Application of circuit board hole-filling electroplating leveling agent

A leveling agent and circuit board technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve problems such as unsatisfactory, and achieve the effect of superior hole filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

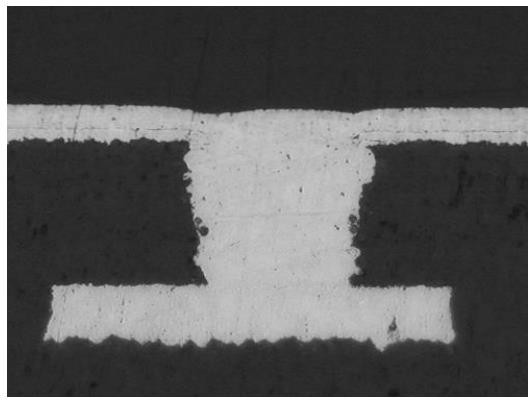

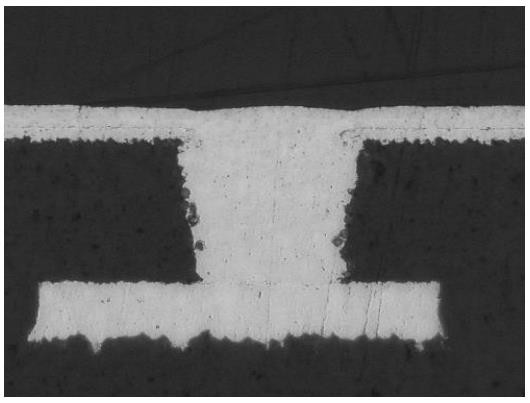

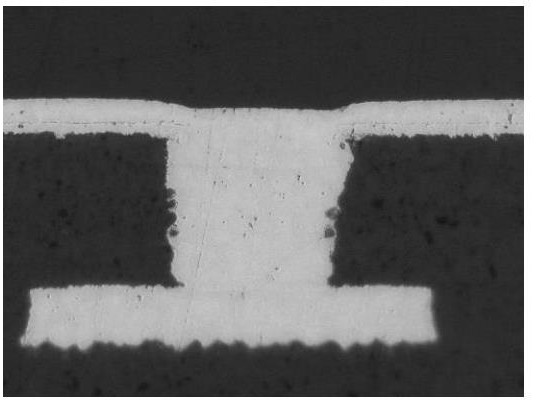

Image

Examples

Embodiment 1

[0030] Take a 250ml double-necked round bottom flask, add 40mL xylene, dissolve 10.2g (0.1mol) valeric acid and 10.32g (0.1mol) diethylenetriamine successively in the reaction system at room temperature, and stir at room temperature for 10min; Subsequently, the reaction temperature was raised to 150°C, and after 5 hours of reaction, the temperature was raised to 200°C for cyclization reaction for 2 hours to obtain alkenylamine ethyl imidazoline; cooled to 90°C, slowly added dropwise to the alkenylamine ethyl imidazoline 12.66g (0.1 mol) benzyl chloride, heat preservation reaction 3 h to get alkenylbenzylamine ethyl imidazoline quaternary ammonium chloride; slowly add 7.61 g (0.1mol) of thiourea was reacted at 110°C for 2 h, and dried in vacuo to obtain a khaki solid—thioureido imidazoline quaternary ammonium salt. The product does not need to be further purified, it can be directly dissolved in water and used as a leveling agent, code 1#.

Embodiment 2

[0032] Take a 250ml double necked round bottom flask, add 40mL xylene, dissolve 17.2g (0.1mol) capric acid and 10.32g (0.1mol) diethylenetriamine successively in the reaction system at room temperature, and stir at room temperature for 10min; Subsequently, the reaction temperature was raised to 160°C, and after 4 hours of reaction, the temperature was raised to 200°C for cyclization reaction for 2 hours to obtain alkenylamine ethyl imidazoline; cooled to 90°C, slowly added dropwise to the alkenylamine ethyl imidazoline 12.66 g (0.1 mol) benzyl chloride, heat preservation reaction for 3 h to obtain alkenylbenzylamine ethyl imidazoline quaternary ammonium chloride; slowly add 7.61 g (0.1mol) thiourea was reacted at 110°C for 2 h, and dried under vacuum to obtain a khaki solid—thioureido imidazoline quaternary ammonium salt. The product does not need further purification, and can be directly dissolved in water and used as a leveling agent. No. 2#.

[0033] In order to further di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com