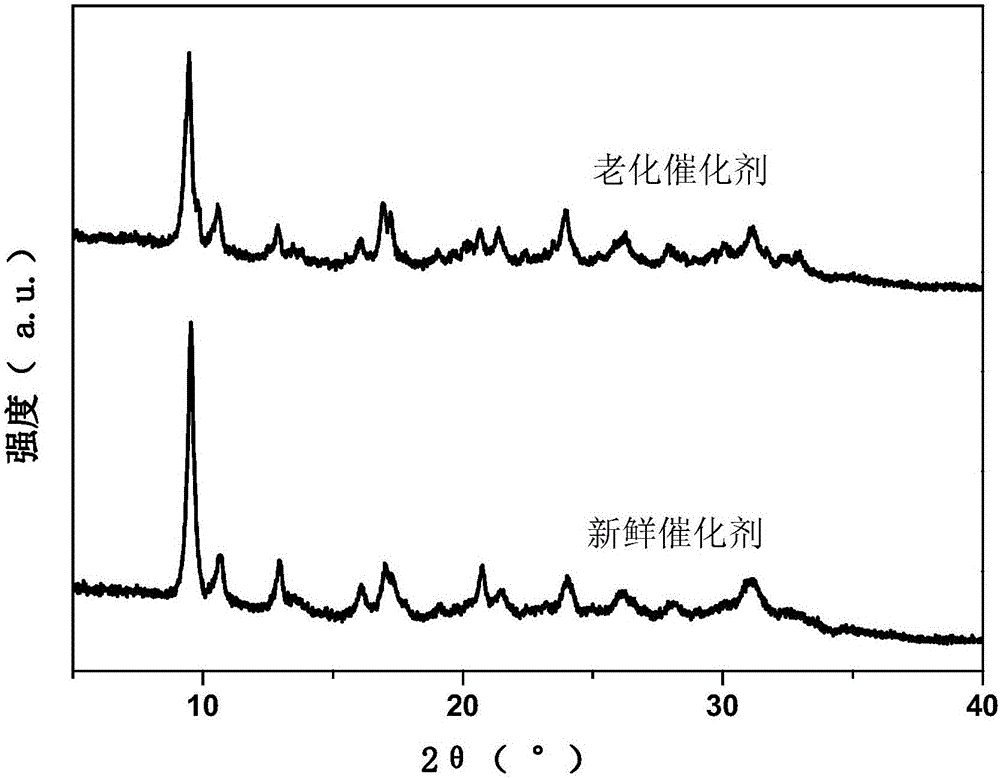

Preparing method for Cu-SAPO-18 molecular sieve catalyst of high hydrothermal stability

InactiveCN106315617AHigh activityHigh hydrothermal stabilityMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sievePhosphate

The invention provides a preparing method for Cu-SAPO-18 molecular sieve catalyst of high hydrothermal stability. The invention relates to the field of treatment technology of exhaust gas of diesel engine. The sources of aluminum, phosphorus, silicon, and template for the in-situ synthesis of Cu-SAPO-18 molecular sieve catalyst are respectively Al2O3, phosphate, silica sol, trien and DMDMP, the source of metal is copper sulfate pentahydrate; by weight, it comprises 49 parts of Al2O3, 85 parts of phosphate, 27 parts of 40 wt % silica sol, 16.4 parts of trien, 12.6 parts of DMDMP and 10-25 parts of copper sulfate pentahydrate. Compared with the prior art, the Cu-SAPO-18 molecular sieve catalyst produced by the method has such advantages as high activity and high hydrothermal stability; new catalyst can have a conversion efficiency of more than 90% at the temperature range of 230-465oC; aged catalyst can maintain a conversion efficiency of more than 86% at the temperature range of 230-465oC after being placed in an environment of 750oC for 13h; the highest conversion efficiency of traditional V-W-TiO2 based catalyst is less than 60% after aging.

Owner:HEFEI SHENZHOU CATALSIS PURIFIER CO LTD

Cleaning agent for damping rubber pad

InactiveCN109706003AEasy to cleanImprove cleanlinessInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphatePotassium

The invention discloses a cleaning agent for a damping rubber pad. The cleaning agent is composed of acetic acid, polydimethylsiloxane, potassium silicate, copper sulfate pentahydrate, tetrapotassiumpyrophosphate, phosphate, a surfactant, ethanol, citric acid, butyl acetate and water. A raw material composition comprises the following components in parts by weight: 15-25 parts of acetic acid, 6-12 parts of polydimethylsiloxane, 8-10 parts of potassium silicate, 5-10 parts of copper sulfate pentahydrate, 6-10 parts of potassium pyrophosphate, 15-20 parts of phosphate, 8-12 parts of a surfactant, 6-9 parts of ethanol, 10-15 parts of citric acid, 6-8 parts of butyl acetate and 45-65 parts of water. The cleaning agent prepared by the invention can be used to effectively clean out oil stains and dust on the damping pad, and neatness of the damping pad is improved, so that competitiveness of an enterprise is improved. In addition, hands and rubber products are not damaged, the smell is fresh and non-pungent, environment friendliness is achieved, use is safe, and the cleaning effect is good.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

Low-foam cleaning agent for cleaning wool carpet

InactiveCN103060108AGood removal effectDoes not damage the materialOrganic detergent compounding agentsSurface-active detergent compositionsFiberCleansing Agents

The invention discloses a low-foam cleaning agent for cleaning a wool carpet. The low-foam cleaning agent comprises the following raw materials: Span-65, Tween-85, sodium tripolyphosphate, 2-butoxyethanol, benzalkonium chloride, inositol hexaphosphate, oxalic acid, polyether, polydimethylsiloxane, copper sulfate pentahydrate and water. Compared with the prior art, the low-foam cleaning agent disclosed by the invention has excellent pollution removing ability and can basically avoid the production of foam during the cleaning process, and the water consumption for rinsing is obviously lower than that of an existing product. Furthermore, harmful bacteria in gaps between fibers of the carpet can be effectively killed, the material of the wool carpet is not damaged, and the original color, luster and hand feeling can be restored after cleaning.

