Bonding sheet, preparation method thereof and metal foil-clad laminated board comprising bonding sheet

A bonding sheet and metal-clad technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of difficulty in further improving the thermal conductivity of copper-clad laminates, low strength, and application limitations, and achieve good local Effect of heat dissipation, improvement of heat dissipation and hole filling performance, and bonding force between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a copper clad laminate, the preparation method of which is as follows:

[0049] (1) Preparation of reinforced material with holes:

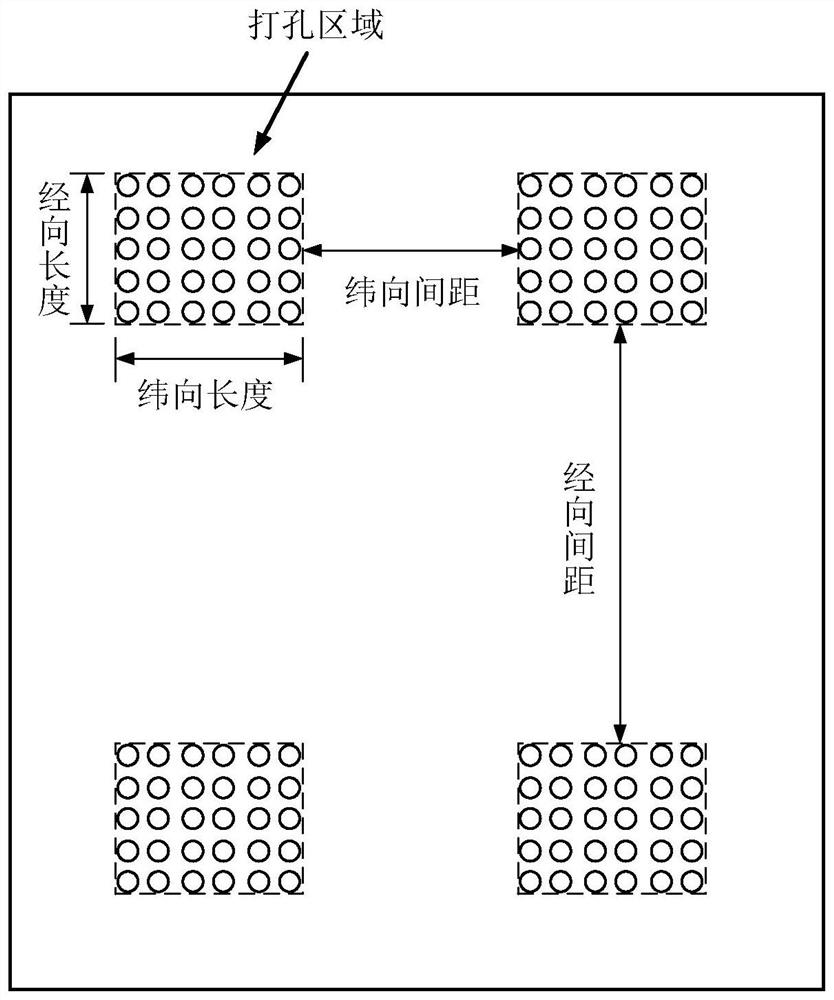

[0050] Use laser to punch holes in 2116 glass cloth, its structure is as follows figure 1 As shown, the hole diameter is 1mm, each punching area has 30 holes, and the spacing between the holes in each punching area is 1mm; the warp length of each punching area is 9mm, and the latitude length is 11mm; two adjacent The longitudinal spacing between the perforated areas is 100mm, and the latitudinal spacing is 200mm.

[0051] (2) Preparation of bonding sheet:

[0052] The above-mentioned perforated glass cloth was soaked with the glue of the high thermal conductivity resin composition 1, and then baked at 150°C for 3 minutes to make a bonding sheet (thickness 0.15mm).

[0053] (3) Preparation of copper clad laminate:

[0054] Stack the 2 prepared adhesive sheets neatly, align the punching positions up and down, cov...

Embodiment 2

[0056] This embodiment provides a copper-clad laminate. The difference from Embodiment 1 is that, when the bonding sheets are stacked, the perforated position of one bonding sheet corresponds to the unperforated position of the other bonding sheet.

Embodiment 3

[0058] This embodiment provides a circuit board, the preparation method of which is to use a bonding sheet prepared in embodiment 1 to be sandwiched between two core boards etched with lines, and pressed into a multi-layer board, wherein the punching positions correspond to Locations with high heat dissipation requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com