Nickel-based alloy as-cast grain corrosion method for ultra-supercritical turboset

A technology of nickel-based alloys and steam turbines, which is applied in the field of metallographic detection and corrosion, can solve the problems that it is difficult to display the as-cast grain boundary, the morphology of as-cast grains, the average size of grains, and the change of grains. Good effect, good reproducibility and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

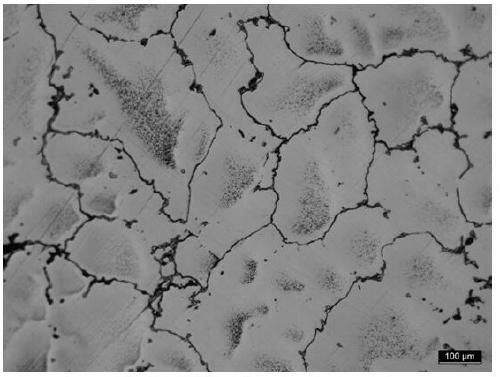

[0024] The present embodiment uses this method to corrode the as-cast grain size of the modified IN617 nickel-based alloy, and the specific steps are as follows:

[0025] Step 1: Prepare the metallographic detection sample of the modified IN617 alloy

[0026] The sample is subjected to mechanical rough grinding, fine grinding, polishing, cleaning and drying according to the conventional preparation method of metallographic samples;

[0027] Step 2: Oxidize the polished sample

[0028] Raise the temperature of the ordinary heat treatment furnace to 600°C, put the polished sample into the furnace, keep it warm for 2 hours, and then take it out of the furnace to air cool, and pay attention to the protection of the polished surface during the heat treatment process;

[0029] Step 3: Preparation of copper sulfate corrosion solution

[0030] According to the ratio of copper sulfate pentahydrate: water: concentrated hydrochloric acid: concentrated sulfuric acid = 20g: 80ml: 150ml: ...

Embodiment 2

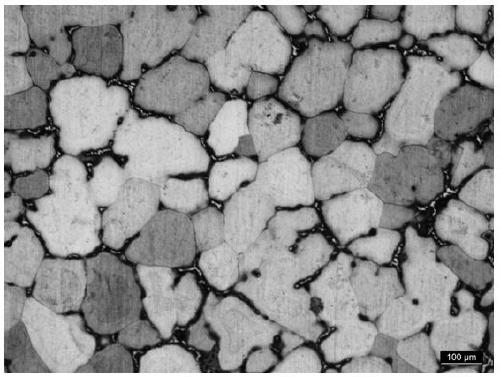

[0034] The present embodiment uses this method to corrode the as-cast grain size of the modified IN706 nickel-based alloy, and the specific steps are as follows:

[0035] Step 1: Prepare the metallographic detection sample of the modified IN706 alloy

[0036] The sample is subjected to mechanical rough grinding, fine grinding, polishing, cleaning and drying according to the conventional preparation method of metallographic samples;

[0037] Step 2: Oxidize the polished sample

[0038] Raise the temperature of the ordinary heat treatment furnace to 800°C, put the polished sample into the furnace, keep it warm for 3 hours, and then take it out of the furnace to air cool, and pay attention to the protection of the polished surface during the heat treatment;

[0039] Step 3: Preparation of copper sulfate corrosion solution

[0040] According to the ratio of copper sulfate pentahydrate: water: concentrated hydrochloric acid: concentrated sulfuric acid = 20g: 80ml: 150ml: 5ml, add...

Embodiment 3

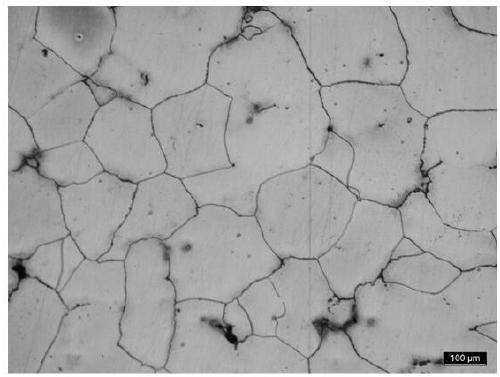

[0044] Present embodiment is to adopt this method to corrode the as-cast grain size of IN740 nickel-base alloy, and concrete steps are as follows:

[0045] Step 1: Prepare test samples of IN740 alloy

[0046] The sample is subjected to mechanical coarse grinding, fine grinding, polishing, cleaning and drying according to the conventional preparation method of metallographic samples;

[0047] Step 2: Oxidize the polished sample

[0048] Raise the temperature of the ordinary heat treatment furnace to 750°C, put the polished sample into the furnace, keep it warm for 2 hours, and then take it out of the furnace to air cool, and pay attention to the protection of the polished surface during the heat treatment;

[0049] Step 3: Preparation of copper sulfate corrosion solution

[0050] According to the ratio of copper sulfate pentahydrate: water: concentrated hydrochloric acid: concentrated sulfuric acid = 20g: 80ml: 150ml: 5ml, add water, concentrated sulfuric acid, copper sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com