Owner:如皋市五山漂染有限责任公司

Hydroponic plant nutrient solution and preparation method thereof

InactiveCN104030770AWide variety of sourcesLow priceFertilizer mixturesSodium iodideNutrient solution

The invention provides a hydroponic plant nutrient solution and a preparation method thereof. The nutrient solution comprises liquids A and B in a volume ratio of 1:1, wherein the liquid A comprises plant ash, animal manure and water and the liquid B comprises calcium nitrate, boric acid, manganese sulfate tetrahydrate, zinc vitriol, copper sulfate pentahydrate, magnesium sulfate, sodium iodide, ammonium dihydrogen phosphate and water. The preparation method comprises the following steps: weighing plant ash, animal manure and water, putting the plant ash, animal manure and water in an airtight container, uniformly stirring, standing for over 7 days and filtering; weighing calcium nitrate, boric acid, manganese sulfate tetrahydrate, zinc vitriol, copper sulfate pentahydrate, magnesium sulfate, sodium iodide, ammonium dihydrogen phosphate and water, and uniformly stirring; and mixing the liquids A and B and water in the volume ratio, and uniformly stirring and standing to obtain the nutrient solution. The liquid A is prepared from easily available materials and is low in price; the hydroponic plant nutrient solution contains more nutritional elements, not only has various trace elements, but also has organic nutrients beneficial to be absorbed by plants. The preparation method of the hydroponic plant nutrient solution is simple and can be put into industrial production easily.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

