Preparation method for antioxidant copper nanopowder

A nano-copper powder, anti-oxidation technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of good dispersion, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

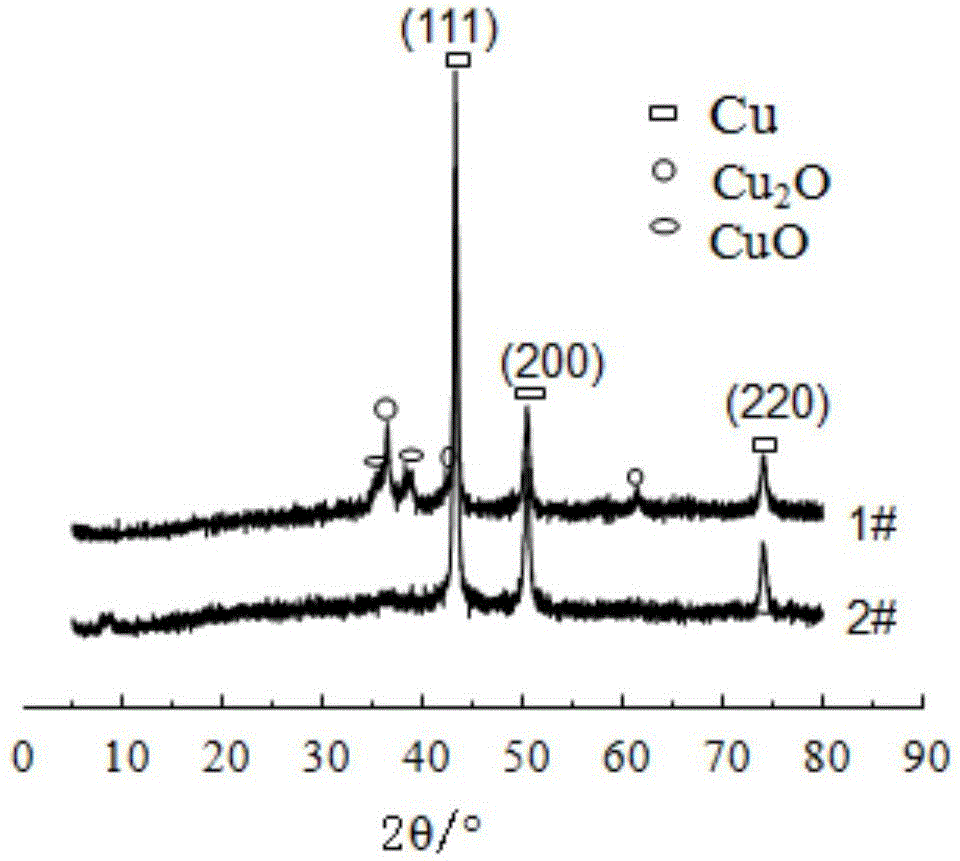

[0029] Weigh 3g of copper sulfate pentahydrate and dissolve it in a beaker with 100mL of deionized water, adjust the pH value to 11 with concentrated nitric acid or concentrated ammonia water, and make solution A. In addition, weigh 2.26g of hydrazine hydrate and add 100mL of deionized water to form solution B. Drop solution B into solution A at a rate of 20mL / min, magnetically stir at a constant temperature of 30°C, and continue stirring for 30 minutes after dropping to obtain copper sol, which is flocculent and poorly dispersible. Centrifuge the copper sol to separate the copper particles, wash them three times with deionized water and once with absolute ethanol, and dry them under vacuum at 60°C to obtain copper powder. figure 1 As shown in 1#, there is a small amount of Cu on the surface 2 O and CuO, the average particle size of copper powder measured by laser particle size analyzer is 600nm.

