Insensitive primary explosive prepared by using electrostatic spraying process and preparation method thereof

A detonating and insensitivity technology, applied in explosives, offensive equipment, explosives processing equipment, etc., can solve the problem of not completely independent detonating explosives, etc., and achieve the effects of low static electricity and friction sensitivity, simple operation and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

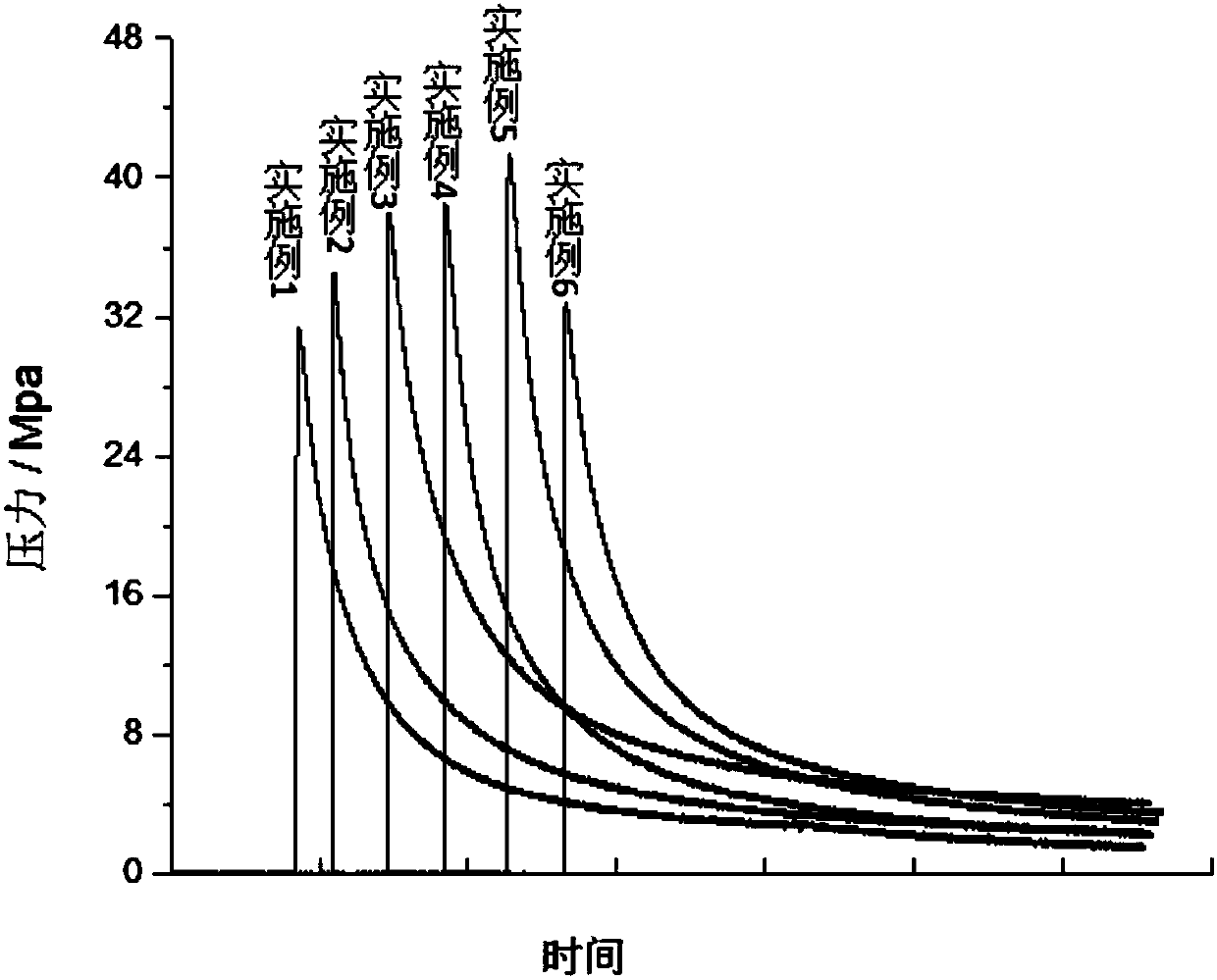

[0022] Weigh 1.8mg and dissolve in 2ml of isopropanol, disperse 0.25g of copper sulfate pentahydrate and 0.108g of nano-aluminum powder in the nitrocellulose solution, and ultrasonically form a precursor solution. Add the precursor solution into the syringe of the electrostatic spray device, collect it with aluminum foil and dry it, its appearance is as follows figure 1 shown. The sample is placed in a closed explosive device and ignited to obtain a P-t curve such as figure 2 .

Embodiment 2

[0024] Weigh 2.0 mg and dissolve in 2 ml of isopropanol, disperse 0.25 g of copper sulfate pentahydrate and 0.135 g of nano-aluminum powder in the nitrocellulose solution, and ultrasonically form a precursor solution. Add the precursor solution into the syringe of the electrostatic spray device, collect it with aluminum foil and dry it. The sample is placed in a closed explosive device and ignited to obtain a P-t curve such as figure 2 .

Embodiment 3

[0026] Weigh 2.1 mg and dissolve in 2 ml of isopropanol, disperse 0.25 g of copper sulfate pentahydrate and 0.162 g of nano-aluminum powder in the nitrocellulose solution, and ultrasonically form a precursor solution. Add the precursor solution into the syringe of the electrostatic spray device, collect it with aluminum foil and dry it. The sample is placed in a closed explosive device and ignited to obtain a P-t curve such as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com