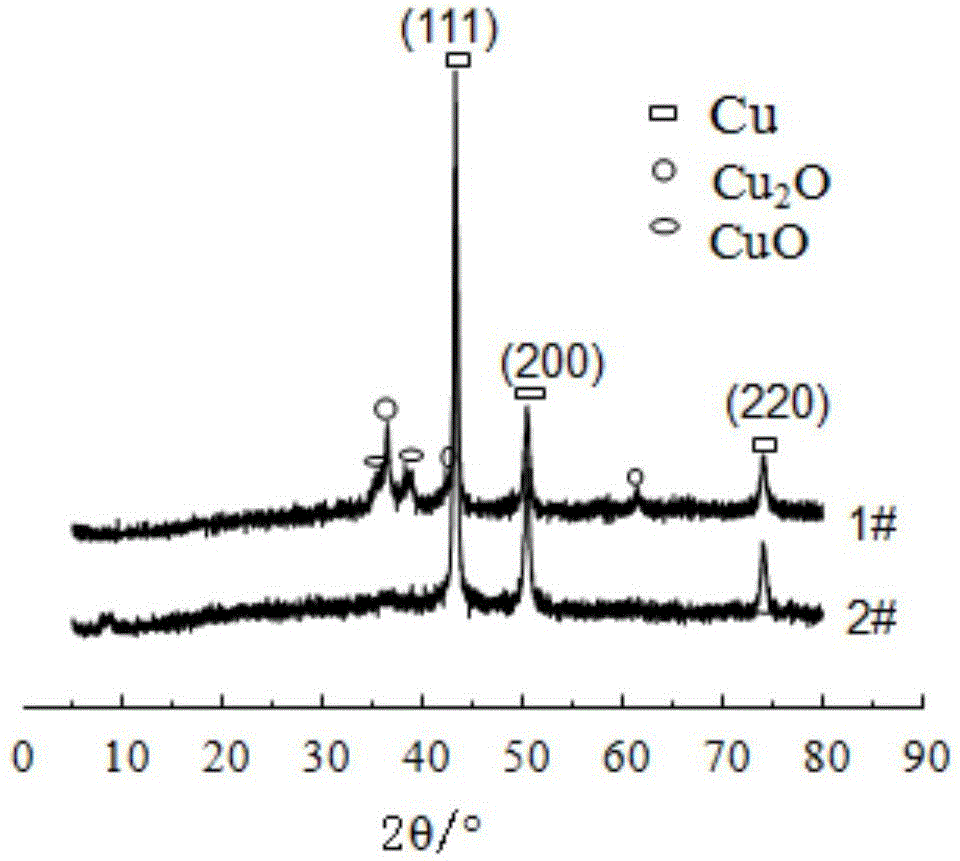

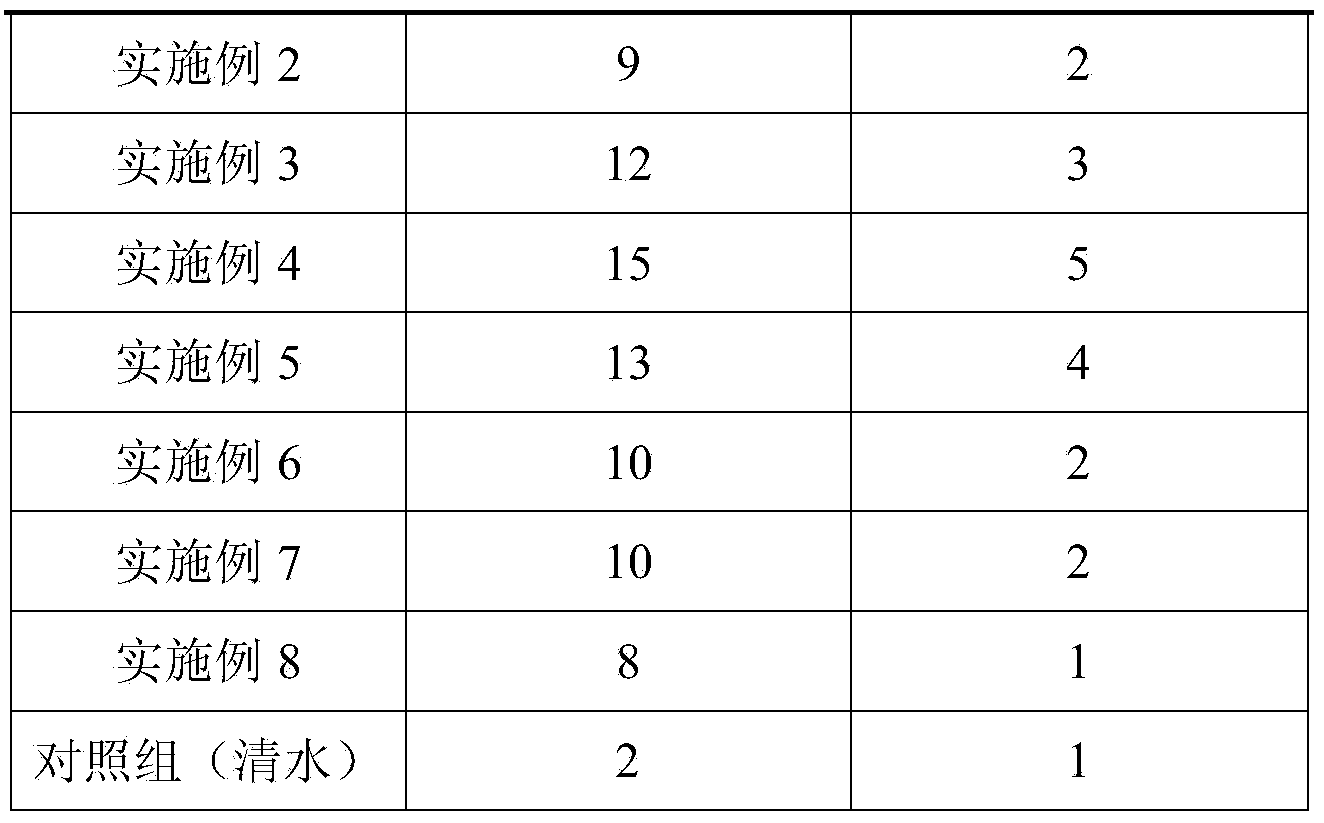

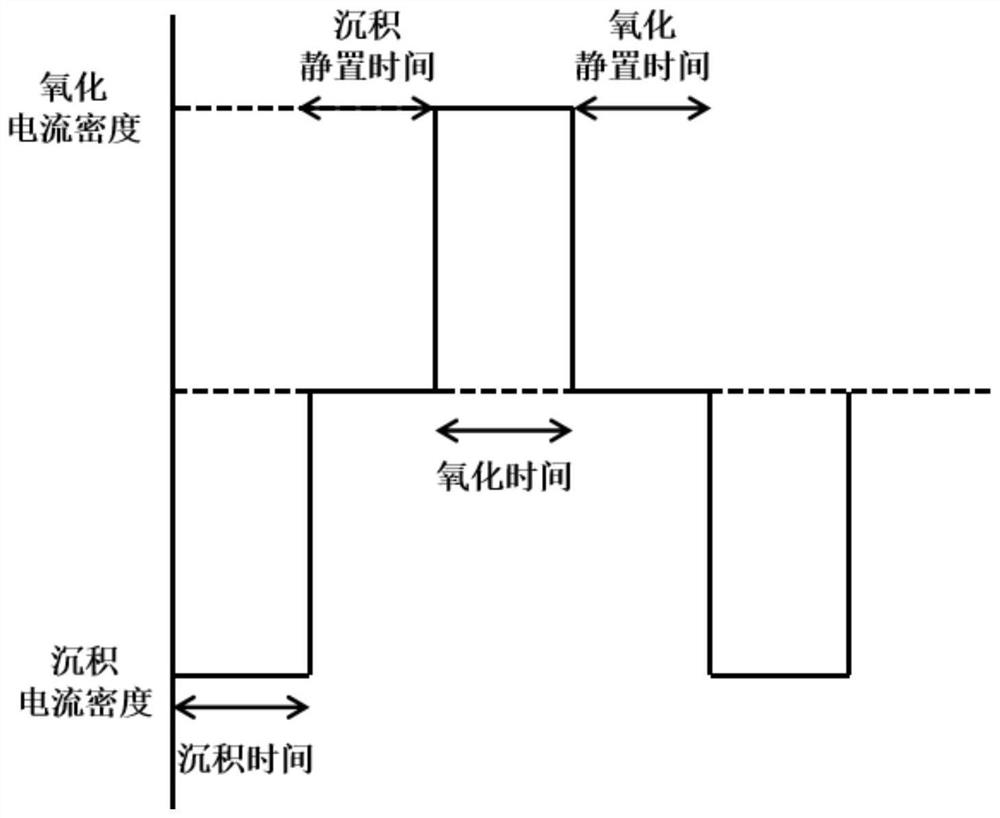

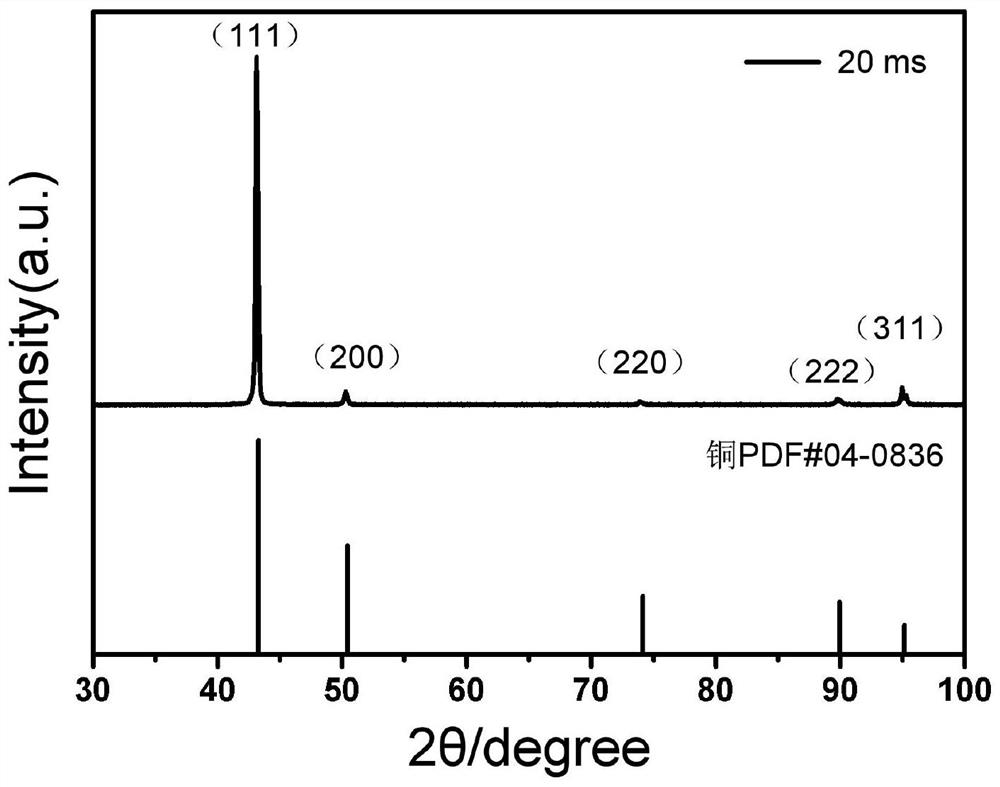

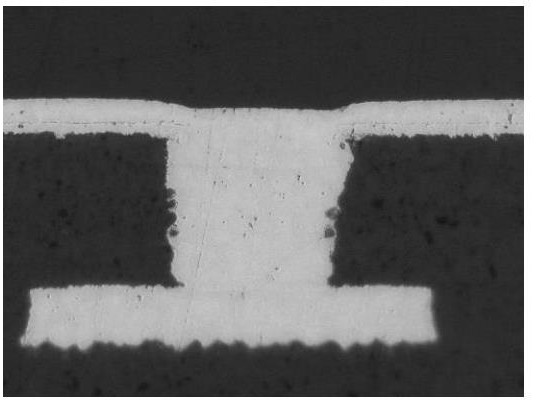

Room-temperature electro-deposition preparation method of copper foil with high crystal face preferred orientation

