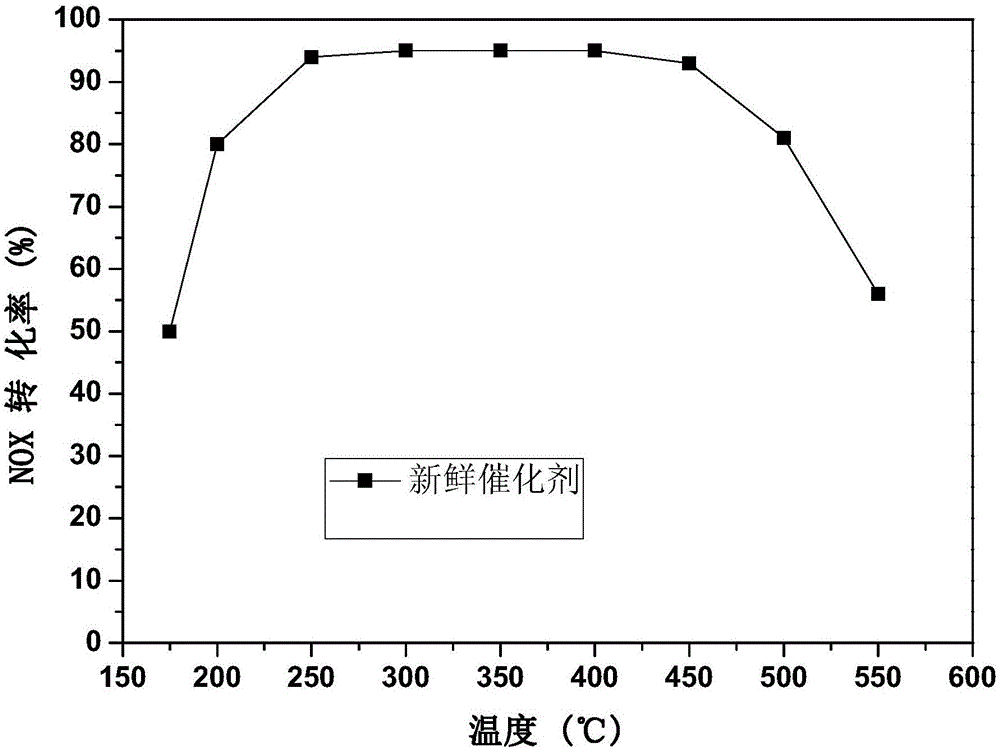

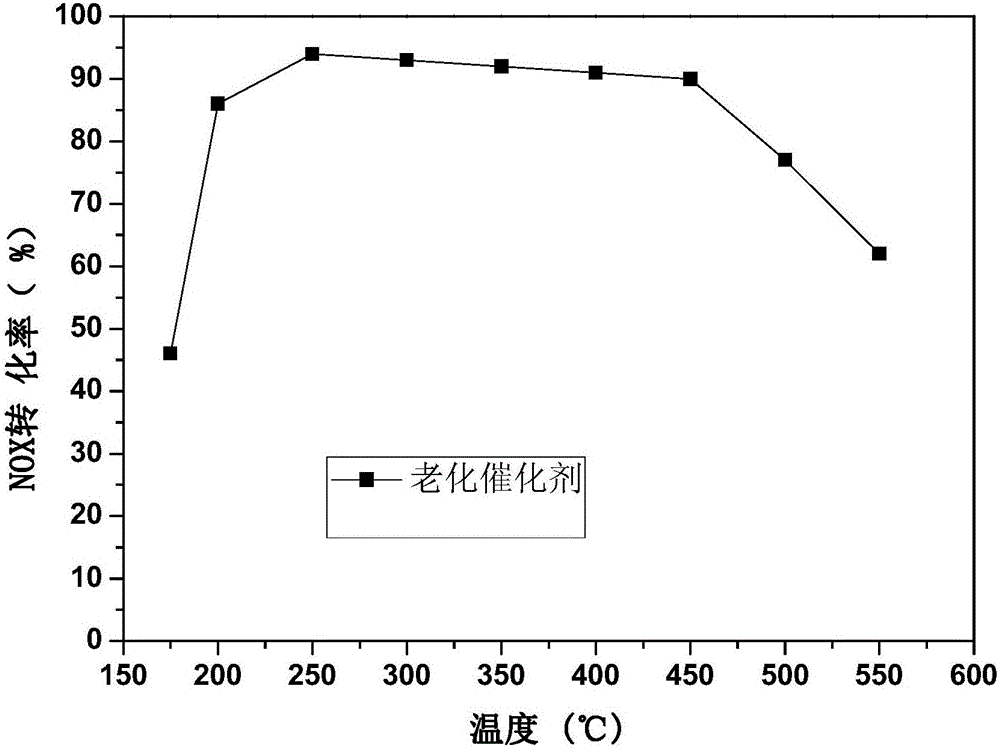

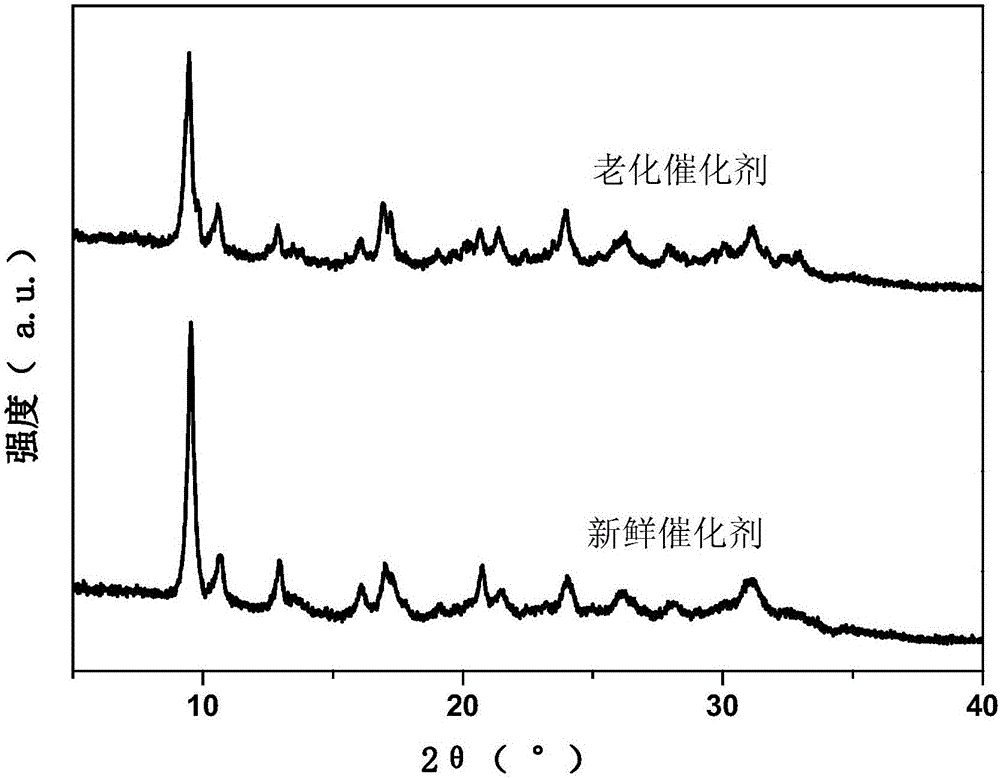

Preparing method for Cu-SAPO-18 molecular sieve catalyst of high hydrothermal stability

A thermal stability and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, molecular sieves and alkali-exchanged phosphates, etc. The effect of hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation method of Cu-SAPO-18 molecular sieve catalyst with high hydrothermal stability. The aluminum source, phosphorus source, silicon source, template agent, and co-template agent for in-situ synthesis of Cu-SAPO-18 molecular sieve catalyst are Al 2 O 3 , Phosphoric acid, silica sol, triethylenetetramine, DMDMP (N,N-dimethyl-3,5-dimethylpiperidinium), the metal source is copper sulfate pentahydrate;

[0028] Proportion by mass: Al 2 O 3 49 parts, 85 parts of phosphoric acid, 27 parts of 40wt% silica sol, 16.4 parts of triethylenetetramine, 12.6 parts of DMDMP, 10-25 parts of copper sulfate pentahydrate;

[0029] The in-situ synthesis of Cu-SAPO-18 molecular sieve catalyst includes the following steps:

[0030] (1) DMDMP synthesis

[0031] According to the mass ratio, add 10 parts of 3,5-dimethylpiperidine and 19 parts of potassium bicarbonate to 120 parts of methanol, then add 110 parts of methyl iodide dropwise, and stir for 0.5-5 days at room temperature to obtain Solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com