Embodiment 2

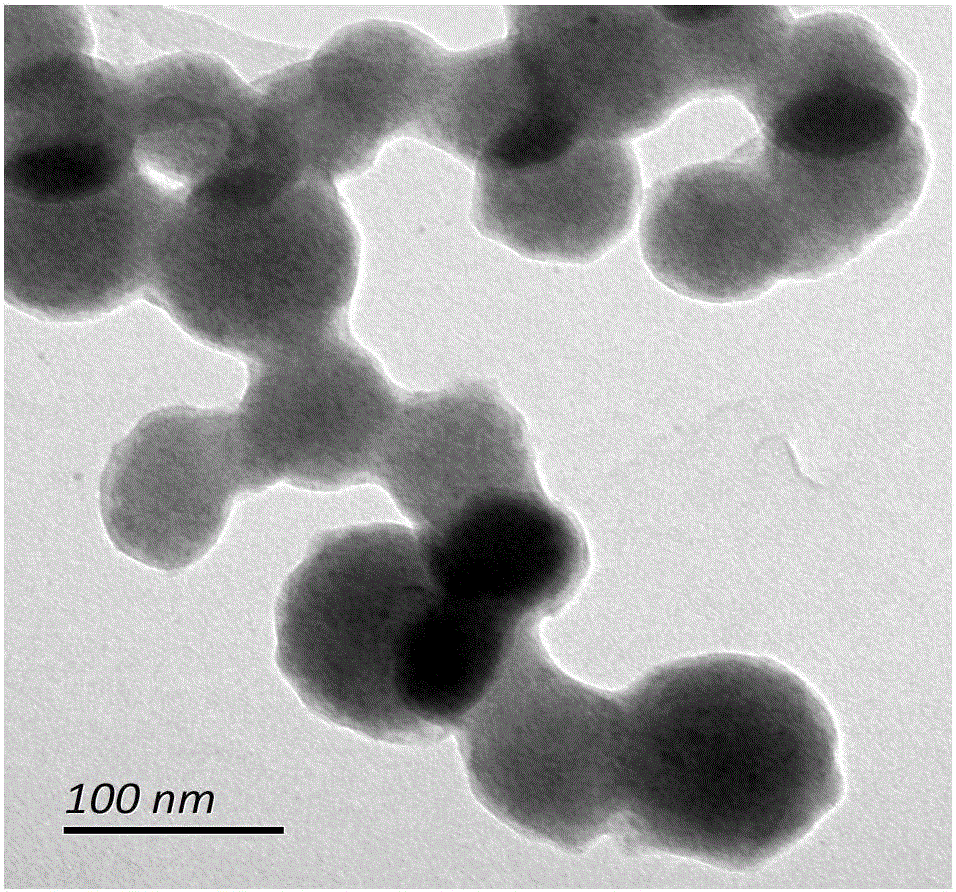

[0031] Weigh 5g of copper sulfate pentahydrate and 1g of polyvinylpyrrolidone (PVP) and dissolve them in a beaker with 100mL of deionized water, add 0.2g of benzotriazole (BTA) into 5mL of absolute ethanol to dissolve them and add them to the copper sulfate solution. Adjust the pH value to 11 with nitric acid or concentrated ammonia water to prepare solution A. In addition, weigh 3.76g of hydrazine hydrate and add 100mL of deionized water to form solution B. Drop solution B into solution A at a rate of 10mL / min, magnetically stir at a constant temperature of 30°C, and continue stirring for 30min after dropping to obtain a copper sol without agglomeration. The copper sol was centrifuged to separate the copper particles, washed three times with deionized water and one time with absolute ethanol, and dried in vacuum at 60°C to obtain copper powder, which was tested by XRD as shown in figure 1 As shown in 2#, compared with Example 1 as a comparative example, there is no oxide on ...

Embodiment 3

[0033] Weigh 5g of copper sulfate pentahydrate and 1g of PVP with 100mL of deionized water and dissolve in a beaker, add 0.2g of BTA into 5mL of absolute ethanol to dissolve, adjust the pH value to 11 with concentrated nitric acid or concentrated ammonia water, and make solution A. Another 6.27g of hydrazine hydrate was weighed and added to 100mL of deionized water to form solution B. The B solution was dripped into the A solution at a rate of 10 mL / min, magnetically stirred at a constant temperature of 30 ° C, and continued to stir for 30 min after the drop was completed to obtain a copper sol. Copper sol was centrifuged to separate copper particles, washed three times with deionized water and once with absolute ethanol, and dried in vacuum at 60°C to obtain copper powder. The average particle size was 372nm as measured by a laser particle size analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com