InactiveCN113802155ASimple recipeSimple methodCellsElectroforming processesElectrolytic agentCopper foil

The invention discloses a room-temperature electro-deposition preparation method of a copper foil with high crystal face preferred orientation. The method comprises the following steps of (1) dissolving copper sulfate pentahydrate with deionized water, and adding a small amount of concentrated sulfuric acid to prepare an electrolyte with the pH value of 0.9-1.1 and the copper sulfate content of 240-260 g / L; (2) applying pulse current for electro-deposition by serving a copper sheet as an anode and a titanium sheet as a cathode, wherein the electro-deposition parameter ranges are as follows: the deposition current density is 0.5 A / cm<2>, the deposition time is 50 ms, the deposition standing time is 0-500 ms, the oxidation current density is 0.05 A / cm<2>, the oxidation time is 20 ms, and the oxidation standing time is 20 ms; and (3) taking out the cathode, and alternately cleaning with dilute sulphuric acid and deionized water to obtain the copper foil with high crystal face preferred orientation. The method is rapid and easy to amplify, no additive is contained, and the prepared electrolytic copper foil has high copper (111) and copper (220) crystal face preferred orientation and has excellent electronic conductivity.

Owner:NANKAI UNIV

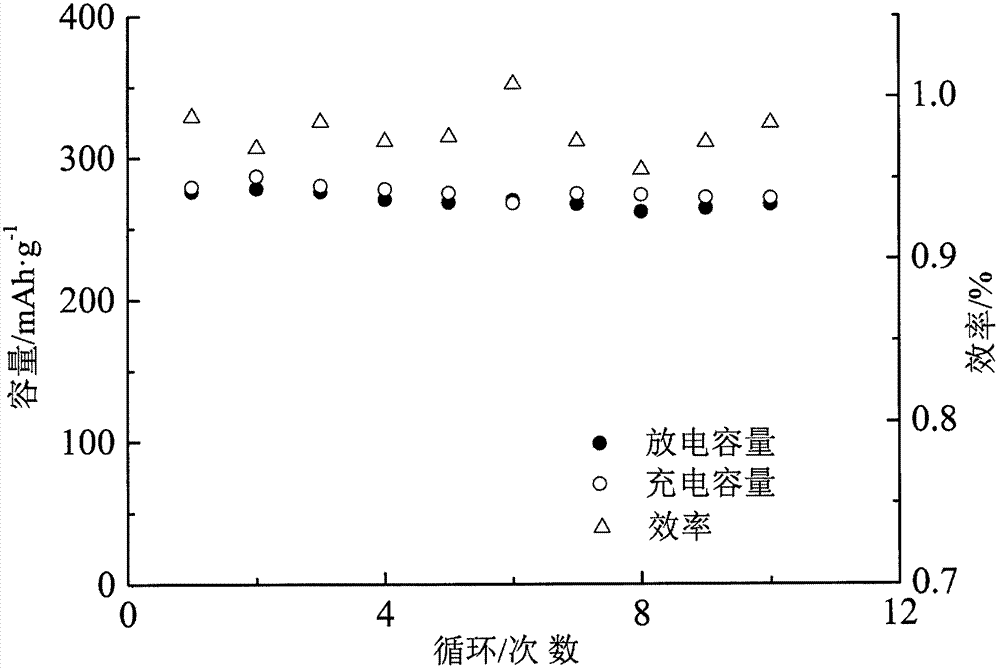

Continuous conductive liquid phase synthesized C/Cu/CuF2 composite copper fluoride lithium ion battery positive electrode material and preparation method thereof

InactiveCN106972157AImprove electronic conductivityIncrease capacityCell electrodesSecondary cellsCarbon filmDouble salt

The invention relates to a continuous conductive liquid phase synthesized C / Cu / CuF2 composite copper fluoride lithium ion battery positive electrode material and a preparation method thereof. According to the method, side-reaction products such as various compound salts of copper fluoride in liquid phase reaction are prevented by designing a mixing mode of raw materials of copper sulfate pentahydrate and ammonium fluoride and an addition mode and addition rate of water; meanwhile, a high-conductivity continuous carbon film with a hole and gap structure is formed by the drying process under a low-temperature and high-vacuum condition and the subsequent thermal treatment process, and the electron conductivity of a composite material is substantially improved; and moreover, a certain amount of copper is reduced on surface of copper fluoride particles in an in-situ way, a homogeneous crystal core is provided for an electrode material during discharging, dynamics blocking formed by a new phase is reduced, and the capacity of the material, the cycle capacity stability and a potential of a discharge platform are improved.

Owner:宁波吉电鑫新材料科技有限公司

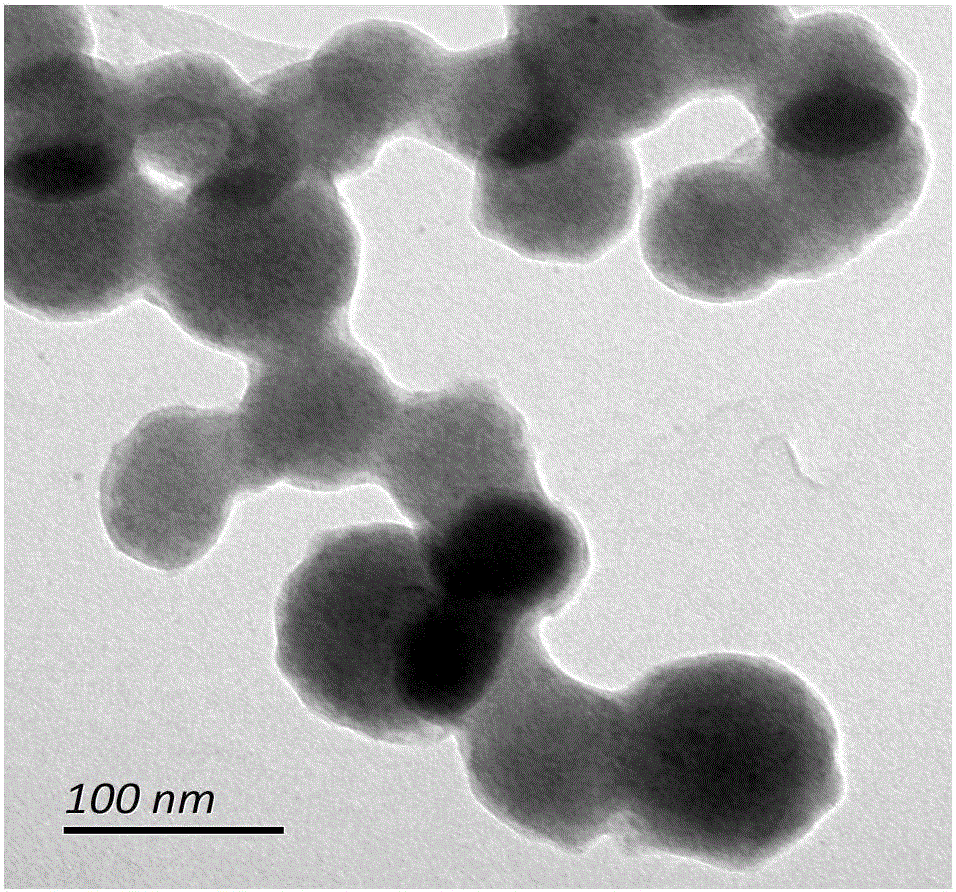

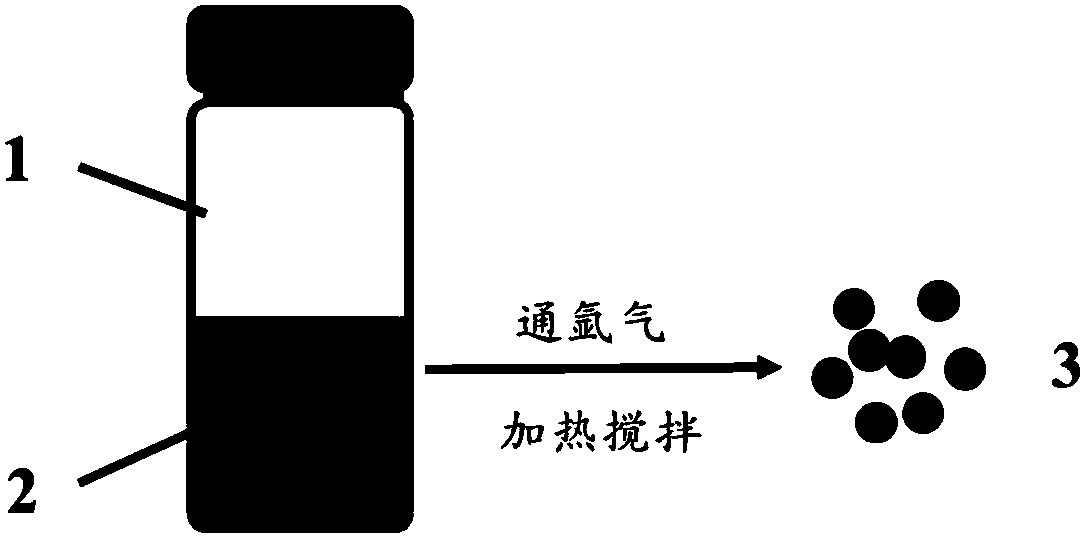

Method for preparing copper nanoparticles from modified polysaccharide

ActiveCN108372311AGood biocompatibilityEffective protectionMaterial nanotechnologyTransportation and packagingOxidation resistantCopper sulfate

The invention belongs to a preparation method of metal copper nanoparticles, and in particular relates to a method for preparing copper nanoparticles with excellent oxidation resistance by using a modified natural polysaccharide as a reducing agent and an amino-containing polymer as a protective agent in a liquid phase. The method comprises the steps that an aldehyde group is introduced into a starch chain framework by oxidation of sodium periodate, and then the starch is dissolved in a sodium hydroxide-urea solution to obtain a dialdehyde starch solution; the dialdehyde starch solution, copper sulfate pentahydrate and polyethyleneimine are sequentially added into a vessel and stirred, and after introducing argon gas for reaction for a certain period of time, the copper nanoparticles are obtained. The method provided by the invention has the advantages of simple operation, low cost, no need of high temperature condition, no need of any toxic reagents, energy saving and environmental protection. Also, the prepared nanoparticles can be stored in the form of dry powder under ambient conditions for at least three months.

Owner:UNIV OF SCI & TECH BEIJING

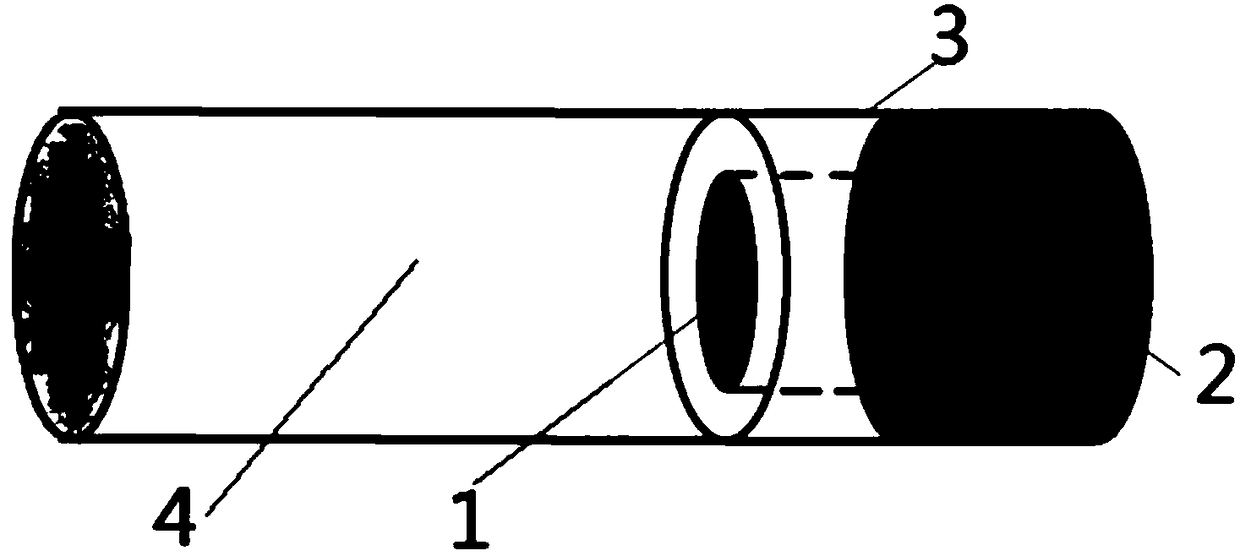

Cooling cigarette holder, preparation method and heated non-combustible cigarette

InactiveCN109430937AReduce the temperatureImprove drynessTobacco smoke filtersTobacco devicesSodium phosphatesEngineering

The invention relates to a cooling cigarette holder, a heated non-combustible cigarette and an application. The cooling cigarette holder comprises a cooling section, the cooling section comprises carriers, cooling materials are applied onto the surfaces of the carriers, the carriers are distributed in the cooling section to form a plurality of channels penetrating the cooling section, the coolingmaterials are provided with a crystallization water compound, the crystallization water compound is at least one of ferrous sulfate, aluminum potassium sulfate dodecahydrate, sodium phosphate dibasicdodecahydrate, magnesium sulfate heptahydrate, copper sulfate pentahydrate and sodium sulfate decahydrate, and preferably, the carriers are provided with paper. According to the cooling cigarette holder, the temperature of smoke entering a mouth of a smoker can be effectively reduced by 10 DEG C or more, the crystallization water compound absorbs heat and releases crystallization water, the temperature of smoke of the heated non-combustible cigarette can be effectively reduced in first, second and third times of smoking.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Application of circuit board hole-filling electroplating leveling agent

ActiveCN113430597AGood hole filling abilityPrinted element electric connection formationThioureaPhysical chemistry

The invention provides application of a circuit board hole-filling electroplating leveling agent, and relates to the technical field of hole-filling electroplating. The circuit board hole-filling electroplating leveling agent is thioureido imidazoline quaternary ammonium salt, namely thioureido is introduced into leveling agent molecules, and when the leveling agent is added into an electroplating solution system for hole-filling electroplating, the surface copper thickness is small and is smaller than 15 micrometers; and the hole-filling performance is excellent, and the leveling agent can adapt to increasingly fine development of fine circuit processing. An electroplating solution used during electroplating is composed of 40 to 120 g / L of sulfuric acid, 120 to 240 g / L of copper sulfate pentahydrate, 40 to 80 ppm of chloride ions, 2 to 10 ppm of an accelerator, 600 to 1000 ppm of an inhibitor and 3 to 10 ppm of the thioureido imidazoline quaternary ammonium salt, and holes filled through electroplating are one or more of blind holes, through holes and buried holes.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

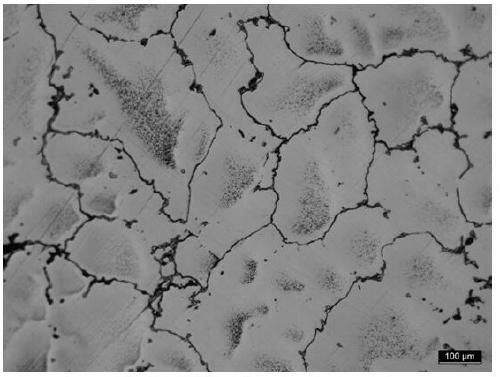

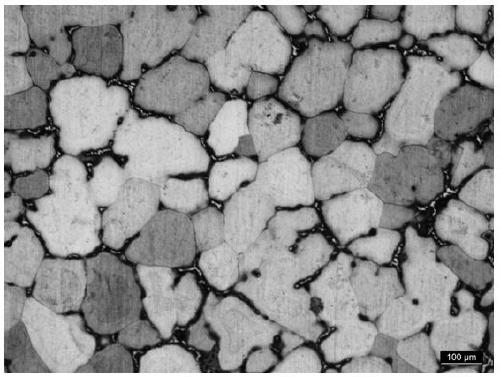

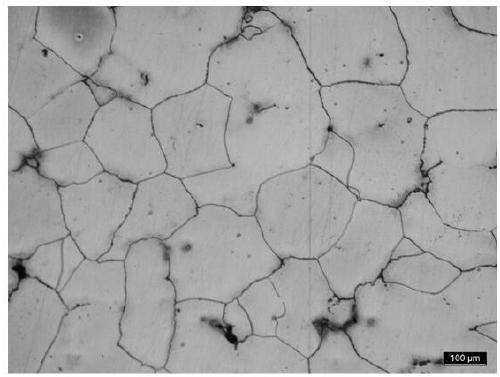

Nickel-based alloy as-cast grain corrosion method for ultra-supercritical turboset

ActiveCN111077006AFacilitate research workIncrease low temperature oxidation treatmentPreparing sample for investigationSuperalloyCopper sulfate

The invention discloses a nickel-based alloy as-cast grain corrosion method for an ultra-supercritical turboset. The method is suitable for several typical nickel-based high-temperature alloys and nickel-based alloys obtained by optimizing and improving the components of the nickel-based high-temperature alloys, such as IN617, IN706, IN740, IN625, Hynes282 and improved alloys thereof. Firstly, a nickel-based alloy as-cast metallographic specimen is subjected to mechanical grinding, polishing, cleaning and blow-drying; then the metallographic specimen is put into a heat treatment furnace and subjected to oxidation treatment for 1-3 hours under the condition that the temperature is kept at 600-800 DEG C; after discharging and air cooling, an original polished surface is directly and moderately polished, cleaned and blow-dried; and then the polished surface is immersed into newly prepared copper sulfate corrosive liquid with the ratio of copper sulfate pentahydrate to water to concentrated hydrochloric acid to concentrated sulfuric acid being 20g: 80ml: 150ml: 5ml to be corroded for 10-30 seconds, and a clear and complete grain boundary can be obtained after cleaning and blow-drying.The method is safe, efficient, stable in display effect and good in reproducibility.

Owner:CHINA FIRST HEAVY IND +1

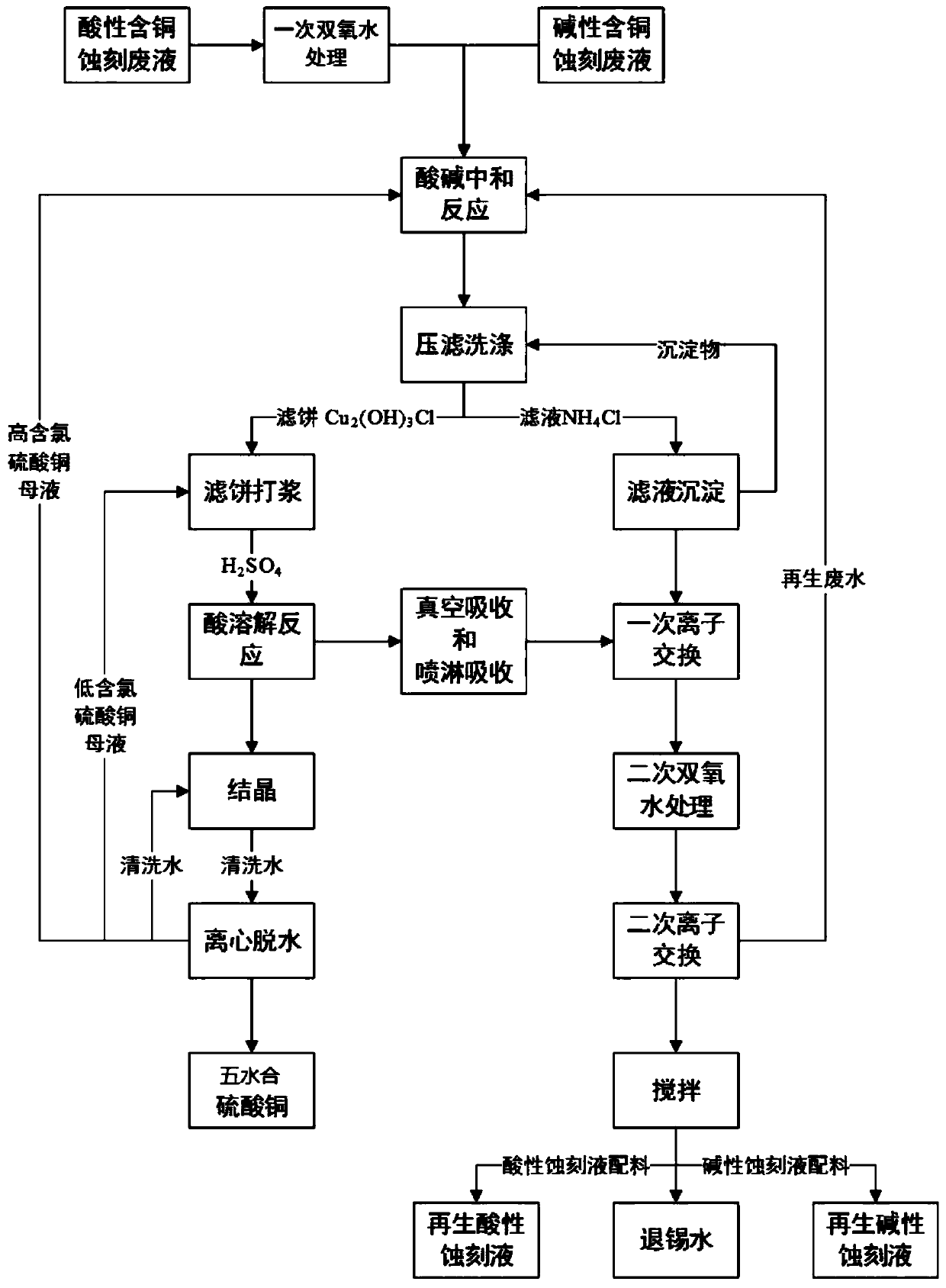

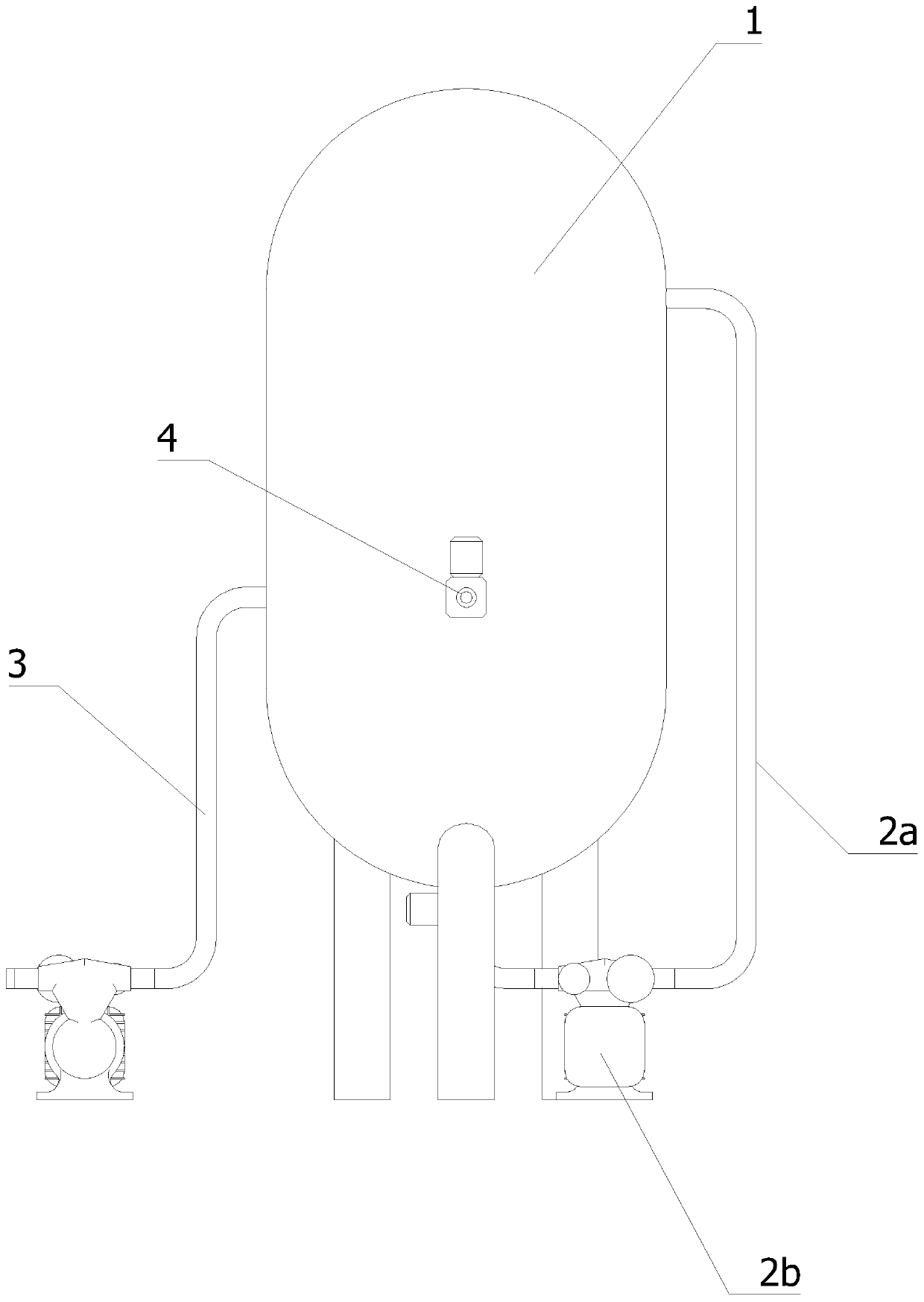

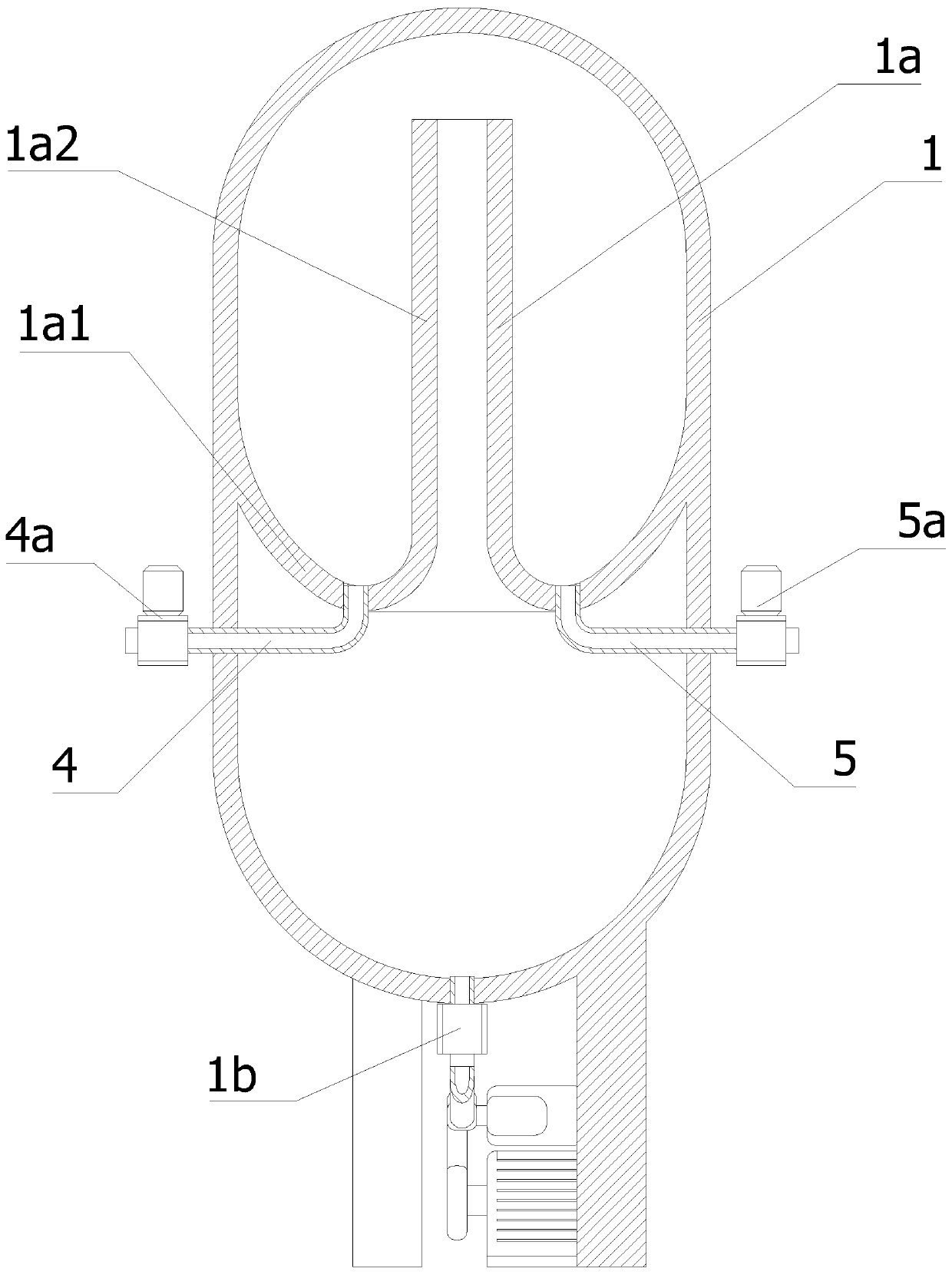

Etching liquid recycling process

ActiveCN110408938AEfficient replacementHigh economic valueProcess efficiency improvementIon exchangeCopper sulfate

The invention relates to the field of etching liquid recycling, in particular to an etching liquid recycling process. The etching liquid recycling process comprises the following steps that one time of hydrogen peroxide treatment is carried out on acidic copper-containing etching waste liquid, acid-base neutralization and filter pressing are performed on the acidic copper-containing etching wasteliquid and alkaline copper-containing etching waste liquid, and a filter cake and filtrate are generated; and the filter cake is subjected to pulping, then 98% sulfuric acid is added, copper sulfate,water and hydrochloric acid are generated, centrifugal dewatering treatment is carried out after the copper sulfate is crystallized, copper sulfate pentahydrate and copper sulfate mother liquor are produced, the filtrate is precipitated and transported to an ion exchange tank for ion exchange, waste liquid is transported to a mixing tank, an appropriate number of solid materials are added to be stirred for sufficient mixing and dissolving, and etching son liquid and solder stripping liquid are pumped into storage tanks after production is finished. By means of the process, copper ions in the copper-containing etching waste liquid can be efficiently displaced through the steps of ion exchange, oxidation aeration and ion exchange, a regenerated etching solution is prepared, meanwhile, by-products, namely the copper sulfate pentahydrate can be generated, and the very high economic value is achieved.

Owner:广东省博罗县湘澧精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com